- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

Table of Contents

- Understanding Industrial Laser Cleaning Technology: A Comprehensive Overview

- Key Components of Laser Cleaning Machines: How They Work Together

- The Process of Laser Cleaning: Step-by-Step Breakdown

- Advantages of Laser Cleaning Over Traditional Methods

- Impact on Operational Efficiency and Cost Savings in Industry

- Future Trends in Laser Cleaning Technologies and Their Implications

- FAQS

- Conclusion

- Related Posts

In recent years, the use of Industrial Laser Cleaning Machines has gained significant traction within various manufacturing sectors, showcasing a profound impact on operational efficiency and environmental sustainability. According to a report by MarketsandMarkets, the industrial laser cleaning market is projected to grow from USD 220 million in 2021 to USD 353 million by 2026, reflecting a compound annual growth rate (CAGR) of 9.8%. This growth can be attributed to the advantages offered by laser cleaning technology, such as its precision, eco-friendliness, and ability to reduce downtime compared to traditional cleaning methods. As a professional manufacturer of industrial laser equipment, Fortune Laser Technology Co., Ltd. has been at the forefront since its inception in 2016, providing innovative solutions that integrate R&D, production, sales, and maintenance services. Understanding the technology behind these machines not only underscores their efficiency-enhancing capabilities but also highlights their role in advancing cleaner industrial processes.

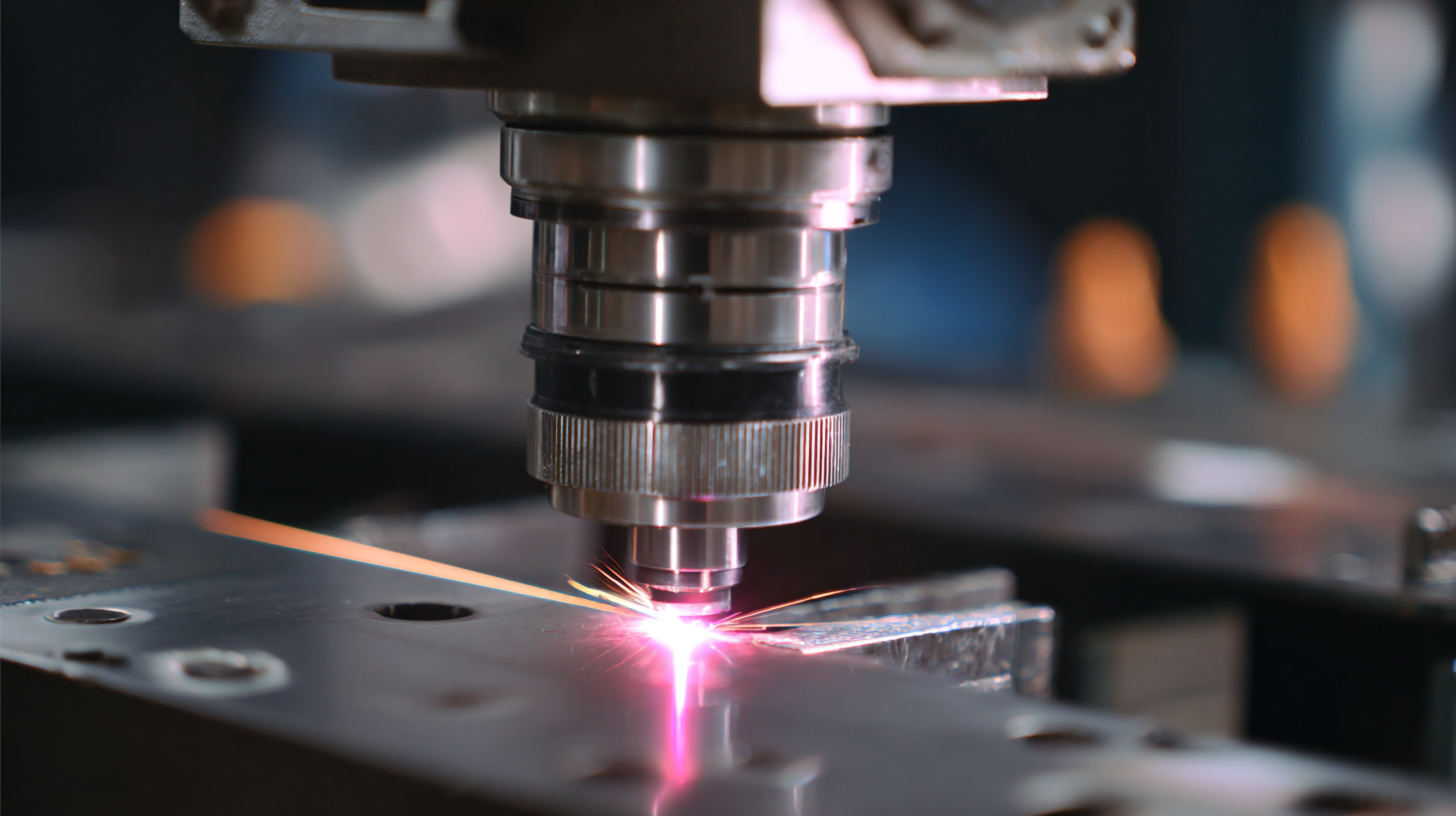

Understanding Industrial Laser Cleaning Technology: A Comprehensive Overview

Industrial laser cleaning technology has emerged as a revolutionary solution in various manufacturing sectors, significantly enhancing operational efficiency. This method utilizes high-intensity laser beams to effectively remove contaminants from surfaces, such as rust, paint, and other residues, without the need for abrasive chemicals or harmful solvents. The precision offered by laser cleaning not only minimizes the risk of damaging the underlying materials but also accelerates the cleaning process, allowing companies to reduce downtime and improve productivity.

Fortune Laser Technology Co., Ltd., established in 2016 and located in Shenzhen, is at the forefront of this innovative field. As a professional manufacturer of industrial laser equipment, we integrate research and development, production, sales, and maintenance services to provide high-quality solutions tailored to meet the diverse needs of our clients. Our cutting-edge industrial laser cleaning machines exemplify the efficiency and effectiveness of laser technology, enabling businesses to achieve cleaner surfaces and enhanced operational excellence while adhering to environmental standards.

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

| Parameter | Description | Impact on Efficiency |

|---|---|---|

| Laser Type | Fiber Lasers, CO2 Lasers, Nd:YAG | Different lasers have varying efficiencies in material removal. |

| Power Output | Ranges from 100 W to 3 kW | Higher power increases cleaning speed but may affect surface integrity. |

| Pulse Duration | From nanoseconds to microseconds | Shorter pulses can improve precision but may reduce cleaning efficiency. |

| Scanning Speed | Typically ranges from 0.1 m/s to 2 m/s | Higher speeds can enhance productivity but may lead to incomplete cleaning. |

| Material Compatibility | Metals, plastics, coatings, and organic materials | Versatile options allow for a wide range of applications, improving utilization. |

| Environmental Impact | Minimal waste generation, no chemicals required | Promotes sustainable practices in industrial cleaning. |

| Operational Costs | Maintenance and energy consumption | Lower long-term operational costs compared to traditional methods. |

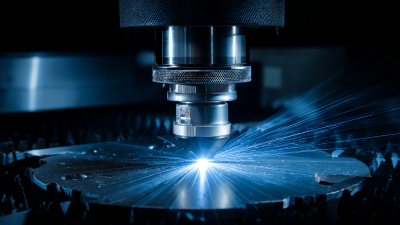

Key Components of Laser Cleaning Machines: How They Work Together

Industrial laser cleaning machines have gained popularity due to their efficiency and precision in removing contaminants from various surfaces. The key components that drive their operation include the laser source, optics, control systems, and the robotic arms that direct the laser beam. The laser source, often a solid-state or fiber laser, generates high-intensity light that can effectively ablate rust, paint, and other residues. Optics play a crucial role in focusing and directing this laser beam onto the target surface, ensuring optimal cleaning performance.

Industrial laser cleaning machines have gained popularity due to their efficiency and precision in removing contaminants from various surfaces. The key components that drive their operation include the laser source, optics, control systems, and the robotic arms that direct the laser beam. The laser source, often a solid-state or fiber laser, generates high-intensity light that can effectively ablate rust, paint, and other residues. Optics play a crucial role in focusing and directing this laser beam onto the target surface, ensuring optimal cleaning performance.

To maximize the effectiveness of laser cleaning, it’s important to consider the settings of the laser parameters such as pulse duration and intensity. Adjusting these settings based on the material being cleaned can significantly improve results. Additionally, regular maintenance of the optics and robotic systems is essential to avoid performance degradation over time.

When selecting a laser cleaning machine, look for features such as automation capabilities and user-friendly interfaces. Automated systems can enhance efficiency by reducing manual labor, while intuitive controls allow operators to adjust settings quickly. Remember, investing in the right equipment and understanding its core components can lead to greater operational efficiency and cost savings in the long run.

The Process of Laser Cleaning: Step-by-Step Breakdown

The process of laser cleaning utilizes focused laser beams to remove contaminants from surfaces, providing a precise and efficient method for various industrial applications. The first step involves selecting the appropriate laser technology, commonly fiber or pulsed lasers, based on the specific materials and contaminants to be addressed. Industry reports indicate that laser cleaning can achieve up to 95% cleaning efficiency for various surfaces, including metals, plastics, and ceramics. This high level of effectiveness is largely attributed to the ability of lasers to target dirt and rust without harming the underlying material. Once the laser type is chosen, the process moves to calibration and setup. Operators must carefully adjust parameters such as laser power, pulse duration, and scanning speed to optimize cleaning performance. Research from the Laser Institute of America shows that effective parameter optimization can reduce cleaning times by as much as 50% compared to traditional methods. Following the setup, the beam is directed over the contaminated area where the intense light energy converts contaminants into vapor, leaving behind a clean surface ready for further processing or coating. This method not only enhances operational efficiency but also supports sustainable practices by minimizing waste and the need for harmful chemicals in cleaning processes.

Once the laser type is chosen, the process moves to calibration and setup. Operators must carefully adjust parameters such as laser power, pulse duration, and scanning speed to optimize cleaning performance. Research from the Laser Institute of America shows that effective parameter optimization can reduce cleaning times by as much as 50% compared to traditional methods. Following the setup, the beam is directed over the contaminated area where the intense light energy converts contaminants into vapor, leaving behind a clean surface ready for further processing or coating. This method not only enhances operational efficiency but also supports sustainable practices by minimizing waste and the need for harmful chemicals in cleaning processes.

Advantages of Laser Cleaning Over Traditional Methods

Laser cleaning technology has revolutionized surface preparation in various industries, providing distinct advantages over traditional cleaning methods. One of the most significant benefits is its ability to remove contaminants—rust, paint, oils, and other residues—without damaging the underlying material. Conventional methods, such as sandblasting or chemical cleaning, often involve harsh abrasives or caustic substances that can degrade surfaces or contribute to environmental pollution. In contrast, laser cleaning utilizes focused beams of light to effectively dislodge unwanted materials while ensuring the integrity of the substrate is maintained.

Another advantage of laser cleaning is its precision and efficiency. The ability to control the laser’s intensity and focus allows for targeted cleaning, which is particularly valuable in intricate components or sensitive applications. This precision minimizes the need for extensive masking or protection of adjacent areas, saving time and labor costs. Furthermore, laser systems typically require less downtime and offer faster turnaround rates, enhancing overall productivity. With these benefits, industries ranging from manufacturing to heritage conservation are increasingly adopting laser cleaning as a sustainable and effective solution for their cleaning challenges.

Impact on Operational Efficiency and Cost Savings in Industry

Industrial laser cleaning machines are revolutionizing the way industries approach maintenance and surface preparation. By harnessing advanced laser technology, these machines effectively remove contaminants, rust, and coatings without the need for harsh chemicals or abrasive materials. This not only enhances the cleaning quality but also significantly reduces the time required for these processes, leading to improved operational efficiency.

The impact on cost savings is particularly noteworthy. Traditional cleaning methods often involve labor-intensive practices and the purchase of expensive chemical agents. In contrast, laser cleaning minimizes resource consumption and reduces labor costs, as the automation of the cleaning process streamlines operations. Additionally, with less downtime incurred for maintenance and cleaning, production lines can operate more continuously, driving overall productivity and profitability. As industries increasingly adopt this technology, the potential for enhanced efficiency and cost savings becomes a compelling reason to transition from conventional methods.

Future Trends in Laser Cleaning Technologies and Their Implications

The future of laser cleaning technologies is poised for significant advancements, greatly influencing efficiency across various industrial sectors. According to a recent report by MarketsandMarkets, the global laser cleaning market is expected to grow from USD 2.45 billion in 2023 to USD 4.87 billion by 2028, reflecting a compound annual growth rate (CAGR) of 14.7%. This growth is indicative of the increasing adoption of laser cleaning solutions due to their high precision, minimal waste generation, and enhanced safety profiles compared to traditional methods.

Emerging trends in laser cleaning technology include the development of more compact and portable systems, which allow for easier manipulation and application in diverse settings. Furthermore, advancements in fiber laser technology are enhancing the efficiency and effectiveness of laser cleaning. A report from ResearchAndMarkets highlights that fiber lasers are projected to dominate the market due to their superior beam quality and cost-effectiveness. As industries strive for sustainability, the shift towards environmentally friendly cleaning processes is set to revolutionize maintenance practices, leading to reduced operational costs and improved productivity across manufacturing, aerospace, and automotive sectors.

FAQS

: The laser cleaning process involves using focused laser beams to remove contaminants from surfaces, providing a precise and efficient method for various industrial applications.

The most commonly used laser technologies for cleaning are fiber lasers and pulsed lasers, selected based on the specific materials and contaminants.

Laser cleaning can achieve up to 95% cleaning efficiency on various surfaces, such as metals, plastics, and ceramics, often outperforming traditional cleaning methods.

Laser cleaning removes contaminants without damaging the underlying material, in contrast to methods like sandblasting or chemical cleaning that can degrade surfaces.

Calibration involves adjusting parameters such as laser power, pulse duration, and scanning speed to optimize performance, which can reduce cleaning times by up to 50%.

The intense light energy from the laser converts contaminants, such as dirt and rust, into vapor, leaving behind a clean surface.

Yes, laser cleaning's precision allows for targeted cleaning, making it particularly valuable for intricate components and sensitive applications.

Yes, laser cleaning supports sustainable practices by minimizing waste and reducing the need for harmful chemicals in cleaning processes.

Laser cleaning enhances operational efficiency by requiring less downtime and offering faster turnaround rates, thereby increasing overall productivity.

Industries ranging from manufacturing to heritage conservation are increasingly using laser cleaning as a sustainable and effective solution for cleaning challenges.

Conclusion

The blog titled "What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency" provides a thorough exploration of the advanced technology driving industrial laser cleaning machines. It begins by offering a comprehensive overview of the laser cleaning process, detailing the key components that work collaboratively to deliver optimal performance. The step-by-step breakdown of the laser cleaning process highlights its effectiveness in removing contaminants compared to traditional cleaning methods.

Moreover, the article emphasizes the significant advantages of using an industrial laser cleaning machine, including enhanced operational efficiency and substantial cost savings for industries. By examining future trends in laser cleaning technologies, the blog underscores the transformative implications these advancements will have on industrial cleaning practices. With a focus on Fortune Laser Technology Co., Ltd., a leader in manufacturing industrial laser equipment, the blog illustrates how innovation is shaping the landscape of industrial cleaning.

Related Posts

-

Exploring the Versatile Applications of Best Industrial Laser Cutting Equipment in Aerospace and Automotive Industries

-

5 Essential Features of the Best Metal Tube Laser Cutting Machine You Can't Overlook

-

5 Best Pulsed Laser Cleaning Machines for Global Buyers in 2023

-

2025 Trends in Precision: Elevating Jewelry Production with the Best Laser Cutting Technology

-

7 Key Advantages of Using High Power Laser Cutters in Modern Manufacturing

-

Innovative Solutions for Enhancing Productivity with Square Tube Cutting Machines