- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Revolutionizing Surface Restoration with High Power Laser Cleaning Technology

Table of Contents

- Enhancing Efficiency in Surface Restoration with Laser Cleaning Solutions

- Comparative Analysis: Laser Cleaning vs Traditional Surface Restoration Methods

- Environmental Benefits of High Power Laser Cleaning Technology in Industry

- Market Growth Projections for Laser Cleaning Technology by 2025

- Case Studies: Successful Applications of Laser Cleaning in Various Sectors

- Technical Innovations Driving Advances in High Power Laser Cleaning Systems

- FAQS

- Conclusion

- Related Posts

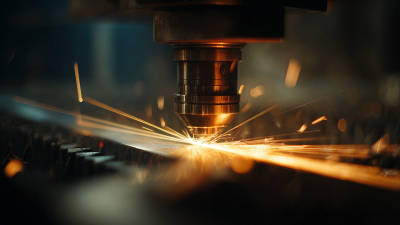

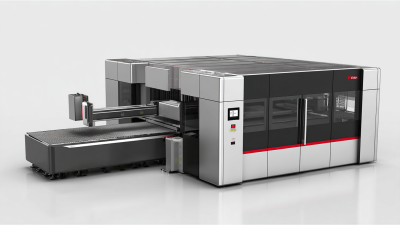

In recent years, the industrial landscape has witnessed a significant transformation driven by technological advancements, particularly in the field of surface restoration. Among these innovations, the High Power Laser Cleaning Machine stands out as a game-changer, revolutionizing traditional cleaning methods with its precision, efficiency, and environmental sustainability. Fortune Laser Technology Co., Ltd., a professional manufacturer of industrial laser equipment established in 2016 and located in Shenzhen, is at the forefront of this technological revolution. With a strong commitment to research and development, production, sales, and maintenance services, Fortune Laser is dedicated to providing cutting-edge solutions that enhance surface restoration processes. This introduction explores the unprecedented capabilities of High Power Laser Cleaning Machines and their impact on various industries, highlighting how Fortune Laser Technology continues to lead the charge in advancing cleaning technology for a cleaner and more efficient future.

Enhancing Efficiency in Surface Restoration with Laser Cleaning Solutions

In the realm of surface restoration, laser cleaning technology has emerged as a groundbreaking solution that significantly enhances efficiency and effectiveness. At Fortune Laser Technology Co., Ltd., we specialize in crafting state-of-the-art industrial laser equipment tailored for diverse surface restoration needs. Our high power laser cleaning technology utilizes precision and advanced controls to bring surfaces back to their original condition, minimizing downtime and maximizing productivity for businesses across various industries.

Investing in laser cleaning solutions can yield remarkable benefits. For instance, laser cleaning not only removes rust, paint, and contaminants effectively but also preserves the integrity of the underlying material, making it ideal for sensitive applications. Additionally, these solutions are environmentally friendly, eliminating the need for harsh chemicals and reducing waste.

Tip: When considering laser cleaning technology for your surface restoration projects, assess the specific requirements of your materials and the extent of contamination. This will help in selecting the right power settings and focus for optimal results. Furthermore, regular maintenance of your laser equipment is essential to ensure consistent performance and longevity.

Comparative Analysis: Laser Cleaning vs Traditional Surface Restoration Methods

Laser cleaning technology has emerged as a game-changer in the realm of surface restoration, particularly when compared to traditional methods. According to a report by the International Journal of Surface Engineering, laser cleaning can remove contaminants with a precision rate of over 90%, significantly outperforming sandblasting and chemical cleaning, which typically have rates around 70% to 80%. The precision and efficiency of laser systems reduce the risk of damaging underlying materials, increasing the longevity of restored surfaces.

Moreover, the environmental benefits of laser cleaning cannot be overstated. Traditional methods often involve chemical solvents and abrasive materials, which contribute to hazardous waste and pollution. A study from the Laser Institute of America indicates that laser cleaning reduces waste generation by at least 50%, providing a sustainable alternative for industries striving to meet stricter environmental regulations. As industries increasingly prioritize eco-friendly solutions, laser cleaning stands out not only for its effectiveness but also for its ability to align with sustainability goals.

Comparative Analysis of Surface Restoration Methods

Environmental Benefits of High Power Laser Cleaning Technology in Industry

High power laser cleaning technology is emerging as a game-changer in various industrial applications due to its significant environmental benefits. Traditional cleaning methods often rely on harsh chemicals and extensive water use, leading to environmental degradation and increased operational costs. In contrast, laser cleaning utilizes focused light energy to remove contaminants, presenting a sustainable alternative with minimal environmental impact. According to a report by the International Laser Cleaning Association (ILCA), adopting high power laser cleaning could reduce chemical waste by up to 90%, significantly lowering the carbon footprint of industrial cleaning processes.

Moreover, this technology not only minimizes harmful emissions but also conserves water resources. For example, a study conducted by the Environmental Protection Agency (EPA) revealed that laser cleaning could reduce water usage in surface preparation tasks by approximately 75%. This capability is critical in industries facing increasing pressure to adopt cleaner technologies and streamline workflows. As companies strive for sustainability, high power laser cleaning offers a practical solution that aligns with environmental regulations and corporate social responsibility goals, ensuring a greener future for industrial operations.

Market Growth Projections for Laser Cleaning Technology by 2025

As the demand for efficient and environmentally friendly cleaning solutions rises, the laser cleaning technology market is projected to witness remarkable growth. According to a recent market analysis report, the global laser cleaning market is expected to reach approximately $400 million by 2025, with a compound annual growth rate (CAGR) of around 15.5% from 2022 to 2025. This surge reflects industries’ increasing adoption of high-power laser systems for surface restoration, which offer precision and reduced material damage compared to traditional methods.

The appealing aspects of laser cleaning technology include its ability to remove rust, contaminants, and coatings without the use of harmful chemicals, aligning with stringent environmental regulations. Moreover, a survey by Allied Market Research indicates that nearly 70% of manufacturing firms are considering transitioning to laser cleaning due to its cost-effectiveness and low maintenance requirements.

Tip: For businesses contemplating the switch to laser cleaning, it's crucial to invest in training for staff to maximize equipment efficiency and ensure safety protocols are followed. Additionally, integrating laser cleaning systems with existing production lines can significantly enhance productivity and lower operational costs over time.

Case Studies: Successful Applications of Laser Cleaning in Various Sectors

Laser cleaning technology has emerged as a groundbreaking solution for surface restoration across various sectors, proving particularly effective in industries such as manufacturing, automotive, and historical preservation. Case studies illustrate the versatility of high-power laser cleaning; for instance, auto manufacturers have employed this technology to remove contaminants without damaging sensitive components, resulting in improved quality control and reduced waste. Similarly, heritage sites have benefited, where lasers precisely remove layers of grime while preserving the integrity of ancient structures and artworks.

Laser cleaning technology has emerged as a groundbreaking solution for surface restoration across various sectors, proving particularly effective in industries such as manufacturing, automotive, and historical preservation. Case studies illustrate the versatility of high-power laser cleaning; for instance, auto manufacturers have employed this technology to remove contaminants without damaging sensitive components, resulting in improved quality control and reduced waste. Similarly, heritage sites have benefited, where lasers precisely remove layers of grime while preserving the integrity of ancient structures and artworks.

Tips for effective laser cleaning include thoroughly assessing the surface material and level of contamination before beginning the process. Understanding the specific requirements of the application can lead to optimal settings for laser power and pulse duration, ensuring the best results. Additionally, it's crucial to maintain a safe working environment by using appropriate protective gear and ensuring proper ventilation, particularly when cleaning surfaces that may release harmful substances. By following these guidelines, businesses can fully leverage the advantages of laser cleaning technology and achieve outstanding restoration results.

Technical Innovations Driving Advances in High Power Laser Cleaning Systems

High power laser cleaning technology is revolutionizing surface restoration, offering an efficient and eco-friendly alternative to traditional cleaning methods. Recent industry reports indicate that the global market for laser cleaning systems is projected to reach $1.2 billion by 2026, driven by advancements in laser technology and increasing applications across various sectors, including metalworking, aerospace, and automotive industries. These technical innovations are not only improving cleaning efficiency but also reducing the environmental impact typically associated with traditional cleaning solvents and abrasive materials.

The latest developments in high power laser systems are centered around the integration of advanced optics and precise control mechanisms, which enhance the cleaning process's effectiveness. For instance, innovations such as fiber lasers and pulsed laser technologies deliver high energy output with minimal surface damage, making them ideal for delicate materials. According to a report by MarketsandMarkets, the fiber laser segment is expected to witness the highest growth, owing to its reliability and superior performance in diverse applications. As these technologies continue to evolve, industries are increasingly adopting laser cleaning solutions, highlighting the shift towards sustainable practices and improved operational efficiencies.

Revolutionizing Surface Restoration with High Power Laser Cleaning Technology

| Feature | Description | Advantage | Application |

|---|---|---|---|

| High Power Output | Lasers that operate at higher power levels. | Increased efficiency in surface cleaning. | Industrial metal cleaning. |

| Customization | Adjustable settings for different materials. | Versatile use on various surface types. | Restoration of artworks and historical artifacts. |

| Minimal Residue | Leaves little to no residue post-cleaning. | Reduces the need for additional cleaning processes. | Cleaning of electronics and delicate components. |

| Eco-friendly | Uses no harsh chemicals. | Safer for the environment and operators. | Cleaning in sensitive environments. |

| Speed | Rapid cleaning capabilities. | Reduces downtime during maintenance. | Maintenance in manufacturing facilities. |

FAQS

: Laser cleaning technology is a method used for surface restoration that utilizes high power lasers to effectively remove rust, paint, and contaminants from surfaces while preserving the integrity of the underlying material.

Industries such as manufacturing, automotive, and historical preservation can benefit significantly from laser cleaning solutions due to their effectiveness and versatility across various applications.

Laser cleaning is more efficient as it eliminates the need for harsh chemicals, reduces waste, and minimizes damage to sensitive components compared to traditional cleaning methods.

The advantages of laser cleaning include effective removal of contaminants, preservation of the material’s integrity, environmental friendliness, and minimized downtime for businesses.

It's important to assess the specific requirements of the materials and the extent of contamination to select the appropriate power settings and focus for optimal cleaning results.

Businesses can ensure effectiveness by thoroughly assessing the surface material and level of contamination before starting, and by adjusting laser settings accordingly for optimal performance.

Proper protective gear should be worn, and adequate ventilation should be ensured to maintain a safe working environment, especially when cleaning surfaces that might release harmful substances.

Laser cleaning technology is environmentally friendly as it reduces the necessity for harsh chemical cleaners and minimizes waste generation during the cleaning process.

Regular maintenance of laser equipment is essential to ensure consistent performance, durability, and longevity of the laser cleaning systems.

Yes, laser cleaning is ideal for delicate and historical surfaces as it allows for precise cleaning while preserving the integrity of important materials and artworks.

Conclusion

The article "Revolutionizing Surface Restoration with High Power Laser Cleaning Technology" explores the transformative impact of high power laser cleaning machines in the surface restoration industry. It highlights how these advanced solutions enhance efficiency compared to traditional methods, delivering significant time and cost savings. The comparative analysis reveals the superior effectiveness of laser cleaning in restoring surfaces while minimizing damage, thus paving the way for wider adoption.

Additionally, the article discusses the environmental benefits associated with high power laser cleaning technology, emphasizing its potential to reduce harmful waste and promote sustainability in industrial applications. Market growth projections suggest a robust expansion of this technology by 2025, driven by ongoing technical innovations and successful case studies across various sectors. As a leading manufacturer in this domain, Fortune Laser Technology Co., Ltd. is poised to contribute significantly to the industry's evolution through its R&D and high-quality laser equipment.

Related Posts

-

Revolutionizing Surface Restoration: Benefits of the Portable Laser Cleaning Machine

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine

-

How to Optimize Your Laser Cleaning Device for Maximum Efficiency