- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Revolutionizing Metal Fabrication with Innovative Handheld Laser Welding Technology

Table of Contents

- Benefits of Handheld Laser Welding Technology in Metal Fabrication

- Comparison of Traditional Welding Methods versus Laser Welding

- Key Innovations in Handheld Laser Welding Equipment

- Applications of Handheld Laser Welding Across Industries

- Future Trends in Metal Fabrication and Laser Technology

- Challenges and Solutions in Adopting Handheld Laser Welding

- FAQS

- Conclusion

- Related Posts

In recent years, the metal fabrication industry has experienced a significant transformation driven by advancements in laser technology. According to a report by Research and Markets, the global laser welding machine market is projected to reach USD 1.63 billion by 2025, with a notable shift towards portable solutions like the Handheld Laser Welding Machine. This innovation is revolutionizing how manufacturers approach welding tasks, offering improved efficiency, precision, and versatility in various applications.

Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, is at the forefront of this transformation, providing state-of-the-art industrial laser equipment backed by dedicated research and development, production, and comprehensive maintenance services. As the demand for efficient and adaptable welding solutions continues to grow, the Handheld Laser Welding Machine is poised to redefine traditional welding practices, making it an essential tool for modern metal fabrication.

Benefits of Handheld Laser Welding Technology in Metal Fabrication

Handheld laser welding technology is transforming the landscape of metal fabrication by offering a range of benefits that cater to both efficiency and precision. Unlike traditional welding methods, which often require extensive setup and preparation, handheld laser welding allows for quicker deployments and less hassle. This innovation minimizes heat input on the metal surfaces, reducing warping and distortion, which is particularly advantageous for high-precision components in aerospace, automotive, and general manufacturing sectors.

One of the significant advantages of handheld laser welding is its ability to facilitate welding in hard-to-reach areas. This versatility enables operators to perform complex welds without the need for extensive reconfiguration of the workpiece. Moreover, the high energy concentration of the laser creates stronger, cleaner welds with minimal post-processing required. As a result, manufacturers can realize not only enhanced product quality but also increased productivity.

Tips: When utilizing handheld laser welding technology, ensure the workspace is well-lit and free of obstructions to enhance visibility and safety. Additionally, regular maintenance of the laser equipment will help maintain optimal performance and welding quality. Finally, training operators thoroughly in the specific techniques of handheld laser welding can significantly reduce errors and improve overall efficiency in metal fabrication projects.

Comparison of Traditional Welding Methods versus Laser Welding

Traditional welding methods, such as MIG, TIG, and stick welding, have long been staples in the metal fabrication industry. These processes typically involve the application of heat to melt and join metal parts, requiring both skill and experience to achieve strong welds. However, drawbacks such as heat distortion, limited accessibility, and the necessity for extensive post-weld cleanup remain prevalent. Moreover, traditional techniques can struggle to meet the demands for precision and rapid completion in modern manufacturing environments.

In contrast, handheld laser welding technology is emerging as a revolutionary alternative. This method utilizes concentrated laser beams to create high-quality welds with minimal heat input, which significantly reduces distortion and improves overall weld integrity. Additionally, the portability of handheld laser systems allows for greater flexibility and access to hard-to-reach areas that traditional methods may not accommodate efficiently. The precision inherent in laser welding not only enhances the aesthetic quality of the welds but also decreases the need for extensive finishing work, streamlining production processes and ultimately saving time and costs in metal fabrication.

Key Innovations in Handheld Laser Welding Equipment

The advancement of handheld laser welding technology is transforming the metal fabrication industry by offering unprecedented precision and versatility. Key innovations in equipment design have made these tools more user-friendly and efficient, allowing welders to perform intricate work in a variety of environments. For instance, many modern handheld laser welders are now equipped with lightweight, ergonomic designs that reduce operator fatigue, enabling longer work hours without compromising quality.

Tips for choosing the right handheld laser welding equipment include considering the power output, which affects the thickness of materials that can be welded. Additionally, assess the cooling system of the welder, as efficient cooling is vital for maintaining optimal performance during extended use. Finally, look for models with built-in safety features, such as automatic shut-off or integrated protective shields, to ensure a safe working environment.

As industries continue to embrace these innovations, the integration of smart technology, such as real-time monitoring and diagnostics, is becoming increasingly common. This advancement not only enhances the welding process but also reduces downtime, allowing for higher productivity in metal fabrication projects. Investing in state-of-the-art handheld laser welding equipment is essential for businesses looking to stay competitive in an ever-evolving market.

Applications of Handheld Laser Welding Across Industries

Handheld laser welding technology is transforming metal fabrication across various industries, showcasing its versatility in applications ranging from automotive to aerospace. According to a recent report by MarketsandMarkets, the global laser welding market is projected to grow from $5.3 billion in 2022 to $8.5 billion by 2027, driven significantly by advancements in handheld laser systems. These tools provide flexibility and precision, allowing manufacturers to perform high-quality welds in hard-to-reach locations, thus enhancing productivity and reducing downtime.

In the automotive sector, handheld laser welding is increasingly utilized for joining lightweight materials, which are pivotal for enhancing fuel efficiency and reducing emissions. A study by the International Energy Agency highlights that light-weighting strategies, supported by effective joining techniques like laser welding, could reduce vehicle mass by up to 40%. Similarly, in the aerospace industry, the ability to weld intricate components with minimal thermal distortion is critical. Research indicates that manufacturers utilizing handheld laser systems can achieve weld speeds up to 25% faster than traditional methods, significantly improving production timelines while maintaining the stringent safety standards required in high-stakes environments.

Future Trends in Metal Fabrication and Laser Technology

The future of metal fabrication is being significantly reshaped by advancements in laser technology, particularly evident at recent industry gatherings such as FABTECH 2025 in Chicago. The global market for metal fabrication equipment is expected to grow from $64.64 billion in 2025 to $82.78 billion by 2032, at a CAGR of 3.6%. This growth is largely driven by innovations in laser welding techniques, which are becoming crucial for modern manufacturing processes. Notably, high-power laser cutting and welding are transforming the landscape due to their efficiency and precision, catering to the increasing demands for high-quality fabrication.

As the laser welding market is projected to ascend to USD 4.2 billion, with a CAGR of 3.7% during the period from 2025 to 2035, the emphasis on integrating advanced laser technologies in industrial applications is undeniable. Companies like Fortune Laser Technology Co., Ltd. are at the forefront of this revolution, combining R&D, production, and service to deliver cutting-edge solutions. This convergence of technology and manufacturing not only enhances operational efficiency but also opens avenues for innovative applications in metal fabrication, highlighting a significant trend towards automation and smart manufacturing practices in the industry.

Challenges and Solutions in Adopting Handheld Laser Welding

The adoption of handheld laser welding technology presents significant challenges for companies venturing into this innovative field. One primary concern is the need for skilled operators who can effectively manage and manipulate the laser equipment, as the precision required for high-quality welds is considerably higher than traditional methods. Fortune Laser Technology Co., Ltd., with its extensive experience in the laser equipment industry, addresses this issue by offering comprehensive training programs, ensuring that operators are well-equipped to utilize the technology efficiently and safely.

Another challenge is the integration of handheld laser welding into existing production workflows. Many manufacturers have established processes that may not align seamlessly with new technology. Fortune Laser Technology emphasizes the importance of customizable solutions that can be tailored to specific production needs. By collaborating closely with clients, the company helps to design and implement solutions that enhance productivity while minimizing disruptions. This proactive approach not only streamlines the adoption process but also exemplifies Fortune Laser Technology's commitment to innovation and customer satisfaction in the metal fabrication industry.

FAQS

: Handheld laser welding technology utilizes concentrated laser beams to create high-quality welds, providing a more efficient and precise alternative to traditional welding methods.

The main benefits include quicker deployments, less preparation, reduced heat input minimizing warping and distortion, enhanced product quality, and increased productivity.

Handheld laser welding allows operators to perform complex welds in hard-to-reach areas without the need for extensive reconfiguration of the workpiece.

Traditional welding methods often face issues such as heat distortion, limited accessibility, requirement for skilled operators, and extensive post-weld cleanup.

Laser welding offers superior precision, enhancing the aesthetic quality of welds and decreasing the need for extensive finishing work, which streamlines production processes.

Regular maintenance of the laser equipment is important for maintaining optimal performance and welding quality, along with ensuring the workspace is well-lit and free of obstructions.

The minimal heat input of laser welding reduces distortion and improves overall weld integrity, allowing for cleaner and stronger welds.

Yes, thoroughly training operators in the specific techniques of handheld laser welding can significantly reduce errors and improve overall efficiency in metal fabrication projects.

Yes, by streamlining production processes and minimizing post-weld cleanup, handheld laser welding can save time and costs in metal fabrication.

Handheld laser welding is particularly beneficial in sectors such as aerospace, automotive, and general manufacturing due to its high precision and efficiency.

Conclusion

The article "Revolutionizing Metal Fabrication with Innovative Handheld Laser Welding Technology" explores the transformative impact of handheld laser welding machines in the metal fabrication industry. As highlighted, these machines offer numerous benefits over traditional welding methods, including increased precision, reduced heat distortion, and enhanced portability. The comparison reveals that while traditional welding techniques may still hold value in certain applications, the efficiency and versatility of handheld laser welding are reshaping industry standards.

Key innovations in handheld laser welding equipment are discussed, such as improvements in power efficiency and user-friendly designs, which open up new applications across various sectors, from automotive to aerospace. Furthermore, the article sheds light on future trends in metal fabrication and laser technology, emphasizing the potential of handheld laser welding machines to address common challenges faced by manufacturers. As a leader in industrial laser equipment, Fortune Laser Technology Co., Ltd. is well-positioned to drive these advancements within the market.

Related Posts

-

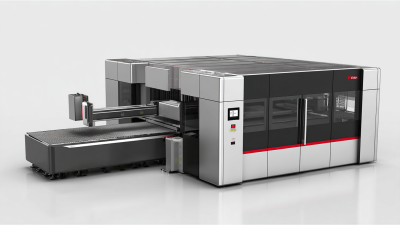

Explore the Advantages of the Best Exchange Table Fiber Laser Cutting Machine: Top Industry Examples and Data Insights

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

2025 Trends in Precision: Elevating Jewelry Production with the Best Laser Cutting Technology

-

Finding Top Suppliers for Best 3015 Fiber Laser Cutter Your Essential Checklist Guide

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

How to Choose the Right Laser Welding Machine for Your Business Needs

Blog Tags: