- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Revolutionize Your Industrial Cleanliness: The Future of Pulse Laser Cleaning Machines

Table of Contents

- Benefits of Pulse Laser Cleaning Machines in Industrial Applications

- Understanding the Technology Behind Pulse Laser Cleaning

- Comparative Analysis: Pulse Laser vs. Traditional Cleaning Methods

- Cost-Effectiveness and Efficiency Metrics of Laser Cleaning Solutions

- Future Trends: Advancements in Laser Cleaning Technology for Industries

- Environmental Impact: Sustainability of Pulse Laser Cleaning Machines

- FAQS

- Conclusion

- Related Posts

In recent years, the industrial cleaning sector has witnessed a transformative shift towards advanced technologies, particularly with the advent of the Pulse Laser Cleaning Machine. According to a report by MarketsandMarkets, the global laser cleaning market is projected to reach USD 1.2 billion by 2026, growing at a CAGR of 4.2% from 2021. This growth underscores the increasing demand for efficient and environmentally friendly cleaning solutions across various industries, including manufacturing, automotive, and maintenance.

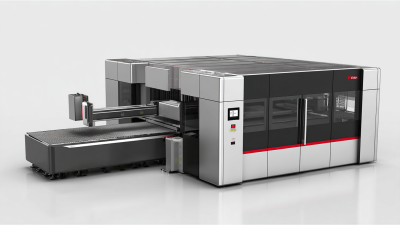

Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, is at the forefront of this technological revolution. As a professional manufacturer of industrial laser equipment, we specialize in the research, development, production, and maintenance services of Pulse Laser Cleaning Machines. By leveraging cutting-edge laser technology, we aim to set new standards for cleanliness, safety, and sustainability in industrial applications, promising a brighter and cleaner future for the industry.

Benefits of Pulse Laser Cleaning Machines in Industrial Applications

Pulse laser cleaning machines are transforming industrial cleanliness, offering significant benefits across various applications. These advanced tools utilize ultrafast femtosecond lasers to precisely remove contaminants, such as rust and paint, from surfaces without damaging the underlying materials. This capability not only enhances the cleaning process but also promotes sustainability by minimizing the use of harsh chemicals traditionally employed in industrial cleaning.

The adoption of pulse laser cleaning technology is on the rise, driven by its efficiency and effectiveness. Industries are witnessing decreased downtime as machinery and equipment can be cleaned in place, reducing the need for disassembly. Furthermore, the precision of laser cleaning minimizes waste, ensuring that surfaces are left intact, which is particularly advantageous in sectors like aerospace and automotive manufacturing. As more companies recognize these benefits, pulse laser cleaning machines are set to redefine standards for cleanliness and maintenance in industrial environments.

Understanding the Technology Behind Pulse Laser Cleaning

Pulse laser cleaning technology represents a groundbreaking advancement in industrial cleanliness, harnessing the power of concentrated light to effectively remove contaminants from various surfaces. Unlike traditional cleaning methods that often resort to harsh chemicals or abrasive techniques, pulse laser systems use short bursts of high-energy light to target specific pollutants. This energy is absorbed by the contaminants, resulting in their rapid thermal expansion and subsequent removal without damaging the underlying material. This precision makes pulse laser cleaning suitable for a wide range of applications, from delicate components in electronics to heavy machinery in manufacturing.

The technology behind pulse laser cleaning lies in its ability to generate high-intensity pulses within fractions of a second. These pulses can be finely tuned to optimize the cleaning process for different materials and types of contaminants, including rust, paint, and dirt. The integration of advanced optics and control systems allows operators to adjust parameters such as pulse duration and intensity, maximizing efficiency while minimizing waste and environmental impact. As industries increasingly prioritize sustainability and efficiency, pulse laser cleaning machines are poised to become essential tools in achieving superior cleanliness in industrial settings.

Comparative Analysis: Pulse Laser vs. Traditional Cleaning Methods

The cleaning industry is experiencing a significant shift as pulse laser cleaning machines emerge as a formidable alternative to traditional methods. While conventional techniques often rely on harsh chemicals and abrasive materials, pulse laser cleaning offers a non-invasive solution that minimizes surface damage and environmental impact. This innovative method effectively removes contaminants such as rust, paint, and grease using high-intensity laser pulses, making it an attractive option for various sectors, including manufacturing and automotive industries.

Recent market analysis indicates a growing trend toward laser cleaning technologies, projected to enhance market share significantly in the coming years. By breaking down the market by laser type—comprising solid state lasers, YAG lasers, fiber lasers, gas lasers, excimer lasers, and CO2 lasers—it becomes clear that different industries will adopt specific laser solutions based on their cleaning needs. Industries like general manufacturing, aerospace, and electronics are increasingly recognizing the efficiency and versatility of pulse laser cleaning, positioning it as a key player in the future of industrial cleanliness.

Cost-Effectiveness and Efficiency Metrics of Laser Cleaning Solutions

As industries increasingly focus on sustainability and efficiency, pulse laser cleaning machines are poised to become pivotal solutions in enhancing industrial cleanliness. The laser cleaning market is expected to grow significantly, projected to reach USD 1.05 billion by 2032. This growth is fueled by the demand for non-contact, eco-friendly cleaning methods that provide precise surface treatment across various sectors, such as automotive and aerospace.

Cost-effectiveness is a critical metric in evaluating laser cleaning solutions. Recent advancements in technologies, such as the incorporation of YOLOv8-seg and Mask R-CNN for laser cleaning processes, enhance precision and operational efficiency. These innovations allow for improved monitoring and verification during cleaning operations, minimizing waste and maximizing output. As industries adopt these methods, they can achieve substantial long-term savings through reduced material usage and increased productivity, ultimately driving down operational costs and improving return on investment.

Revolutionize Your Industrial Cleanliness: The Future of Pulse Laser Cleaning Machines - Cost-Effectiveness and Efficiency Metrics of Laser Cleaning Solutions

| Metric | Value | Unit |

|---|---|---|

| Initial Investment Cost | $50,000 | USD |

| Annual Maintenance Cost | $2,000 | USD |

| Operating Efficiency | 90% | Percentage |

| Cleaning Speed | 50 | m²/h |

| Energy Consumption | 10 | kWh/m² |

| Return on Investment (ROI) | 300% | Percentage |

| Average Lifespan | 10 | Years |

Future Trends: Advancements in Laser Cleaning Technology for Industries

The rapid evolution of laser technology is transforming industrial cleanliness, heralding a future where pulse laser cleaning machines are at the forefront. Future trends indicate that industrial femtosecond laser advancements are set to drive next-generation applications across various sectors.

Higher power outputs, enhanced pulse repetition frequencies, and shorter wavelengths are paving the way for more efficient and versatile cleaning solutions. Industry reports suggest that the global laser cleaning market is expected to experience significant growth, with projections estimating an annual growth rate of over 20% from 2025 to 2030.

In this context, eco-friendly and chemical-free solutions for rust removal are gaining traction, exemplified by innovations showcased in international events. These advancements not only contribute to sustainable manufacturing practices but also optimize operational efficiency. At Fortune Laser Technology Co., Ltd., we are at the cutting edge of these developments, committed to integrating research and production to deliver top-tier industrial laser equipment. As laser cleaning technology continues to progress, industries will benefit from increased productivity and a marked reduction in environmental impact.

Environmental Impact: Sustainability of Pulse Laser Cleaning Machines

Pulse laser cleaning machines represent a transformative advancement in industrial cleanliness, especially concerning environmental sustainability. Unlike traditional cleaning methods that often rely on harsh chemicals and generate significant waste, pulse laser technology provides a non-contact and eco-friendly alternative. This method minimizes the use of solvents and abrasive materials, aligning with the growing trend towards sustainable practices across various industries, such as automotive and aerospace.

Pulse laser cleaning machines represent a transformative advancement in industrial cleanliness, especially concerning environmental sustainability. Unlike traditional cleaning methods that often rely on harsh chemicals and generate significant waste, pulse laser technology provides a non-contact and eco-friendly alternative. This method minimizes the use of solvents and abrasive materials, aligning with the growing trend towards sustainable practices across various industries, such as automotive and aerospace.

Moreover, recent studies have highlighted the application of laser-induced texturing in enhancing the self-cleaning capabilities of solar panels, showcasing the potential for lasers not only in cleaning but also in promoting sustainability in renewable energy technologies. As the laser cleaning market is projected to grow significantly, reaching over USD 1 billion by 2032, it is clear that these innovations will play a crucial role in reducing the environmental impact of industrial processes. By adopting pulse laser cleaning machines, businesses can significantly lower their carbon footprint while maintaining high standards of cleanliness and operational efficiency.

FAQS

: Pulse laser cleaning machines are used to precisely remove contaminants like rust, paint, and grease from surfaces without damaging the underlying materials, enhancing the cleaning process and promoting sustainability.

Unlike traditional methods that rely on harsh chemicals and abrasive materials, pulse laser cleaning offers a non-invasive solution that minimizes surface damage and environmental impact.

Industries such as manufacturing, aerospace, automotive, and electronics are increasingly recognizing the efficiency and versatility of pulse laser cleaning machines.

The benefits include reduced downtime as machinery can be cleaned in place, minimized waste due to precise cleaning, and enhanced sustainability with less use of harmful chemicals.

The laser cleaning market is projected to grow significantly, reaching USD 1.05 billion by 2032, driven by the demand for eco-friendly cleaning solutions.

Advancements like the incorporation of YOLOv8-seg and Mask R-CNN enhance precision and operational efficiency, allowing for better monitoring and verification during cleaning operations.

Cost-effectiveness is measured by reductions in material usage, increased productivity, and long-term savings that contribute to improved return on investment.

Yes, pulse laser cleaning machines can effectively clean a variety of surfaces without causing damage, making them suitable for diverse industrial applications.

The shift is due to the efficiency, effectiveness, and environmental benefits of laser cleaning technologies compared to conventional cleaning methods.

Different types of lasers used include solid state lasers, YAG lasers, fiber lasers, gas lasers, excimer lasers, and CO2 lasers, chosen based on specific cleaning needs.

Conclusion

The article "Revolutionize Your Industrial Cleanliness: The Future of Pulse Laser Cleaning Machines" highlights the transformative benefits of adopting Pulse Laser Cleaning Machines in various industrial applications. These machines utilize advanced technology to efficiently remove contaminants without causing damage to surfaces, setting them apart from traditional cleaning methods. A comprehensive comparative analysis demonstrates their superior cost-effectiveness and efficiency metrics, making them an attractive solution for modern industries.

Furthermore, the article explores future trends in laser cleaning technology, including advancements that will enhance performance and sustainability. As a professional manufacturer dedicated to innovation, Fortune Laser Technology Co., Ltd. is at the forefront of this industry, committed to providing cutting-edge Pulse Laser Cleaning Machines that meet the evolving needs of industrial cleanliness while minimizing environmental impact.

Related Posts

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

5 Best Pulsed Laser Cleaning Machines for Global Buyers in 2023

-

Revolutionizing Surface Restoration with Laser Cleaner Rust Removal for Industrial Applications

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

What is a Pulsed Laser Cleaner and How Does It Transform Surface Cleaning?

-

Revolutionizing Surface Restoration: Benefits of the Portable Laser Cleaning Machine