- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

What is the Purpose of Square Pipe Cutting Machines in Modern Manufacturing

Table of Contents

- The Evolution of Square Pipe Cutting Machines in Manufacturing

- Key Features and Technologies of Modern Square Pipe Cutting Machines

- The Benefits of Using Square Pipe Cutting Machines in Production Efficiency

- Applications of Square Pipe Cutting Machines Across Various Industries

- Future Innovations in Square Pipe Cutting Technology and Their Implications

- Comparing Square Pipe Cutting Machines to Other Cutting Technologies in Manufacturing

- FAQS

- Conclusion

- Related Posts

In the ever-evolving landscape of modern manufacturing, the utilization of advanced machinery has become critical for enhancing efficiency and precision in production processes. Among these innovations, the Square Pipe Cutting Machine plays a pivotal role, enabling manufacturers to achieve intricate designs and optimal material utilization with minimal waste. According to a recent industry report, the global demand for metal cutting machinery, including square pipe cutting technologies, is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030, driven by industries such as construction, automotive, and furniture.

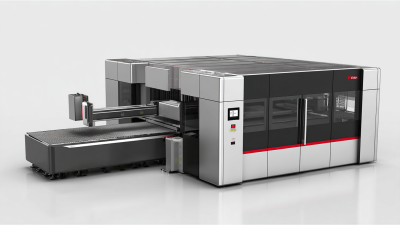

Established in 2016, Fortune Laser Technology Co., Ltd. has positioned itself as a leading manufacturer of industrial laser equipment, offering cutting-edge solutions that not only streamline operations but also enhance product quality. By integrating research and development with production, sales, and maintenance services, Fortune Laser Technology ensures that clients are equipped with the most advanced Square Pipe Cutting Machines, tailored to meet the challenges of today’s manufacturing demands.

The Evolution of Square Pipe Cutting Machines in Manufacturing

The evolution of square pipe cutting machines has been remarkable, significantly enhancing the efficiency and precision in modern manufacturing processes. Initially, these machines were rudimentary, offering limited capabilities that often resulted in inaccurate cuts and material wastage. However, with advancements in technology, particularly the integration of CNC (Computer Numerical Control) systems, contemporary square pipe cutting machines now provide exceptional precision, capable of achieving tolerances of ±0.5 mm. According to a recent report by MarketsandMarkets, the global market for cutting machines is projected to reach $4.91 billion by 2025, reflecting an annual growth rate of 6.5%, largely driven by the demand for automation and precision in manufacturing.

Moreover, the introduction of laser and plasma cutting technologies has transformed the landscape of square pipe fabrication. These methods not only increase cutting speeds but also improve the quality of the cuts by reducing the heat-affected zones, which can compromise the integrity of the material. A study by Grand View Research indicated that laser cutting technology alone is expected to witness a compound annual growth rate (CAGR) of 5.8% from 2020 to 2027. This trend towards highly efficient cutting solutions underscores the critical role that advanced square pipe cutting machines play in modern manufacturing, enabling businesses to meet stringent production deadlines while maintaining high standards of quality.

Key Features and Technologies of Modern Square Pipe Cutting Machines

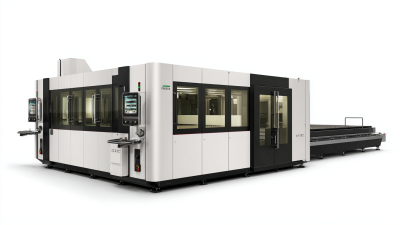

Modern square pipe cutting machines play a vital role in enhancing efficiency and precision in manufacturing processes. One of the key features of these machines is their advanced cutting technology, which often includes laser, plasma, or water jet cutting. These methods not only yield clean edges but also reduce material wastage, thus optimizing production costs. Additionally, the automation capabilities of modern machines facilitate faster operation, allowing manufacturers to meet tight deadlines without compromising quality.

Another significant aspect of modern square pipe cutting machines is their integration with smart technology and IoT systems. These machines are equipped with sensors and software that enable real-time monitoring and adjustments during the cutting process. This feature not only enhances accuracy but also minimizes human error. Moreover, the programmable settings allow for customization based on specific project requirements, making these machines versatile for various applications in industries ranging from construction to automotive. The combination of precision, speed, and smart technology positions square pipe cutting machines as indispensable tools in today's competitive manufacturing landscape.

What is the Purpose of Square Pipe Cutting Machines in Modern Manufacturing - Key Features and Technologies of Modern Square Pipe Cutting Machines

| Feature | Description | Benefits | Technologies Used |

|---|---|---|---|

| Precision Cutting | High accuracy in cutting square pipes to required dimensions. | Minimized wastage of material and enhanced product quality. | CNC Technology, Laser Cutting. |

| Versatility | Ability to cut various sizes and thicknesses of square pipes. | Useful in diverse applications across industries. | Hydraulic Systems, Adjustable Jigs. |

| Efficiency | Fast cutting speeds that reduce production time. | Increased throughput and productivity in manufacturing. | Automatic Feed Systems, Advanced Software. |

| User-Friendly Interface | Intuitive controls and programming for easy operation. | Reduced training time for operators, leading to smoother operations. | Touch Screen Controls, Programmable Logic Controllers (PLC). |

| Safety Features | Built-in safety mechanisms to protect operators during use. | Minimized risk of accidents and injuries in the workplace. | Emergency Stop Systems, Safety Guards. |

The Benefits of Using Square Pipe Cutting Machines in Production Efficiency

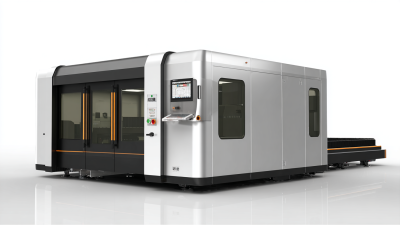

Square pipe cutting machines play a crucial role in enhancing production efficiency within modern manufacturing settings. By automating the cutting process, these machines significantly reduce the time and labor required compared to traditional manual cutting methods. This automation not only speeds up the production line but also minimizes human error, leading to a higher consistency in cut quality. As a result, manufacturers can increase their throughput without compromising on precision.

Additionally, the use of square pipe cutting machines allows for better resource management. These machines are designed to optimize material usage by providing precise cuts that minimize waste. With advanced features such as programmable settings and a range of cutting speeds, manufacturers can tailor operations to meet specific project requirements. This flexibility enables businesses to respond quickly to changing demands and ultimately enhances overall productivity, making square pipe cutting machines an invaluable asset in the contemporary manufacturing landscape.

Applications of Square Pipe Cutting Machines Across Various Industries

Square pipe cutting machines play a vital role across various industries by enhancing precision and efficiency in manufacturing processes. In the construction and structural engineering sectors, these machines are essential for producing accurate cuts on square pipes, which are commonly used in frameworks, supports, and braces. Their ability to handle various materials, such as steel and aluminum, ensures that engineers can rely on them for consistent quality in building elements, greatly reducing waste and improving overall productivity.

Square pipe cutting machines play a vital role across various industries by enhancing precision and efficiency in manufacturing processes. In the construction and structural engineering sectors, these machines are essential for producing accurate cuts on square pipes, which are commonly used in frameworks, supports, and braces. Their ability to handle various materials, such as steel and aluminum, ensures that engineers can rely on them for consistent quality in building elements, greatly reducing waste and improving overall productivity.

In the automotive industry, square pipe cutting machines are utilized for fabricating parts for vehicles, including chassis and exhaust systems. The machines enable manufacturers to create complex shapes and sizes required for modern vehicle designs, contributing significantly to innovation and performance. Additionally, in the furniture manufacturing sector, these machines facilitate the crafting of various furniture frames and structures, allowing for both mass production and bespoke designs without compromising on quality. The versatility of square pipe cutting machines hence makes them indispensable in various applications, streamlining operations and ensuring high standards in product fabrication.

Future Innovations in Square Pipe Cutting Technology and Their Implications

The future of square pipe cutting technology is poised for remarkable advancements that will redefine manufacturing processes. Innovations such as automated robotic systems are set to enhance precision in cutting operations, reducing the margin for error significantly. These systems utilize advanced sensors and AI algorithms to ensure that each cut meets strict quality standards, which not only improves product consistency but also minimizes waste, ultimately contributing to more sustainable manufacturing practices.

Moreover, the integration of smart technologies is expected to revolutionize maintenance and operational efficiency. With IoT capabilities, machines can provide real-time data analytics and predictive maintenance alerts, allowing manufacturers to optimize workflows and reduce downtime. As these innovations unfold, the implications for the industry will be profound, driving competitiveness and enabling manufacturers to meet the increasingly complex demands of the market while maintaining high levels of productivity and efficiency. These advancements signify a critical shift towards smarter, more adaptive manufacturing environments that can respond rapidly to the evolving needs of customers.

Comparing Square Pipe Cutting Machines to Other Cutting Technologies in Manufacturing

In modern manufacturing, square pipe cutting machines play a crucial role in enhancing efficiency and precision compared to traditional cutting technologies. According to a report by MarketsandMarkets, the global cutting machines market is expected to reach $7.26 billion by 2025, with square pipe cutting technologies gaining a larger share owing to their adaptability in various applications. These machines not only streamline the cutting process but also ensure tighter tolerances, ultimately reducing waste and production costs.

When comparing square pipe cutting machines to other cutting technologies, such as laser or plasma cutting, it's evident that each has its unique advantages. Recent industry analyses highlight that laser cutting is favored for its intricate detail capabilities, while plasma cutting is known for speed. However, square pipe cutting machines excel in processing larger batches with uniformity. The versatility of square pipe machines allows manufacturers to efficiently handle a range of materials, including steel, aluminum, and plastic, ensuring that they remain competitive in a rapidly evolving market. This adaptability is a significant driver behind the increasing adoption of square pipe cutting technologies across various sectors.

FAQS

: Initial square pipe cutting machines were rudimentary and offered limited capabilities, resulting in inaccurate cuts and material wastage. Modern machines have evolved significantly with the integration of CNC systems, achieving exceptional precision with tolerances of ±0.5 mm.

The global market for cutting machines is projected to reach $4.91 billion by 2025, with a compound annual growth rate (CAGR) of 6.5%, driven largely by increased demand for automation and precision in manufacturing.

Laser and plasma cutting technologies have improved cutting speeds and quality by reducing heat-affected zones, which helps maintain the integrity of the material during the cutting process.

Laser cutting technology is expected to witness a compound annual growth rate (CAGR) of 5.8% during the period from 2020 to 2027.

Modern square pipe cutting machines incorporate advanced cutting technologies such as laser, plasma, or water jet cutting, which yield clean edges and reduce material wastage, optimizing production costs.

Automation facilitates faster operation, allowing manufacturers to meet tight deadlines without compromising quality while enhancing efficiency in the cutting process.

Smart technology and IoT systems enable real-time monitoring and adjustments, enhancing accuracy and minimizing human error during the cutting process.

Yes, modern machines come with programmable settings that allow for customization based on specific project requirements, making them versatile for various applications across different industries.

They are used across diverse industries, including construction and automotive, due to their precision, speed, and versatility.

They enable businesses to meet stringent production deadlines while maintaining high standards of quality, making them indispensable tools in competitive manufacturing environments.

Conclusion

Square Pipe Cutting Machines have become essential tools in modern manufacturing, significantly advancing the efficiency and precision of production processes. As these machines have evolved, their cutting-edge features and technologies have allowed manufacturers to achieve higher productivity while maintaining quality. The benefits of utilizing Square Pipe Cutting Machines include enhanced operational efficiency, reduced waste, and increased competitiveness across various industries.

At Fortune Laser Technology Co., Ltd., we recognize the importance of these machines and have been committed to developing innovative solutions since our establishment in 2016. Our expertise in industrial laser equipment, combined with a focus on R&D and maintenance services, positions us to meet the growing demands of manufacturing sectors. Looking ahead, the future innovations in Square Pipe Cutting Technology will continue to shape production dynamics, ensuring businesses can adapt and thrive in an ever-changing market.

Related Posts

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

The Ultimate Guide to Choosing the Best Fiber Laser Cutting Equipment for Your Business Needs

-

5 Essential Tips for Maximizing Efficiency with Fiber Laser Cutting Machines

-

5 Incredible Benefits of Using a Laser Cleaner Handheld Device

-

Exploring Laser Cleaning Machine Innovations at 2025 China Import and Export Fair: Industry Trends and Market Growth

-

How to Choose the Right Fully Enclosed Fiber Laser Cutter for Your Business Needs

Blog Tags: