- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

Table of Contents

- Benefits of Using a Large Format Laser Cleaning Machine in Your Workflow

- Key Features to Look for in a Large Format Laser Cleaning Machine

- Step-by-Step Guide to Setting Up Your Laser Cleaning Machine

- Best Practices for Maintenance and Care of Your Laser Cleaning Equipment

- Common Applications of Large Format Laser Cleaning in Various Industries

- Tips for Maximizing Efficiency with Your Laser Cleaning Processes

- FAQS

- Conclusion

- Related Posts

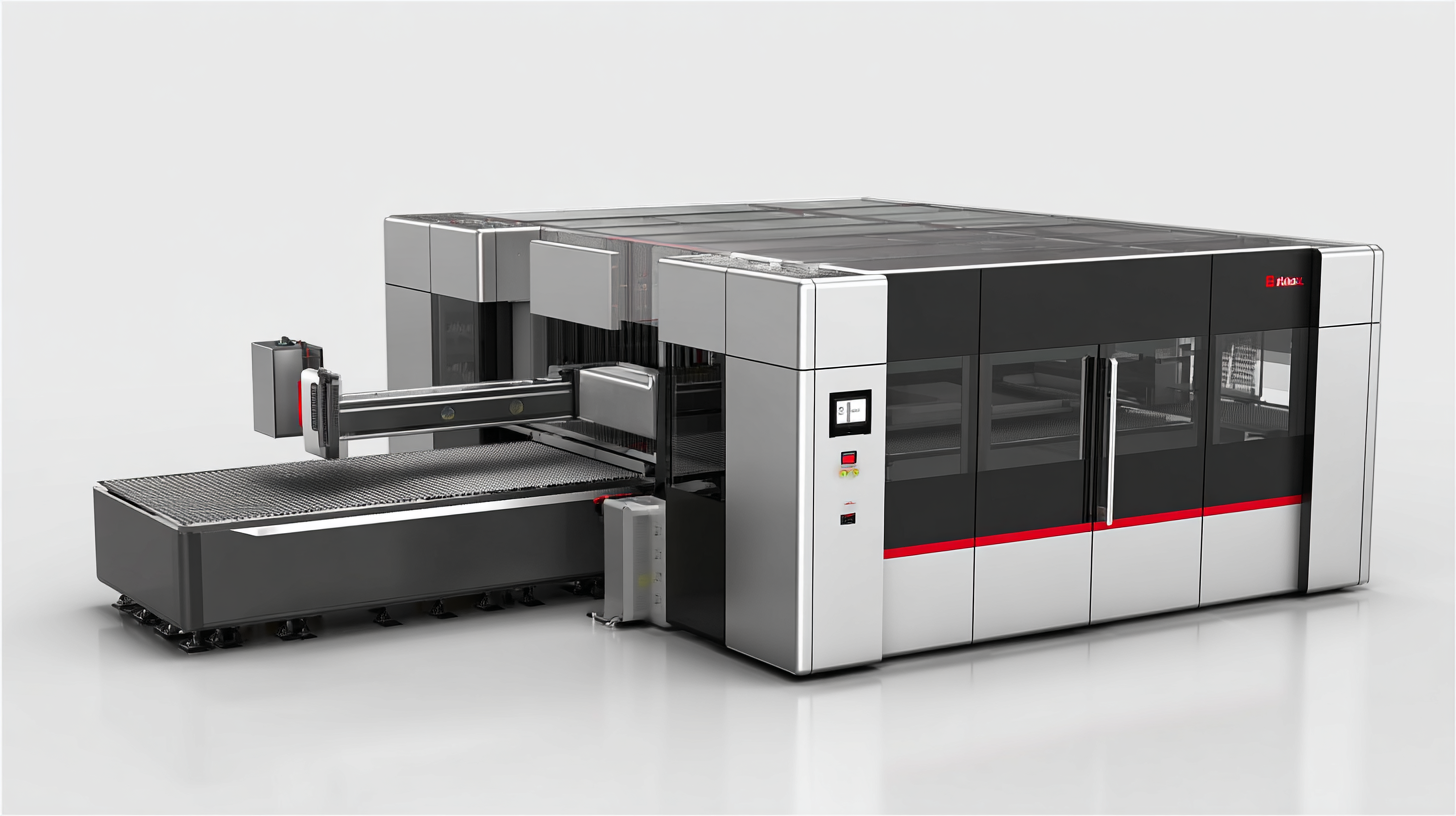

In today's fast-paced industrial landscape, efficiency and precision are paramount, and the introduction of the Large Format Laser Cleaning Machine is revolutionizing how companies optimize their workflows. At Fortune Laser Technology Co., Ltd., a leading manufacturer of industrial laser equipment based in Shenzhen, we understand the critical role that advanced technology plays in enhancing productivity. Established in 2016, our company combines R&D, production, sales, and maintenance services to provide cutting-edge solutions tailored to the needs of various industries. This blog will explore the numerous benefits of integrating a Large Format Laser Cleaning Machine into your operations, showcasing how it can lead to significant time savings, improved cleanliness, and cost efficiency, ultimately fostering a streamlined workflow that meets the demands of modern manufacturing.

In today's fast-paced industrial landscape, efficiency and precision are paramount, and the introduction of the Large Format Laser Cleaning Machine is revolutionizing how companies optimize their workflows. At Fortune Laser Technology Co., Ltd., a leading manufacturer of industrial laser equipment based in Shenzhen, we understand the critical role that advanced technology plays in enhancing productivity. Established in 2016, our company combines R&D, production, sales, and maintenance services to provide cutting-edge solutions tailored to the needs of various industries. This blog will explore the numerous benefits of integrating a Large Format Laser Cleaning Machine into your operations, showcasing how it can lead to significant time savings, improved cleanliness, and cost efficiency, ultimately fostering a streamlined workflow that meets the demands of modern manufacturing.

Benefits of Using a Large Format Laser Cleaning Machine in Your Workflow

In today's competitive industrial landscape, optimizing workflow is crucial for efficiency and productivity. One standout solution gaining traction is the large format laser cleaning machine. Specifically designed to handle extensive cleaning tasks, these machines bring numerous benefits that can significantly enhance your operations. By utilizing advanced laser technology, they can effectively remove contaminants like rust, paint, and dirt without damaging the underlying materials, ensuring high-quality results every time.

As a leading manufacturer in the field, Fortune Laser Technology Co., Ltd. understands the importance of integrating effective cleaning solutions into industrial workflows. Our large format laser cleaning machines not only streamline the maintenance processes but also reduce the need for chemical cleaners, promoting a more environmentally friendly approach. Furthermore, their ability to operate with minimal downtime allows businesses to maintain productivity levels, making them an invaluable asset in any manufacturing setting. With our commitment to innovation and quality, we are dedicated to providing machines that cater to the evolving needs of industries worldwide.

Key Features to Look for in a Large Format Laser Cleaning Machine

When considering a large format laser cleaning machine, there are several key features that can significantly enhance your workflow. One of the most important aspects is the machine's versatility. Look for a model that can handle various surfaces, including metals, plastics, and composites, to ensure it can meet your diverse cleaning needs. Additionally, a user-friendly interface can streamline operations, allowing your team to focus more on productivity and less on complex setups.

Another crucial feature to consider is the machine's efficiency. High-powered lasers with adjustable power settings can provide precise cleaning without damaging the substrate. This feature is essential for industrial applications where the integrity of the material is paramount. Moreover, features such as automatic focusing and a large cleaning area can reduce downtime and increase throughput, enabling your business to tackle larger projects with ease. Fortune Laser Technology Co., Ltd. specializes in manufacturing such advanced laser cleaning machines, ensuring that you have access to reliable technology that supports your operational goals.

Step-by-Step Guide to Setting Up Your Laser Cleaning Machine

Setting up a large format laser cleaning machine requires a systematic approach to optimize your workflow. First, ensure that you have the right environment for the installation. According to a recent industry report by the Laser Institute of America, facilities equipped with adequate ventilation and safety measures can increase operational efficiency by up to 30%. This step is essential, as it allows for effective fume extraction and prevents contamination of the work area, ensuring a safe and productive environment.

Next, calibrate your machine settings appropriately for the materials you will be cleaning. Research shows that adjusting the laser intensity and pulse frequency according to the substrate types can enhance cleaning effectiveness by 50%. For example, different metals require different settings to achieve optimal results without compromising the integrity of the surface. A step-by-step guide to these settings often includes leveraging the machine’s built-in software, which can provide valuable feedback and adjustments tailored to your specific needs. By following these guidelines, users can significantly improve both the quality of cleaning and the overall efficiency of their operations.

Best Practices for Maintenance and Care of Your Laser Cleaning Equipment

Maintaining a large format laser cleaning machine is crucial to ensuring its efficiency and longevity. According to a report by Research and Markets, the global laser cleaning equipment market is projected to reach $1 billion by 2025, emphasizing the growing reliance on advanced technologies in industrial applications. Regular maintenance practices such as checking the cooling system, cleaning the optics, and inspecting the laser source can significantly enhance equipment performance and extend service life. Implementing a structured maintenance schedule not only boosts productivity but also minimizes unexpected downtimes, which can be costly.

At Fortune Laser Technology Co., Ltd., established in 2016, we understand the importance of proper care for laser cleaning machines. Our commitment to R&D means we constantly adapt our equipment to meet industry standards, ensuring optimal performance. A specialized maintenance team can help identify potential issues early, thereby reducing the risk of extensive repairs. Additionally, utilizing original parts for replacements can further maintain the integrity of the machinery. As the industry evolves, companies that prioritize the maintenance of their laser cleaning equipment will likely experience higher operational efficiency and lower long-term costs.

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine - Best Practices for Maintenance and Care of Your Laser Cleaning Equipment

| Maintenance Task | Frequency | Recommended Tools | Notes |

|---|---|---|---|

| Clean the lens | Weekly | Lens cleaning solution, cotton swabs | Ensure the machine is off before cleaning |

| Check the alignment | Monthly | Alignment tools | Proper alignment ensures optimal performance |

| Inspect electrical components | Quarterly | Multimeter, screwdriver | Look for any signs of wear or damage |

| Update software | As needed | Computer with internet access | Keep the software up to date for best functionality |

| Coolant level check | Weekly | Coolant fluid | Low coolant can cause overheating |

Common Applications of Large Format Laser Cleaning in Various Industries

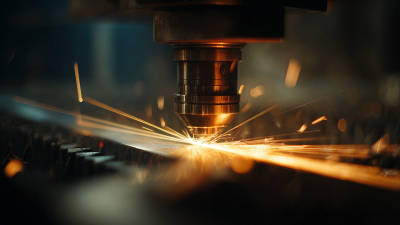

Large format laser cleaning machines are gaining traction across various industries due to their effectiveness and versatility. These machines utilize fiber laser technology, which can be categorized into continuous wave, pulsed, quasi-continuous wave, and mode-locked fiber lasers. Each type serves different applications, making laser cleaning a go-to solution for diverse tasks. Industries such as manufacturing, automotive, and aerospace are now leveraging these technologies to enhance their workflow and outcomes.

One of the most common applications is in the removal of contaminants from surfaces, including rust, paint, and oxidation. For example, in the automotive sector, large format laser cleaning machines are employed to prepare metal surfaces for painting or coating, ensuring superior adhesion and finish. In the manufacturing realm, they are used for cleaning delicate components without causing damage, thus prolonging the lifespan of machinery and tools.

As businesses continue to seek efficiency and sustainability, the adoption of laser cleaning technologies is expected to grow, presenting opportunities for advancements in fiber laser applications and market expansion.

Tips for Maximizing Efficiency with Your Laser Cleaning Processes

Maximizing efficiency in your laser cleaning processes begins with understanding the capabilities and settings of your large format laser cleaning machine. First and foremost, ensure that you have a thorough knowledge of the material you are working with and the specific contaminants you aim to remove. Adjusting the laser power, speed, and focal distance to match the requirements of the task at hand can significantly enhance the cleaning effectiveness and speed. Regularly calibrating the machine and testing various settings on sample materials can lead to optimal performance and reduce trial-and-error time during actual cleaning jobs.

Another essential tip for boosting efficiency is the strategic organization of your workspace. Position your laser cleaning machine within close reach of the parts being cleaned to minimize handling time. Implementing an efficient workflow, such as a step-by-step process for loading and unloading materials, can streamline operations. Additionally, keeping tools and materials organized will reduce downtime and improve overall productivity. Consider utilizing software solutions to track cleaning schedules and maintenance logs, ensuring that your machine operates at peak performance while maintaining a seamless workflow.

FAQS

: When selecting a large format laser cleaning machine, consider its versatility to handle different surfaces, a user-friendly interface for streamlined operations, and efficiency features like high-powered lasers with adjustable settings, automatic focusing, and a large cleaning area.

The efficiency of a laser cleaning machine is crucial as high-powered lasers with adjustable settings provide precise cleaning without damaging materials, which is essential in industrial applications where material integrity is vital.

Regular maintenance practices such as checking the cooling system, cleaning optics, and inspecting the laser source can significantly enhance equipment performance and extend its service life.

A structured maintenance schedule boosts productivity, minimizes unexpected downtimes, and helps in identifying potential issues early, thereby reducing the risk of extensive repairs.

To maximize efficiency, thoroughly understand the material and contaminants, adjust machine settings accordingly, regularly calibrate the equipment, and organize your workspace to minimize handling time.

Proper care leads to higher operational efficiency, lower long-term costs, and ensures that the equipment meets industry standards for optimal performance.

Utilizing software solutions can help track cleaning schedules and maintenance logs, ensuring that your machine operates at peak performance and maintains a seamless workflow.

Fortune Laser Technology Co., Ltd. specializes in manufacturing advanced laser cleaning machines and is committed to R&D to adapt equipment to meet industry standards and enhance operational efficiency.

Conclusion

Optimizing your workflow with a Large Format Laser Cleaning Machine can significantly enhance productivity and efficiency across various industries. These machines offer numerous benefits, including reduced downtime and improved environmental safety. When selecting a laser cleaning machine, it's essential to consider key features such as laser power, cleaning speed, and versatility to handle different materials.

To effectively set up your Large Format Laser Cleaning Machine, follow a step-by-step guide that includes installation, calibration, and safety checks. Regular maintenance practices will ensure your equipment remains in top condition, prolonging its lifespan and performance. Additionally, understanding common applications can help you leverage this technology in your operations. By implementing best practices and efficiency tips, you can maximize the benefits of your laser cleaning processes, ultimately leading to streamlined operations and enhanced output.

Related Posts

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

-

Innovative Solutions for Effective Laser Cleaning High Power Technology

-

Finding Top Suppliers for Best 3015 Fiber Laser Cutter Your Essential Checklist Guide

-

Unlocking Efficiency with Cnc Sheet Metal Laser Cutter Advantages for Global Buyers

-

The Ultimate Guide to Choosing the Right Industrial Laser Machine for Your Production Needs