- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

How to Optimize Production Efficiency with an Industrial Laser Cutting Machine

Table of Contents

- Understanding the Basics of Industrial Laser Cutting Technology

- Identifying Key Factors Affecting Production Efficiency

- Implementing Best Practices for Optimal Machine Setup

- Regular Maintenance and Calibration for Consistent Performance

- Leveraging Advanced Software for Cutting Path Optimization

- Training Your Workforce for Enhanced Operation and Productivity

- FAQS

- Conclusion

- Related Posts

In today's competitive manufacturing landscape, optimizing production efficiency is paramount, and one of the most effective tools to achieve this is the Industrial Laser Cutting Machine. Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen city, has emerged as a leading manufacturer in the field of industrial laser equipment. With a dedicated focus on research and development, production, sales, and maintenance services, Fortune Laser provides innovative solutions that enhance productivity and precision in various industries. This article will explore the best practices for leveraging the capabilities of an Industrial Laser Cutting Machine to streamline operations, reduce waste, and ultimately drive profitability. By implementing advanced laser cutting techniques and optimizing machine settings, manufacturers can realize significant improvements in their production processes, positioning themselves for success in a rapidly evolving market.

Understanding the Basics of Industrial Laser Cutting Technology

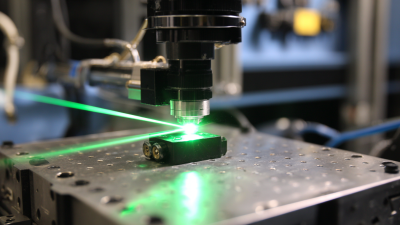

Industrial laser cutting technology has revolutionized the manufacturing process by offering precision and efficiency unmatched by traditional cutting methods. Laser cutting works by focusing a high-powered beam of light on the material, which melts or vaporizes it. This method not only ensures clean cuts but also reduces material waste, leading to significant cost savings. Furthermore, it supports a variety of materials—including metals, plastics, and wood—making it a versatile choice for many industries.

Industrial laser cutting technology has revolutionized the manufacturing process by offering precision and efficiency unmatched by traditional cutting methods. Laser cutting works by focusing a high-powered beam of light on the material, which melts or vaporizes it. This method not only ensures clean cuts but also reduces material waste, leading to significant cost savings. Furthermore, it supports a variety of materials—including metals, plastics, and wood—making it a versatile choice for many industries.

Tips:

When integrating laser cutting into your production line, consider investing in a machine equipped with advanced software for better control and precision. Regular maintenance of the laser cutting equipment is crucial to avoid downtime and ensure optimal performance. Additionally, training your staff on the operational protocols will enhance safety and efficiency in the production process.

Maximizing production efficiency also involves understanding the settings for different materials. Adjusting parameters like speed, power, and frequency based on material type can drastically improve cutting quality and speed. Familiarizing yourself with these settings can lead to not only quicker production times but also a superior end product.

Identifying Key Factors Affecting Production Efficiency

When it comes to optimizing production efficiency with industrial laser cutting machines, several key factors play a critical role. According to a report by MarketsandMarkets, the global laser processing market is projected to grow from $4.67 billion in 2020 to $7.05 billion by 2025, emphasizing the increasing reliance on laser technology in manufacturing. One crucial factor affecting efficiency is the choice of laser type. CO2 lasers, for example, are renowned for their versatility and high-speed cutting capabilities, making them ideal for non-metal materials, while fiber lasers are often more efficient for metals due to their high absorption rates.

Another significant factor is the quality of the optical components. A study by the American Society for Precision Engineering highlights that improvements in lens and mirror technology can lead to a 30% increase in beam quality, thereby enhancing cutting precision and reducing material waste. Additionally, the integration of advanced software solutions that utilize real-time data analytics accelerates production processes by optimizing cutting paths and minimizing downtime. By focusing on these key factors, manufacturers can harness the full potential of their laser cutting systems, resulting in substantial gains in overall production efficiency.

Implementing Best Practices for Optimal Machine Setup

When optimizing production efficiency with an industrial laser cutting machine, proper machine setup is crucial. First, operators should focus on selecting the right parameters tailored to the specific material being processed. This includes adjusting the laser power, cutting speed, and focus point. Each material has unique characteristics, and settings that work for one may not be suitable for another. Conducting material tests can help identify the ideal settings for achieving clean cuts while minimizing waste and production time.

In addition to parameter tuning, maintaining the laser cutting equipment is vital for optimal performance. Regular maintenance routines, such as cleaning lenses and mirrors, inspecting the cutting head, and checking gas supplies, ensure that the machine operates at peak efficiency. Implementing structured maintenance checks can prevent downtime caused by equipment failure and enhance the longevity of the machine. Furthermore, training operators on best practices for setup and maintenance fosters a skilled workforce that can adapt to evolving production needs, ensuring consistent results and high-quality output.

Regular Maintenance and Calibration for Consistent Performance

Regular maintenance and calibration of industrial laser cutting machines are crucial for ensuring optimal production efficiency. These machines operate under high precision conditions, and even minor misalignments or wear can lead to significant deviations in cutting quality. A well-structured maintenance schedule, including routine checks of laser optics, coolant levels, and mechanical components, can help detect issues before they escalate into costly downtime.

Calibration is equally essential. It entails adjusting the machine settings to align with specific production requirements and material types. Regular calibration ensures that the cutting speed, power levels, and focus remain consistent, resulting in superior cut quality and reduced material wastage. By prioritizing these processes, manufacturers not only maximize the lifespan of their equipment but also enhance overall productivity, leading to faster turnaround times and improved competitiveness in the market.

Leveraging Advanced Software for Cutting Path Optimization

In today’s competitive manufacturing landscape, optimizing production efficiency is paramount, and advanced software plays a pivotal role in enhancing the capabilities of industrial laser cutting machines. By leveraging sophisticated algorithms for cutting path optimization, manufacturers can significantly reduce material waste and improve cycle times. According to a report by MarketsandMarkets, the global laser cutting market is expected to grow from $3.7 billion in 2020 to $5.2 billion by 2025, reflecting the increasing adoption of laser technology driven by such efficiencies.

Advanced software solutions utilize real-time data analytics and simulation techniques to create the most efficient cutting paths. This not only minimizes the time spent on each cut but also ensures that the machine operates at optimal speeds and power levels, thereby prolonging the lifespan of the equipment. A study from the International Journal of Advanced Manufacturing Technology indicates that implementing path optimization software can lead to production speed enhancements of up to 30%, which translates to substantial cost savings and a reduction in energy consumption during operations. Consequently, as industries strive for sustainability and efficiency, adopting cutting-edge software tools for laser cutting is becoming an essential strategy.

Optimization of Production Efficiency with Industrial Laser Cutting Machines

Training Your Workforce for Enhanced Operation and Productivity

Training your workforce is crucial for optimizing production efficiency with industrial laser cutting machines. At Fortune Laser Technology Co., Ltd., we understand that even the most advanced laser equipment is only as effective as the skills of the operators handling it. Investing in comprehensive training programs ensures that your team is not only familiar with the machine’s capabilities but also proficient in best practices for operation and maintenance. This includes understanding software interfaces, managing settings for different materials, and troubleshooting common issues that may arise during the cutting process.

Furthermore, a well-trained workforce leads to increased productivity and reduced downtime. Employees who are confident in their skills can perform tasks more swiftly and with greater precision, thereby maximizing the utilization of your laser cutting machine. At Fortune Laser, we advocate for ongoing training sessions and workshops, enabling staff to stay updated on the latest technologies and advancements in laser cutting. Such initiatives not only enhance operational efficiency but also foster a culture of continuous improvement within your organization.

FAQS

: The global laser processing market is projected to grow from $4.67 billion in 2020 to $7.05 billion by 2025.

CO2 lasers are ideal for non-metal materials due to their versatility and high-speed cutting capabilities.

Fiber lasers are often more efficient for metals because of their high absorption rates.

Improvements in lens and mirror technology can lead to a 30% increase in beam quality, which enhances cutting precision and reduces material waste.

Advanced software utilizes real-time data analytics to optimize cutting paths, significantly reducing material waste and improving cycle times.

The global laser cutting market is expected to grow from $3.7 billion in 2020 to $5.2 billion by 2025.

Implementing path optimization software can lead to production speed enhancements of up to 30%.

Advanced software minimizes the time spent on cuts, ensures optimal machine operation, prolongs equipment lifespan, and results in substantial cost savings and reduced energy consumption.

As industries strive for sustainability and efficiency, adopting cutting-edge software tools for laser cutting is becoming an essential strategy.

By focusing on these key factors, manufacturers can harness the full potential of their laser cutting systems, leading to substantial gains in overall production efficiency.

Conclusion

In today's competitive manufacturing landscape, optimizing production efficiency is essential, and the Industrial Laser Cutting Machine stands out as a powerful tool to achieve this goal. Understanding the fundamentals of laser cutting technology, along with key factors that influence production efficiency, is crucial. Implementing best practices for machine setup and ensuring regular maintenance and calibration can significantly enhance performance. Additionally, leveraging advanced software for cutting path optimization can lead to increased precision and reduced material waste.

Training your workforce is equally vital for maximizing the potential of Industrial Laser Cutting Machines. By equipping employees with the necessary skills and knowledge, companies can foster an environment of enhanced operation and productivity. As a professional manufacturer of industrial laser equipment, Fortune Laser Technology Co., Ltd. is dedicated to driving advancements in laser technology from R&D to maintenance, ensuring clients can fully harness the capabilities of their laser cutting solutions.

Related Posts

-

How to Choose the Perfect Laser Cutting Machine for Your Business Needs

-

Trust in Global Manufacturing Excellence Discover the Best Industrial Laser Cutting Machines from China's Leading Factory

-

Ultimate Guide to Choosing the Right Laser Cutting Machines for Your Business

-

Craftsmanship Meets Technology: Explore the Finest Mini Laser Cutting Machines from China

-

Unlocking Efficiency and Precision with the Best Fiber Laser Cutting Machine Benefits to Your Business

-

Understanding Challenges with Affordable Fiber Laser Cutter Reliability