- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

How to Optimize Your Production Efficiency with a CNC Sheet Metal Cutting Machine

Table of Contents

- Understanding CNC Sheet Metal Cutting Machines and Their Advantages

- Key Metrics for Measuring Production Efficiency in Metal Fabrication

- Real-world Case Studies: Companies that Boosted Efficiency with CNC Technology

- Cost-Benefit Analysis: Investing in CNC Machines for Long-Term Gains

- Best Practices for Maintaining CNC Machines to Maximize Production Output

- Emerging Trends in CNC Technology and Their Impact on Sheet Metal Cutting

- FAQS

- Conclusion

- Related Posts

In today's competitive manufacturing landscape, optimizing production efficiency is paramount for businesses aiming to maintain a competitive edge. One of the key tools driving this enhancement is the CNC sheet metal cutting machine, which has revolutionized the way metal components are produced. According to a recent industry report by MarketsandMarkets, the global CNC machine market is expected to reach $117.17 billion by 2025, highlighting the growing reliance on automated solutions in various sectors.

Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, stands at the forefront of this technological advancement, offering state-of-the-art CNC sheet metal cutting machines that integrate R&D, production, sales, and maintenance services. Embracing such innovative equipment not only streamlines operations but also significantly reduces waste and production time, paving the way for enhanced profitability and sustainability in metal fabrication.

Understanding CNC Sheet Metal Cutting Machines and Their Advantages

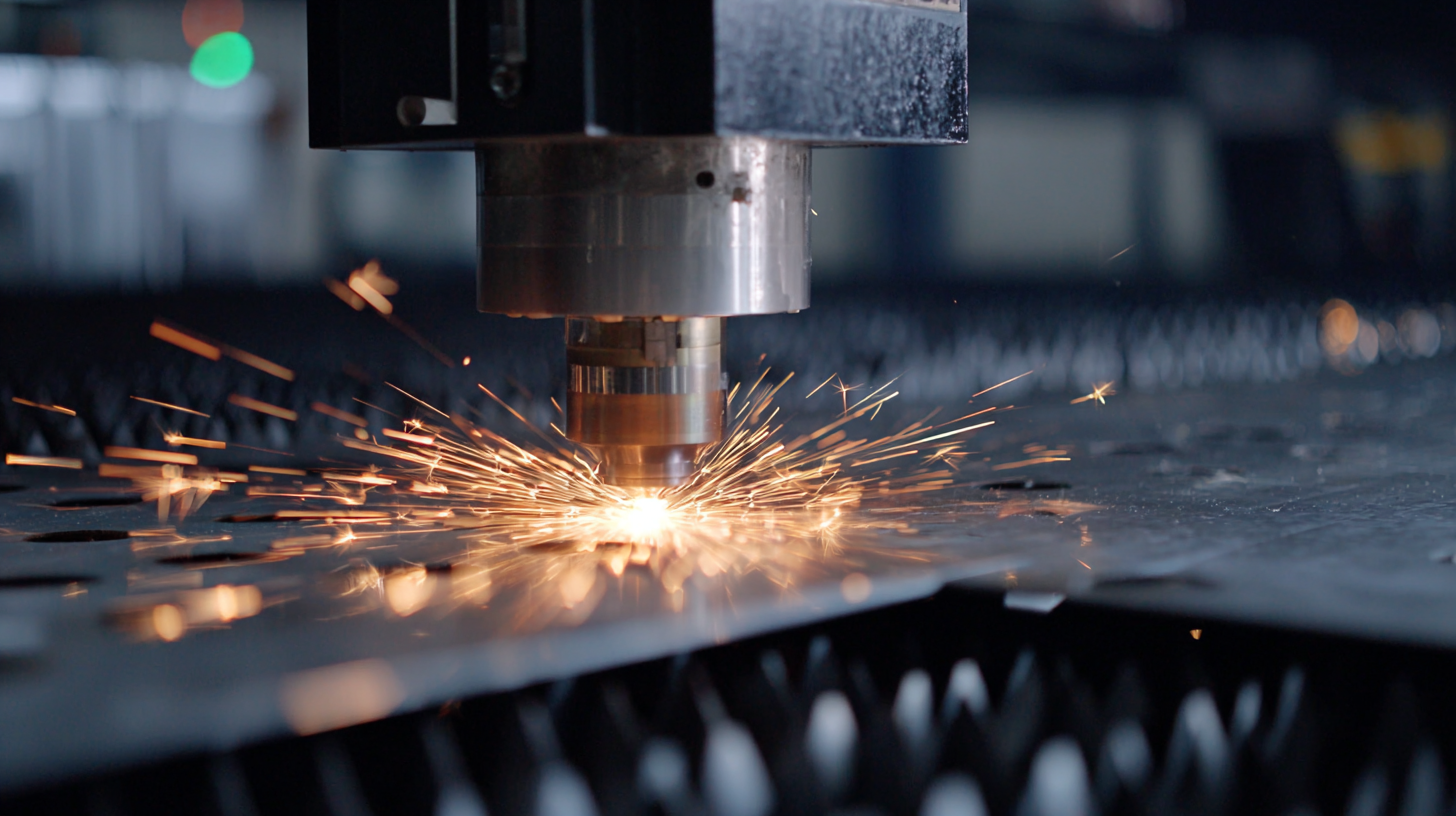

CNC sheet metal cutting machines represent a significant advancement in manufacturing technology, allowing for highly precise and efficient cutting processes. These machines utilize computer numerical control to automate the cutting process, ensuring consistent results and minimizing human error. By programming the CNC machine with specific designs, manufacturers can achieve complex shapes and intricate patterns that would be difficult to replicate by hand. This level of precision not only enhances product quality but also reduces waste, ultimately leading to cost savings.

One of the primary advantages of CNC sheet metal cutting machines is their ability to work with various materials, including aluminum, steel, and copper. This versatility makes them ideal for diverse applications across different industries, from automotive to aerospace. Additionally, CNC machines can operate at high speeds, significantly increasing production rates compared to traditional cutting methods. As businesses seek to optimize their production efficiency, investing in CNC technology can provide a competitive edge by streamlining operations and improving turnaround times, allowing manufacturers to meet growing market demands effectively.

Key Metrics for Measuring Production Efficiency in Metal Fabrication

When optimizing production efficiency in metal fabrication, it’s crucial to identify and measure key metrics that can significantly impact your operations. Among the most essential metrics are cycle time, yield rate, and downtime. Cycle time refers to the total time it takes to complete a task from start to finish. By closely monitoring this metric, operators can pinpoint bottlenecks in the CNC cutting process and streamline workflow for improved efficiency.

Tips for reducing cycle time include regular maintenance of your CNC machine to prevent unexpected breakdowns, as well as implementing training programs for operators to ensure they are utilizing the machine effectively. Another important metric is yield rate, which reflects the amount of usable material produced compared to the raw material used. Maximizing yield rate can substantially decrease costs and waste.

To optimize yield rate, consider conducting regular quality checks throughout the production process and adjusting cutting speeds or tool settings as needed. Additionally, monitoring downtime—both planned and unplanned—helps manufacturers understand production interruptions. Utilizing a system for tracking machine hours can provide insights into scheduling maintenance and reducing unnecessary delays. By focusing on these key metrics, metal fabricators can enhance their overall production efficiency with CNC sheet metal cutting machines.

Real-world Case Studies: Companies that Boosted Efficiency with CNC Technology

In recent years, several companies have successfully integrated CNC sheet metal cutting machines into their production processes, significantly boosting their operational efficiency. One notable case is a mid-sized furniture manufacturer that struggled with high labor costs and production delays. After implementing a CNC cutting machine, they streamlined their workflow, reducing cutting time by over 50%. The precise automation not only minimized material waste but also allowed the company to meet tighter deadlines, ultimately leading to increased customer satisfaction and higher profit margins.

Another compelling example comes from an automotive parts supplier that faced challenges in maintaining consistent quality in their products. By adopting CNC technology, they improved their cutting accuracy, which in turn enhanced the overall product quality. This transition meant fewer defects and reworks, thereby saving both time and resources. Their experience underscores how CNC sheet metal cutting machines can transform traditional manufacturing practices, driving efficiency and quality improvements that resonate throughout the entire supply chain.

Cost-Benefit Analysis: Investing in CNC Machines for Long-Term Gains

Investing in CNC machines represents a pivotal shift for businesses aiming to enhance their production efficiency. A cost-benefit analysis reveals that the initial capital outlay for these advanced machines can yield significant long-term gains. Automation technology, such as CNC sheet metal cutting, not only streamlines manufacturing processes but also reduces labor costs, mitigates human error, and increases the precision of the output. These factors collectively contribute to a quicker turnaround time and a boost in overall productivity.

As industries evolve, especially with the integration of new technologies that reshape the labor market, companies must adapt or risk falling behind. Enhanced data collection and analysis are crucial for understanding the impacts of automation. By using tools such as ROI calculations in Excel, businesses can better assess the financial implications of investing in CNC machines. Such assessments provide valuable insights, enabling organizations to make informed decisions that align with their strategic goals while enhancing their competitive edge in the market.

Production Efficiency: Cost-Benefit Analysis of CNC Sheet Metal Cutting Machines

Best Practices for Maintaining CNC Machines to Maximize Production Output

Maintaining CNC machines is critical to maximizing production output in sheet metal cutting operations. According to the International Federation of Robotics, a well-maintained CNC machine can achieve productivity rates up to 20% higher than that of machines facing regular neglect. Regular calibration and preventive maintenance help ensure that machines operate at peak performance, thus reducing downtime and increasing overall efficiency.

Implementing a routine maintenance schedule is essential for prolonging the lifespan of CNC machines. The Society of Manufacturing Engineers reports that companies that adhere to a strict maintenance schedule can reduce equipment failure rates by up to 30%. This involves checking components such as the cutting tools, coolant systems, and electronic controls regularly. Additionally, investing in training for operators on proper usage and maintenance techniques can lead to more effective machine handling, further enhancing production capacity. By prioritizing maintenance, manufacturers can secure significant improvements in output and operational efficiency.

Emerging Trends in CNC Technology and Their Impact on Sheet Metal Cutting

The landscape of CNC technology is rapidly evolving, significantly impacting the efficiency of sheet metal cutting processes. With the global metal forming tools market projected to grow from $29.41 billion in 2025 to $51.67 billion by 2032, a remarkable CAGR of 8.4%, it’s evident that companies are increasingly investing in advanced CNC technologies. This investment is driven by the need for improved precision, speed, and adaptability in production processes, ensuring that manufacturers can meet rising customer demands without compromising on quality.

Emerging trends like automation, energy efficiency, and real-time monitoring are revolutionizing how CNC sheet metal cutting machines operate. Recent reports indicate that energy efficiency improvements and environmental impact reduction are critical concerns in the manufacturing industry, leading to innovations such as energy-saving technologies in metal forming processes. Additionally, the plasma cutting machine market is also seeing significant growth, with advancements in both manual and automated product types enhancing performance across various industrial applications. These trends not only optimize production efficiency but also position manufacturers to better respond to sustainability challenges in the metalworking sector.

FAQS

: CNC technology refers to computer numerical control machines that automate manufacturing processes. They benefit companies by reducing cutting time, minimizing material waste, improving product quality, and increasing overall operational efficiency.

Yes, a mid-sized furniture manufacturer integrated CNC cutting machines into their workflow and reduced cutting time by over 50%, leading to higher customer satisfaction and profit margins.

CNC technology reduces labor costs by automating processes, which decreases reliance on manual labor and mitigates human error, resulting in cost savings for businesses.

CNC technology can help overcome challenges such as high labor costs, production delays, inconsistent quality, and high rates of defects, helping companies streamline operations and improve product quality.

Companies should consider the initial capital investment, potential long-term gains, labor cost reduction, precision output, and the overall impact on productivity and efficiency.

Businesses can assess the financial implications by conducting a cost-benefit analysis, utilizing tools like ROI calculations in Excel to evaluate the expected gains from the investment.

Long-term gains from implementing CNC technology include increased productivity, reduced waste, improved product quality, and the ability to meet tighter deadlines, all of which enhance a company's competitive edge.

CNC technology improves product quality by enhancing cutting accuracy, which reduces defects and the need for reworks, enabling companies to produce higher quality products consistently.

Enhanced data collection is crucial for understanding the impacts of automation, allowing businesses to make informed decisions and strategize effectively in a rapidly evolving market.

Companies that do not adapt to CNC technology risk falling behind in efficiency and quality, potentially losing their competitive edge in the market.

Conclusion

In today's competitive manufacturing landscape, optimizing production efficiency is crucial, and a CNC Sheet Metal Cutting Machine plays a pivotal role in achieving this goal. Understanding the advantages of CNC machines, such as precision, speed, and versatility, lays the foundation for measuring key metrics that indicate production efficiency in metal fabrication. Through real-world case studies, companies have demonstrated significant improvements in operational performance by integrating CNC technology into their processes.

Furthermore, a cost-benefit analysis reveals that investing in CNC Sheet Metal Cutting Machines leads to long-term gains, justifying the initial expenditure. To maximize production output, best practices for maintaining these machines are essential. As the industry evolves, emerging trends in CNC technology promise to further enhance sheet metal cutting capabilities, solidifying the importance of these machines in modern manufacturing. At Fortune Laser Technology Co., Ltd., we are committed to providing cutting-edge solutions in CNC technology, bolstering our clients' production efficiency.

Related Posts

-

What is the Best CNC Laser Machine? A Comprehensive Overview with Industry Insights and Data

-

Top Strategies for Selecting the Best Laser Optics Cleaner for Optimal Performance

-

The Future of Precision Engineering with the Best Laser Cutting Device

-

How to Choose the Best Mini Laser Cutting Machine for 2025 Industry Trends

-

Unveiling Consistent Quality in Chinese Manufacturing with Best Laser Tube Cutting Machines

-

Finding Top Suppliers for Best 3015 Fiber Laser Cutter Your Essential Checklist Guide

Blog Tags: