- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

How to Optimize Your Laser Cleaning Device for Maximum Efficiency

Table of Contents

- Understanding the Principles of Laser Cleaning Technology

- Choosing the Right Laser Source for Your Cleaning Device

- Adjusting Parameters for Optimal Material Removal Rates

- Maintaining and Servicing Your Laser Cleaning System Effectively

- Utilizing Advanced Accessories for Enhanced Performance

- Monitoring and Evaluating Cleaning Results for Continuous Improvement

- FAQS

- Conclusion

- Related Posts

In the ever-evolving landscape of industrial technology, optimizing the performance of your Laser Cleaning Device can significantly enhance operational efficiency and reduce costs. At Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, we pride ourselves on being at the forefront of laser equipment innovation, offering comprehensive solutions including research and development, production, sales, and maintenance services. As laser cleaning becomes increasingly pivotal in various applications—from restoring historical artifacts to maintaining machinery—achieving maximum efficiency with your Laser Cleaning Device is essential. This article will guide you through effective strategies and best practices to fine-tune your system for optimal performance, ensuring that your investment not only meets but exceeds industry standards.

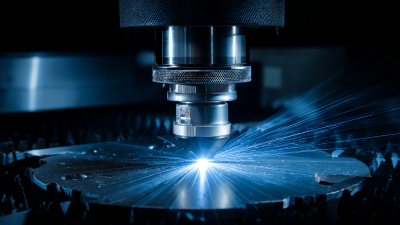

Understanding the Principles of Laser Cleaning Technology

Laser cleaning technology has emerged as a revolutionary method for surface preparation and restoration across various industries. At the core of this technology are principles that harness the power of high-intensity laser beams to remove contaminants from surfaces without the need for harsh chemicals or abrasive materials. According to a recent report by MarketsandMarkets, the global laser cleaning market is expected to reach $709 million by 2026, with a compound annual growth rate (CAGR) of 10.3%, demonstrating the growing demand for efficient and eco-friendly cleaning solutions.

Understanding the principles behind laser cleaning is crucial for optimizing these devices for maximum efficiency. The effectiveness of a laser cleaning device is determined by factors such as laser wavelength, pulse duration, and focus. For instance, a shorter wavelength laser often provides higher absorption rates for certain materials, which can enhance cleaning efficacy. Fortune Laser Technology Co., Ltd., a leading manufacturer founded in 2016 in Shenzhen, integrates advanced research and development with cutting-edge production techniques to offer tailored solutions that meet the specific needs of various industries, ensuring optimal performance of their laser cleaning systems. By leveraging these fundamental principles along with innovative technology, businesses can achieve superior cleaning results while reducing operational costs.

How to Optimize Your Laser Cleaning Device for Maximum Efficiency

| Parameter | Recommended Value | Impact on Efficiency |

|---|---|---|

| Laser Power (W) | 500 - 1000 | Higher power increases cleaning speed and effectiveness |

| Pulse Frequency (Hz) | 10 - 20 | Optimal frequency maximizes material removal rate |

| Beam Focus | 0.5 - 1.0 mm | Focused beam increases precision and reduces damage |

| Cleaning Speed (m/min) | 1 - 3 | Faster speed reduces runtime, improving efficiency |

| Operating Distance (m) | 0.1 - 0.3 | Proper distance ensures efficient beam dispersion |

Choosing the Right Laser Source for Your Cleaning Device

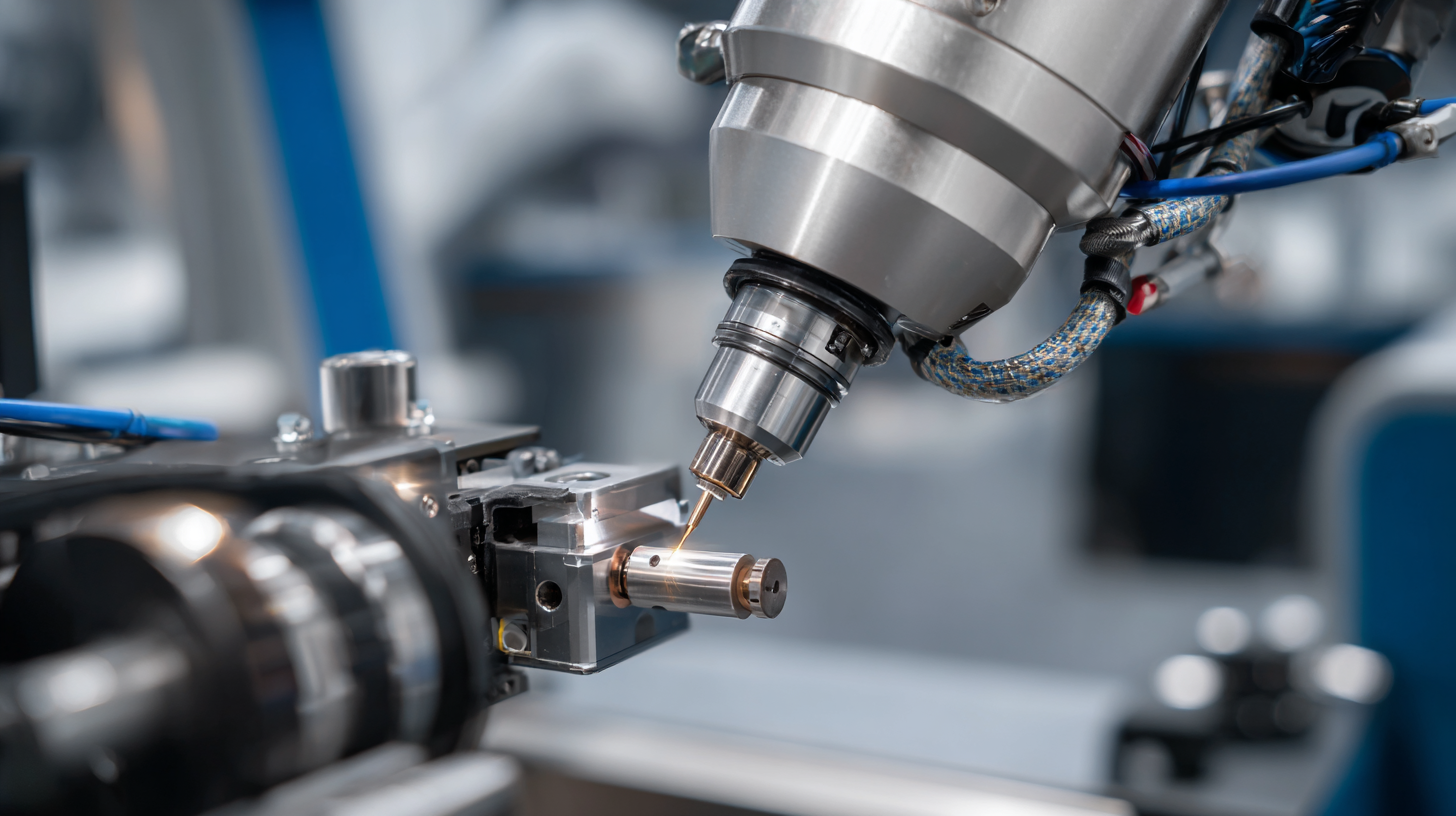

Selecting the appropriate laser source is crucial for optimizing the efficiency of your laser cleaning device. Different laser types, such as fiber lasers, CO2 lasers, and solid-state lasers, each have unique characteristics that can significantly impact the cleaning process. Fiber lasers, for example, offer exceptional beam quality and efficiency, making them ideal for removing rust, paint, and other contaminants from various surfaces. The choice of wavelength also plays a critical role; shorter wavelengths can be more effective for metal surfaces, while longer wavelengths work better on organic materials.

When evaluating laser sources, consider factors like power output, pulse duration, and beam focusability. High power levels may enable faster cleaning speeds, but the pulse duration and focus can influence the precision of material removal. For delicate surfaces, a longer pulse duration may prevent damage, whereas a short pulse can provide rapid, high-energy bursts necessary for tougher contaminants. Additionally, analyzing the compatibility of the laser source with your specific substrate materials will ensure optimal performance and longevity of both the cleaning device and the surfaces being treated.

Adjusting Parameters for Optimal Material Removal Rates

To achieve optimal material removal rates using laser cleaning devices, adjusting parameters such as laser power, frequency, and speed is essential. By fine-tuning these settings, operators can enhance the efficiency of the cleaning process, ensuring that contaminants are removed effectively without damaging the underlying substrate. For example, increasing the laser power can accelerate the removal rate for tougher materials, while adjusting the frequency can influence the interaction time between the laser and the surface.

At Fortune Laser Technology Co., Ltd., we understand the importance of precise parameter adjustments in laser cleaning applications. Our state-of-the-art industrial laser equipment is designed with flexibility in mind, allowing users to customize their settings based on specific material types and cleaning requirements. Founded in 2016 and headquartered in Shenzhen, we are committed to providing comprehensive R&D, production, and maintenance services that empower our clients to achieve maximum efficiency and effectiveness in their laser cleaning processes. By leveraging our industry expertise, customers can ensure that their operations are not only productive but also cost-effective.

Maintaining and Servicing Your Laser Cleaning System Effectively

Maintaining and servicing your laser cleaning system is crucial for ensuring optimal performance and longevity. Regular inspections and timely maintenance can significantly reduce downtime and operational costs. According to a study by the Laser Institute of America, proper maintenance can enhance the efficiency of laser cleaning devices by as much as 30%. This optimization not only improves the cleaning outcomes but also extends the life of the equipment. For example, routine checks on the laser optics and cooling systems can prevent failures that typically lead to costly repairs or replacements.

In addition to routine maintenance, implementing a comprehensive servicing schedule tailored to specific operational demands is essential. Industry experts recommend performing annual service checks, which include calibrating the laser intensity and checking the integrity of safety features. A report by the International Society for Optics and Photonics emphasizes that systems subjected to regular servicing significantly outperform those with sporadic maintenance, achieving up to 95% of their theoretical cleaning efficiency. By prioritizing effective servicing practices, businesses can ensure their laser cleaning systems remain productive and efficient over time.

Utilizing Advanced Accessories for Enhanced Performance

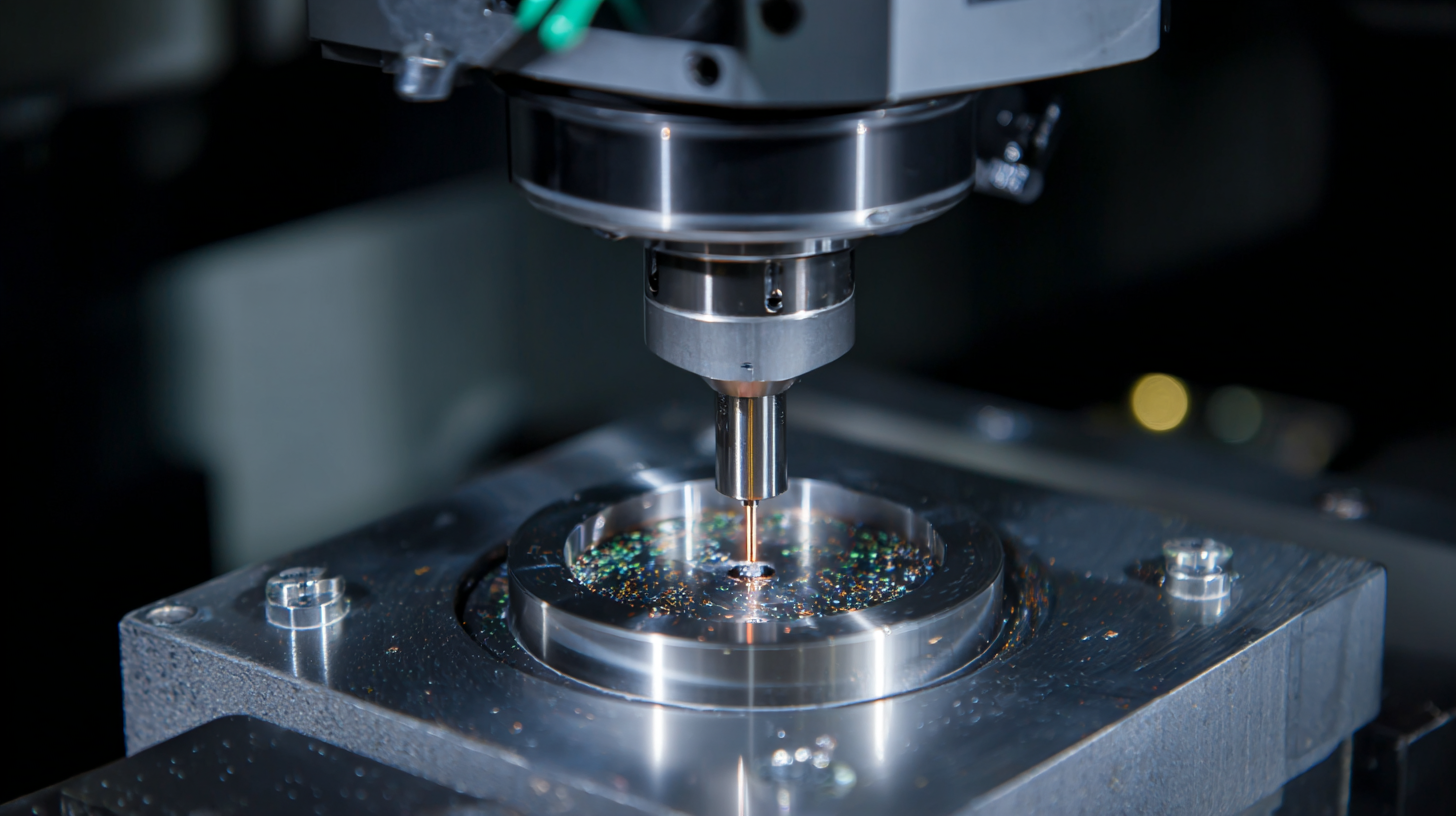

To optimize your laser cleaning device, utilizing advanced accessories can significantly enhance performance and efficiency. One crucial accessory is the focused lens, which allows for better precision during the cleaning process. By narrowing the beam, you can more effectively target contaminants while minimizing the risk of damaging the underlying material. This not only improves the quality of the cleaning but also reduces the time spent on each job.

Another essential accessory is a robust extraction system. Integrating a high-quality fume extraction unit ensures that any hazardous particles or vapors produced during the cleaning process are swiftly removed from the work area. This not only creates a safer environment for operators but also prevents these contaminants from interfering with the laser's performance. Additionally, investing in adjustable nozzles can provide greater versatility, allowing you to adapt the cleaning process to various surfaces and contamination types. By incorporating these advanced accessories, you can maximize the efficiency of your laser cleaning device and achieve superior results.

Monitoring and Evaluating Cleaning Results for Continuous Improvement

Monitoring and evaluating the cleaning results of a laser cleaning device is crucial for ensuring continuous improvement in its operational efficiency. According to a report by Markets and Markets, the laser cleaning market is expected to grow from USD 2.6 billion in 2021 to USD 4.5 billion by 2026, driven largely by advancements in technology and increasing demand for eco-friendly cleaning solutions. Regular assessments can help identify inconsistencies in cleaning outcomes, enabling operators to tweak parameters such as laser intensity, cleaning speed, and nozzle design, ultimately leading to higher efficiency rates.

Monitoring and evaluating the cleaning results of a laser cleaning device is crucial for ensuring continuous improvement in its operational efficiency. According to a report by Markets and Markets, the laser cleaning market is expected to grow from USD 2.6 billion in 2021 to USD 4.5 billion by 2026, driven largely by advancements in technology and increasing demand for eco-friendly cleaning solutions. Regular assessments can help identify inconsistencies in cleaning outcomes, enabling operators to tweak parameters such as laser intensity, cleaning speed, and nozzle design, ultimately leading to higher efficiency rates.

Moreover, utilizing advanced monitoring tools like performance analytics software can further enhance cleaning processes. For instance, a study published in the Journal of Cleaner Production found that by implementing real-time monitoring strategies, companies could reduce operational costs by up to 30% while improving cleaning effectiveness. This emphasis on data analysis not only helps in pinpointing the optimal settings for specific applications but also contributes to a culture of continuous improvement, allowing businesses to adapt promptly to evolving industry standards and client needs.

FAQS

: Laser cleaning technology is a method for surface preparation and restoration that utilizes high-intensity laser beams to remove contaminants without the use of harsh chemicals or abrasive materials.

The effectiveness of a laser cleaning device is influenced by factors such as laser wavelength, pulse duration, and focus.

Understanding the principles behind laser cleaning is essential for optimizing the devices for maximum efficiency and achieving superior cleaning results while reducing operational costs.

The global laser cleaning market is projected to reach $709 million by 2026, with a compound annual growth rate (CAGR) of 10.3%.

Proper maintenance can enhance the efficiency of laser cleaning devices by up to 30%, reduce downtime, and extend the life of the equipment.

Regular inspections, routine checks on laser optics and cooling systems, and annual service checks to calibrate laser intensity and ensure safety features are recommended.

A comprehensive servicing schedule tailored to operational demands can significantly improve cleaning outcomes and enhance the overall performance of the laser cleaning systems.

Systems that undergo regular servicing can achieve up to 95% of their theoretical cleaning efficiency, outperforming those with sporadic maintenance.

Fortune Laser Technology Co., Ltd. is a leading manufacturer in the laser cleaning industry that integrates advanced research with production techniques to offer tailored cleaning solutions.

Yes, by leveraging effective laser cleaning principles and maintaining systems properly, businesses can achieve superior results and reduce operational costs.

Conclusion

To achieve maximum efficiency with your Laser Cleaning Device, it is essential to understand the fundamental principles of laser cleaning technology. Selecting the appropriate laser source tailored to your specific cleaning needs will significantly impact material removal rates. Fine-tuning parameters such as laser power, pulse duration, and distance from the surface ensures optimal performance.

Regular maintenance and servicing of your Laser Cleaning Device will prolong its lifespan and enhance effectiveness. Incorporating advanced accessories can further improve cleaning results, while systematic monitoring and evaluating of the outcomes enable continuous refinement of processes. As a leader in industrial laser equipment, Fortune Laser Technology Co., Ltd. is committed to providing innovative solutions that enhance the performance and reliability of laser cleaning systems.

Related Posts

-

5 Reasons Why Best Laser Cleaning Car Parts Are Revolutionizing Automotive Maintenance

-

7 Key Benefits of Investing in Laser Cleaning Equipment for Your Business

-

Exploring the Unique Features and Applications of the Best Precise Fiber Laser Cutters in Modern Manufacturing

-

The Ultimate Guide to Choosing the Right Industrial Laser Machine for Your Production Needs

-

7 Key Advantages of Using High Power Laser Cutters in Modern Manufacturing

-

2025 Trends in Precision: Elevating Jewelry Production with the Best Laser Cutting Technology

Blog Tags: