- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

What is a Metal Sheet Fiber Laser Cutter and How Does It Revolutionize Metal Fabrication?

Table of Contents

- Understanding the Basics: What is a Metal Sheet Fiber Laser Cutter?

- Key Advantages of Fiber Laser Cutting Over Traditional Methods

- Applications of Fiber Laser Cutters in Various Industries

- How Fiber Laser Cutting Technology Enhances Precision and Efficiency

- Future Trends: The Evolution of Metal Fabrication with Laser Technology

- FAQS

- Conclusion

- Related Posts

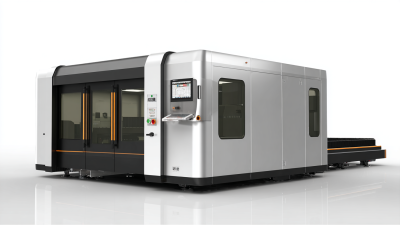

In the rapidly evolving landscape of metal fabrication, the emergence of the Metal Sheet Fiber Laser Cutter has marked a significant technological advance, transforming traditional manufacturing processes. As industries increasingly seek efficiency and precision, this innovation stands out not only for its ability to deliver intricate design capabilities but also for its cost-effectiveness and speed. Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, has been at the forefront of this revolution, combining cutting-edge research and development with comprehensive production and maintenance services. By integrating advanced laser technology into metalworking, Fortune Laser is empowering businesses to enhance their operational efficiency and product quality, ultimately paving the way for a new era in metal fabrication that meets the challenges of modern demands.

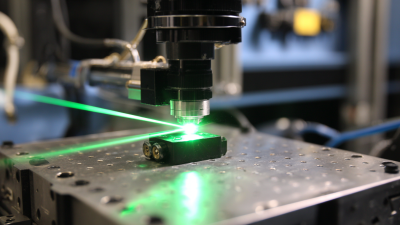

Understanding the Basics: What is a Metal Sheet Fiber Laser Cutter?

A metal sheet fiber laser cutter is an advanced tool in the field of metal fabrication, utilizing a concentrated beam of light to precisely cut through various types of metal sheets. This technology offers exceptional speed and accuracy, making it a preferred choice for industries where precision is paramount. According to a report by MarketsandMarkets, the global fiber laser market is expected to reach $5.9 billion by 2025, growing at a CAGR of 12.6%, reflecting the rising demand for efficient metal cutting solutions.

One of the key advantages of fiber laser cutters is their ability to handle diverse materials such as stainless steel, aluminum, and brass with ease. The cutting process is not only faster than traditional methods but also results in cleaner edges and reduced waste. For businesses looking to enhance their operations, investing in a fiber laser cutter can significantly reduce production times and increase output efficiency.

Tip: When selecting a fiber laser cutter, consider the thickness of the metal sheets you will be working with, as different machines cater to varying thickness levels. Additionally, ensure that you have adequate training for your team to maximize the technology's capabilities.

Another advantage is the lower operational costs associated with fiber laser technology. They require less maintenance compared to CO2 laser cutting systems and consume less electricity. This efficiency translates into lower overall production costs, making fiber lasers a smart investment for businesses looking to remain competitive.

Tip: Regularly maintain your laser cutter’s optics, as clean optics can lead to improved cutting quality and longevity of the equipment. Consider implementing a maintenance schedule to keep your machinery in optimal condition.

Key Advantages of Fiber Laser Cutting Over Traditional Methods

Fiber laser cutting technology has emerged as a groundbreaking advancement in the metal fabrication industry, offering several key advantages over traditional cutting methods. One of the most significant benefits is the enhanced precision it provides. With fiber lasers, manufacturers can achieve exceptionally fine details and intricate designs that were often challenging with conventional cutting techniques. This precision not only improves the quality of the finished product but also reduces material wastage, making the process more efficient and cost-effective.

Another major advantage of fiber laser cutting is its speed and versatility. Fiber lasers can cut through various materials, including stainless steel, aluminum, and even copper, at remarkable speeds. This capability allows for quicker turnaround times on projects, which is crucial in today's fast-paced manufacturing environment. Additionally, fiber lasers require minimal maintenance compared to traditional cutting tools, resulting in lower downtime and operational costs. As a result, businesses can streamline their production processes, increase productivity, and maintain a competitive edge in the market.

What is a Metal Sheet Fiber Laser Cutter and How Does It Revolutionize Metal Fabrication?

| Feature | Fiber Laser Cutting | Traditional Methods |

|---|---|---|

| Cutting Speed | High (up to 30 m/min) | Moderate (5-15 m/min) |

| Precision | High (±0.1 mm) | Lower (±0.5 mm) |

| Operating Cost | Lower (electricity and maintenance) | Higher (gas and blade replacement) |

| Material Versatility | Wide range of metals (steel, aluminum, etc.) | Limited to specific materials |

| Heat Affected Zone | Minimal | Larger |

| Setup Time | Quick and efficient | Lengthy |

| Maintenance Requirement | Low | High |

Applications of Fiber Laser Cutters in Various Industries

Fiber laser cutters have transformed various industries by offering precision and versatility in metal fabrication. In the automotive sector, for instance, these machines enable the production of intricate parts with exceptional accuracy, reducing the need for secondary operations. This capability not only streamlines manufacturing processes but also enhances the overall quality and durability of automotive components. Additionally, the ability to cut through various materials, including steel, aluminum, and even exotic alloys, makes fiber laser technology suitable for a wide range of applications.

In the architecture and construction sectors, fiber laser cutters are utilized for creating detailed designs in metal facades and structural components. Their ability to produce complex shapes and fine details allows architects to push the boundaries of conventional designs, leading to innovative and aesthetically pleasing structures. Moreover, fiber laser cutters are gaining traction in the aerospace industry, where their precision is crucial for manufacturing lightweight, high-strength parts that meet stringent regulatory standards. This versatility across industries showcases the significant impact of fiber laser technology on modern metal fabrication processes.

Applications of Fiber Laser Cutters in Various Industries

How Fiber Laser Cutting Technology Enhances Precision and Efficiency

Fiber laser cutting technology stands at the forefront of metal fabrication, enhancing both precision and efficiency in ways previously unimaginable. Utilizing a solid-state laser, fiber laser cutters deliver highly concentrated light to create remarkable accuracy in cutting metal sheets. According to a report by Research and Markets, the fiber laser cutting market is projected to reach $6.4 billion by 2027, underscoring the growing reliance on this technology within various industries from automotive to aerospace.

One of the key advantages of fiber laser cutting is its ability to cut thicker materials at higher speeds compared to traditional laser methods. Industry feedback indicates that businesses using fiber lasers experience a 30-50% increase in processing speeds, translating to significant time savings and cost reductions. To maximize the benefits of this technology, it's essential to regularly maintain your fiber laser cutter, ensuring optimal performance and longevity.

Tips: Always keep your lens and mirrors clean, as dirt can significantly affect the beam quality and cutting precision. Additionally, optimizing your cutting parameters for different materials can further enhance efficiency and reduce operational costs, keeping your production at its peak performance.

Future Trends: The Evolution of Metal Fabrication with Laser Technology

The evolution of metal fabrication is heavily influenced by advancements in laser technology, particularly with the introduction of metal sheet fiber laser cutters. These machines offer unprecedented precision and speed, allowing manufacturers to produce intricate designs that were once deemed impossible with traditional methods. As industries increasingly demand more complex components, fiber laser cutters provide a solution that not only meets these demands but also significantly enhances productivity and efficiency.

Looking ahead, the future of metal fabrication is set to embrace a multitude of innovations. As laser cutting technology continues to advance, we can expect improvements in software integration, automation, and even artificial intelligence. These developments will streamline production processes, reduce waste, and ultimately lower costs for manufacturers. Additionally, the ability to work with various materials and thicknesses will expand, making fiber laser technology a versatile choice for a wide range of applications. This ongoing evolution will not only redefine manufacturing standards but also empower industries to innovate and respond to changing market needs more effectively.

FAQS

: A metal sheet fiber laser cutter is an advanced tool that uses a concentrated beam of light to cut through various types of metal sheets with high speed and precision.

Fiber laser cutters offer benefits such as faster cutting speeds, cleaner edges, reduced waste, lower operational costs, and less maintenance compared to traditional CO2 laser cutting systems.

Fiber laser cutters can efficiently cut a variety of materials, including stainless steel, aluminum, and brass.

Fiber laser cutting technology enhances efficiency by allowing businesses to cut thicker materials at higher speeds, leading to significant time savings and cost reductions, often reported as a 30-50% increase in processing speeds.

Industries such as automotive, architecture, construction, and aerospace benefit from fiber laser cutters due to their precision, versatility, and ability to produce intricate designs and high-strength parts.

Regular maintenance includes keeping the optics clean to improve cutting quality, implementing a maintenance schedule, and optimizing cutting parameters for different materials to enhance overall performance.

Precision is crucial in metal fabrication as it ensures the quality and durability of components, reduces the need for secondary operations, and allows for innovative designs and applications.

Businesses should consider the thickness of the metal sheets they will be cutting and ensure adequate training for their team to effectively operate the technology.

The global fiber laser market is projected to reach $5.9 billion by 2025, reflecting a growth rate of 12.6%, driven by the demand for efficient metal cutting solutions.

Fiber laser cutting technology offers faster cutting speeds and the ability to process thicker materials, surpassing the capabilities of traditional laser methods.

Conclusion

The "Metal Sheet Fiber Laser Cutter" is a groundbreaking tool that is transforming the landscape of metal fabrication. This advanced technology utilizes a highly focused beam of light to cut through metal sheets with unmatched precision and speed. Unlike traditional cutting methods, fiber laser cutting offers key advantages such as reduced operational costs, minimal waste, and the ability to handle complex designs effortlessly. Industries ranging from automotive to aerospace are increasingly integrating fiber laser cutters into their production processes, enhancing overall efficiency and product quality.

As a pioneer in this field, Fortune Laser Technology Co., Ltd., founded in 2016 and based in Shenzhen, has been at the forefront of developing innovative industrial laser equipment. With a commitment to research and development, as well as maintenance services, Fortune Laser is committed to driving the future of metal fabrication, paving the way for more sophisticated applications and continued advancements in laser technology.

Related Posts

-

Craftsmanship Meets Technology: Explore the Finest Mini Laser Cutting Machines from China

-

Future of Best CNC Laser Cutters in 2025 Embracing Emerging Technologies for Increased Efficiency and Precision

-

Finding Top Suppliers for Best 3015 Fiber Laser Cutter Your Essential Checklist Guide

-

Understanding Challenges with Affordable Fiber Laser Cutter Reliability

-

How to Choose the Right Fully Enclosed Fiber Laser Cutter for Your Business Needs

-

Ultimate Guide to Selecting the Best Laser Welders for Global Manufacturing Efficiency

Blog Tags: