- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

5 Essential Tips for Maximizing Efficiency with Fiber Laser Cutting Machines

Table of Contents

- Understanding the Basics of Fiber Laser Cutting Technology

- Key Factors Affecting Efficiency in Laser Cutting Processes

- Best Practices for Optimizing Material Settings and Parameters

- Innovative Techniques to Reduce Setup Time and Increase Productivity

- Maintenance Tips for Prolonging the Life of Fiber Laser Cutting Machines

- Utilizing Software Solutions for Enhanced Workflow Management

- FAQS

- Conclusion

- Related Posts

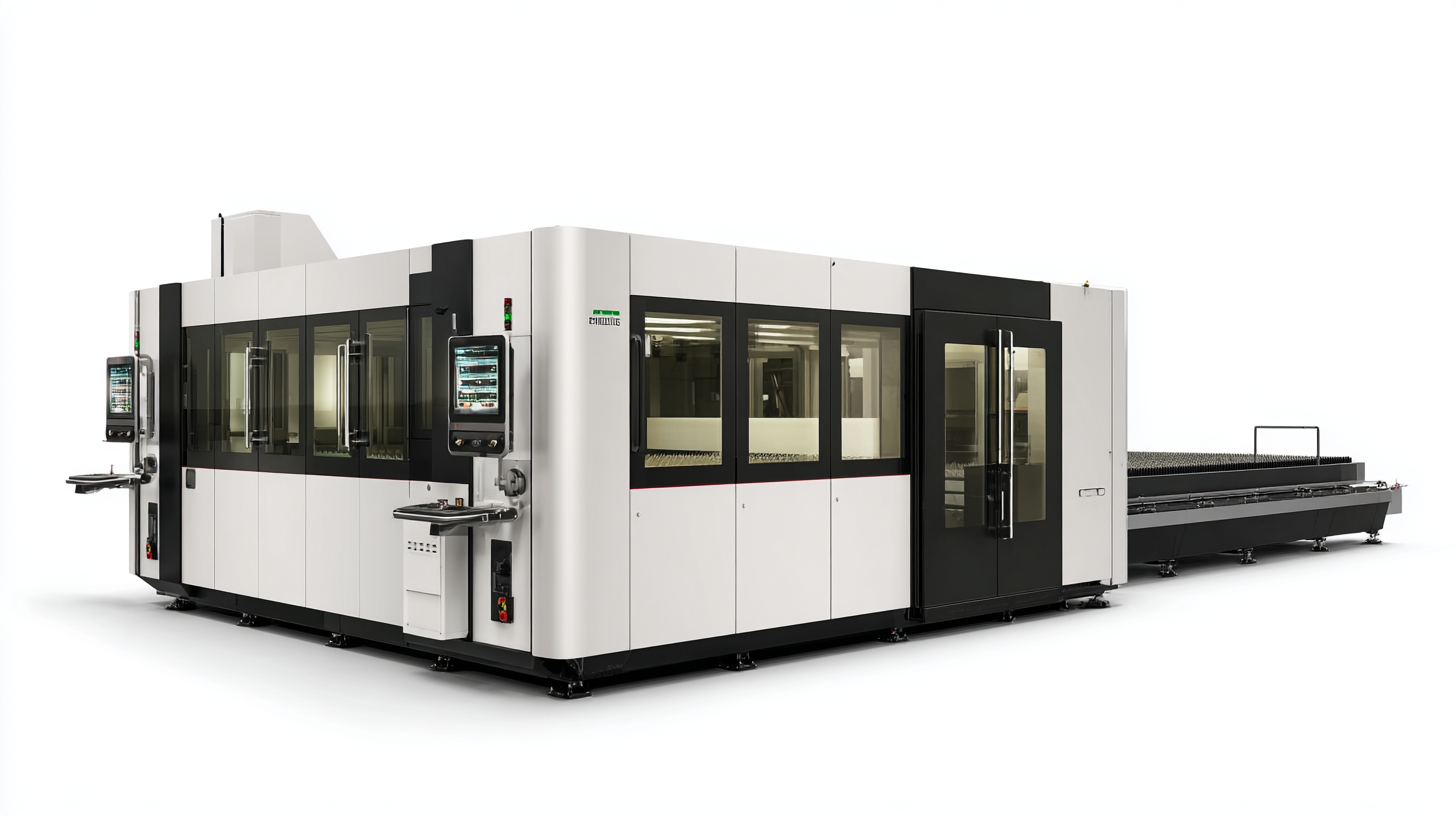

In the rapidly evolving landscape of industrial manufacturing, the Fiber Laser Cutting Machine has emerged as a pivotal tool in enhancing production efficiency and precision. According to recent industry reports, the global fiber laser cutting machine market is projected to reach $4.1 billion by 2025, driven by advancements in laser technology and increasing demand for high-quality metal fabrication.

As a leading manufacturer in this field, Fortune Laser Technology Co., Ltd., established in 2016 in Shenzhen, specializes in providing state-of-the-art laser equipment and integrated services that cater to diverse industrial needs. To harness the full potential of these cutting-edge machines, it is essential to adopt best practices that optimize their performance and operational efficiency.

In this blog, we will explore five essential tips to maximize efficiency with Fiber Laser Cutting Machines, contributing to improved productivity and cost-effectiveness in manufacturing processes.

Understanding the Basics of Fiber Laser Cutting Technology

Fiber laser cutting technology has revolutionized the manufacturing industry, offering remarkable precision and efficiency. This technology leverages the properties of fiber optics to produce a concentrated beam of light, which can then be focused to cut through a variety of materials with minimal waste. Recent industry reports indicate that fiber laser cutting machines can achieve cutting speeds of up to 100 inches per minute, significantly reducing production time compared to traditional cutting methods. The integration of advanced cooling systems further enhances performance, allowing for sustained operation without overheating.

The synergy between fiber laser cutting and innovative technologies like AI is transforming operational workflows. For instance, systems that employ intelligent automation are redefining how laser cutting is executed, optimizing the use of materials and energy. A report from a leading technology firm highlights that companies adopting AI-powered solutions in manufacturing have reported a 20% increase in efficiency. As fiber laser technology continues to evolve, the prospects for streamlining production processes and enhancing product quality remain promising, positioning businesses to thrive in a competitive landscape.

Key Factors Affecting Efficiency in Laser Cutting Processes

When it comes to maximizing efficiency in laser cutting processes, several key factors play a significant role. One of the most critical aspects is the selection of the right materials. Different materials react differently to laser cutting, impacting both the speed and quality of the cut. For instance, metals like aluminum and copper may require specific settings to achieve optimal results, while thicker materials might require more power and slower cutting speeds. Understanding the properties of the materials you work with can lead to informed decisions that enhance overall efficiency.

Another crucial factor affecting efficiency is the proper calibration and maintenance of the fiber laser cutting machine. Regularly checking and adjusting settings such as focus, gas pressure, and cutting speed can massively influence cutting precision and speed. Moreover, the cleanliness of the optics and lens directly impacts functionality. Dust or residue can lead to energy losses and decreased cutting quality. Investing time in the routine maintenance of the machine not only prolongs its lifespan but also ensures consistent performance, thereby maximizing productivity in each cutting job.

Best Practices for Optimizing Material Settings and Parameters

When it comes to optimizing material settings and parameters for fiber laser cutting machines, understanding the key variables can significantly impact both efficiency and quality. Firstly, it's essential to consider the type of material being used. Different materials, such as stainless steel, aluminum, or acrylic, each require tailored settings. For instance, thinner materials may require a higher power setting with faster cutting speeds, while thicker materials typically benefit from slower speeds to ensure a clean cut. Adjusting the focal length is also crucial; a precise focus on the material surface can help achieve sharper edges and reduce dross.

Moreover, monitoring the gas type and pressure during the cutting process is vital for enhancing cutting quality. Oxygen or nitrogen can be employed depending on the material; nitrogen is often preferred for stainless steel to prevent oxidation, while oxygen can boost cutting speeds but may sacrifice edge quality. Lastly, regularly checking and maintaining the laser lens and nozzle can prevent common issues like contamination and misalignment, ensuring optimal performance. By fine-tuning these parameters, operators can achieve a balance between speed and precision, ultimately leading to improved efficiency and output quality in fiber laser cutting processes.

Maximizing Efficiency with Fiber Laser Cutting Machines

Innovative Techniques to Reduce Setup Time and Increase Productivity

Maximizing efficiency with fiber laser cutting machines hinges significantly on reducing setup time and increasing productivity. According to a report by the International Laser Manufacturing Federation, optimizing the setup process can lead to a productivity increase of up to 30% in laser cutting operations. One innovative technique is the use of automation in setup processes. Automated tool changers and pre-programmed cutting parameters can drastically minimize manual intervention, allowing operators to transition between jobs more swiftly and efficiently.

Another critical approach involves leveraging advanced software for job scheduling and nesting. By using sophisticated nesting algorithms, manufacturers can optimize material usage and minimize waste, which not only streamlines the cutting process but also enhances overall throughput. Research from the Fabricators & Manufacturers Association indicates that organizations integrating these software solutions often see a reduction in lead time by up to 25%, translating to faster delivery and increased customer satisfaction. By embracing these innovative techniques, businesses can harness the full potential of fiber laser cutting technology, transforming their operational efficiency into a competitive advantage.

Maintenance Tips for Prolonging the Life of Fiber Laser Cutting Machines

Fiber laser cutting machines are invaluable tools in various industries, but to ensure they operate at peak performance, regular maintenance is essential. One of the primary aspects of maintenance is routine cleaning. Dust and debris can accumulate on the lens and optics over time, leading to reduced cutting quality and efficiency. Implementing a consistent cleaning schedule, using appropriate solvents and microfiber cloths, can significantly prolong the lifespan of the machine.

Another crucial aspect of maintenance is monitoring and adjusting the alignment of the laser head. Misalignment can cause inconsistent cutting and unnecessary wear on the machine. It's beneficial to conduct regular checks and recalibrate as needed, ensuring that the laser beam is accurately targeted at the workpiece. Additionally, maintaining the cooling system is vital; regular checks on coolant levels and cleanliness can prevent overheating and promote optimal operation.

Lastly, keeping software and firmware updated is often overlooked but equally important. Updates can provide enhancements in performance and efficiency, ensuring that the machine utilizes the latest technological advancements. By integrating these maintenance strategies, operators can maximize their fiber laser cutting machine's productivity and longevity, ultimately saving time and reducing costs associated with repairs and replacements.

Utilizing Software Solutions for Enhanced Workflow Management

In the realm of fiber laser cutting, leveraging software solutions plays a pivotal role in maximizing operational efficiency. By integrating advanced workflow management software, companies can streamline their processes and significantly reduce downtime. According to a report by Technavio, businesses adopting automated solutions have seen up to a 30% increase in productivity. Such increased efficiency is not merely beneficial for output but also enhances overall quality assurance throughout the production cycle.

One effective tip for optimizing the workflow is to create a centralized digital dashboard that consolidates key operational metrics. This allows teams to monitor machine performance and job progress in real-time, facilitating quick decision-making. Another important aspect is the use of Nesting Software, which optimizes material usage and minimizes waste. A study by the American Welding Society highlights that proper nesting can lead to a 15-20% material savings, underscoring the need for effective software integration.

Furthermore, investing in training for employees to utilize these software tools can dramatically enhance their capabilities and confidence. A recent survey indicated that companies that prioritize employee training in new software report a 25% improvement in job satisfaction and a notable decrease in operational errors. By focusing on these software solutions and fostering a knowledgeable workforce, businesses can achieve a robust workflow that thrives on efficiency and innovation.

FAQS

: The right materials are crucial for efficiency in laser cutting. Metals like aluminum and copper require specific settings, while thicker materials may need more power and slower speeds to achieve optimal results.

Proper calibration and maintenance significantly affect cutting precision and speed. Regular adjustments to settings such as focus, gas pressure, and cutting speed, along with cleaning the optics, enhance functionality and prolong machine lifespan.

Optimizing material settings, including tailored power settings for different thicknesses and precise focal length, is essential for improving cutting quality and efficiency.

The choice of gas and its pressure can enhance cutting quality. For example, nitrogen is preferred for stainless steel to prevent oxidation, while oxygen can increase cutting speeds but may affect edge quality.

Automation in setup processes, such as using automated tool changers and pre-programmed parameters, can significantly minimize manual intervention, allowing for quicker transitions between jobs.

Leveraging advanced software for job scheduling and nesting can optimize material usage and minimize waste. This can lead to reduced lead times and faster delivery, thereby increasing customer satisfaction.

Conclusion

In the rapidly evolving field of industrial manufacturing, maximizing efficiency with Fiber Laser Cutting Machines is crucial for enhancing productivity and reducing costs. Understanding the fundamentals of fiber laser technology and the key factors that influence cutting efficiency lays the groundwork for optimizing operations. Best practices, such as adjusting material settings and parameters, can significantly improve results, while innovative techniques for reducing setup time can streamline workflows.

Moreover, maintaining fiber laser cutting machines is essential for prolonging their lifespan and ensuring consistent performance. By leveraging advanced software solutions for workflow management, companies like Fortune Laser Technology Co., Ltd. can ensure that their clients achieve the highest level of efficiency in their laser cutting processes, ultimately driving success in their manufacturing endeavors.

Related Posts

-

How to Choose the Perfect Laser Cutting Machine for Your Business Needs

-

Exploring the Cutting Edge Alternatives to the Best Fiber Optic Laser Cutting Machine

-

The Ultimate Guide to Choosing the Best Fiber Laser Cutting Equipment for Your Business Needs

-

Unlocking Efficiency and Precision with the Best Fiber Laser Cutting Machine Benefits to Your Business

-

Discover High Quality Open Type Fiber Laser Cutters from Leading Chinese Manufacturers

-

2025 Trends in Precision: Elevating Jewelry Production with the Best Laser Cutting Technology