- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine

Table of Contents

- Understanding the Basics of 100 Watt Fiber Laser Cleaning Machines

- Key Features to Look for in a High-Performance Laser Cleaning Machine

- Optimal Settings for Different Materials and Contaminants

- Best Practices for Maintenance and Longevity of Your Fiber Laser

- Safety Measures When Operating a Fiber Laser Cleaning Machine

- Real-World Applications and Case Studies of Laser Cleaning Efficiency

- FAQS

- Conclusion

- Related Posts

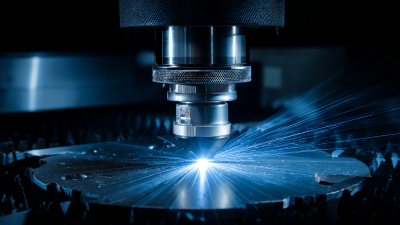

In today's fast-paced industrial landscape, efficiency is paramount, and the adoption of advanced technologies is essential for maintaining competitive edge. One such innovation is the 100 Watt Fiber Laser Cleaning Machine, which has revolutionized the way industries tackle surface preparation and cleaning.

According to a report by Market Research Future, the demand for laser cleaning solutions is expected to grow at a CAGR of 6.5% between 2021 and 2027, emphasizing the increasing importance of these machines in various sectors, including manufacturing and automotive.

Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, has established itself as a leader in the production of industrial laser equipment, combining R&D, manufacturing, and comprehensive maintenance services. By leveraging the capabilities of the 100 Watt Fiber Laser Cleaning Machine, businesses can maximize efficiency, reduce downtime, and enhance overall productivity, setting a new standard for operational excellence in the industry.

According to a report by Market Research Future, the demand for laser cleaning solutions is expected to grow at a CAGR of 6.5% between 2021 and 2027, emphasizing the increasing importance of these machines in various sectors, including manufacturing and automotive.

Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, has established itself as a leader in the production of industrial laser equipment, combining R&D, manufacturing, and comprehensive maintenance services. By leveraging the capabilities of the 100 Watt Fiber Laser Cleaning Machine, businesses can maximize efficiency, reduce downtime, and enhance overall productivity, setting a new standard for operational excellence in the industry.

Understanding the Basics of 100 Watt Fiber Laser Cleaning Machines

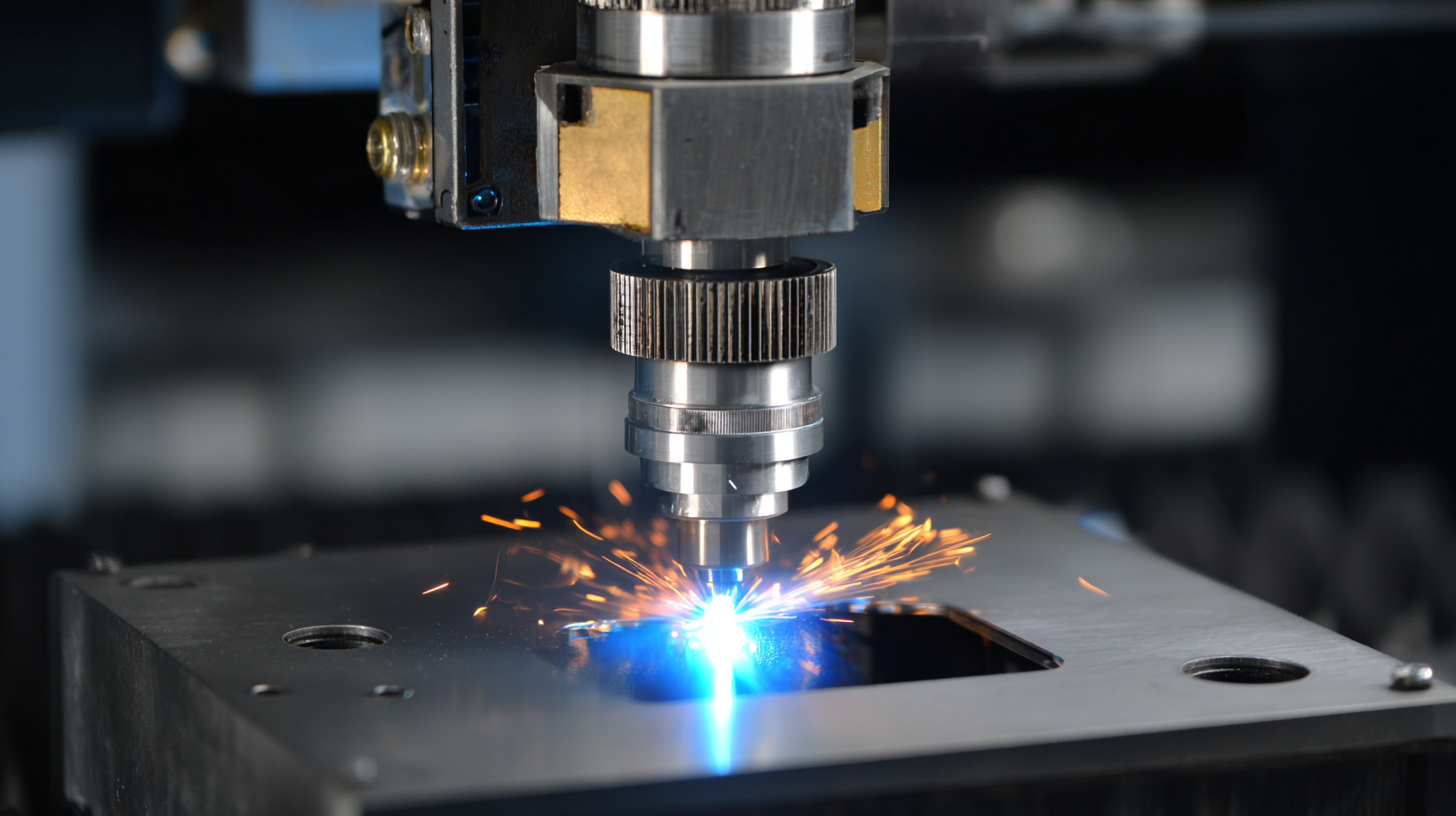

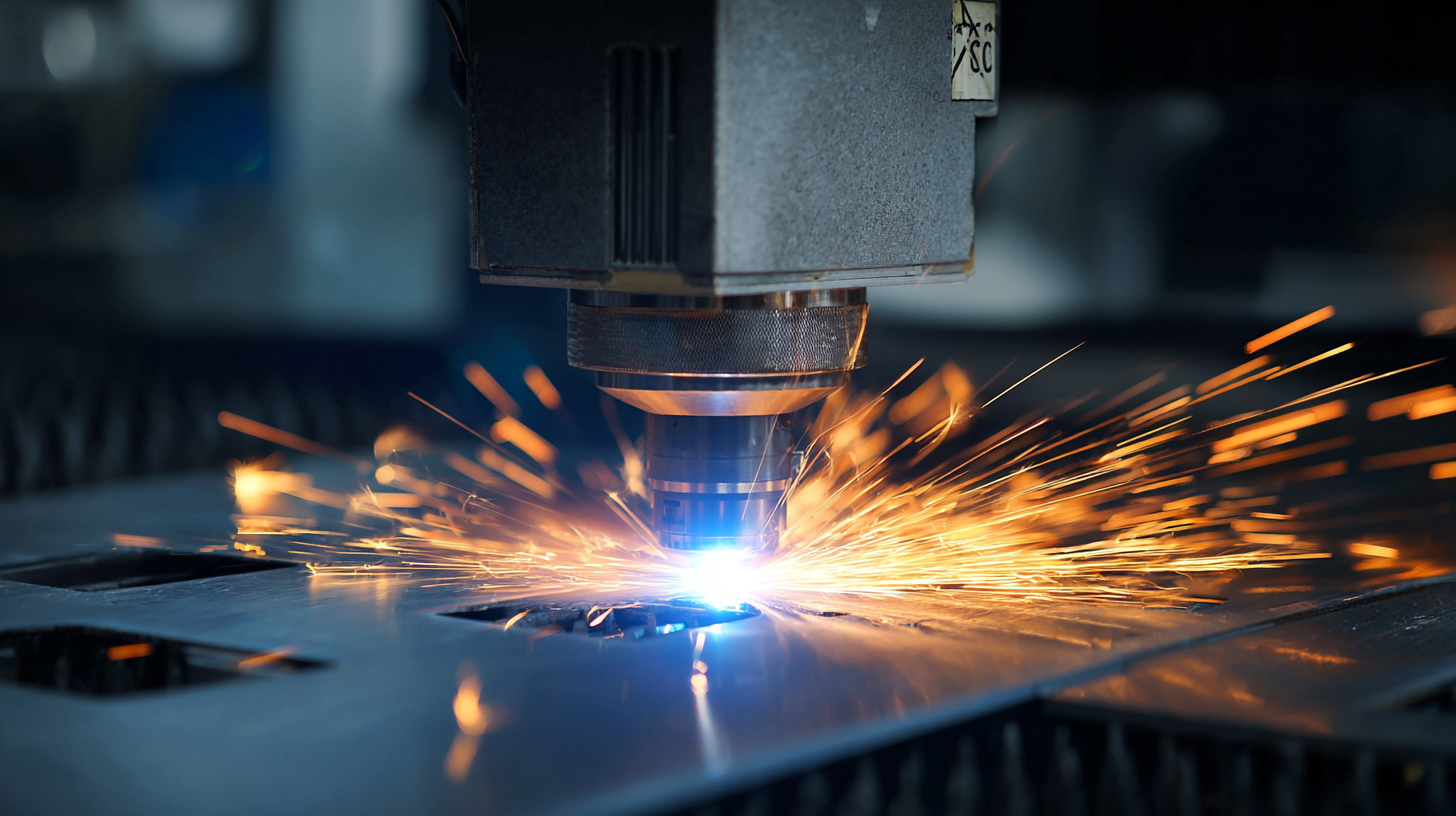

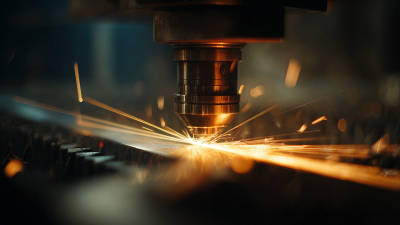

The 100 Watt fiber laser cleaning machine represents a cutting-edge advancement in industrial cleaning technology. Understanding how these machines operate is crucial for maximizing their efficiency in various applications. Fiber lasers use a process called "photo-thermal" interaction, where the laser beam is absorbed by contaminants on a surface, causing them to evaporate or be blown away. This non-abrasive method allows for precise cleaning without damaging the underlying material.

When utilizing a 100 Watt fiber laser cleaner, it's essential to focus on optimizing the cleaning speed and the distance between the laser head and the surface. For instance, adjusting the speed to match the type and thickness of contaminants can significantly improve results.

**Tip:** Always conduct a test run on a small, inconspicuous area to calibrate your settings before proceeding with larger cleaning tasks. Additionally, ensure that the machine’s cooling system is functioning effectively, as overheating can affect performance. Proper maintenance and regular checks will prolong the lifespan of your laser cleaner and enhance its efficiency in delivering outstanding cleaning results.

Key Features to Look for in a High-Performance Laser Cleaning Machine

When considering a high-performance 100 watt fiber laser cleaning machine, there are several key features that can significantly enhance efficiency and effectiveness. First and foremost, look for machines with adjustable power settings. This allows for meticulous control over the cleaning process, enabling you to handle a variety of materials and thicknesses without the risk of damage.

Another important feature is the capability of marking and engraving. Some advanced laser cleaning machines offer dual functionality, allowing you to not only clean surfaces but also mark or engrave them as needed. This versatility can be beneficial for businesses that require multiple applications from a single machine.

Tip: When selecting a machine, pay attention to the cooling system as well. An efficient cooling system can prolong the life of the laser, ensuring that it maintains optimal performance even during extensive cleaning tasks.

Tip: Additionally, consider the weight and portability of the machine. A lightweight model that can be easily moved will offer greater flexibility in different work environments, allowing you to maximize productivity in various locations. With the right features, your laser cleaning machine can significantly streamline your cleaning operations.

Optimal Settings for Different Materials and Contaminants

When utilizing a 100 Watt fiber laser cleaning machine, achieving optimal settings is crucial for effectively removing various contaminants from different materials. The effectiveness of laser cleaning largely depends on parameters such as pulse duration, energy density, and scanning speed. For instance, softer materials like plastics may need lower energy settings to prevent damage, while tougher surfaces such as metals may require higher intensities to achieve the desired cleanliness. Fine-tuning these settings can ensure that the contaminants—be it grease, rust, or coatings—are removed efficiently without adversely affecting the substrate.

Recent studies have underscored the importance of optimizing cleaning techniques based on the specific contaminants and substrates involved. For instance, the application of nanocomposites for contaminant removal demonstrates the benefits of tailored approaches. Various materials, such as those based on environmentally friendly biodegradable options, are now being developed as effective adsorbents. Integrating such advanced materials with the precision of fiber laser technology allows for enhanced efficiency in various cleaning scenarios. By continuously analyzing and adjusting the cleaning parameters, users can significantly improve their operational efficiency while maintaining a focus on sustainability.

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine - Optimal Settings for Different Materials and Contaminants

| Material | Contaminant | Power Setting (W) | Speed Setting (mm/s) | Frequency (Hz) | Passes | Result |

|---|---|---|---|---|---|---|

| Stainless Steel | Rust | 90 | 200 | 20 | 2 | Excellent |

| Aluminum | Anodizing | 85 | 150 | 18 | 3 | Good |

| Brass | Oil | 80 | 100 | 25 | 1 | Very Good |

| Plastic | Paint | 70 | 120 | 30 | 1 | Good |

| Carbon Steel | Oxidation | 95 | 180 | 15 | 2 | Excellent |

Best Practices for Maintenance and Longevity of Your Fiber Laser

Maintaining a 100 Watt fiber laser cleaning machine is essential for optimizing its efficiency and extending its operational lifespan. Regular maintenance routines should include checking the optics for any dust or debris that could impede performance. Clean the lens and mirrors with appropriate tools to ensure maximum light transmission, which is crucial for maintaining the power and accuracy of the laser. Additionally, inspect the cooling system frequently, as lasers can generate substantial heat. Keeping the cooling system clean and functioning properly prevents overheating and prolongs the lifespan of the machine.

Maintaining a 100 Watt fiber laser cleaning machine is essential for optimizing its efficiency and extending its operational lifespan. Regular maintenance routines should include checking the optics for any dust or debris that could impede performance. Clean the lens and mirrors with appropriate tools to ensure maximum light transmission, which is crucial for maintaining the power and accuracy of the laser. Additionally, inspect the cooling system frequently, as lasers can generate substantial heat. Keeping the cooling system clean and functioning properly prevents overheating and prolongs the lifespan of the machine.

Another best practice is to regularly update the software that controls the laser. Software updates often include improvements that enhance functionality and efficiency, ensuring that your machine operates at peak performance. Furthermore, train operators to adhere to guidelines regarding operational practices, such as not overloading the machine or using it for purposes outside its specified capacity. By establishing a routine maintenance schedule and ensuring that staff are well-informed, you can significantly enhance the longevity and efficiency of your fiber laser cleaning machine.

Safety Measures When Operating a Fiber Laser Cleaning Machine

When operating a 100 Watt fiber laser cleaning machine, safety should always be the foremost concern. Laser cleaning technology, while efficient and effective, comes with inherent risks that require careful management.

Firstly, PPE (personal protective equipment) is essential. Operators should wear protective goggles specifically designed to filter the wavelengths of the laser being used to prevent eye damage. Additionally, gloves and protective clothing must be worn to safeguard against accidental exposure to the laser or debris generated during the cleaning process.

Moreover, it is crucial to implement safety protocols in the workspace. This includes ensuring that the area is well-ventilated to mitigate the accumulation of harmful fumes and particles that can be released during laser cleaning.

It’s also important to establish a clear perimeter around the machine to prevent unauthorized access while in operation.

Regular maintenance and inspection of the laser equipment itself will help identify potential issues before they become hazards, ensuring that the machine operates smoothly and safely.

By prioritizing these safety measures, operators can maximize efficiency while minimizing risks associated with fiber laser cleaning technology.

Real-World Applications and Case Studies of Laser Cleaning Efficiency

Laser cleaning technology has revolutionized various industrial applications, particularly with the advent of high-efficiency 100 Watt fiber laser machines. A recent report from the Laser Institute of America highlights that laser cleaning can reduce the time required for surface preparation by up to 80% compared to traditional methods like sandblasting. This significant time-saving translates to enhanced productivity, allowing manufacturers to allocate resources more effectively.

In practical applications, industries such as automotive, aerospace, and heritage conservation have reported remarkable successes using laser cleaning.

For instance, a case study on a major automotive manufacturer demonstrated a reduction in cleaning costs by over 60% after switching to a fiber laser system. Moreover, a project involving the restoration of historic monuments recorded a 90% decrease in the use of chemical solvents, aligning with environmental sustainability goals. These real-world examples underscore the versatility and efficiency of 100 Watt fiber laser cleaning machines, illustrating not just their operational benefits but also their positive impact on both cost and environmental considerations in industry practices.

FAQS

: Operators should wear protective goggles, gloves, and protective clothing to prevent eye damage and accidental exposure to the laser or debris.

Proper ventilation is crucial to mitigate the accumulation of harmful fumes and particles that can be released during the cleaning process.

Establishing a clear perimeter around the machine during operation can help prevent unauthorized access.

Regular maintenance and inspection of the laser equipment are important to identify potential issues before they become hazards.

Laser cleaning can reduce the time required for surface preparation by up to 80% compared to traditional methods like sandblasting.

Industries such as automotive, aerospace, and heritage conservation have reported remarkable successes with laser cleaning.

The automotive manufacturer demonstrated a reduction in cleaning costs by over 60% after switching to a fiber laser system.

In a project restoring historic monuments, there was a 90% decrease in the use of chemical solvents after switching to laser cleaning, supporting environmental sustainability efforts.

Conclusion

In the realm of industrial cleaning technology, the 100 Watt Fiber Laser Cleaning Machine stands out as a powerful tool designed to enhance efficiency across various applications. Understanding the fundamentals of these machines is crucial, as they utilize highly focused laser beams to remove contaminants from surfaces without causing damage. Key features to consider include beam quality, control systems, and portability, which significantly impact cleaning performance.

To achieve optimal results, operators must adjust settings tailored to different materials and types of contaminants. Regular maintenance practices ensure the longevity of the machine while safety measures are paramount to protect users during operation. Real-world applications demonstrate the remarkable efficiency of the 100 Watt Fiber Laser Cleaning Machine, showcasing its versatility in industries ranging from manufacturing to restoration. At Fortune Laser Technology Co., Ltd., founded in 2016, we strive to provide top-notch laser cleaning solutions backed by our commitment to R&D and superior service.

Related Posts

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

The Ultimate Guide to Choosing the Best Fiber Laser Cutting Equipment for Your Business Needs

-

5 Best Pulsed Laser Cleaning Machines for Global Buyers in 2023

-

7 Key Advantages of Using High Power Laser Cutters in Modern Manufacturing

-

7 Key Benefits of Investing in Laser Cleaning Equipment for Your Business

Blog Tags: