- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

What is a Laser Cutter and How Can it Transform Your Manufacturing Process?

Table of Contents

- Understanding Laser Cutting Technology and Its Components

- Key Benefits of Laser Cutting in Modern Manufacturing Processes

- Industry Statistics: The Impact of Laser Cutters on Production Efficiency

- Case Studies: Successful Implementations of Laser Cutting in Various Sectors

- Future Trends: Innovations in Laser Cutting Technology and Their Implications

- Cost Analysis: Evaluating Investment vs. ROI in Laser Cutter Adoption

- FAQS

- Conclusion

- Related Posts

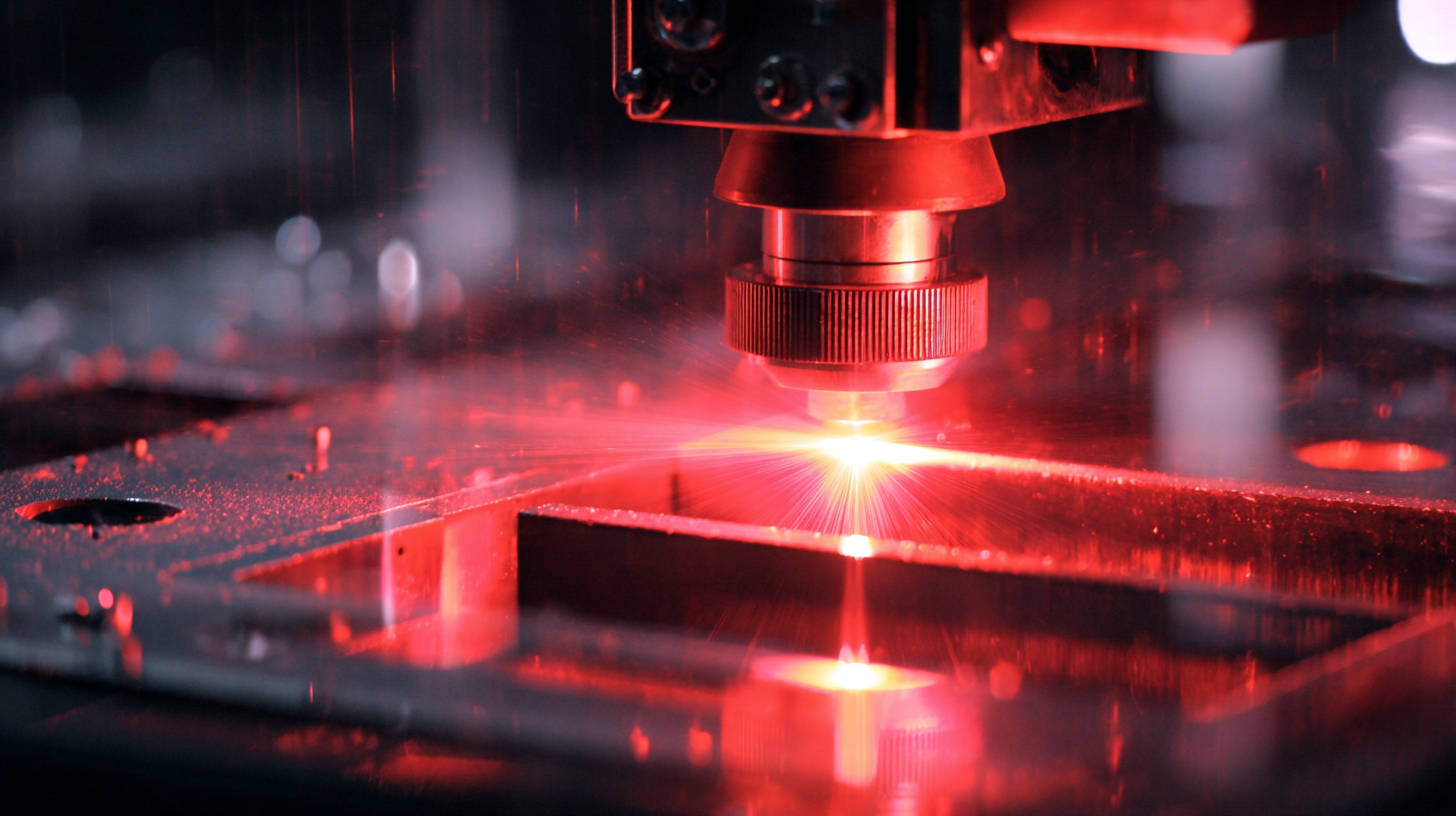

In today's fast-paced manufacturing landscape, the integration of advanced technologies is crucial for staying competitive. One such innovation that is revolutionizing the industry is the Laser Cutter. This powerful tool utilizes focused laser beams to precisely cut, engrave, and mark materials, offering unparalleled accuracy and efficiency.

Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, has positioned itself as a leader in the field of industrial laser equipment manufacturing. With a strong emphasis on research and development, production, and comprehensive sales and maintenance services, Fortune Laser Technology is dedicated to helping businesses transform their manufacturing processes.

By adopting Laser Cutters, manufacturers can achieve higher productivity, reduce material waste, and enhance product quality, all while keeping operational costs in check. This blog will explore the various benefits of Laser Cutters and how they can fundamentally change the way you approach manufacturing.

Understanding Laser Cutting Technology and Its Components

Laser cutting technology is revolutionizing the manufacturing landscape by providing precise, efficient, and versatile cutting solutions for various materials. At the core of this technology are key components such as the laser source, optics, and motion systems, which work together to create clean, intricate cuts with minimal waste. According to a market analysis report, the global metal fabrication equipment market is anticipated to grow significantly, with cutting equipment accounting for a substantial share due to the rising demand for automation and precision in manufacturing processes.

The efficiency of laser cutters allows manufacturers to quickly adapt to changing design requirements. For instance, as industries increasingly seek customizable products, laser cutting technology offers a rapid prototyping capability that traditional methods struggle to match. The flexibility of laser cutting systems enables the processing of not just metals but also materials like plastics and composites, further broadening their application scope. Recent advancements in laser technology, including the development of high-power lasers, have contributed to a marked improvement in cutting speeds and quality, making it an attractive option for businesses looking to streamline their production lines and enhance overall efficiency.

Key Benefits of Laser Cutting in Modern Manufacturing Processes

Laser cutting technology is revolutionizing modern manufacturing processes by offering precision, efficiency, and versatility. According to a report by Markets and Markets, the global laser cutting market size is projected to reach USD 4.21 billion by 2025, growing at a CAGR of 6.2%. This impressive growth highlights the increasing adoption of laser cutting across various industries, driven by its capability to produce intricate designs and maintain tight tolerances, which traditional cutting methods often fail to achieve.

At Fortune Laser Technology Co., Ltd., we are at the forefront of this transformation. Since our inception in 2016, we have been dedicated to advancing industrial laser equipment. The key benefits of laser cutting include reduced material waste due to its high accuracy, the ability to cut various materials such as metals, plastics, and wood seamlessly, and the enhancement of production speed. With laser cutting machines, manufacturers can expect up to 50% faster processing times compared to conventional methods, allowing for greater productivity and efficiency in operations. As industries continue to evolve, integrating advanced laser solutions will be crucial in maintaining a competitive edge.

Industry Statistics: The Impact of Laser Cutters on Production Efficiency

Laser cutters are revolutionizing the manufacturing industry by significantly enhancing production efficiency. According to recent industry statistics, businesses that have integrated laser cutting technology have reported up to a 50% reduction in production time. This dramatic increase in efficiency allows manufacturers to meet tighter deadlines and respond more swiftly to market demands. Additionally, laser cutters minimize material waste by providing precise cuts, leading to cost savings and environmentally sustainable practices.

When considering the implementation of laser cutters, it is essential to prioritize employee training. Ensuring that staff are proficient in operating this technology can lead to smoother workflow transitions and prevent costly errors. Furthermore, regular maintenance of the laser cutting equipment is critical; this not only prolongs the lifespan of the machines but also maintains their accuracy and efficiency.

Finally, incorporating laser cutting into a production line can facilitate innovation. With the ability to create intricate designs quickly, manufacturers are empowered to explore new product lines and custom solutions. Embracing this technology enables companies to stay competitive in a rapidly evolving market, paving the way for future growth and development.

What is a Laser Cutter and How Can it Transform Your Manufacturing Process? - Industry Statistics: The Impact of Laser Cutters on Production Efficiency

| Metric | Value |

|---|---|

| Average Cutting Speed (mm/min) | 8000 |

| Material Types Used | Metals, Wood, Acrylic, Textiles |

| Reduction in Waste (%) | 30 |

| Increase in Production Efficiency (%) | 25 |

| Typical Maintenance Frequency (months) | 6 |

| Typical Laser Power (W) | 1000-6000 |

| Training Time Required (hours) | 20 |

| Common Applications | Signage, Prototyping, Custom Fabrication |

Case Studies: Successful Implementations of Laser Cutting in Various Sectors

Laser cutting has revolutionized various manufacturing sectors by providing a high-precision and efficient method for material processing. For instance, in the automotive industry, companies like Tesla have harnessed laser cutting technology to streamline their production lines. By using laser cutters, they can achieve intricate designs on body panels and components with unmatched accuracy, resulting in reduced waste and faster turnaround times. This not only enhances the overall quality of the vehicles but also allows for greater design flexibility, helping manufacturers stay competitive in a rapidly evolving market.

Another notable implementation is in the aerospace sector, where manufacturers face stringent safety and performance regulations. Companies such as Boeing utilize laser cutting to produce critical parts for aircraft. The ability to cut through tough materials like titanium while maintaining strict tolerances ensures that every component meets the required standards. Moreover, laser cutting facilitates the complex shapes needed for optimal aerodynamics, ultimately enhancing the efficiency of the aircraft. As demonstrated in these case studies, the adoption of laser cutting technology is transforming traditional manufacturing processes, enabling more innovative and cost-effective solutions across various industries.

Future Trends: Innovations in Laser Cutting Technology and Their Implications

Recent advancements in laser cutting technology are paving the way for a transformative future in manufacturing processes. Innovations such as ultra-fast laser cutting and fiber lasers are significantly enhancing precision and efficiency. According to industry reports, the global laser cutting market is expected to grow at a CAGR of over 6% from 2020 to 2025, driven by increased demand for precision in various sectors including automotive, aerospace, and electronics. The integration of nanotechnology within laser cutting is particularly noteworthy, as it enables the manipulation of materials at the nanoscale, resulting in enhanced performance and functionality across applications.

Tip: When considering laser cutting for your manufacturing needs, evaluate the specific requirements of your materials. Different lasers, such as CO2 and fiber lasers, deliver varying results based on the material properties and thickness.

Furthermore, innovations in software that optimize cutting paths and integrate IoT capabilities allow for real-time monitoring and adjustments, leading to reduced waste and improved throughput. As industry leaders prioritize sustainability, more companies are exploring energy-efficient laser solutions that cut resource consumption without compromising cutting quality.

Tip: Stay ahead of the curve by exploring advancements in laser cutting technology offerings. Investing in newer, eco-friendly models not only aligns with sustainable practices but can also yield significant long-term cost savings.

Cost Analysis: Evaluating Investment vs. ROI in Laser Cutter Adoption

Investing in a laser cutter can significantly enhance the efficiency of manufacturing processes, especially when considering the long-term return on investment (ROI). While the initial costs of acquiring advanced laser cutting technology can be substantial, businesses must evaluate the potential savings and productivity gains over time. According to recent market analyses, the glass cutting machine sector alone is expected to expand from USD 615.2 million in 2025 to USD 818.8 million by 2035, growing at a compound annual growth rate (CAGR) of 3.2%. This growth underscores the industry's shift towards automation and precision, areas where laser cutters excel.

For small businesses contemplating the adoption of laser cutting technology, understanding the timeline for ROI is crucial. The question of when they should expect to see returns hinges not only on the machine's capabilities, but also on the operational efficiencies they can achieve. With reports indicating that construction projects often exceed timelines by up to 20%, laser cutters can help mitigate delays by streamlining material processing. By integrating artificial intelligence into production, companies can also optimize workflow, reducing downtime and making the investment in laser technology not just a cost, but a transformative asset.

FAQS

: The key benefits of laser cutting include high precision, reduced material waste, the ability to cut various materials seamlessly, and increased production speed, allowing for up to 50% faster processing times compared to conventional methods.

Laser cutting technology significantly enhances production efficiency, with businesses reporting up to a 50% reduction in production time, allowing them to meet tighter deadlines and respond more rapidly to market demands.

Laser cutting technology can cut a variety of materials including metals, plastics, and wood.

By providing precise cuts, laser cutting minimizes material waste, leading to cost savings and encouraging environmentally sustainable practices.

It's essential to prioritize employee training to ensure staff are proficient in operating laser cutting machines, which aids in smoother workflow transitions and helps prevent costly errors.

Regular maintenance is critical as it prolongs the lifespan of the machines and maintains their accuracy and efficiency.

The ability to create intricate designs quickly allows manufacturers to explore new product lines and custom solutions, enabling companies to stay competitive and paving the way for future growth.

The growth of the laser cutting market is driven by its increasing adoption across various industries due to its capability for intricate designs and tight tolerances that traditional cutting methods often cannot achieve.

According to a report, the global laser cutting market size is projected to reach USD 4.21 billion by 2025, growing at a CAGR of 6.2%.

Embracing laser cutting technology enables companies to improve productivity and efficiency, respond better to market changes, and maintain a competitive edge in a rapidly evolving industry.

Conclusion

In the ever-evolving landscape of manufacturing, a Laser Cutter stands out as a pivotal tool that significantly enhances production efficiency and precision. Understanding the technology behind laser cutting and its components reveals the advantages it brings to modern manufacturing processes, including reduced material waste and the ability to create intricate designs with ease. As highlighted in industry statistics, the adoption of laser cutters has shown remarkable improvements in production efficiency across various sectors.

Fortune Laser Technology Co., Ltd., established in 2016 in Shenzhen, exemplifies the advancements in laser cutting technology. With a focus on R&D, production, sales, and maintenance, the company demonstrates the transformative potential of laser cutters in manufacturing. Case studies of successful implementations illustrate how industries are benefiting from this innovation, while future trends signal continued growth and advancements in laser cutting technology. A careful cost analysis underscores the favorable ROI for businesses investing in laser cutter adoption, making it a wise choice for the future.

Related Posts

-

Ultimate Guide to Choosing the Right Laser Cutting Machines for Your Business

-

Unlocking Efficiency and Precision with the Best Fiber Laser Cutting Machine Benefits to Your Business

-

Innovative Solutions for Pipe Fiber Laser Cutting Machine Efficiency

-

Unlocking Efficiency with Cnc Sheet Metal Laser Cutter Advantages for Global Buyers

-

The Future of Precision Engineering with the Best Laser Cutting Device

-

Discover High Quality Open Type Fiber Laser Cutters from Leading Chinese Manufacturers

Blog Tags: