- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Unveiling the Future: How Laser Cleaning High Power Revolutionizes Industrial Maintenance

Table of Contents

- The Evolution of Laser Cleaning Technology in Industrial Maintenance

- Comparative Analysis: Laser Cleaning vs. Traditional Methods in Cost Efficiency

- Data-Driven Insights: Environmental Benefits of High-Power Laser Cleaning

- Maximizing Downtime Reduction: The Impact of Laser Technology on Maintenance Schedules

- Industry Case Studies: Successful Implementations of Laser Cleaning Solutions

- Future Trends: Innovations Shaping the Next Generation of Industrial Cleaning Systems

- FAQS

- Conclusion

- Related Posts

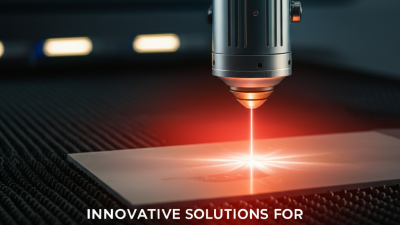

As industries continue to seek innovative solutions for maintenance challenges, "Laser Cleaning High Power" has emerged as a transformative technology that significantly enhances operational efficiency. According to a report by Research and Markets, the global laser cleaning market is projected to reach USD 835 million by 2025, highlighting the growing demand for effective and sustainable cleaning methods. Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, stands at the forefront of this revolution, offering cutting-edge industrial laser equipment that integrates R&D, production, sales, and maintenance services. The adoption of high-power laser cleaning not only reduces the need for harmful chemicals and abrasive materials but also delivers superior precision and speed, making it an ideal choice for various industrial applications. As we unveil the future of industrial maintenance, the impact of "Laser Cleaning High Power" promises to redefine traditional practices, setting new standards for performance and sustainability in the sector.

The Evolution of Laser Cleaning Technology in Industrial Maintenance

The evolution of laser cleaning technology has steadily transformed industrial maintenance, positioning it as a crucial component in sustainable manufacturing. In recent years, advancements have allowed laser systems to provide non-contact, eco-friendly solutions that dramatically reduce downtime and improve efficiency. The technology, which was once limited to controlled environments, is making significant inroads into areas such as ship hull cleaning and oilfield equipment maintenance. This shift highlights a growing recognition of the need for sustainable practices in an industry that often relies on more traditional, polluting methods.

**Tips:** When considering the integration of laser cleaning technology in your operations, focus on the compatibility of the system with existing maintenance protocols. Additionally, training personnel on the nuances of laser operation can optimize efficiency and safety. Staying informed about the latest advancements in this field will also help companies leverage the full potential of laser systems, ensuring they meet both current and future industrial demands.

Comparative Analysis: Laser Cleaning vs. Traditional Methods in Cost Efficiency

As industrial maintenance continues to evolve, laser cleaning has emerged as a game-changer, offering distinct advantages over traditional methods. When comparing the cost efficiency of laser cleaning versus conventional techniques, it becomes clear that while the initial investment for laser systems may be higher, the long-term savings are significant. Laser cleaning minimizes material usage, reduces disposal costs associated with chemical cleaning agents, and provides faster processing times, ultimately leading to a lower total cost of ownership.

Tips: When transitioning to laser cleaning, consider starting with a pilot project to assess its effectiveness in your specific application. Additionally, evaluate different laser types—solid-state, YAG, fiber, and gas lasers can all offer unique benefits based on the materials and contaminants you are working with.

The market for laser cleaning is expanding, fueled by its versatility across various industries such as general manufacturing, automotive, and aerospace. As more businesses recognize the efficiency and environmental benefits of laser cleaning, its adoption is likely to accelerate, leading to greater market share and innovative developments. Being proactive in understanding these trends can position companies to stay ahead in this competitive landscape.

Data-Driven Insights: Environmental Benefits of High-Power Laser Cleaning

High-power laser cleaning technology is ushering in a new era of industrial maintenance, significantly benefiting the environment. By utilizing high-powered lasers to remove contaminants, manufacturers can minimize the use of harsh chemicals and reduce waste production. This process not only improves operational efficiency but also aligns with the global drive for sustainability, showcasing how advanced technology can address pressing environmental concerns.

Tips: When considering laser cleaning solutions, evaluate the types of surfaces and materials involved in your operation—some lasers are more effective on specific substrates. Additionally, ensure that the technology you choose meets current environmental regulations to maximize both compliance and sustainability.

The rise of laser cleaning reflects a broader trend in laser technology towards eco-friendliness and efficiency. With Fortune Laser Technology Co., Ltd. leading the way since 2016, businesses can tap into innovative laser solutions that not only enhance maintenance practices but also contribute to an overall greener future. Leveraging data-driven insights, companies can identify opportunities for improvement and incorporate advanced laser cleaning techniques into their operational strategies.

Maximizing Downtime Reduction: The Impact of Laser Technology on Maintenance Schedules

The integration of laser cleaning technology into industrial maintenance is poised to dramatically alter maintenance schedules, especially as companies strive to maximize uptime and efficiency. By utilizing high-power lasers, industries can effectively eliminate contaminants from equipment surfaces without the need for harsh chemicals or lengthy manual cleaning processes. This innovation not only speeds up maintenance procedures but also reduces the overall downtime associated with routine maintenance tasks.

In a world where operational efficiency is paramount, tips for maximizing efficiency in tube and pipe mills can also apply to laser cleaning techniques. For instance, ensuring that all equipment is regularly maintained can prevent unexpected breakdowns and enhance operational flow. Additionally, scheduling maintenance during off-peak hours can minimize production disruptions, allowing for laser cleaning to become an integral part of regular maintenance routines.

As industries embrace advanced technologies, including automation and artificial intelligence, the impact of laser technology on maintenance schedules cannot be underestimated. Incorporating high-power laser cleaning ensures that machinery remains in optimal condition, ultimately contributing to a significant reduction in downtime and enhanced productivity across various sectors.

Unveiling the Future: Impact of Laser Cleaning Technology on Maintenance Schedules

This chart illustrates the reduction in maintenance downtime achieved with the implementation of laser cleaning technology in various industrial sectors over a three-year period. The adoption of this advanced technology has demonstrated significant efficiency improvements.

Industry Case Studies: Successful Implementations of Laser Cleaning Solutions

Laser cleaning technology is transforming the landscape of industrial maintenance, offering efficient solutions to traditional cleaning challenges. At the forefront of this revolution is Fortune Laser Technology Co., Ltd., which has been pioneering advancements in high-power laser cleaning equipment since its establishment in 2016. With a strong emphasis on research and development, Fortune Laser has successfully integrated sales and maintenance services to ensure that industries have access to top-of-the-line laser cleaning solutions.

Numerous case studies showcase the successful implementation of laser cleaning across various sectors. For instance, in the automotive industry, manufacturers have adopted laser technology to remove rust and contaminants from components with exceptional precision and speed, leading to significant reductions in downtime. Similarly, in the oil and gas sector, facilities have implemented laser cleaning to maintain pipelines and machinery, improving safety and efficiency while minimizing the use of harsh chemicals.

These success stories illustrate the potential of laser cleaning as a sustainable and effective alternative for industrial maintenance, reinforcing Fortune Laser's commitment to innovation and excellence in the field.

Future Trends: Innovations Shaping the Next Generation of Industrial Cleaning Systems

The landscape of industrial cleaning systems is evolving rapidly, driven by innovations that aim to enhance efficiency and environmental sustainability. One of the most promising trends is the integration of laser cleaning technology. This method not only eliminates the need for harsh chemicals but also minimizes waste and downtime. By harnessing the precision of lasers, facilities can achieve a higher level of cleanliness while protecting the underlying materials from damage.

Tips: When considering laser cleaning for your operations, assess the specific needs of your materials and contaminants. This will help in selecting the right power and wavelength for optimal results. Additionally, training staff on the equipment can significantly enhance safety and effectiveness.

Moreover, advancements in automation and AI are beginning to play a critical role in shaping the future of industrial cleaning. Automated systems can monitor cleaning processes and adapt in real-time, ensuring consistent results while reducing labor costs. As these technologies interface more seamlessly with existing systems, industries will benefit from unprecedented efficiency and reliability.

Tips: Keep an eye on emerging technologies and be open to upgrading your systems for better performance. Implementing pilot programs can also help gauge the effectiveness of these innovations before a full rollout.

FAQS

: Laser cleaning technology is a non-contact, eco-friendly solution that uses high-powered lasers to remove contaminants from surfaces, significantly improving efficiency and reducing downtime in industrial maintenance.

While the initial investment for laser cleaning systems may be higher, the long-term savings are significant due to minimized material usage and reduced disposal costs, leading to a lower total cost of ownership.

Laser cleaning technology is expanding in industries such as general manufacturing, automotive, and aerospace, where its efficiency and environmental benefits are increasingly recognized.

High-power laser cleaning minimizes the use of harsh chemicals and reduces waste production, aligning with sustainability goals and improving operational efficiency.

Companies should consider the compatibility of laser systems with existing maintenance protocols, train personnel on laser operation, and stay informed about the latest advancements in the field.

Different types of lasers—such as solid-state, YAG, fiber, and gas lasers—offer unique benefits depending on the materials and contaminants being addressed in a cleaning project.

Businesses are encouraged to start with a pilot project to evaluate laser cleaning's effectiveness and efficiency for their specific applications before fully integrating it into their operations.

Fortune Laser Technology Co., Ltd. has been a leader in the field since 2016, providing innovative laser solutions that enhance maintenance practices and contribute to a greener future.

Companies should ensure that the chosen laser cleaning technology meets current environmental regulations to maximize both compliance and sustainability efforts.

Adopting laser cleaning technology can improve operational efficiency, reduce the reliance on traditional, polluting methods, and help companies meet both current and future industrial demands.

Conclusion

The article "Unveiling the Future: How Laser Cleaning High Power Revolutionizes Industrial Maintenance" explores the transformative impact of high-power laser cleaning technology on the industrial maintenance sector. It begins by tracing the evolution of laser cleaning technology, highlighting its progressive integration into maintenance practices. A comparative analysis reveals the cost efficiency of laser cleaning over traditional methods, while data-driven insights emphasize its significant environmental benefits, contributing to sustainable industrial operations.

Notably, the article discusses how Laser Cleaning High Power minimizes downtime, optimizing maintenance schedules and enhancing overall productivity. Industry case studies showcase successful implementations of this technology, reaffirming its effectiveness and reliability. Finally, the article anticipates future trends and innovations poised to further revolutionize industrial cleaning systems, indicating a promising trajectory for companies like Fortune Laser Technology Co., Ltd., which specializes in cutting-edge laser equipment manufacturing and solutions.

Related Posts

-

Innovative Solutions for Effective Laser Cleaning High Power Technology

-

How to Optimize Your Laser Cleaning Device for Maximum Efficiency

-

5 Reasons Why Best Laser Cleaning Car Parts Are Revolutionizing Automotive Maintenance

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

5 Incredible Benefits of Using a Laser Cleaner Handheld Device