- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

7 Key Advantages of Using High Power Laser Cutters in Modern Manufacturing

Table of Contents

- Key Advantages of High Power Laser Cutters in Precision Engineering

- Enhancing Production Speed with High Power Laser Cutting Technology

- Improved Material Versatility: Cutting a Wide Range of Materials

- Cost Efficiency: Long-term Savings of High Power Laser Cutting

- Sustainable Manufacturing: Eco-friendly Benefits of Laser Cutters

- Superior Cutting Quality: Achieving Perfect Edges and Details

- FAQS

- Conclusion

- Related Posts

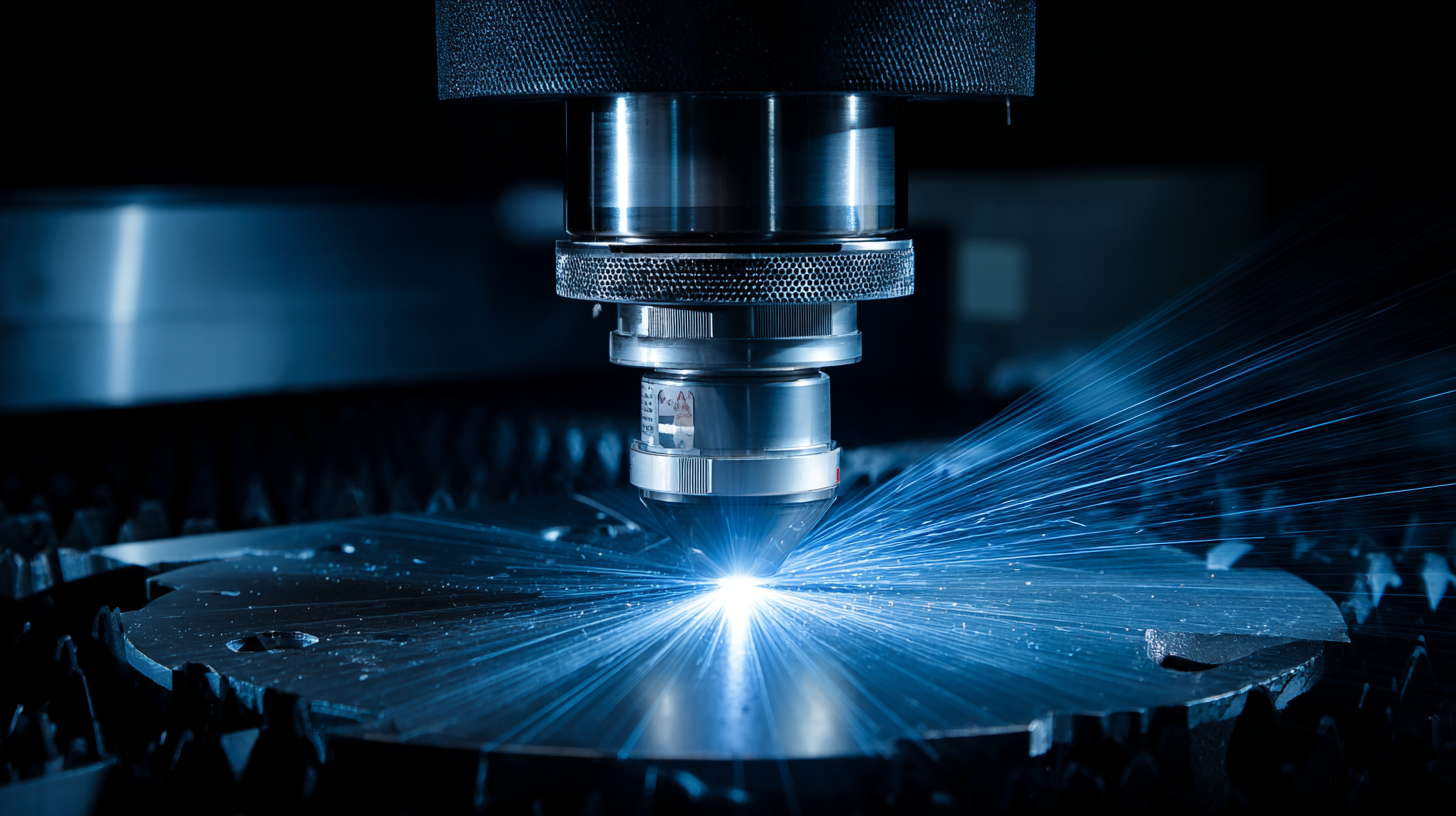

In the ever-evolving landscape of modern manufacturing, the adoption of cutting-edge technology is paramount for staying ahead of the competition. Among these advancements, the High Power Laser Cutter stands out as a transformative tool that significantly enhances precision and efficiency in the production process.

At Fortune Laser Technology Co., Ltd., founded in 2016 and based in Shenzhen, we specialize in developing high-quality industrial laser equipment that meets the rigorous demands of today's manufacturing environment. Our commitment to innovation and excellence allows us to provide not only cutting-edge machinery but also comprehensive R&D, production, sales, and maintenance services. In this blog, we will explore seven key advantages of using High Power Laser Cutters that underscore their impact on productivity, cost-effectiveness, and overall manufacturing excellence, providing a comparison that highlights why they are the preferred choice for manufacturers worldwide.

At Fortune Laser Technology Co., Ltd., founded in 2016 and based in Shenzhen, we specialize in developing high-quality industrial laser equipment that meets the rigorous demands of today's manufacturing environment. Our commitment to innovation and excellence allows us to provide not only cutting-edge machinery but also comprehensive R&D, production, sales, and maintenance services. In this blog, we will explore seven key advantages of using High Power Laser Cutters that underscore their impact on productivity, cost-effectiveness, and overall manufacturing excellence, providing a comparison that highlights why they are the preferred choice for manufacturers worldwide.

Key Advantages of High Power Laser Cutters in Precision Engineering

The landscape of modern manufacturing is increasingly shaped by high power laser cutters, especially in the realm of precision engineering. These advanced machines leverage cutting-edge laser technology to deliver unparalleled accuracy, efficiency, and flexibility in various manufacturing processes. Industries capitalize on the precision offered through laser cutting, welding, engraving, and marking, allowing for the fabrication of intricate designs and components that were previously unattainable with traditional methods.

As manufacturing moves toward higher-end, intelligent, and precise solutions, the market for laser processing equipment is expanding rapidly. The COVID-19 pandemic has only accelerated this trend, highlighting the need for automation and advanced technology in production settings. Techniques such as fiber lasers, CO2 lasers, and solid-state lasers are at the forefront, providing diverse applications for cutting, welding, and even micro-machining. With events like the upcoming 2025 Wuhan Laser Exhibition, stakeholders in the laser sector will gather to explore innovations that empower the entire industry chain, from cutting to cleaning and marking. Companies like ours, grounded in research and development, are pivotal in driving these advancements, ensuring that the potential of laser technology can be fully realized in modern manufacturing processes.

Enhancing Production Speed with High Power Laser Cutting Technology

In today's fast-paced manufacturing landscape, enhancing production speed is paramount, and high power laser cutting technology is emerging as a game changer. According to a recent industry report, manufacturers utilizing high power laser cutters can achieve production speeds up to 60% faster compared to traditional cutting methods. This significant increase in efficiency is primarily due to the high precision and rapid material processing capabilities of laser cutters, which can easily handle various materials, including metals, plastics, and composites.

Fortune Laser Technology Co., Ltd., founded in 2016, stands at the forefront of this technological revolution. With our state-of-the-art laser equipment and integrated services in R&D, production, and maintenance, we empower manufacturers to optimize their processes and reduce downtime. A study by the International Journal of Advanced Manufacturing Technology highlights that companies leveraging high power laser systems not only boost their production rates but also minimize waste and improve product quality. As industries continually seek competitive advantages, embracing advanced laser cutting technology from established manufacturers like Fortune Laser will be crucial for sustained growth and operational excellence.

7 Key Advantages of Using High Power Laser Cutters in Modern Manufacturing

| Advantage | Description | Impact on Production |

|---|---|---|

| High Precision | Laser cutters provide exceptional precision, allowing for intricate designs and cuts. | Reduced material waste and improved product quality. |

| Speed | High power lasers operate at fast speeds, significantly increasing throughput. | Higher production rates lead to better meeting of deadlines. |

| Material Versatility | Can cut various materials including metals, plastics, and wood. | Ability to handle diverse projects without changing equipment. |

| Lower Labor Costs | Automation reduces the need for manual labor in cutting processes. | Significant cost savings on labor expenses. |

| Safety | Laser cutting reduces physical risks compared to traditional cutting methods. | Safer working environment for operators. |

| Minimal Heat Affected Zone | Laser cutting minimizes the heat impact on surrounding materials. | Preserves the integrity of the material being cut. |

| Cost Efficiency | While initial setup may be high, long-term operational costs are reduced. | Higher return on investment over time. |

Improved Material Versatility: Cutting a Wide Range of Materials

Laser cutting technology has revolutionized modern manufacturing, particularly due to its capability of cutting a diverse range of materials with precision and efficiency. Unlike traditional cutting methods, high power laser cutters can effortlessly handle metals like AISI 304 tempered steel, as highlighted by recent research utilizing response surface methodology to enhance plasma cutting techniques. This adaptability allows for the processing of both rigid and flexible materials, making laser cutters an indispensable tool in industries ranging from automotive to textiles.

Furthermore, innovations such as electrospinning and nanofiber technology emphasize the importance of versatility in manufacturing processes. By enabling the production of complex structures with controlled morphology, manufacturers can create advanced materials that meet specific application requirements. As Fortune Laser Technology Co., Ltd. leads the way in industrial laser equipment, their commitment to research and development ensures that they remain at the forefront of these transformative technologies, allowing manufacturers to leverage high power laser cutting for improved material versatility and enhanced operational efficiency.

Cost Efficiency: Long-term Savings of High Power Laser Cutting

High power laser cutting technology is revolutionizing modern manufacturing by offering significant cost efficiencies that translate into long-term savings. As industries increasingly adopt ultrahigh-power fiber lasers, companies can achieve high-quality cutting at remarkable speeds, particularly when working with thick materials such as steel. According to recent reports, these lasers not only reduce operational time but also minimize material waste, resulting in lower overall production costs. The high precision of laser cutters ensures that manufacturers can maintain stringent quality standards while optimizing resource usage.

Furthermore, advancements such as diode-pumped solid-state lasers (DPSSLs) have expanded their application in high-power metals processing. Their ability to deliver consistent performance under demanding conditions allows manufacturers to scale production without compromising affordability. Reports indicate that investment in high power laser solutions can yield savings of up to 30% when considering maintenance and material costs over time. By investing in these cutting-edge technologies, manufacturers position themselves for sustainable growth while benefiting from the inherent efficiency and cost savings of laser cutting.

Sustainable Manufacturing: Eco-friendly Benefits of Laser Cutters

The emergence of high power laser cutters in modern manufacturing brings significant eco-friendly benefits, supporting the industry's shift toward sustainable practices. According to a study by the International Journal of Advanced Manufacturing Technology, laser cutting processes produce up to 40% less waste compared to traditional methods. This reduction in material waste not only benefits manufacturers’ bottom lines but also minimizes environmental impact, demonstrating a compelling case for adopting laser technology.

Moreover, laser cutting is known for its energy efficiency. A report from the U.S. Department of Energy highlights that laser systems can operate at 90% efficiency, significantly higher than traditional cutting technologies. This efficiency translates into lower energy consumption during production, which contributes to a reduced carbon footprint. As industries increasingly prioritize sustainability, high power laser cutters represent a strategic advancement towards eco-friendly manufacturing, aligning with global initiatives to mitigate climate change while enhancing operational productivity.

Superior Cutting Quality: Achieving Perfect Edges and Details

In the rapidly evolving landscape of modern manufacturing, achieving superior cutting quality is paramount. High power laser cutters have emerged as a revolutionary tool, offering unparalleled precision and detail. With their ability to cut through various materials—such as metal, wood, and plastics—these advanced machines ensure perfect edges and intricate designs that traditional methods often struggle to replicate. This level of accuracy not only enhances the final product's aesthetic appeal but also plays a crucial role in maintaining dimensional integrity during the production process.

In the rapidly evolving landscape of modern manufacturing, achieving superior cutting quality is paramount. High power laser cutters have emerged as a revolutionary tool, offering unparalleled precision and detail. With their ability to cut through various materials—such as metal, wood, and plastics—these advanced machines ensure perfect edges and intricate designs that traditional methods often struggle to replicate. This level of accuracy not only enhances the final product's aesthetic appeal but also plays a crucial role in maintaining dimensional integrity during the production process.

At Fortune Laser Technology Co., Ltd., we understand the significance of delivering high-quality cutting solutions. Since our establishment in 2016, we have dedicated ourselves to the research and development of cutting-edge industrial laser equipment. Our commitment to quality and innovation allows us to provide manufacturers with powerful laser cutting tools that improve efficiency and output. By investing in high power laser cutters, businesses can achieve optimal cutting quality, streamline their operations, and stay ahead in an increasingly competitive market.

FAQS

: High power laser cutters can cut a wide range of materials, including metals like AISI 304 tempered steel, as well as both rigid and flexible materials across various industries.

Laser cutting technology offers significant cost efficiencies by reducing operational time and minimizing material waste, which leads to lower overall production costs while maintaining high quality.

Investing in high power laser solutions can yield savings of up to 30% in maintenance and material costs over time due to their efficiency and precision.

Laser cutters produce up to 40% less waste compared to traditional cutting methods, contributing to reduced material waste and a lower environmental impact.

High power laser cutting systems can operate at 90% efficiency, which significantly reduces energy consumption during production compared to traditional cutting technologies.

Fortune Laser Technology Co., Ltd. is a leader in industrial laser equipment, focusing on research and development to enhance material versatility and operational efficiency in laser cutting technologies.

Laser cutting technology aligns with sustainable practices by minimizing waste and energy use, thus contributing to a reduced carbon footprint and supporting global initiatives to mitigate climate change.

Recent advancements include the development of ultrahigh-power fiber lasers and diode-pumped solid-state lasers (DPSSLs), which enhance performance in high-power metals processing.

High power laser cutters are utilized in various industries, including automotive and textiles, due to their versatility and efficiency.

The high precision and speed of laser cutting improve operational productivity, allowing manufacturers to scale production without compromising quality or increasing costs.

Conclusion

High Power Laser Cutters have revolutionized modern manufacturing by providing numerous advantages that enhance precision engineering and production efficiency. With their ability to cut a wide range of materials, these advanced machines ensure improved material versatility, making them suitable for diverse applications. Moreover, the technology significantly boosts production speed, allowing manufacturers to meet tight deadlines while maintaining superior cutting quality that achieves perfect edges and intricate details.

Cost efficiency is another key benefit, as High Power Laser Cutters often lead to long-term savings through reduced material waste and lower operational costs. Additionally, Fortune Laser Technology Co., Ltd., established in 2016 in Shenzhen, exemplifies the integration of R&D and production in the development of such eco-friendly solutions that promote sustainable manufacturing practices. By embracing High Power Laser Cutters, businesses can not only enhance their operations but also contribute positively to the environment.

Related Posts

-

Exploring the Unique Features and Applications of the Best Precise Fiber Laser Cutters in Modern Manufacturing

-

Trust in Global Manufacturing Excellence Discover the Best Industrial Laser Cutting Machines from China's Leading Factory

-

Future of Best CNC Laser Cutters in 2025 Embracing Emerging Technologies for Increased Efficiency and Precision

-

How to Choose the Best Mini Laser Cutting Machine for 2025 Industry Trends

-

Finding Top Suppliers for Best 3015 Fiber Laser Cutter Your Essential Checklist Guide

-

Unlocking Efficiency with Cnc Sheet Metal Laser Cutter Advantages for Global Buyers