- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

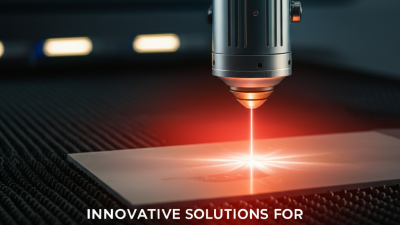

Innovative Solutions for Effective Surface Restoration with Large Format Laser Cleaning Machines

Table of Contents

- Innovative Laser Cleaning: Revolutionizing Surface Restoration for Various Industries

- Understanding the Technology Behind Large Format Laser Cleaning Machines

- Comparative Analysis: Laser Cleaning vs. Traditional Restoration Methods

- Key Industry Statistics: Growth and Impact of Laser Cleaning Solutions

- Case Studies: Successful Surface Restoration Projects Utilizing Laser Technology

- Future Trends in Surface Restoration: The Role of Digital Innovation and Laser Machinery

- FAQS

- Conclusion

- Related Posts

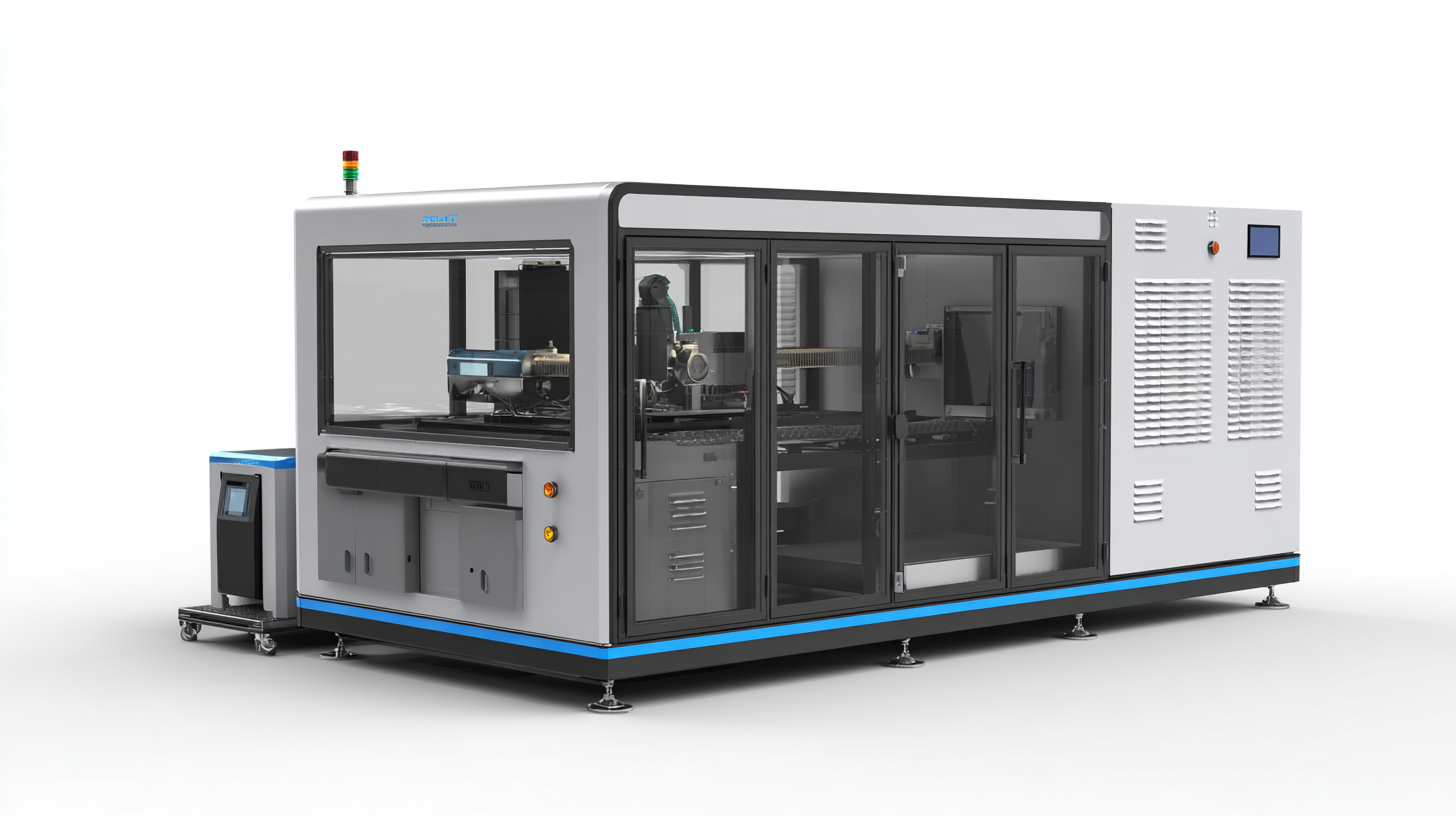

In the realm of industrial surface restoration, the advent of the Large Format Laser Cleaning Machine marks a transformative leap in efficiency and effectiveness. Fortune Laser Technology Co., Ltd., established in 2016 and based in the vibrant city of Shenzhen, has been at the forefront of this innovation, providing cutting-edge solutions that seamlessly integrate research and development with practical applications. Our commitment to excellence ensures that each machine is designed not only to meet but exceed the demands of today’s rigorous cleaning standards. In this blog, we will explore various innovative techniques and best practices for utilizing Large Format Laser Cleaning Machines, demonstrating how they can revolutionize surface restoration processes across industries. Whether you are looking to enhance the quality of your work or streamline operations, understanding the potential of these machines is crucial for staying competitive in an ever-evolving market.

Innovative Laser Cleaning: Revolutionizing Surface Restoration for Various Industries

In recent years, innovative laser cleaning technologies have emerged as a game-changer for surface restoration across various industries. Fortune Laser Technology Co., Ltd., established in 2016 in Shenzhen, is at the forefront of this revolution, specializing in large format laser cleaning machines that provide effective solutions for a myriad of applications. From historical restoration projects to industrial maintenance, these advanced machines deliver superior performance, ensuring surfaces are impeccably cleaned without damaging the underlying material.

Tip 1: When selecting a laser cleaning solution, consider the specific type of surface you intend to restore. Different materials may require tailored laser parameters for optimal results.

Laser cleaning not only enhances aesthetic appeal but also prolongs the lifespan of equipment and structures. Fortune Laser's commitment to high-quality manufacturing and comprehensive maintenance services ensures that users benefit from state-of-the-art technology and sustained operational efficiency.

Tip 2: Regular maintenance of your laser cleaning equipment is essential to maintain its effectiveness and longevity. Schedule routine checks to prevent any potential downtime.

By harnessing the power of innovative laser cleaning, industries can now achieve exceptional surface restoration results, driving both productivity and sustainability.

Understanding the Technology Behind Large Format Laser Cleaning Machines

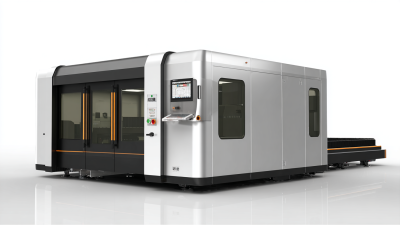

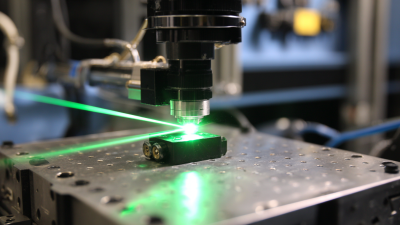

Large format laser cleaning machines are revolutionizing surface restoration by leveraging advanced laser technology for effective cleaning applications. Understanding the mechanics behind these machines is crucial for appreciating their impact on various industries. By emitting high-intensity laser beams, these machines can remove contaminants, rust, and other surface imperfections without the need for harsh chemicals or physical abrasives. This eco-friendly method not only enhances surface quality but also prolongs the lifespan of the materials being treated.

**Tips for Effective Use of Laser Cleaning Technology:**

1. Ensure proper calibration of the laser cleaning machine to match the material and condition of the surface being cleaned. This adjustment optimizes efficiency and prevents damage.

2. Regular maintenance of the equipment, including cleaning the laser source and checking power levels, can significantly enhance performance and reliability.

The global laser cleaning market reflects a growing recognition of these technologies, projected to increase from $660 million in 2023 to $1.15 billion by 2032. With a compound annual growth rate (CAGR) of 6.36% during the forecast period, this market underscores the commitment to innovative and sustainable cleaning solutions.

Comparative Analysis: Laser Cleaning vs. Traditional Restoration Methods

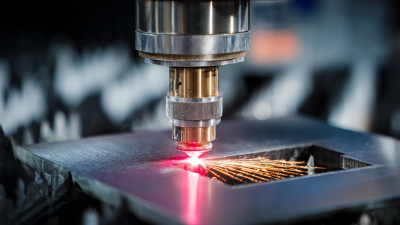

When it comes to surface restoration, the choice between laser cleaning technology and traditional methods can significantly impact the effectiveness and efficiency of the process. Traditional restoration methods, such as sandblasting and chemical cleaning, may produce satisfactory results but often come with drawbacks such as material wear, environmental hazards, and longer downtime. In contrast, large format laser cleaning machines offer a precision-based solution that minimizes substrate damage while effectively removing contaminants. This innovative approach not only enhances safety but also reduces waste, making it a more sustainable choice for restoration projects.

A comparative analysis of these two approaches reveals that laser cleaning surpasses traditional methods in several key areas. For instance, the ability of lasers to selectively target contaminants without affecting the underlying material leads to superior results, especially on delicate surfaces. Furthermore, the speed of laser cleaning operations can significantly decrease project timelines, enabling quicker turnarounds for businesses. While traditional methods may still have their place, the advancements offered by laser technology establish it as a leader in modern surface restoration, proving that it is not just an alternative but a preferable method for many applications.

Key Industry Statistics: Growth and Impact of Laser Cleaning Solutions

The laser cleaning industry is experiencing unprecedented growth, driven by the increasing demand for effective and environmentally friendly surface restoration solutions. Recent statistics indicate that the market is projected to grow at a CAGR of over 25% in the next five years. This surge is primarily attributed to the rising need for maintenance in various sectors, including manufacturing, aerospace, and historic preservation. As industries seek to enhance operational efficiency while adhering to stringent environmental regulations, large format laser cleaning machines emerge as a sustainable alternative to traditional cleaning methods.

Moreover, the impact of laser cleaning technology on operational costs cannot be overstated. Businesses that implement these innovative machines report significant reductions in both labor and material expenses. Furthermore, the precision and versatility of laser cleaning allow for meticulous surface restoration without causing damage to substrates, which is a common issue with conventional cleaning techniques. This has led to increased adoption across diverse applications, underscoring the vital role laser cleaning solutions play in modern industrial processes. The combination of efficiency, cost-effectiveness, and environmental compliance positions large format laser cleaning machines as game-changers in the pursuit of effective surface restoration.

Case Studies: Successful Surface Restoration Projects Utilizing Laser Technology

Laser technology has emerged as a game-changer in the realm of surface restoration, offering innovative solutions that are both effective and efficient. Case studies highlight several successful projects that demonstrate the versatility and precision of large format laser cleaning machines. For instance, a historic building restoration in a major city utilized laser cleaning to remove decades of grime and paint without damaging the underlying materials. The laser's ability to selectively target contaminants allowed restorers to preserve the integrity of delicate architectural features while revitalizing the structure's appearance.

Another compelling example involves the automotive industry, where laser cleaning was used to restore vintage vehicles. In one case, a classic car was meticulously cleaned to remove rust and old paint, showcasing the laser's effectiveness in handling intricate designs and surfaces. The results not only enhanced the car's aesthetic value but also improved its marketability. Through these projects, the advantages of using laser technology in surface restoration are evident, highlighting its potential to address a wide range of applications with unparalleled precision and care.

Future Trends in Surface Restoration: The Role of Digital Innovation and Laser Machinery

Future trends in surface restoration are significantly being reshaped by digital innovation and advanced laser machinery, which collectively enhance the efficiency and effectiveness of restoration processes. As industries strive toward sustainability and the adoption of eco-friendly practices, large format laser cleaning machines are gaining traction. According to a market report, the non-metal laser engraving machine market is projected to grow from $359.1 million in 2024 to $575.9 million by 2032, demonstrating a compound annual growth rate of 6.1%. This growth signals a pivotal shift in how industries approach surface restoration, leveraging cutting-edge technology to deliver superior results while minimizing environmental impact.

Tips: When considering laser cleaning solutions, evaluate the specific needs of your project. Ensure that the chosen technology aligns with your sustainability goals and restoration requirements. Additionally, staying informed about advancements in laser technology can provide a competitive edge in the market.

Moreover, the integration of laser technology with modern IoT applications opens new doors for precision and automation in surface restoration. As highlighted by recent trends in the ICT sector, the push toward smart and green innovations is not just a fleeting phase but a foundational change in how industries operate. Adapting to these digital trends will be crucial for businesses looking to thrive in an increasingly competitive landscape.

Tips: Invest in training and development programs to keep your team updated on the latest laser technologies and their applications in surface restoration. Embrace collaborations that offer insight into digital innovations, which can facilitate smoother transitions into new operational methodologies.

Innovative Solutions for Effective Surface Restoration with Large Format Laser Cleaning Machines

| Technology | Cleaning Method | Surface Material | Efficiency (%) | Digital Integration |

|---|---|---|---|---|

| Fiber Laser | Pulsed Laser Cleaning | Metal | 95 | Yes |

| CO2 Laser | Continuous Wave Cleaning | Plastic | 88 | Yes |

| Ultrafast Laser | Ablation Cleaning | Composites | 90 | Yes |

| Nd:YAG Laser | Selective Cleaning | Concrete | 92 | No |

FAQS

: Laser cleaning technology utilizes high-intensity laser beams to effectively remove contaminants, rust, and other surface imperfections without damaging the underlying material.

Laser cleaning can be applied in various industries, including historical restoration, industrial maintenance, and any sector where surface restoration is crucial.

Laser cleaning offers several advantages over traditional methods, such as minimal substrate damage, reduced waste, and faster project timelines, making it a more efficient and sustainable choice.

It's important to consider the specific type of surface being restored, as different materials may require tailored laser parameters for optimal cleaning results.

Regular maintenance, including routine checks, cleaning the laser source, and checking power levels, is essential to maintain the effectiveness and longevity of laser cleaning equipment.

The global laser cleaning market is projected to increase from $660 million in 2023 to $1.15 billion by 2032, reflecting a growing recognition and commitment to these innovative technologies.

Laser cleaning does not require harsh chemicals or physical abrasives, making it an environmentally friendly method for surface restoration.

Laser cleaning allows for careful and precise restoration of delicate surfaces, preserving the integrity of historical materials while effectively removing unwanted contaminants.

Conclusion

In recent years, Large Format Laser Cleaning Machines have emerged as a groundbreaking solution for surface restoration across various industries. These innovative devices utilize advanced laser technology to efficiently eliminate contaminants, leading to superior surface quality and reduced downtime compared to traditional restoration methods. Understanding the technology behind these machines reveals their capability to adapt to different materials and applications, making them versatile tools for modern manufacturing and maintenance.

At Fortune Laser Technology Co., Ltd., we are committed to leading the charge in this transformation. Since our establishment in 2016, we have focused on integrating research, production, and maintenance services to provide top-quality industrial laser equipment. The growing adoption of laser cleaning solutions is highlighted by key industry statistics, demonstrating both their impact and potential for future trends. Through successful case studies, we have showcased the effectiveness of our Large Format Laser Cleaning Machines, paving the way for digital innovation in surface restoration.

Related Posts

-

How to Choose the Right Fully Enclosed Fiber Laser Cutter for Your Business Needs

-

Innovative Solutions for Enhancing Productivity with Square Tube Cutting Machines

-

Understanding Challenges with Affordable Fiber Laser Cutter Reliability

-

Innovative Solutions for Pipe Fiber Laser Cutting Machine Efficiency

-

The Future of Precision in Metal Sheet Laser Cutting Technology

-

Innovative Solutions for Effective Laser Cleaning High Power Technology