- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Innovative Solutions for Enhancing Productivity with Square Tube Cutting Machines

Table of Contents

- Understanding the Basics of Square Tube Cutting Machines

- The Role of Technology in Enhancing Cutting Precision

- Innovative Features to Boost Productivity in Tube Cutting

- Comparative Analysis of Manual vs. Automated Tube Cutting Solutions

- Cost-Benefit Assessment of Upgrading Cutting Machines

- Future Trends in Square Tube Cutting Machine Technology

- FAQS

- Conclusion

- Related Posts

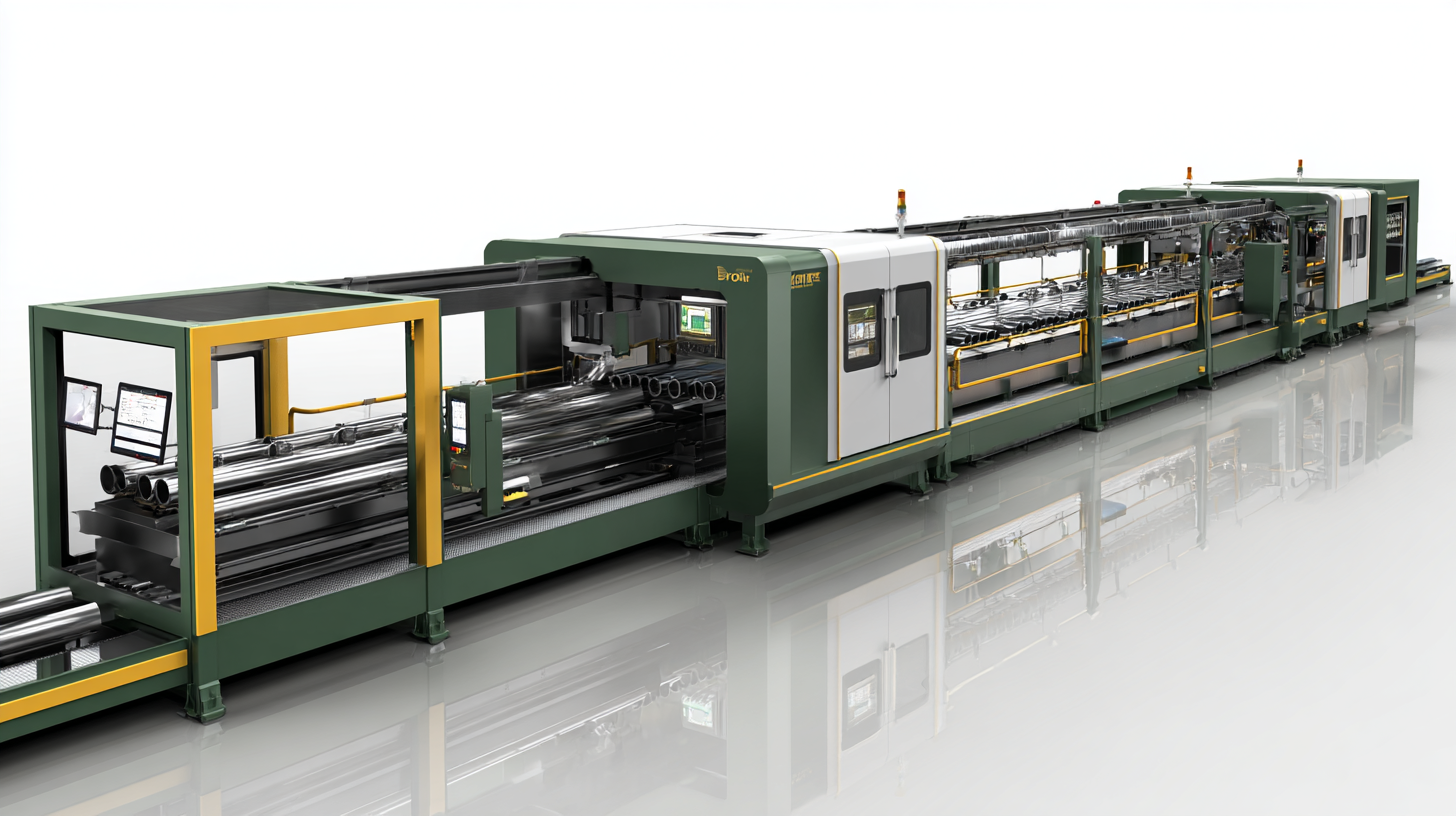

In today's fast-paced industrial landscape, enhancing productivity is a top priority for manufacturers seeking competitive advantages. The Square Tube Cutting Machine has emerged as a pivotal tool in this endeavor, streamlining operations and optimizing resource use.

At Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen city, we specialize in delivering cutting-edge industrial laser equipment designed to meet the dynamic needs of modern fabrication. Our commitment to innovation drives us to develop solutions that not only improve efficiency but also ensure precision and quality in square tube cutting processes.

In this blog, we will explore the top strategies for leveraging Square Tube Cutting Machines to boost productivity, incorporating insights from our extensive experience in R&D, production, sales, and maintenance services.

At Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen city, we specialize in delivering cutting-edge industrial laser equipment designed to meet the dynamic needs of modern fabrication. Our commitment to innovation drives us to develop solutions that not only improve efficiency but also ensure precision and quality in square tube cutting processes.

In this blog, we will explore the top strategies for leveraging Square Tube Cutting Machines to boost productivity, incorporating insights from our extensive experience in R&D, production, sales, and maintenance services.

Understanding the Basics of Square Tube Cutting Machines

Square tube cutting machines are essential tools in metal fabrication, particularly in industries that require precise and efficient processing of tubular materials. These machines operate by utilizing advanced cutting technologies such as laser, plasma, and water jet cutting, which significantly enhance the output quality and operational efficiency.

According to a report by MarketsandMarkets, the global market for CNC cutting machines, including those for square tube applications, is expected to reach $8.3 billion by 2025, growing at a CAGR of 5.3%. This growth highlights the increasing demand for automation and precision in manufacturing processes. Understanding the fundamental mechanisms behind square tube cutting machines can lead to more informed purchasing decisions and improved workplace productivity.

**Tip:** Regular maintenance of your cutting machine can prevent costly downtimes. Schedule routine inspections to check for wear and tear, ensuring optimal performance.

Moreover, investing in advanced software that integrates with your square tube cutting machinery can enhance production workflows by streamlining design changes and reducing setup times. With the right tools and knowledge, manufacturers can increase their productivity while maintaining high-quality standards.

**Tip:** Consider training your staff on the latest cutting technologies. Well-trained operators can maximize machine capabilities and minimize errors, leading to better resource management.

Innovative Solutions for Enhancing Productivity with Square Tube Cutting Machines

| Feature | Description | Benefits | Usage Scenario |

|---|---|---|---|

| High Precision Cutting | Machines designed to cut square tubes with tight tolerances. | Reduces material waste and improves the quality of finished products. | Ideal for custom fabrications in metalworking. |

| Automatic Load and Unload | Integrated systems that automatically handle materials. | Increases operational efficiency and reduces labor costs. | Perfect for high-volume production lines. |

| User-Friendly Interface | Touchscreen controls for easy operation and programming. | Minimizes training time for new operators. | Suitable for workshops with varying skill levels. |

| Versatile Material Handling | Capable of cutting various materials including aluminum, steel, and plastic. | Enhances flexibility to cater to diverse projects. | Applicable in automotive, construction, and furniture industries. |

| Advanced Safety Features | Equipped with safety guards and emergency stop functions. | Ensures operator safety and reduces the risk of accidents. | Essential in high-risk manufacturing environments. |

The Role of Technology in Enhancing Cutting Precision

The development of cutting-edge technology has significantly transformed the landscape of square tube cutting machines, enhancing their precision and operational efficiency. Precision is crucial in industries such as construction, automotive, and manufacturing, where even a minor error can lead to substantial financial loss and safety hazards. Modern machines are equipped with advanced features like laser-guided cutting systems and automated measurement tools, which drastically reduce human error and ensure that each cut meets the specified dimensions.

The development of cutting-edge technology has significantly transformed the landscape of square tube cutting machines, enhancing their precision and operational efficiency. Precision is crucial in industries such as construction, automotive, and manufacturing, where even a minor error can lead to substantial financial loss and safety hazards. Modern machines are equipped with advanced features like laser-guided cutting systems and automated measurement tools, which drastically reduce human error and ensure that each cut meets the specified dimensions.

In addition to enhancing precision, technology plays a pivotal role in streamlining the cutting process. Features like real-time monitoring and predictive maintenance not only optimize workflow but also minimize downtime associated with equipment failure. With the integration of data analytics, operators can adjust settings dynamically based on material behavior, ensuring uniformity in the final product. As these innovations continue to evolve, we can expect an even greater impact on productivity, propelling industries toward greater efficiency and higher standards of quality.

Innovative Features to Boost Productivity in Tube Cutting

In the rapidly evolving landscape of manufacturing, square tube cutting machines have emerged as a game-changer in enhancing productivity. Recent industry reports indicate that automated tube cutting technology can increase operational efficiency by up to 30%, reducing material waste and labor costs significantly. Innovative features such as laser-guided cutting and real-time monitoring systems allow for precise cuts and minimal downtime, ensuring that production schedules remain on track.

In the rapidly evolving landscape of manufacturing, square tube cutting machines have emerged as a game-changer in enhancing productivity. Recent industry reports indicate that automated tube cutting technology can increase operational efficiency by up to 30%, reducing material waste and labor costs significantly. Innovative features such as laser-guided cutting and real-time monitoring systems allow for precise cuts and minimal downtime, ensuring that production schedules remain on track.

Tip: To maximize the benefits of your tube cutting machines, consider investing in staff training programs focused on advanced operating techniques. Skilled operators not only deliver higher-quality cuts but also ensure that the machines perform optimally, leading to less wear and tear over time.

Furthermore, many modern machines come equipped with smart technology that integrates with inventory management systems. This innovation enables seamless tracking of materials, reducing delays caused by inventory shortages. Reports suggest that companies implementing such integrated systems have seen a 25% improvement in turnaround time.

Tip: Regularly review and update your machine software to take full advantage of new features and enhancements. Staying current with technology will provide a competitive edge and further boost your production capabilities.

Comparative Analysis of Manual vs. Automated Tube Cutting Solutions

In the realm of metal fabrication, the choice between manual and automated tube cutting solutions significantly impacts productivity and efficiency.

Manual cutting methods, while cost-effective and versatile, often lead to inconsistencies in quality and increased labor demands.

Workers must possess a high level of skill and experience to achieve precise cuts, which can slow down production and increase the likelihood of errors.

This traditional approach is best suited for smaller operations or projects requiring unique specifications, but it can struggle to meet the demands of larger scale productions.

On the other hand, automated tube cutting machines offer a transformative alternative that streamlines the cutting process.

These machines not only enhance precision and reliability but also boost productivity by reducing the time spent on each cut.

With advanced programming capabilities, automated systems can handle complex designs and repeat high-volume orders with ease, ensuring uniformity across products.

As industries strive for greater efficiency, the adoption of automated solutions is gaining momentum, positioning businesses to meet market demands quickly and effectively while minimizing waste and labor costs.

Cost-Benefit Assessment of Upgrading Cutting Machines

Upgrading square tube cutting machines can offer significant cost benefits that enhance productivity in industrial settings. As businesses continuously seek to optimize their operations, investing in advanced cutting technology, such as those provided by Fortune Laser Technology Co., Ltd., can lead to measurable improvements. With state-of-the-art features designed for efficiency, these machines not only reduce material wastage but also minimize operational downtimes, allowing for smoother production flows.

Fortune Laser Technology, founded in 2016 in Shenzhen, is at the forefront of this innovation. By integrating research and development with manufacturing and maintenance services, the company ensures that its cutting machines meet the evolving needs of the industry. A cost-benefit assessment reveals that the initial investment in upgraded machines is often outweighed by the long-term savings and productivity gains. By enhancing precision and speed in square tube cutting processes, businesses can achieve higher output levels while maintaining quality, ultimately leading to increased profitability and competitiveness in the market.

Future Trends in Square Tube Cutting Machine Technology

The landscape of square tube cutting machine technology is evolving rapidly, driven by advancements in automation, precision, and efficiency. As industries strive for enhanced productivity, Fortune Laser Technology Co., Ltd. stands at the forefront, pioneering innovative solutions that cater to the growing demands of modern manufacturing. With a strong emphasis on research and development, our state-of-the-art machines not only increase cutting accuracy but also significantly reduce production time, allowing businesses to maximize output while minimizing costs.

Tip: To fully leverage the capabilities of square tube cutting machines, ensure proper training for operators. A well-trained workforce can significantly enhance machine utilization, which directly impacts productivity.

Future trends indicate a shift toward smarter technologies, including the integration of AI and IoT in manufacturing processes. These advancements offer real-time data analytics, making it easier for operators to monitor and optimize cutting operations. Fortune Laser Technology is committed to integrating these technologies into our products, ensuring our clients remain competitive in a rapidly changing market.

Tip: Regular maintenance and updates to your cutting machines are crucial. Staying updated with the latest technology will help maintain efficiency and avoid costly downtimes.

Innovative Solutions for Enhancing Productivity with Square Tube Cutting Machines

FAQS

: Manual cutting methods are cost-effective and versatile but can lead to inconsistencies in quality and require skilled labor, making them suitable for smaller operations. Automated tube cutting machines, however, enhance precision, reliability, and productivity, making them ideal for larger scale productions.

Upgrading to advanced cutting technology can lead to significant cost benefits, including reduced material wastage and minimized downtime, ultimately enhancing productivity and profitability.

Fortune Laser Technology integrates research and development with manufacturing and maintenance services to provide innovative cutting machines that meet the evolving needs of the industry, promoting efficiency and productivity.

Future trends include the integration of AI and IoT in manufacturing processes, which will provide real-time data analytics for monitoring and optimizing cutting operations.

Proper training for operators enhances machine utilization, directly impacting productivity and allowing businesses to maximize the capabilities of their cutting machines.

Regular maintenance and updates are crucial for maintaining efficiency, avoiding costly downtimes, and ensuring cutting machines operate at peak performance as technology advances.

Conclusion

In today's fast-paced manufacturing landscape, the Square Tube Cutting Machine stands out as a pivotal tool for enhancing productivity. Understanding the basics of these machines is essential, as they leverage advanced technology to improve cutting precision significantly. Innovative features integrated into modern machines enable higher throughput, while a comparative analysis of manual versus automated solutions reveals the clear advantages of investing in automation for efficiency and accuracy.

At Fortune Laser Technology Co., Ltd., we recognize the importance of cost-benefit assessments when considering upgrades to cutting machines. Our commitment to innovation ensures that we stay ahead of future trends in Square Tube Cutting Machine technology, providing unparalleled solutions that meet the evolving needs of the industry. By integrating research and development with production and maintenance services, we strive to deliver state-of-the-art equipment that maximizes productivity for our clients.

Related Posts

-

The Future of Precision Engineering with the Best Laser Cutting Device

-

5 Reasons Why Best Laser Cleaning Car Parts Are Revolutionizing Automotive Maintenance

-

Exploring the Versatile Applications of Best Industrial Laser Cutting Equipment in Aerospace and Automotive Industries

-

Ultimate Guide to Selecting the Best Laser Welders for Global Manufacturing Efficiency

-

How to Choose the Perfect Laser Cutting Machine for Your Business Needs

-

The Ultimate Guide to Choosing the Best Fiber Laser Cutting Equipment for Your Business Needs