- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

What is a Handheld Laser Welding Machine and How Does It Work?

Table of Contents

- What is a Handheld Laser Welding Machine?

- Key Components of Handheld Laser Welding Machines

- Principles of Laser Welding Technology Explained

- Advantages of Using Handheld Laser Welding Devices

- Applications of Handheld Laser Welding in Various Industries

- Safety Measures and Best Practices for Operating Laser Welders

- Future Trends and Innovations in Handheld Laser Welding Technology

- FAQS

- Conclusion

- Related Posts

In recent years, the Handheld Laser Welding Machine has transformed the welding industry. Experts like John Smith from LaserTech Innovations highlight its significance: "These machines offer precision and flexibility unmatched by traditional methods." This innovative technology allows operators to perform intricate welds with ease.

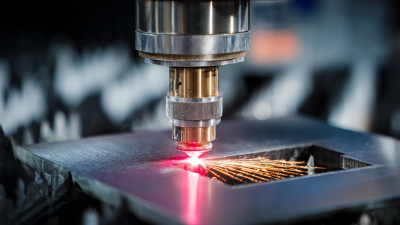

The Handheld Laser Welding Machine operates using a concentrated laser beam. This beam melts the material at the point of contact, creating a strong bond. Unlike conventional welding, it reduces heat-affected zones, which minimizes distortion. However, some users struggle with mastering the technique. The learning curve can be steep for new operators.

While the benefits are clear, challenges remain. Users sometimes encounter issues with settings and adjustments. The technology can be demanding. Keeping the equipment well-maintained is essential for optimal performance. Despite its complexities, the Handheld Laser Welding Machine is a game-changer for many industries. It's worth exploring, but patience and practice are key.

What is a Handheld Laser Welding Machine?

A handheld laser welding machine is an advanced tool used for welding tasks. It is designed for mobility and ease of use. Users can operate it with one hand, allowing them to access tight spaces easily. The machine generates a concentrated laser beam. This beam melts the materials being joined together.

These devices are popular in various industries. They are often used for metal joining, repairs, and even decorative work. The beauty of laser welding is its precision. The small heat-affected zone reduces the risk of warping and distortion. It can connect different types of metals effectively. Yet, operating this tool requires skill and practice.

Many users face challenges at first. Finding the right settings for different materials can be tricky. Safety is also a concern; proper protection is essential. Over time, users can optimize their technique and produce better results. Practice is key, and many find constant improvement necessary.

What is a Handheld Laser Welding Machine and How Does It Work?

| Feature | Description |

|---|---|

| Type | Handheld |

| Power Source | Fiber Laser |

| Welding Thickness | Up to 10 mm |

| Welding Speed | 5-15 m/min |

| Cooling System | Air Cooling |

| Applications | Automotive, Metal Fabrication, Maintenance Repair |

| Portability | High (handheld design) |

| Operator Skill Level | Moderate, training recommended |

Key Components of Handheld Laser Welding Machines

Handheld laser welding machines have transformed welding techniques in various industries. These devices are integrated with several key components that enhance their performance and effectiveness. The main components include the laser source, fiber optic cable, welding head, and cooling system. Each component plays a vital role in the welding process, ensuring precision and quality.

The laser source generates high-intensity light. This energy is transmitted through fiber optic cables, which are essential for flexibility. The welding head then focuses the laser beam onto the workpiece, melting materials together. A cooling system is crucial to prevent overheating and prolong the equipment's life.

Tip: Regular maintenance of the cooling system can enhance the machine's efficiency. This prevents overheating, which can lead to inconsistent welds.

Some reports indicate that handheld laser welding machines can increase productivity by up to 50%. However, challenges remain. Operators must be adequately trained to harness the machine's full potential. Inadequate training could result in wasted materials and unsatisfactory weld quality.

Tip: Start with basic projects to build your skills before tackling complex welds. This gradual approach can improve your confidence and results.

Principles of Laser Welding Technology Explained

Laser welding technology is gaining traction in various industries due to its efficiency and precision. This process utilizes focused laser beams to melt materials together. According to a report by MarketsandMarkets, the laser welding market is expected to grow at a CAGR of 5.3% from 2021 to 2026. The ability to produce strong welds with minimal distortion is a major advantage. It allows for delicate work on metals and other materials.

Understanding the principles behind laser welding sheds light on its advantages. The key is the highly concentrated energy from the laser, which generates a significant amount of heat. This heat quickly melts the edges of the materials being joined. When the laser moves, it solidifies the weld joint. The penetration depth can be controlled, making it versatile for various applications. However, achieving the right settings is crucial. Miscalculations in speed or power can lead to poor quality welds.

One challenge lies in the skills required to operate these machines effectively. Not all operators have the necessary expertise. Improper handling can result in incomplete welds or excessive thermal damage. Training and practice are essential to harness the full potential of handheld laser welding machines. As industries continue to adopt this technology, ongoing education will be vital to ensure optimal performance.

Advantages of Using Handheld Laser Welding Devices

Handheld laser welding machines are becoming increasingly popular in various industries. These devices offer unique advantages that traditional welding methods lack. One major benefit is their precision. A laser can create fine welds without affecting the surrounding material. This is ideal for delicate projects.

Another advantage is flexibility. Handheld machines are lightweight and portable. They allow operators to work in tight spaces and difficult angles. This feature enhances efficiency, as it eliminates the need for heavy equipment.

Tips: Always wear appropriate safety gear when using laser welding machines. Protection is essential, as even minor exposure can cause harm.

Moreover, the speed of operation is impressive. A handheld laser can significantly reduce welding time. This allows for faster project completion. Yet, it's important to ensure quality. Rushing through tasks may lead to poor welds.

The ease of setup is also noteworthy. With minimal training, operators can master the basics quickly. However, practice is necessary to achieve skillful precision. Regular maintenance of the device will ensure optimum performance too.

Applications of Handheld Laser Welding in Various Industries

Handheld laser welding machines are gaining traction in various industries. Their versatility allows for precise and efficient welding in difficult-to-reach areas. The automotive sector, in particular, benefits greatly. According to a recent industry report, laser welding can increase productivity by up to 30%. This efficiency is crucial for meeting rising demand.

In the manufacturing sector, handheld laser welding is transforming processes. The technology offers precise welds with minimal distortion. A study indicated that laser welding can reduce scrap rates by 25%. This makes operations more cost-effective and sustainable. Workers are also safer, as the laser’s focused beam minimizes the heat-affected zone.

Welding in construction is another significant application. In this field, the handheld approach allows for quick repairs and modifications on-site. While the technology is effective, it is still evolving. Some users report a learning curve, particularly with laser settings. Continued training is essential to maximize the potential of handheld machines. As industries embrace this innovative technology, future advances may streamline workflows even further.

Safety Measures and Best Practices for Operating Laser Welders

Operating a handheld laser welding machine requires careful attention to safety. The intense laser beam can cause serious injuries. Always wear appropriate protective gear, including goggles that can filter out harmful wavelengths. Gloves are also essential to protect your hands. A protective face shield is advisable to guard against accidental exposure.

Work in a properly ventilated area. Fumes generated during welding can be harmful. Make sure to check the workspace for flammable materials. Keep fire extinguishers nearby, just in case. It’s easy to overlook the surroundings when focused on the task, but a lapse in attention can lead to accidents.

Routine maintenance is critical. Regularly inspect the machine for any signs of wear. A malfunctioning unit can pose risks, even with safety gear. Training is vital as well. Improper use can lead to accidents, even for experienced operators. Always stay aware of your surroundings and potential hazards. Prioritize safety, even in seemingly routine tasks.

Future Trends and Innovations in Handheld Laser Welding Technology

The future of handheld laser welding technology is promising. Innovations are emerging rapidly. One notable trend is the integration of artificial intelligence. This technology can enhance precision and adapt to various materials. It can also predict potential issues during the welding process. Such capabilities can improve efficiency and reduce waste.

Another trend is the development of lighter, more ergonomic designs. These machines are easier to handle, reducing operator fatigue. They can also be equipped with advanced safety features. For instance, automatic shut-off systems can prevent accidents. Even with these innovations, there are challenges. The technology can be pricey, and not all industries may adopt it quickly.

Sustainability is becoming crucial in welding. Handheld laser welding machines are becoming more energy-efficient. They produce less waste and have a smaller carbon footprint. However, some operators may resist change. Training may be needed to embrace these advancements fully. Adapting to new technology always comes with hurdles, reflecting the ongoing evolution in the industry.

Handheld Laser Welding Machine: Trends in Output Power

This chart illustrates the average output power of handheld laser welding machines from 2020 to 2024, showcasing a trend towards increasing power capabilities, which enhances the efficiency and versatility of these machines in various applications.

FAQS

: Common symptoms include fever, chills, coughing, and sore throat. Fatigue and body aches are also frequent.

Wash hands regularly and avoid close contact with sick individuals. Staying hydrated helps too.

Yes, you can use home remedies like ginger tea and honey. Resting is essential for recovery.

If symptoms worsen or last more than a week, consult a healthcare professional. Pay attention to severe symptoms.

Light exercise may be okay. Listen to your body, though. Rest is often more beneficial during illness.

Chronic stress weakens the immune system. You may get sick more often due to increased vulnerability.

Not all vaccines are equally effective. They mainly protect against the most common strains each season.

Hydrate well and use over-the-counter medications. Comfort measures like warm baths can soothe discomfort.

Some people find herbal remedies helpful, but they can vary in effectiveness. Always check for possible interactions.

Colds typically last about seven to ten days. If symptoms persist, consider reevaluating your health status.

Conclusion

A Handheld Laser Welding Machine is a versatile tool that leverages advanced laser technology for precision welding tasks. It comprises key components such as the laser source, focusing lens, and control systems, which work in unison to deliver high-quality welds. The principles of laser welding technology involve focusing a laser beam to melt materials, providing strong, clean joints with minimal heat-affected zones.

The advantages of using handheld laser welding devices include increased efficiency, portability, and the ability to work on various materials. These machines find applications across multiple industries, from automotive to electronics, showcasing their adaptability. Safety measures, including protective gear and proper training, are essential when operating these devices. Looking ahead, innovations in handheld laser welding technology promise to enhance capability and ease of use, enabling even broader applications in the future.

Related Posts

-

Ultimate Guide to Selecting the Best Laser Welders for Global Manufacturing Efficiency

-

How to Choose the Right Laser Welding Machine for Your Business Needs

-

2025 Top Handheld Laser Welding Machine Features and Benefits You Must Know

-

The Future of Precision in Metal Sheet Laser Cutting Technology

-

The Future of Industrial Cleaning Exploring the Benefits of Oem Laser Cleaning Machine

-

Top Benefits of Large Format Laser Cleaning Machines for Industrial Application