- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Ultimate Guide to Choosing the Right Laser Cutting Machines for Your Business

Table of Contents

- Factors to Consider When Selecting Laser Cutting Machines for Your Business

- Types of Laser Cutting Technologies Explained: CO2 vs. Fiber vs. Solid-State

- Key Features to Look for in a Laser Cutting Machine: Power, Speed, and Versatility

- Understanding Your Material Needs: Choosing a Laser for Different Materials

- Budgeting for Your Laser Cutting Machine: Costs, ROI, and Financing Options

- Maintenance and Support: Ensuring Longevity and Efficiency of Your Investment

- FAQS

- Conclusion

- Related Posts

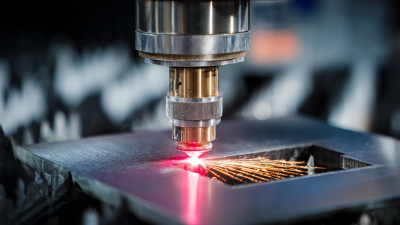

In today's rapidly evolving manufacturing landscape, the significance of Laser Cutting Machines has surged, serving as essential tools for precision and efficiency in various industries. According to a report by MarketsandMarkets, the global laser cutting machine market is expected to reach USD 5.51 billion by 2025, growing at a CAGR of 5.9% from 2020. This surge reflects the increasing demand for high-quality cutting solutions that can enhance productivity while reducing operational costs.

Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, stands at the forefront of this technological advancement as a professional manufacturer of industrial laser equipment. Our expertise in R&D, production, sales, and maintenance services enables us to offer comprehensive solutions tailored to meet the diverse needs of businesses seeking to optimize their manufacturing processes.

Exploring the right laser cutting machine can thus transform your operations, offering precision, speed, and reliability.

Factors to Consider When Selecting Laser Cutting Machines for Your Business

When selecting the right laser cutting machine for your business, several key factors must be taken into account to ensure optimal performance and efficiency. First and foremost, assess the materials you will be working with, as different machines are designed for specific materials such as metal, wood, or plastics. Understanding the thickness and type of material is crucial, as it directly impacts the required power and speed specifications of the machine.

Another vital consideration is the machine's cutting area. Depending on the scale of your projects, you may need a machine with a larger bed size to accommodate bigger workpieces. Additionally, evaluate the available technology types, such as CO2, fiber, or solid-state lasers, each offering unique advantages for precision and speed.

Lastly, consider the machine's compatibility with software and overall ease of operation, as integrating it into your workflow should be straightforward to enhance productivity and reduce downtime. By carefully weighing these factors, you can ensure that your investment meets your business's unique needs and supports its growth.

Types of Laser Cutting Technologies Explained: CO2 vs. Fiber vs. Solid-State

When selecting a laser cutting machine for your business, understanding the various technologies available is crucial. The three primary types of laser cutting technologies are CO2, fiber, and solid-state lasers, each with distinct features that cater to different industrial needs. CO2 lasers, renowned for their versatility, excel in cutting non-metal materials such as wood, acrylic, and fabric. Their longer wavelength allows for deep penetration, making them ideal for thicker materials, though they may be slower compared to other technologies.

On the other hand, fiber lasers have gained popularity for their efficiency and speed, particularly in cutting metals. With a shorter wavelength, fiber lasers can focus more energy onto the cutting surface, resulting in cleaner cuts and reduced heat-affected zones. This technology is especially beneficial for businesses focusing on high-precision metal work. Solid-state lasers, while less common, offer unique advantages in certain applications, including extremely fine cutting and engraving with outstanding reliability. Choosing the right technology depends on your specific materials, desired precision, and production volume, ensuring you invest in the solution that best fits your business's laser cutting requirements.

Key Features to Look for in a Laser Cutting Machine: Power, Speed, and Versatility

When selecting the right laser cutting machine for your business, three key features stand out: power, speed, and versatility. Power determines the material thickness that can be efficiently cut, making it crucial for industries that require high precision and depth. A machine with higher wattage not only enhances cutting capabilities but also ensures faster completion of projects, thus improving productivity.

Speed plays an equally important role, particularly in fast-paced manufacturing environments. The ability to quickly execute cuts means more work can be done in less time, allowing businesses to meet tight deadlines and increase throughput. However, speed should not compromise the quality of the cut; therefore, investing in a machine that balances both speed and precision is essential.

Versatility is the third pillar of a robust laser cutting machine. An adaptable tool can handle a variety of materials, from metals to plastics, giving businesses the flexibility to take on diverse projects. Fortune Laser Technology Co., Ltd. exemplifies this versatility with its range of industrial laser equipment designed to meet varied customer needs while providing integrated R&D, production, sales, and maintenance services. By understanding these core features, businesses can make informed decisions that align with their operational goals and expand their capabilities.

Understanding Your Material Needs: Choosing a Laser for Different Materials

When it comes to selecting the right laser cutting machine for your business, understanding the materials you will be working with is paramount. Different materials require specific laser technologies to achieve clean cuts and desired finishes. For instance, CO2 lasers are ideal for cutting non-metal materials such as wood, acrylic, and glass due to their ability to produce a high-quality beam that effectively vaporizes these materials. If your projects frequently involve materials like leather or textiles, a CO2 laser will also provide the precision and smooth edges you need for professional results.

On the other hand, if your focus is on cutting metals, fiber lasers are the way to go. They excel in processing thin to medium-thick metals like stainless steel, aluminum, and brass. The fiber laser's capability of delivering high power and a focused beam makes it perfect for intricate designs and fast cutting speeds, which can significantly enhance productivity in your workshop. Understanding these material requirements ensures that you choose a laser cutting machine that not only meets your operational needs but also maximizes efficiency and quality across diverse projects.

Budgeting for Your Laser Cutting Machine: Costs, ROI, and Financing Options

When budgeting for a laser cutting machine, understanding the costs involved and potential return on investment (ROI) is crucial for any business. According to a report by IBISWorld, the laser cutting industry has seen an annual growth rate of approximately 3.5%, indicating a robust market that can justify investment. The initial purchase price of a laser cutting machine can range from $10,000 to over $200,000, depending on the technology and capabilities you require. Additionally, the operational costs, including maintenance, energy consumption, and material expenses, must also be factored into your financial plans.

Financing options can significantly ease the burden of the upfront costs associated with acquiring a laser cutting machine. Many companies offer leasing options, allowing businesses to use the equipment without the hefty initial expenditure. According to a survey by Equipment Leasing and Finance Association (ELFA), around 80% of businesses leverage some form of finance to acquire new technology, often citing improved cash flow management as a primary benefit. Evaluating different financing methods, including loans and leasing, can help align the investment with your business cash flow and growth objectives, ultimately enhancing your bottom line.

Maintenance and Support: Ensuring Longevity and Efficiency of Your Investment

When investing in laser cutting machines, prioritizing maintenance and support is essential for ensuring longevity and efficiency. A well-maintained machine not only performs better but also provides a higher return on investment over its lifespan. Leveraging advanced technologies such as predictive maintenance can significantly enhance your operational efficiency. This approach allows businesses to foresee potential issues before they arise, enabling timely interventions that can save costs and prolong the equipment's lifespan.

Tip: Regularly monitor your machines and conduct routine checks to identify wear and tear early. Invest in an asset management system that aligns with your sustainability goals, enabling better governance and proactive maintenance strategies.

Additionally, consider building a strong support network with your equipment suppliers. They can provide ongoing assistance and access to the latest upgrades or retrofit options that enhance reliability. By establishing these partnerships, you can ensure that your laser cutting machines are equipped with cutting-edge technology, helping you to maintain their effectiveness in a competitive market.

Tip: Establish a maintenance schedule based on your machine's operational demands and follow up with the supplier for technical support as needed. This proactive approach ensures optimal performance and maximizes your investment's lifespan.

FAQS

: The three primary types of laser cutting technologies are CO2 lasers, fiber lasers, and solid-state lasers.

CO2 lasers are best suited for cutting non-metal materials such as wood, acrylic, glass, leather, and textiles.

Fiber lasers are popular for metal cutting because they are efficient and fast, making clean cuts with reduced heat-affected zones, and are particularly effective on thin to medium-thick metals like stainless steel and aluminum.

Solid-state lasers offer unique advantages in applications requiring extremely fine cutting and engraving, along with outstanding reliability.

The wavelength of a laser affects cutting performance by determining how well the laser energy penetrates the material; CO2 lasers have a longer wavelength that allows deep penetration, while fiber lasers have a shorter wavelength that focuses energy more effectively.

When choosing a laser cutting machine, consider the specific materials you will be working with, the desired precision, and your production volume to ensure the technology fits your business needs.

Conclusion

In today's competitive landscape, choosing the right laser cutting machines is crucial for any business looking to enhance productivity and efficiency. This ultimate guide outlines key factors to consider, including the type of laser technology best suited for specific applications—CO2, Fiber, or Solid-State—along with essential features such as power, speed, and versatility. It also delves into understanding material needs, ensuring that businesses can select machines tailored for various materials.

Budgeting is another critical area, where we discuss costs, return on investment, and available financing options, making it easier for companies to plan their purchases. Lastly, the guide emphasizes the importance of maintenance and support to ensure the longevity and efficiency of your investment. At Fortune Laser Technology Co., Ltd., we pride ourselves on our expertise in manufacturing laser cutting machines, offering comprehensive services that include research, production, sales, and maintenance, helping you make informed decisions for your business success.

Related Posts

-

How to Choose the Perfect Laser Cutting Machine for Your Business Needs

-

The Ultimate Guide to Choosing the Best Fiber Laser Cutting Equipment for Your Business Needs

-

Unveiling Consistent Quality in Chinese Manufacturing with Best Laser Tube Cutting Machines

-

The Future of Precision in Metal Sheet Laser Cutting Technology

-

5 Key Features to Look for in the Best Metal Laser Cutting Equipment

-

5 Essential Features of the Best Metal Tube Laser Cutting Machine You Can't Overlook