- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

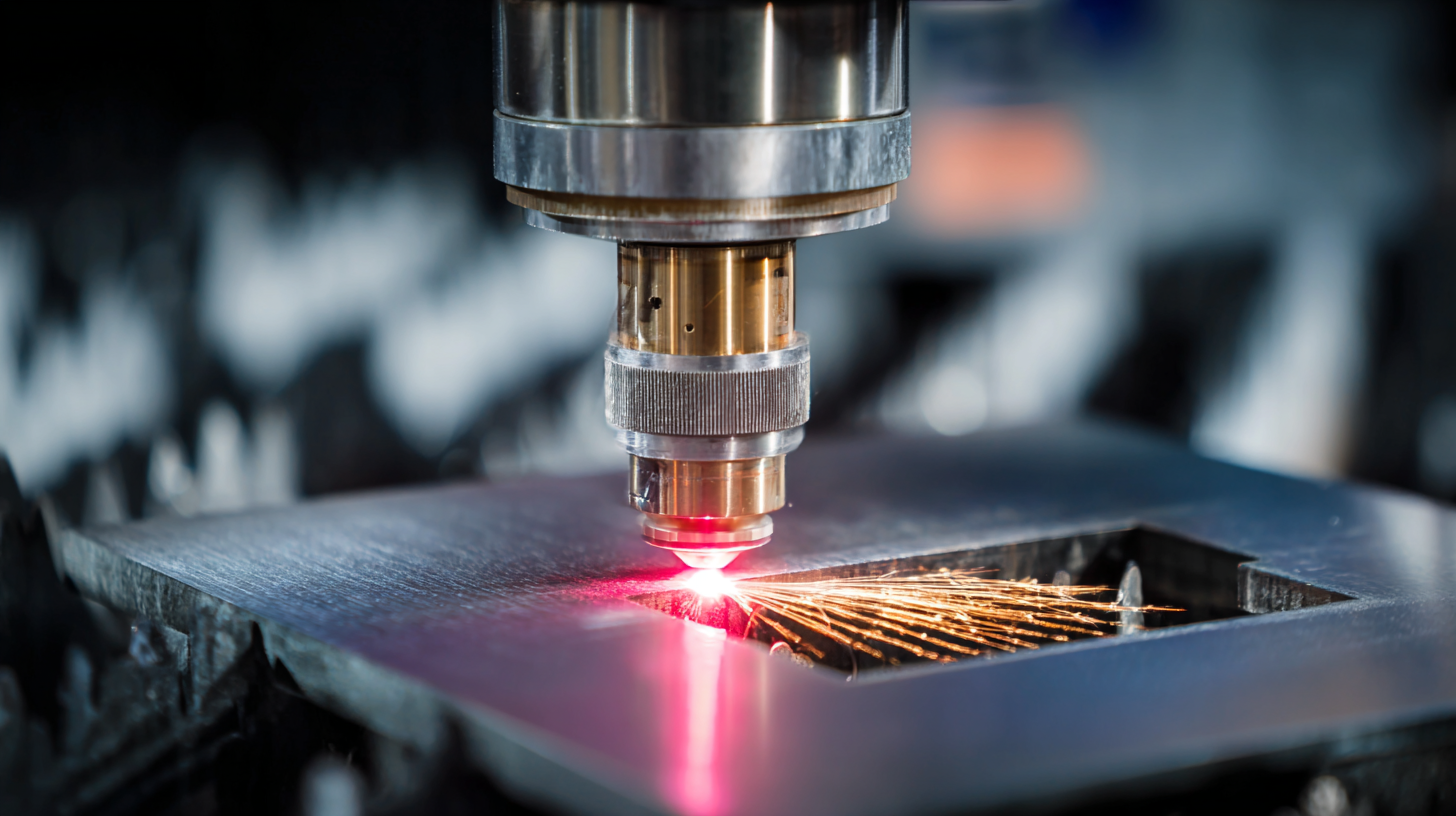

The Future of Precision in Metal Sheet Laser Cutting Technology

Table of Contents

- The Evolution of Metal Sheet Laser Cutting Technology

- Key Factors Influencing Precision in Laser Cutting

- Comparison of CO2 and Fiber Laser Technologies

- Impact of Automation on Cutting Accuracy and Efficiency

- Future Trends in Laser Cutting Techniques and Innovations

- Case Studies: Precision Cutting Applications Across Industries

- FAQS

- Conclusion

- Related Posts

In recent years, the metal processing industry has witnessed a significant transformation driven by advancements in technology, particularly in laser cutting solutions. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach USD 6.4 billion by 2025, growing at a CAGR of 5.5%. This growth is primarily fueled by the increasing demand for precision in metal sheet fabrication and the ability of Metal Sheet Laser Cutting Machines to deliver high-quality cuts with minimal material waste. Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen city, stands at the forefront of this evolution, specializing in the manufacture of industrial laser equipment. With a strong emphasis on R&D, production, and maintenance services, Fortune Laser is committed to meeting the burgeoning needs of the metal processing sector through innovative technology and unparalleled precision in laser cutting solutions.

This innovative approach by Fortune Laser has set new standards in the industry, allowing businesses to significantly enhance their production capabilities while reducing costs.

The Evolution of Metal Sheet Laser Cutting Technology

The evolution of metal sheet laser cutting technology has been marked by remarkable advancements, particularly in precision and efficiency. With the continuous development of laser sources, cutting methods have drastically improved, enabling manufacturers to create intricate designs with minimal material waste. This has positioned laser cutting as a superior alternative to traditional stamping processes, especially when fabricating thin steel components. As companies recognize the benefits of laser cutting, its role in mass production becomes increasingly significant.

When considering the latest trends in laser technology, it's crucial to focus on the importance of choosing the right equipment. Tips for optimization include investing in high-quality laser sources to achieve superior beam brilliance, which directly influences cutting precision. Additionally, understanding the specific requirements of your project can guide the selection of the appropriate cutting techniques—whether it's for complex shapes or high-speed production needs.

Moreover, staying updated on advancements in rapid prototyping technologies can enhance your product design process. Tips such as integrating laser cutting with 3D modeling can significantly streamline operations, allowing for faster iterations and more flexible design adjustments. Embracing these technological shifts not only fosters innovation but also positions businesses to better meet the evolving demands of the market.

The Future of Precision in Metal Sheet Laser Cutting Technology

This chart illustrates the evolution of laser cutting technology in terms of precision and efficiency from 2015 to 2023. The data reflects advancements in laser power, cutting speed, and precision measured in microns.

Key Factors Influencing Precision in Laser Cutting

The precision in metal sheet laser cutting technology is largely influenced by several key factors, which are essential for achieving optimal results in manufacturing processes. One of the primary factors is the laser cutting parameters, including power, speed, and focus distance. Adjusting these parameters can significantly impact the kerf width and surface quality of different metal alloys, such as titanium, steel, and aluminum. A comprehensive review of these influential elements highlights the importance of fine-tuning settings to ensure minimal thermal distortion and enhanced edge quality.

Additionally, the type of laser system used plays a crucial role in precision. Different lasers, such as fiber and CO2, provide varying capabilities in cutting through materials and achieving the desired finish. The integration of advanced technologies, including automated monitoring systems and adaptive control mechanisms, can further enhance cutting accuracy. As the metal cutting tools market continues to grow, projected to reach $113.04 billion by 2030, the evolution of laser cutting technology remains pivotal in meeting the demands of modern manufacturing, ensuring higher efficiency and precision in producing complex components.

Comparison of CO2 and Fiber Laser Technologies

The evolution of laser cutting technology has led to significant advancements in precision and efficiency, particularly in metal sheet processing. A recent industry report highlights that the global metal laser cutting market is projected to reach USD 7.2 billion by 2026, driven largely by the increasing demand for high-quality cutting in various sectors, including automotive and aerospace. Central to this advancement are two predominant laser technologies: CO2 and fiber lasers, each offering distinct benefits.

CO2 lasers have been a staple in the industry for years, known for their ability to efficiently cut thicker materials with exceptional edge quality. However, fiber lasers have emerged as a formidable contender due to their higher efficiency and lower operational costs. According to market insights, fiber lasers boast energy efficiencies exceeding 30%, compared to around 15% for CO2 lasers. This has led to a significant shift in market preference, with fiber laser technology expected to capture over 60% of the laser market by 2025. As manufacturers continue to seek improvements in speed and precision, the competition between CO2 and fiber laser technologies is set to define the future landscape of the laser cutting industry.

The Future of Precision in Metal Sheet Laser Cutting Technology - Comparison of CO2 and Fiber Laser Technologies

| Feature | CO2 Laser Technology | Fiber Laser Technology |

|---|---|---|

| Wavelength | 10.6 µm | 1.07 µm |

| Material Compatibility | Metals, Plastics, Wood | Metals (especially reflective ones) |

| Cutting Speed | Moderate | High |

| Efficiency | Lower | Higher |

| Power Consumption | High | Lower |

| Maintenance | Moderate | Low |

| Initial Cost | Lower | Higher |

| Beam Quality | Moderate | High |

Impact of Automation on Cutting Accuracy and Efficiency

The evolution of automation has significantly transformed the landscape of metal sheet laser cutting technology, substantially enhancing both cutting accuracy and efficiency. With the integration of advanced automation systems, manufacturers can now achieve unparalleled precision in their cutting processes. Automated machines reduce the likelihood of human error, allowing for consistent results that meet exact specifications. Furthermore, automation enables real-time monitoring and adjustments, ensuring that any discrepancies can be corrected instantly, thus maintaining optimal cutting performance.

For those involved in the metal sheet cutting industry, here are a few tips to leverage automation effectively. Firstly, invest in high-quality laser cutting machines equipped with the latest software that can automate various settings. This not only boosts productivity but also ensures that cuts are made with precision. Secondly, regular maintenance of automated systems is crucial; keeping machinery in top condition prevents potential downtimes and maintains efficiency. Lastly, consider implementing training programs for staff to understand and manage automated systems better, maximizing the technology's benefits.

As automation continues to advance, the future of metal sheet laser cutting looks promising. By adopting smart technologies and best practices, companies can enhance their cutting accuracy and efficiency, ultimately staying competitive in an evolving market.

Future Trends in Laser Cutting Techniques and Innovations

The future of precision in metal sheet laser cutting technology is poised for significant advancements, driven by ongoing innovations and shifting industry demands. As laser cutting techniques evolve, the market for laser cutting equipment is projected to grow substantially. Recent forecasts indicate that by 2024, the laser processing equipment market in China alone could reach approximately 89.9 billion yuan, with a steady increase in exports and a focus on domestic production.

Emerging trends point toward higher precision and automation in laser cutting applications. As manufacturers increasingly integrate smart technologies and automation systems, the demand for super-precision laser cutting machines is on the rise. Reports suggest that the super-precision laser cutting machine market could achieve substantial growth by 2033, underscoring the importance of precision in the future landscape of manufacturing. Moreover, industry experts highlight that developments in laser welding and cutting technologies are critical to enhancing efficiency and quality in production processes, aligning with the broader advancements in smart and digital manufacturing ecosystems.

Case Studies: Precision Cutting Applications Across Industries

The precision of metal sheet laser cutting technology is reshaping various industries through its ability to deliver intricate designs and flawless cuts. For instance, in the automotive sector, manufacturers are increasingly turning to laser cutting to create components with complex geometries that fit perfectly within precision-engineered vehicles. A notable case is the adoption of laser-cut chassis parts, which have not only reduced material waste but also enhanced the overall performance and durability of the vehicles.

Similarly, the aerospace industry benefits from laser cutting's unparalleled accuracy. The production of lightweight yet robust aircraft parts demands exceptional precision, and laser technology fulfills this requirement seamlessly. One case study illustrates how a leading aircraft manufacturer utilized laser cutting to produce intricate wing structures, resulting in significant weight savings without compromising structural integrity. This advancement not only lowers fuel consumption but also elevates the overall efficiency of modern aircraft, demonstrating the transformative impact of precision laser cutting across critical sectors.

FAQS

: The key factors include laser cutting parameters such as power, speed, and focus distance, as well as the type of laser system used.

Adjusting laser cutting parameters can significantly impact kerf width and surface quality, which are crucial for different metal alloys like titanium, steel, and aluminum.

Different laser types, such as fiber and CO2, have varying capabilities in cutting through materials, thus influencing the overall precision and finish.

The integration of automated monitoring systems and adaptive control mechanisms enhances cutting accuracy and helps achieve optimal results.

The metal cutting tools market is projected to reach $113.04 billion by 2030, indicating a significant growth trajectory in the industry.

Future trends include higher precision, increased automation, and the integration of smart technologies in laser cutting applications.

The laser processing equipment market in China is projected to reach approximately 89.9 billion yuan by 2024.

The demand for super-precision laser cutting machines is rising as manufacturers look for enhanced efficiency and accuracy in producing complex components.

Developments in laser welding and cutting technologies are essential for improving efficiency and quality in production processes, aligning with advancements in smart and digital manufacturing ecosystems.

Conclusion

In the rapidly evolving landscape of industrial manufacturing, the precision of Metal Sheet Laser Cutting Machines has become paramount. This blog explores the evolution of laser cutting technology, highlighting key factors that influence precision, such as beam quality and cutting speed. A comparison of CO2 and fiber laser technologies reveals significant differences in efficiency and accuracy, important for industries requiring meticulous detail.

Moreover, the impact of automation on both cutting accuracy and operational efficiency cannot be overlooked, paving the way for innovations that will shape future trends in laser cutting. Through case studies, we illustrate how various industries harness precision cutting applications to enhance productivity. As a leading manufacturer in this field, Fortune Laser Technology Co., Ltd. is dedicated to pushing the boundaries of what Metal Sheet Laser Cutting Machines can achieve, driving advancements that will define the future of manufacturing.

Related Posts

-

The Ultimate Guide to Choosing the Best Fiber Laser Cutting Equipment for Your Business Needs

-

Unveiling Consistent Quality in Chinese Manufacturing with Best Laser Tube Cutting Machines

-

5 Essential Features of the Best Metal Tube Laser Cutting Machine You Can't Overlook

-

5 Key Features to Look for in the Best Metal Laser Cutting Equipment

-

How to Choose the Perfect Laser Cutting Machine for Your Business Needs

-

Explore the Advantages of the Best Exchange Table Fiber Laser Cutting Machine: Top Industry Examples and Data Insights