- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

The Future of Industrial Cleaning with High Power Laser Technology

Table of Contents

- The Evolution of Industrial Cleaning: A Historical Perspective

- Understanding High Power Laser Technology in Cleaning Applications

- Advantages of Laser Cleaning Over Traditional Methods

- Potential Challenges and Limitations of Laser Technology in Industry

- Future Trends: Innovations in Laser Cleaning Techniques

- Real-World Applications: Case Studies in Industrial Settings

- FAQS

- Conclusion

- Related Posts

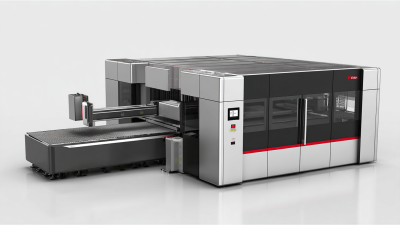

The advent of High Power Laser Cleaning Machines marks a transformative era in the industrial cleaning sector, promising unmatched efficacy and precision. As industries increasingly seek sustainable and efficient cleaning solutions, the integration of advanced laser technology opens new avenues for enhancing operational productivity while reducing environmental impact. Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen city, has been at the forefront of this innovation, specializing in the development and manufacturing of cutting-edge industrial laser equipment. With a strong focus on R&D, production, sales, and maintenance services, Fortune Laser is dedicated to providing high-quality solutions that not only meet the demands of modern industries but also pave the way for future advancements in cleaning technology. As we explore the capabilities and potential of High Power Laser Cleaning Machines, we uncover how these pioneering tools are set to reshuffle the landscape of industrial maintenance and restore cleanliness with unparalleled efficiency.

The Evolution of Industrial Cleaning: A Historical Perspective

The process of industrial cleaning has undergone significant transformations over the decades, evolving from manual labor-intensive methods to the adoption of advanced technologies. Historically, industrial cleaning methods included steam cleaning and abrasive blasting, which, while effective, posed challenges related to efficiency and safety.

According to a report by MarketsandMarkets, the global industrial cleaning market was valued at approximately $20 billion in 2020 and is expected to reach around $30 billion by 2025, illustrating the growing demand for more efficient and environmentally friendly cleaning solutions.

With the advent of high power laser technology, the landscape of industrial cleaning is poised for a revolutionary shift. Lasers offer precision and power that traditional methods cannot match, enabling the removal of contaminants without damaging the substrate. A study from Grand View Research indicates that the laser cleaning segment is expected to witness a compound annual growth rate (CAGR) of over 10% from 2021 to 2028, driven by industries such as manufacturing, automotive, and aerospace.

With the advent of high power laser technology, the landscape of industrial cleaning is poised for a revolutionary shift. Lasers offer precision and power that traditional methods cannot match, enabling the removal of contaminants without damaging the substrate. A study from Grand View Research indicates that the laser cleaning segment is expected to witness a compound annual growth rate (CAGR) of over 10% from 2021 to 2028, driven by industries such as manufacturing, automotive, and aerospace.

Tip: When considering the transition to laser cleaning solutions, companies should evaluate the return on investment based on projected savings in labor and material costs.

As industrial cleaning continues to evolve, it is essential for organizations to stay informed about technological advancements. Considering the sustainability focus in today’s industrial practices, adopting high power laser cleaning can not only enhance operational efficiency but also align with environmental goals.

Tip: Regular training on new technologies and strategies will ensure that your team is equipped to handle the latest innovations in industrial cleaning effectively.

Understanding High Power Laser Technology in Cleaning Applications

High power laser technology is transforming industrial cleaning applications, moving beyond traditional uses to address complex challenges in various sectors. Recent trends indicate that the global laser cleaning market is projected to grow significantly, with an estimated CAGR of approximately 20% through 2027. This surge is largely driven by the rising demand for sustainable and efficient cleaning solutions in industries ranging from oil and gas to manufacturing. The application of lasers in cleaning not only enhances efficiency but also minimizes the use of harmful chemicals, aligning with global sustainability goals.

Innovations such as selective laser cleaning are at the forefront of this shift. By utilizing femtosecond laser pulses, companies can achieve precise cleaning without damaging the underlying substrates. Startups focusing on this technology have proliferated, with over 680 emerging firms reporting advancements in laser methodologies; among them, notable players are developing solutions that optimize material removal and improve operational productivity. The integration of artificial intelligence and deep learning in laser cleaning processes further enhances these capabilities, allowing for real-time adjustments and better outcomes in challenging cleaning environments. As such, businesses are increasingly adopting high power laser technologies, making a substantial impact on operational efficiency and environmental stewardship.

The Future of Industrial Cleaning with High Power Laser Technology

This bar chart illustrates the increasing efficiency of industrial cleaning applications using high power laser technology from 2018 to 2023. The data shows a significant improvement in cleaning efficiency over the years, indicating a trend towards more effective and sustainable cleaning solutions in the industry.

Advantages of Laser Cleaning Over Traditional Methods

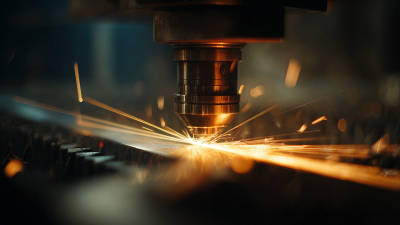

Laser cleaning technology is rapidly emerging as a transformative solution in industrial settings, offering distinct advantages over traditional cleaning methods. Unlike conventional techniques that often rely on harsh chemicals and abrasive materials, laser cleaning utilizes focused beams of light to precisely remove contaminants from surfaces. This not only enhances safety by minimizing the use of toxic substances but also increases efficiency, allowing for quicker cleaning processes with less physical strain on workers.

Recent advancements in laser technology demonstrate its versatility across various industries. For instance, in the maritime sector, lasers effectively eliminate corrosion and scale from metal surfaces without the mess associated with traditional methods. Similarly, in oilfield equipment, high-power lasers are being employed in the toughest environments, showcasing their effectiveness in resource extraction scenarios. Fortune Laser Technology Co., Ltd., established in 2016, stands at the forefront of this innovation, providing high-quality industrial laser equipment. Their commitment to research and development ensures that they remain a competitive player in the evolving landscape of industrial cleaning solutions, paving the way for broader adoption of laser technology in diverse applications.

The Future of Industrial Cleaning with High Power Laser Technology - Advantages of Laser Cleaning Over Traditional Methods

| Dimension | Laser Cleaning | Traditional Methods |

|---|---|---|

| Effectiveness | High precision and efficiency | Medium effectiveness, often requires multiple passes |

| Environmental Impact | Minimal waste and chemical use | Potential for hazardous waste and chemical runoff |

| Cost Efficiency | Lower long-term costs with reduced labor and material expenses | Higher ongoing costs for materials and disposal |

| Safety | Reduced exposure to harmful chemicals | Requires personal protective equipment (PPE) |

| Versatility | Applicable to a variety of materials and surfaces | Limited to specific types of surfaces |

| Speed | Fast cleaning process with immediate results | Slower due to multiple cleaning stages |

Potential Challenges and Limitations of Laser Technology in Industry

The integration of high-power laser technology in industrial cleaning presents exciting opportunities, yet it also brings forth several potential challenges and limitations. While lasers can provide efficient solutions for cleaning surfaces without chemical agents, issues such as high operational costs and the need for specialized training for safe operation must be addressed. Furthermore, the effectiveness of lasers can be influenced by the type of materials involved and the nature of the contaminants, making it critical to understand the specific applications and limits of this technology.

**Tips:** When incorporating laser technology for industrial cleaning, ensure a thorough assessment of the environmental impact and the type of debris to be addressed. It's essential to conduct trials on different materials to evaluate performance, as not all surfaces may respond positively to laser cleaning. Moreover, invest in comprehensive training for your workforce to maximize safety and efficiency when using these advanced systems.

Additionally, the scaling of laser technology in various industrial settings may encounter obstacles such as regulatory hurdles and initial investment requirements. As industries evolve, the challenge will be to develop standardized protocols that ensure consistency in application while addressing safety and operational efficiency. By proactively managing these aspects, businesses can harness the potential of laser technology while navigating its inherent limitations effectively.

Future Trends: Innovations in Laser Cleaning Techniques

Laser cleaning technology is rapidly revolutionizing industrial cleaning processes, ushering in a new era of efficiency and effectiveness. The advancements in high-power laser systems are paving the way for innovative techniques that not only enhance cleaning capabilities but also minimize environmental impacts. These methods utilize focused laser beams to remove contaminants from surfaces without abrasives or harsh chemicals, resulting in a cleaner and safer work environment.

As industries adopt these cutting-edge solutions, there are several trends to watch. First, the integration of artificial intelligence with laser cleaning systems is becoming more prevalent. AI algorithms can optimize cleaning paths and methods based on surface types and levels of contamination, leading to more efficient operations. Additionally, advancements in portable laser cleaning units facilitate on-site maintenance, allowing for quicker service without the need to transport parts to a dedicated cleaning facility.

Tips for businesses looking to implement laser cleaning include assessing the specific surface materials and contaminants involved to choose the right wavelength and power settings for the laser system. Regular training for operators is essential to ensure safety and maximize the benefits of the technology. Lastly, exploring rental options for laser cleaning equipment can be a cost-effective way to evaluate its potential before committing to a purchase.

Real-World Applications: Case Studies in Industrial Settings

High power laser technology is transforming the landscape of industrial cleaning, showcasing remarkable potential in various settings. A report by Research and Markets indicates that the global industrial cleaning market is projected to reach $30 billion by 2025, with advanced technologies driving innovation. One significant application of high power lasers is in the removal of tough coatings and contaminants in manufacturing facilities. For instance, a case study from a leading aerospace manufacturer revealed that using laser cleaning systems reduced the time taken for surface preparation by up to 80%, significantly increasing operational efficiency and decreasing downtime.

Another compelling example can be found in the automotive industry, where laser cleaning is utilized for precise removal of rust and paint. According to a study by the International Journal of Advanced Manufacturing Technology, laser systems can achieve cleanliness levels of 90% or more, far surpassing traditional cleaning methods. As companies strive for sustainability, high power lasers also contribute by minimizing the use of chemicals and water, aligning with environmental regulations and reducing waste. The integration of laser technology not only streamlines the cleaning process but also enhances asset longevity and product quality across various industrial applications.

FAQS

: Industrial cleaning methods have evolved from manual labor-intensive techniques like steam cleaning and abrasive blasting to advanced technologies, including high power laser cleaning.

The global industrial cleaning market was valued at approximately $20 billion in 2020 and is expected to reach around $30 billion by 2025.

High power laser cleaning offers precision and power that traditional methods cannot match, allowing for the removal of contaminants without damaging the substrate.

The laser cleaning segment is expected to witness a compound annual growth rate (CAGR) of over 10% from 2021 to 2028.

The rising demand for sustainable and efficient cleaning solutions across industries, such as manufacturing, automotive, and aerospace, is driving the growth of laser cleaning technologies.

Laser cleaning minimizes the use of toxic substances and abrasive materials, enhancing safety in industrial cleaning processes.

Selective laser cleaning utilizes femtosecond laser pulses to achieve precise cleaning without damaging underlying substrates, improving operational productivity and efficiency.

The integration of artificial intelligence and deep learning in laser cleaning processes enhances capabilities, allowing for real-time adjustments and improved outcomes in challenging environments.

Laser cleaning technology is effectively used in sectors such as maritime for corrosion removal, and oilfield equipment for tough resource extraction scenarios.

Companies should evaluate return on investment based on projected savings in labor and material costs and provide regular training on new technologies to their teams.

Conclusion

The article "The Future of Industrial Cleaning with High Power Laser Technology" explores the transformative impact of high power laser cleaning machines in industrial settings. It begins by tracing the historical evolution of industrial cleaning methods, highlighting how technological advancements have paved the way for more efficient and effective solutions. The article delves into the mechanics of high power laser technology, emphasizing its advantages over traditional cleaning methods, such as superior precision, reduced environmental impact, and cost-effectiveness.

Despite the numerous benefits, the article addresses potential challenges and limitations, including initial investment costs and the need for skilled operators. Looking ahead, it discusses emerging trends and innovations in laser cleaning techniques that continue to enhance performance and accessibility. With real-world case studies illustrating successful industrial applications, the article underscores the significant role of companies like Fortune Laser Technology Co., Ltd. in driving these advancements, showcasing their commitment to research and development in the laser equipment sector.

Related Posts

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

Unveiling the Future: How Laser Cleaning High Power Revolutionizes Industrial Maintenance

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

-

Innovative Solutions for Effective Laser Cleaning High Power Technology

-

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine