- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

5 Essential Tips for Using a Laser Rust Removal Machine Effectively

Table of Contents

- Understanding the Basics of Laser Rust Removal Technology

- Choosing the Right Laser Rust Removal Machine for Your Needs

- Preparing Surfaces for Optimal Laser Rust Removal Results

- Safety Precautions When Using a Laser Rust Removal Machine

- Tips for Maintaining Your Laser Rust Removal Equipment

- Common Mistakes to Avoid in Laser Rust Removal

- Maximizing Efficiency and Effectiveness in Rust Removal Processes

- FAQS

- Conclusion

- Related Posts

In today's fast-paced industrial environment, the Laser Rust Removal Machine stands out as a revolutionary solution for maintaining equipment and prolonging the lifespan of metal surfaces. With traditional rust removal methods often proving to be time-consuming and labor-intensive, the introduction of laser technology has transformed this process into a more efficient and effective operation. However, to harness the full potential of this advanced equipment, operators must be equipped with the right knowledge and techniques.

Understanding how to use a Laser Rust Removal Machine effectively can significantly enhance productivity and ensure optimal results. In this guide, we will explore five essential tips that are crucial for maximizing the performance of your laser rust removal equipment. By adhering to these best practices, users can not only achieve superior cleaning outcomes but also maintain the longevity of their machines, thereby ensuring a smoother and more cost-effective rust removal process. Embracing these insights will empower operators to navigate the intricacies of laser technology and elevate their operational standards.

Understanding the Basics of Laser Rust Removal Technology

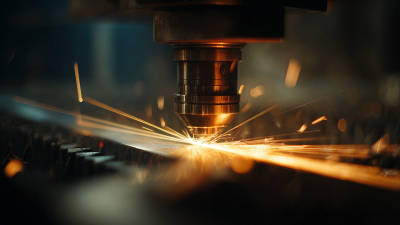

Laser rust removal technology has emerged as a revolutionary method for effectively eliminating rust and corrosion from various surfaces. This process uses concentrated beams of light to target and vaporize rust, making it a non-contact and precise solution. The technology works by delivering high-intensity laser pulses that are absorbed by the rust and rust-covered material, generating enough heat to cause rapid expansion. This expansion results in the breakdown of the rust layer without harming the underlying substrate, which is a significant advantage over traditional methods like sandblasting or chemical rust removers.

One of the key benefits of laser rust removal is its versatility. It can be used on a wide range of materials, including metals, plastics, and even some wood types, making it suitable for diverse applications. Moreover, laser technology allows for meticulous control over the removal process, enabling operators to adjust parameters such as intensity, speed, and focus to suit specific requirements. This level of control not only enhances efficiency but also minimizes the risk of damage to the workpiece. Understanding these fundamentals of laser rust removal technology equips users with the knowledge to utilize this powerful tool effectively in both industrial and DIY projects.

Choosing the Right Laser Rust Removal Machine for Your Needs

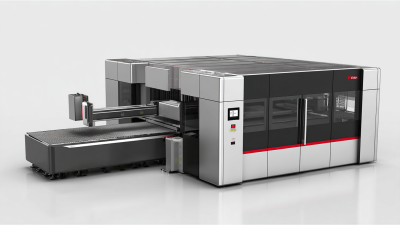

When it comes to choosing the right laser rust removal machine, understanding your specific needs is crucial. The laser technology used in rust removal varies significantly in terms of power, wavelength, and effectiveness on different materials. According to a recent industry report, machines designed with higher wattage can considerably accelerate the rust removal process, leading to increased efficiency and productivity. However, higher power also translates to a higher cost, so it’s essential to balance your budget with the intended application.

Tip 1: Assess the surface area and type of rust you will be dealing with. For extensive rust on larger surfaces, a machine with a higher beam energy is recommended, as it can cover more area in a shorter time. On the other hand, for precision work on delicate surfaces, a lower power setting might be more appropriate to avoid damage while still achieving effective results.

Tip 2: Consider the portability of the machine. If you expect to move the machine between job sites, a lighter model with built-in mobility features can be a game-changer. Industry studies show that portable machines can offer up to 30% more flexibility for on-site repairs, enhancing overall workflow.

Investing time in selecting the appropriate laser rust removal machine tailored to your specific applications will not only result in better outcomes but will also enhance your operational efficiency and save costs in the long run.

Preparing Surfaces for Optimal Laser Rust Removal Results

Preparing surfaces effectively is crucial for achieving optimal results with a laser rust removal machine. Proper surface preparation can significantly enhance the efficiency of the laser cleaning process, leading to quicker results and reduced operational costs. According to industry reports, a well-prepared surface can improve laser cleaning efficiency by up to 30%, allowing operators to complete projects faster while maintaining high-quality outcomes.

Before beginning the laser rust removal process, it’s essential to clean the surface of any loose debris, grease, or contaminants. Studies have shown that contaminants can hinder laser penetration, making the removal process less effective and extending the time required to achieve desired results. Implementing pre-cleaning methods, such as abrasive blasting or chemical cleaning, can create a smooth and uniform surface that maximizes the laser's effectiveness. This step is supported by research indicating that removing surface impurities can lead to a 20-40% improvement in rust removal efficiency.

Moreover, adjusting the distance between the laser nozzle and the surface is another critical factor in surface preparation. Optimal nozzle distance can vary based on the type of substrate and the thickness of the rust layer. Industry findings suggest that maintaining an appropriate distance not only improves laser focus but also minimizes the risk of substrate damage, ultimately resulting in a better finish and prolonging the lifespan of the machinery used. By prioritizing thorough surface preparation, operators can ensure that they are poised to leverage the full potential of their laser rust removal machines, leading to superior performance and outcomes.

5 Essential Tips for Using a Laser Rust Removal Machine Effectively

| Tip | Description | Surface Type | Recommended Power Setting | Cooling Time |

|---|---|---|---|---|

| 1. Prepare the Surface | Ensure the surface is clean and debris-free to enhance rust removal. | Steel | 80-100% | 5 mins |

| 2. Adjust Focus | Optimize the laser focus for effective rust removal depending on thickness. | Aluminum | 70-90% | 3 mins |

| 3. Test on Scrap Material | Always conduct a test on similar scrap material before main job. | Iron | 100% | 4 mins |

| 4. Use Proper Speed | Maintain an optimal speed to avoid overheating the area. | Stainless Steel | 60-80% | 6 mins |

| 5. Safety Precautions | Always wear protective gear to safeguard against laser exposure. | Metal | Variable | N/A |

Safety Precautions When Using a Laser Rust Removal Machine

When using a laser rust removal machine, safety precautions are paramount to ensure the well-being of both the operator and bystanders. First and foremost, protective eyewear is essential. The intense light emitted by the laser can cause serious eye damage, so goggles specifically designed to filter out harmful wavelengths should be worn at all times. Additionally, ensuring that the workspace is well-ventilated can help prevent the buildup of potentially hazardous fumes released during the rust removal process.

Another crucial aspect of safety is proper attire. Operators should wear long sleeves and durable gloves to protect their skin from potential burns or cuts. It's also advisable to keep flammable materials away from the work area, as lasers can ignite such substances if not handled with care. Lastly, understanding the machine's operational guidelines and undergoing thorough training can significantly reduce the risk of accidents, enabling a safer and more efficient rust removal process.

Tips for Maintaining Your Laser Rust Removal Equipment

Maintaining your laser rust removal equipment is crucial for ensuring efficiency and prolonging its lifespan. Regularly inspect the laser lens and mirror for any contaminants or damage. Dust and residue can accumulate and impact performance, so cleaning these components using appropriate solutions and tools will help maintain optimal cutting precision. Additionally, check for any potential misalignments in the system, as even slight deviations can lead to uneven rust removal and reduce productivity.

Another important aspect of maintenance involves monitoring the cooling system. Ensure that the cooling mechanisms are functioning correctly, as overheating can lead to severe damage to the machine. Routinely replace coolant liquids and clean the cooling channels to avoid blockages that could disrupt the cooling process. Finally, always refer to the manufacturer’s guidelines for servicing and maintenance schedules to keep the equipment in peak operating condition, reducing the likelihood of unexpected breakdowns.

Common Mistakes to Avoid in Laser Rust Removal

When utilizing a laser rust removal machine, avoiding common pitfalls is crucial for achieving optimal results. One significant mistake is underestimating the importance of surface preparation. According to a report by the Institute of Corrosion, proper surface conditions can enhance the effectiveness of laser treatments by up to 30%. Users often neglect cleaning the surfaces beforehand, which can lead to uneven laser application and ineffective rust removal, ultimately increasing operational costs and time inefficiencies.

Another frequent error is improper calibration of the laser equipment. Data from a survey conducted by the Laser Institute of America indicates that 20% of laser rust removal professionals do not regularly calibrate their machines, leading to inconsistent performance and subpar results. Ensuring that the laser power settings and focus are accurately adjusted according to the specific type of metal and thickness of rust is essential. This attention to detail not only enhances the cleaning efficiency but also prolongs the life of the equipment, avoiding expensive repairs or replacements. Additionally, always remember to follow the manufacturer's guidelines to prevent damaging the substrate during the removal process.

5 Essential Tips for Using a Laser Rust Removal Machine Effectively

This chart illustrates the importance rating of various essential tips for using a laser rust removal machine effectively. Ensuring proper equipment setup and employing effective cleaning techniques are critical for optimal performance.

Maximizing Efficiency and Effectiveness in Rust Removal Processes

When it comes to maximizing efficiency and effectiveness in rust removal processes, understanding the capabilities of a laser rust removal machine is paramount. First and foremost, proper surface preparation can significantly enhance the results. Ensuring that the area to be treated is free from loose debris, grease, or other contaminants helps the laser focus effectively on the rust. This preparation allows for a more uniform application and reduces the time spent on repetitive passes over the same area.

Another crucial aspect is selecting the appropriate laser settings for the specific type of rust and surface material. Adjusting parameters such as power, speed, and focus can greatly influence the removal efficiency. High power settings may be suitable for heavy rust, while lower settings can prevent damage to delicate surfaces. Furthermore, regular maintenance of the laser equipment ensures optimal performance and longevity, which contributes to a smoother and more efficient rust removal process. By incorporating these considerations into your workflow, you can achieve remarkable results and improve both productivity and effectiveness in your rust removal tasks.

FAQS

: Protective eyewear, specifically goggles designed to filter out harmful wavelengths, should be worn at all times to prevent serious eye damage.

Ensure that the workspace is well-ventilated to prevent the buildup of potentially hazardous fumes released during the rust removal process.

Operators should wear long sleeves and durable gloves to protect their skin from potential burns or cuts.

Regularly inspect the laser lens and mirror for contaminants, clean them with appropriate solutions, and check for any potential misalignments to ensure optimal performance.

Proper functioning of the cooling system prevents overheating, which can lead to severe damage to the machine, so routine checks and maintenance of the cooling system are essential.

Neglecting to clean the surfaces beforehand can lead to uneven laser application, making the rust removal process less effective and increasing costs.

Not regularly calibrating the laser equipment can lead to inconsistent performance and subpar results, so it’s crucial to adjust laser power and focus based on the specific type of metal and rust thickness.

Always refer to the equipment manufacturer’s guidelines to ensure safe and effective operation, preventing damage to the substrate.

Conclusion

The article "5 Essential Tips for Using a Laser Rust Removal Machine Effectively" provides valuable insights into the optimal use of laser rust removal technology. It begins by explaining the fundamental principles behind laser rust removal, emphasizing the importance of selecting the right machine tailored to your specific needs. Preparing surfaces adequately is highlighted as a crucial step to achieve the best results, along with essential safety precautions to ensure user protection during operations.

Furthermore, the article discusses the importance of maintaining your laser rust removal equipment to prolong its lifespan and efficiency. It also outlines common mistakes to avoid, which can hinder the rust removal process. By implementing these tips, users can significantly maximize the efficiency and effectiveness of their rust removal tasks, ensuring a cleaner and more sustainable surface restoration.

Related Posts

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine

-

The Future of Industrial Cleaning with High Power Laser Technology

-

Top 10 Benefits of Continuous Laser Cleaning Machines for Industrial Use

-

7 Key Benefits of Investing in Laser Cleaning Equipment for Your Business