- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

2025 How to Effectively Use Metal Mold Laser Cleaner for Superior Results

Table of Contents

- Understanding Metal Mold Laser Cleaning Technology: Key Benefits and Applications

- Comparative Analysis: Laser Cleaning vs. Traditional Cleaning Methods in Metal Molds

- Industry Standards: Performance Metrics for Optimal Laser Cleaning Results

- Case Studies: Successful Implementations of Laser Cleaning in Manufacturing

- Future Trends: Innovations in Laser Cleaning Technology for Metal Molds in 2025

- FAQS

- Conclusion

- Related Posts

In the competitive landscape of industrial manufacturing, the importance of maintaining mold integrity cannot be overstated. The rising demand for precision and quality in production has led to an increased focus on effective cleaning solutions. Among these, the Metal Mold Laser Cleaner has emerged as a cutting-edge technology that not only enhances the efficiency of mold cleaning processes but also significantly extends the lifespan of the molds themselves. According to a recent industry report by MarketsandMarkets, the global industrial cleaning market is projected to reach USD 14.64 billion by 2025, highlighting the growing trend towards advanced cleaning technologies.

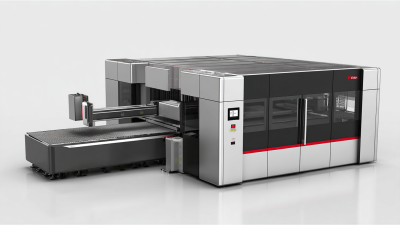

Fortune Laser Technology Co., Ltd. has positioned itself as a leader in this domain, offering state-of-the-art Metal Mold Laser Cleaners that integrate rigorous research and development with practical applications. Founded in 2016 and headquartered in Shenzhen, the company specializes in manufacturing industrial laser equipment that meets the highest standards for performance and sustainability. The Metal Mold Laser Cleaner utilizes laser technology to remove contaminants effectively without damaging the surface, thereby ensuring superior results in mold maintenance. This innovative approach aligns with the increasing industry emphasis on sustainable practices and cost-efficiency, paving the way for manufacturers to improve their operational workflows and product quality.

Understanding Metal Mold Laser Cleaning Technology: Key Benefits and Applications

Metal mold laser cleaning technology has emerged as a cutting-edge solution for enhancing the performance and longevity of manufacturing tools. This process utilizes high-intensity laser beams to remove contaminants such as rust, oil, and other residues from metal molds, paving the way for superior results in production efficiency and quality. By harnessing this technology, manufacturers can significantly reduce downtime and costs associated with traditional cleaning methods, which often involve harsh chemicals and labor-intensive procedures.

According to the Laser Cleaning Market Report, the global laser cleaning market is projected to grow from USD 0.76 billion in 2024 to an estimated USD 1.34 billion by 2035, with a compound annual growth rate (CAGR) of 5.4%. This growth is driven by increased awareness of environmental sustainability and the need for cleaner and more efficient manufacturing practices. As the industry moves toward automation and advanced techniques, metal mold laser cleaning stands out as a viable option for businesses aiming to integrate modern technologies that not only enhance the cleaning process but also contribute to broader operational efficiencies and sustainability commitments.

Comparative Analysis: Laser Cleaning vs. Traditional Cleaning Methods in Metal Molds

In the manufacturing industry, maintaining metal molds is crucial for high-quality production. A comparative analysis of laser cleaning versus traditional cleaning methods reveals significant advancements in efficiency and effectiveness. Traditional methods such as abrasive blasting or chemical solvents are time-consuming and can potentially damage mold surfaces. In contrast, laser cleaning utilizes focused light beams to remove contaminants, enhancing mold longevity and reducing downtime. According to a recent report by the International Society for Optics and Photonics, laser cleaning can be up to 50% faster than traditional methods while also reducing operational costs by approximately 30%.

**Tips:** When considering the switch to laser cleaning, choose a system with adjustable parameters to tailor the cleaning process for different mold types. Regularly maintain the laser equipment to ensure optimal performance and longevity. It's also beneficial to conduct small trials to gauge the effectiveness of laser cleaning on specific contaminants.

Furthermore, laser cleaning is environmentally friendly, generating less waste and avoiding the harmful chemicals often used in traditional cleaning methods. The precision of laser technology minimizes the risk of surface damage, ensuring that molds remain in excellent condition for longer periods. According to a study from the European Laser Institute, users report a 70% reduction in mold rejection rates after implementing laser cleaning solutions. This positions laser cleaning not only as a modern alternative but also as a critical investment for businesses aiming to enhance their production capabilities.

Industry Standards: Performance Metrics for Optimal Laser Cleaning Results

In the realm of industrial cleaning, metal mold laser cleaners are setting new benchmarks for efficiency and effectiveness. Industry standards emphasize the importance of performance metrics to achieve optimal laser cleaning results. For instance, according to a report by the International Journal of Laser Applications, lasers operating at wavelengths between 500 to 1,100 nm show a significant reduction in cleaning time by up to 30% while achieving superior surface cleanliness. Such metrics highlight the need for precise calibrations and suitable power settings to ensure high-quality results without damaging the substrate.

Moreover, consistent monitoring of performance indicators such as energy consumption and throughput can further enhance operational efficiency. The Laser Institute of America has recommended that manufacturers evaluate their systems against established standards—like ISO 9001—to maintain optimal performance. Reports indicate that organizations that adopt these performance benchmarks experience up to a 40% reduction in operational costs and an increase in productivity by 25%, illustrating the significant advantages of utilizing metal mold laser cleaners in line with industry standards.

2025 Metal Mold Laser Cleaner Performance Metrics

Case Studies: Successful Implementations of Laser Cleaning in Manufacturing

In recent years, the adoption of laser cleaning technology in manufacturing has surged, driven by its effectiveness in maintaining and restoring metal molds. A notable case study involves a leading automotive parts manufacturer that implemented a metal mold laser cleaner, resulting in a

30% reduction in cleaning time and a

50% increase in mold lifespan. According to a report by MarketsandMarkets, the global laser cleaning market is expected to reach

USD 1.2 billion by 2025, reflecting the growing recognition of the technology's efficiency and sustainability.

Another successful implementation can be seen in the aerospace sector, where a firm utilized laser cleaning to remove surface contaminants from intricate components. This not only improved adherence for subsequent coatings but also reduced the chemical waste typically associated with traditional cleaning methods by

over 70%. Research by the American Society of Mechanical Engineers (ASME) indicates that laser cleaning can enhance the surface quality by achieving up to

95% cleanliness, making it an attractive solution for industries where precision is essential. These case studies illustrate the transformative impact of laser cleaning technology in enhancing operational efficiency and sustainability in manufacturing processes.

Future Trends: Innovations in Laser Cleaning Technology for Metal Molds in 2025

As we look toward 2025, the landscape of metal mold cleaning is poised for significant advancements, particularly in laser cleaning technology. Innovations in this sector are set to enhance efficiency and effectiveness, driven by the growing demand for precise and environmentally friendly solutions in industrial processes. According to recent industry reports, the global market for laser cleaning is expected to reach $1.2 billion by 2025, reflecting an annual growth rate of 12.8%. This trend highlights the increasing recognition of laser cleaning as a superior alternative to traditional methods, particularly in the mold manufacturing industry.

At Fortune Laser Technology Co., Ltd., we are committed to staying at the forefront of these developments. Our advanced laser equipment, designed with the latest technology, integrates seamlessly with both R&D and production processes. The versatility and effectiveness of our laser cleaners not only improve the quality of metal molds but also contribute to sustainability by minimizing waste and reducing the use of harmful chemicals. As the industry evolves, we anticipate that the adoption of innovative features such as AI-driven cleaning systems and enhanced portability will redefine the standards for mold maintenance, positioning our technologies as essential tools for manufacturers aiming for superior results in 2025 and beyond.

FAQS

: Key performance metrics include cleaning time, surface cleanliness, energy consumption, and throughput, which are essential for achieving optimal results and operational efficiency in laser cleaning processes.

Lasers operating at wavelengths between 500 to 1,100 nm can reduce cleaning time by up to 30% while providing superior surface cleanliness compared to other cleaning methods.

Manufacturers should evaluate their systems against established standards such as ISO 9001 to ensure optimal performance and to maintain high-quality cleaning results.

Organizations can experience up to a 40% reduction in operational costs and a 25% increase in productivity by utilizing metal mold laser cleaners in line with industry standards.

The global market for laser cleaning is expected to reach $1.2 billion by 2025, reflecting an annual growth rate of 12.8%.

Innovations are expected to include AI-driven cleaning systems, enhanced portability, and further advancements that enhance sustainability and efficiency in metal mold cleaning.

Laser cleaners minimize waste and reduce the use of harmful chemicals, making them a more environmentally friendly alternative to traditional cleaning methods.

Advanced laser cleaning technologies provide superior efficiency, better precision, and improved surface cleanliness, making them a preferred choice in the mold manufacturing industry.

Fortune Laser Technology Co., Ltd. aims to lead the industry by continuously integrating the latest technology into their advanced laser equipment and by adapting to market trends and demands.

Real-time performance monitoring of indicators such as energy consumption and throughput enhances operational efficiency and ensures consistent high-quality cleaning results.

Conclusion

The article titled "2025 How to Effectively Use Metal Mold Laser Cleaner for Superior Results" explores the advancements and applications of Metal Mold Laser Cleaner technology. It emphasizes the key benefits of laser cleaning over traditional methods, highlighting its effectiveness in removing contaminants without damaging the metal surface. Comparative analyses reveal that laser cleaning provides superior performance metrics, which align with industry standards, ensuring optimal results for manufacturers. Through various case studies, successful implementations demonstrate the technology's efficiency and reliability in real-world settings.

Looking towards the future, the article discusses the innovations anticipated in laser cleaning technology by 2025, forecasting improvements that will further enhance the capabilities of Metal Mold Laser Cleaner. Fortune Laser Technology Co., Ltd., as a leader in this field, exemplifies the integration of R&D, production, and maintenance services to provide cutting-edge solutions for the manufacturing industry.

Related Posts

-

Discover the Benefits of Using Metal Mold Laser Cleaner in 2025 Top Technologies

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

Revolutionize Your Surface Restoration with Laser Cleaner for Efficient Rust Removal

-

Unlocking Efficiency and Precision with the Best Fiber Laser Cutting Machine Benefits to Your Business

-

Innovative Laser Cutting System Solutions Showcased at 2025 Canton Fair for Industry Advancement

-

Future of Best CNC Laser Cutters in 2025 Embracing Emerging Technologies for Increased Efficiency and Precision