- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Top 10 Benefits of Continuous Laser Cleaning Machines for Industrial Use

Table of Contents

- Advantages of Continuous Laser Cleaning Machines in Industry

- Enhanced Precision in Surface Cleaning with Laser Technology

- Reduction in Equipment Downtime through Continuous Operation

- Environmentally Friendly Cleaning Solutions in Industrial Settings

- Cost-Effectiveness of Laser Cleaning Compared to Traditional Methods

- Improvement in Worker Safety and Reduced Exposure to Harmful Chemicals

- Versatile Applications of Laser Cleaning Across Various Industries

- FAQS

- Conclusion

- Related Posts

In the rapidly evolving landscape of industrial cleaning technologies, Continuous Laser Cleaning Machines have emerged as a game-changing solution for manufacturers seeking efficiency and sustainability. According to Dr. Richard Thompson, a leading expert in laser technology and a consultant for Fortune Laser Technology Co., Ltd., "The adoption of Continuous Laser Cleaning Machines not only enhances operational efficiency but also significantly reduces environmental impact." This innovation is particularly significant considering the increasing demand for eco-friendly cleaning solutions in various industries.

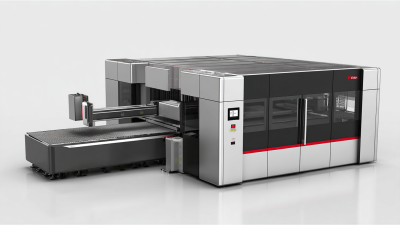

Fortune Laser Technology Co., Ltd., established in 2016 and headquartered in Shenzhen, stands at the forefront of this technological shift. As a professional manufacturer of industrial laser equipment, the company is dedicated to integrating R&D, production, sales, and maintenance services to provide cutting-edge solutions. The benefits of Continuous Laser Cleaning Machines extend from improved cleaning efficacy and reduced downtime to enhanced safety and compliance with environmental standards. As industries continue to prioritize innovation and sustainability, the role of these machines will undoubtedly become more pivotal in the quest for advanced cleaning techniques.

Advantages of Continuous Laser Cleaning Machines in Industry

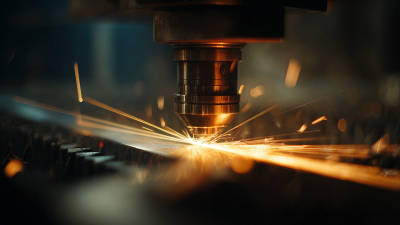

Continuous laser cleaning machines are revolutionizing industrial cleaning processes, providing numerous advantages over traditional methods. One significant benefit is their efficiency; a report from the Laser Institute of America indicates that laser cleaning can reduce cleaning time by up to 70%. This rapid cleaning capability minimizes downtime, allowing for increased productivity in various manufacturing sectors.

Moreover, continuous laser cleaning is environmentally friendly. Unlike chemical cleaning agents that release harmful substances, laser technology utilizes only light and motion, resulting in zero waste generation. A recent market analysis indicates that the global laser cleaning market is expected to grow at a CAGR of 8.5% between 2023 and 2030, fueled by industries seeking sustainable and cost-effective cleaning solutions. With their precision and adaptability, these machines can effectively remove contaminants from a variety of surfaces, including metals, plastics, and coatings, thus improving the overall quality and lifespan of equipment.

The integration of continuous laser cleaning machines aligns with the latest trends in laser technology, including advancements in laser sources and automation. Innovative startups in the field are leveraging AI and machine learning to enhance cleaning processes and ensure optimal performance. As these technologies evolve, businesses must stay informed of these trends to harness the full potential of continuous laser cleaning for their operational needs.

Enhanced Precision in Surface Cleaning with Laser Technology

Laser technology has revolutionized industrial surface cleaning, offering unmatched precision and efficiency. With the advent of continuous laser cleaning machines, industries can achieve superior results without the damage often associated with traditional cleaning methods. This advanced technology ensures that surfaces are meticulously cleaned, removing contaminants while preserving the integrity of materials. Enhanced precision allows for targeted cleaning, making it particularly effective in sectors that demand high standards, such as aerospace and manufacturing.

The recent trends in laser technology reflect an increasing interest in automation and innovation within industrial applications. Noteworthy developments, including electropulsing-enhanced laser shock techniques, demonstrate the potential of combining laser technology with other methodologies to create bio-inspired surfaces. Furthermore, the emergence of startups focused on laser solutions highlights the vibrancy of this sector. These innovations not only improve cleaning processes but also contribute significantly to operational efficiencies and sustainability in industries worldwide.

Top 10 Benefits of Continuous Laser Cleaning Machines for Industrial Use

| Benefit | Description | Impact on Industry |

|---|---|---|

| Enhanced Precision | Ability to target specific areas without damaging surrounding material. | Improved quality of finishes and reduced material waste. |

| Eco-Friendly | Utilizes no harmful chemicals, reducing environmental impact. | Aligns with sustainability initiatives in manufacturing. |

| Cost-Effective | Low operational costs compared to traditional cleaning methods. | Reduces overall maintenance and cleaning budgets. |

| Versatility | Can be used on various surfaces including metals, plastics, and composites. | Applicable across multiple industries including automotive and aerospace. |

| Increased Safety | Minimizes human exposure to toxic substances and reduces risks of accidents. | Enhances workplace safety standards. |

| Minimal Downtime | Quick setup and operation, leading to less interruption in workflows. | Boosts overall productivity in industrial processes. |

| Quality Control | Offers consistent results enhancing product reliability. | Improves customer satisfaction and product quality assurance. |

| Automated Processes | Can be easily integrated into automated systems for streamlined operations. | Enhances efficiency and throughput of cleaning tasks. |

| Long-Term Reliability | Robust technology with a long lifespan leading to fewer replacements. | Reduces long-term capital investment in maintenance equipment. |

| Reduced Labor Costs | Decreases the need for extensive manual labor during cleaning operations. | Allowing workforce reallocation to more skilled tasks. |

Reduction in Equipment Downtime through Continuous Operation

Continuous laser cleaning machines offer significant advantages for industrial applications, particularly in reducing equipment downtime. Traditional cleaning methods often require machines to be taken offline for extensive cleaning procedures, which can disrupt production schedules and lead to decreased operational efficiency. In contrast, continuous laser cleaning technology enables a seamless cleaning process while machines remain operational, minimizing interruptions and keeping workflows on track.

The advanced nature of laser cleaning allows for real-time surface maintenance without the need for manual intervention or significant downtime. As contaminants and residues are removed efficiently with precision, industries can maintain their equipment’s performance and longevity. This not only contributes to an increase in productivity but also results in substantial cost savings, as the need for frequent maintenance shutdowns is significantly reduced. The result is an enhanced operational environment where productivity and efficiency can thrive, underscoring the substantial benefits of integrating continuous laser cleaning into industrial processes.

Environmentally Friendly Cleaning Solutions in Industrial Settings

The demand for environmentally friendly cleaning solutions is growing in industrial settings, driven by a shift towards corporate social responsibility and sustainability. Continuous laser cleaning machines epitomize this trend, offering a safer alternative to traditional cleaning methods that often rely on harmful chemicals. These machines utilize advanced laser technology to remove contaminants without the need for abrasive materials or harsh solvents, minimizing their ecological footprint. With increasing awareness of environmental issues, industries are embracing such innovative solutions to align with global sustainability goals.

This shift is reflected in the expansion of markets for eco-friendly cleaning products, which are projected to significantly grow in the coming years. As companies prioritize green initiatives, adopting laser cleaning technologies can enhance operational efficiency while promoting a cleaner environment. Organizations are now more willing to invest in solutions that not only improve production processes but also contribute positively to their sustainability efforts. In this context, companies like Fortune Laser Technology Co., Ltd. play a crucial role in providing cutting-edge laser cleaning equipment, ensuring that industries adapt to and benefit from this eco-conscious transformation.

Top 10 Benefits of Continuous Laser Cleaning Machines for Industrial Use

Cost-Effectiveness of Laser Cleaning Compared to Traditional Methods

The cost-effectiveness of laser cleaning machines, particularly in industrial applications, is becoming increasingly evident as businesses seek innovative solutions to traditional cleaning methods. Traditional cleaning processes often involve the use of harsh chemicals, labor-intensive efforts, and disposable materials. In contrast, continuous laser cleaning machines offer a sustainable alternative that reduces operational costs by minimizing material waste and labor requirements. Operators can precisely target contaminants with minimal resource use, leading to significant cost savings in both labor and cleaning agents.

At Fortune Laser Technology Co., Ltd., founded in 2016 and based in Shenzhen, we pride ourselves on being at the forefront of industrial laser equipment innovation. Our continuous laser cleaning machines are not only efficient and environmentally friendly but also designed to offer long-term savings for industrial users. The initial investment in laser technology is outweighed by the benefits of reduced maintenance costs, enhanced productivity, and lower ecological impact, making it a smart choice for businesses looking to modernize their cleaning processes while maintaining a keen eye on their budget.

Improvement in Worker Safety and Reduced Exposure to Harmful Chemicals

Continuous laser cleaning machines offer a significant enhancement in worker safety by minimizing exposure to harmful chemicals traditionally used in industrial cleaning processes. Unlike chemical-based cleaners that can pose health risks such as respiratory issues and skin irritations, laser cleaning uses focused light to remove contaminants, dust, and rust without hazardous substances. This not only creates a healthier work environment but also streamlines cleaning procedures, allowing workers to focus on their core tasks without the worry of chemical exposure.

Tips for maintaining a safe workspace with laser cleaning machines include conducting regular training for your team on their proper use and safety protocols. It’s also essential to monitor the cleanliness of the equipment to ensure optimal performance and safety. Additionally, creating a designated area for laser cleaning can help in managing workflow and reducing risks associated with accidental exposure or mishandling.

Furthermore, the minimization of hazardous waste contributes to environmental safety. As laser cleaning generates no residual chemicals, it results in less pollution and waste disposal hassle. Implementing these machines not only advances worker safety but also demonstrates a commitment to sustainable industrial practices. Regular assessments of your facility's air quality and worker feedback can further enhance safety measures around cleaning operations.

Versatile Applications of Laser Cleaning Across Various Industries

The versatility of laser cleaning machines has made them an essential asset across various industries, contributing significantly to operational efficiency and sustainability. According to market reports, the global laser cleaning market is projected to reach $3.6 billion by 2024 and expand to $5.15 billion by 2033, reflecting a compound annual growth rate of 4%. This growth is driven by the increasing adoption of laser technology in sectors such as manufacturing, automotive, and aerospace, where precision and productivity are paramount.

Moreover, in China, the laser equipment market is expected to achieve sales revenue of 91 billion yuan in 2024, marking substantial growth since 2019. Key segments, including laser cutting and cleaning technologies, are becoming increasingly vital to the production processes, enabling manufacturers to meet rigorous quality standards while enhancing their competitive edge. The continuous innovation in laser cleaning technology not only streamlines maintenance tasks but also reduces waste and environmental impact, showcasing its indispensable role in the advancement of precision manufacturing.

FAQS

: Continuous laser cleaning machines offer efficiency, reducing cleaning time by up to 70%, which minimizes downtime and enhances productivity. They are also environmentally friendly, generating zero waste and avoiding harmful substances.

Continuous laser cleaning allows for seamless cleaning while machines remain operational, significantly reducing equipment downtime compared to traditional methods that require machines to be offline.

These machines can effectively remove contaminants from a variety of surfaces, including metals, plastics, and coatings.

The global laser cleaning market is expected to grow at a compound annual growth rate (CAGR) of 8.5% between 2023 and 2030, as industries seek sustainable and cost-effective cleaning solutions.

The real-time maintenance capability allows for efficient cleaning without manual intervention, which enhances productivity, maintains equipment performance, and results in substantial cost savings.

Yes, there are advancements in laser sources and automation, with innovative startups leveraging AI and machine learning to enhance cleaning processes and ensure optimal performance.

By minimizing interruptions and keeping workflows on track, continuous laser cleaning contributes to an enhanced operational environment, allowing productivity and efficiency to thrive.

Various manufacturing sectors can benefit from adopting continuous laser cleaning due to its efficiency and ability to improve equipment quality and lifespan.

Staying informed allows businesses to harness the full potential of continuous laser cleaning and adapt to advancements to improve their operational needs consistently.

Continuous laser cleaning machines utilize only light and motion, resulting in zero waste generation and no harmful emissions, making them a sustainable cleaning solution.

Conclusion

The "Top 10 Benefits of Continuous Laser Cleaning Machines for Industrial Use" highlights the significant advantages that these advanced technologies bring to industrial cleaning processes. Continuous Laser Cleaning Machines offer enhanced precision in surface cleaning, minimizing damage to the underlying materials. Furthermore, they enable reduced equipment downtime, as their continuous operation ensures consistent productivity. These machines also promote environmentally friendly practices by eliminating harmful chemicals, thereby improving worker safety. Cost-effectiveness is another crucial benefit, as laser cleaning often proves more economical than traditional methods over time.

In addition to these advantages, Continuous Laser Cleaning Machines showcase versatile applications across diverse industries, making them a valuable asset for modern manufacturing and maintenance operations. As a professional manufacturer founded in 2016, Fortune Laser Technology Co., Ltd. is dedicated to providing high-quality laser equipment that meets the needs of various industrial users while emphasizing innovation and sustainability.

Related Posts

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

Revolutionize Your Industrial Cleanliness: The Future of Pulse Laser Cleaning Machines

-

The Future of Industrial Cleaning with High Power Laser Technology

-

The Future of Industrial Cleaning Exploring the Benefits of Oem Laser Cleaning Machine

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency