- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

How to Choose the Best Large Format Laser Cleaning Machine?

Table of Contents

- Understanding Large Format Laser Cleaning Machines

- Key Features to Consider in Laser Cleaning Technology

- Different Types of Laser Cleaning Processes Explained

- Evaluating the Efficiency and Speed of Laser Machines

- Assessing Cost vs. Benefit in Laser Cleaning Equipment

- Importance of Manufacturer Reputation and Support

- Maintenance and Safety Considerations for Laser Machines

- FAQS

- Conclusion

- Related Posts

In recent years, the demand for effective surface preparation has surged. According to a report by Smithers Pira, the global laser cleaning market is expected to reach $2.3 billion by 2026. This growth highlights the need for advanced technology like Large Format Laser Cleaning Machines. Businesses seek reliable solutions for diverse applications, from industrial cleaning to restoration.

Choosing the right Large Format Laser Cleaning Machine is crucial. Consider factors such as power, size, and versatility. A machine that is too small may not meet production needs, while one that lacks flexibility might limit operational efficiency. Precision in cleaning is vital, especially in industries like aerospace and automotive, where surface integrity is paramount.

Investing in a quality laser cleaning system could streamline operations. However, finding the ideal match for specific requirements often proves challenging. Users must reflect on their unique needs, considering both short-term costs and long-term benefits. Inadequate research could lead to poor decisions. Therefore, approaching this choice thoughtfully is essential for success.

Understanding Large Format Laser Cleaning Machines

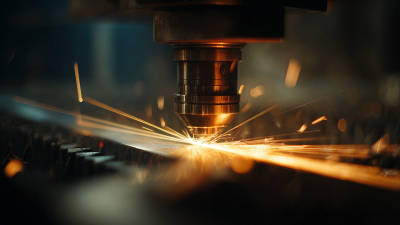

Large format laser cleaning machines have gained popularity due to their effectiveness. They use high-powered lasers to remove contaminants from various surfaces. According to a recent industry report, the global laser cleaning market is expected to grow by over 12% annually. This growth indicates a rising demand for laser cleaning technologies in sectors such as manufacturing and restoration.

Understanding these machines is crucial for making an informed decision. They can handle large surfaces efficiently, which is a significant advantage. However, selecting the right machine requires careful consideration of several factors. The laser's wavelength, power, and cleaning speed play vital roles in performance. It's essential to analyze the material type you plan to clean. Some lasers are better suited for metals, while others excel in handling delicate surfaces.

Not all machines are perfect. Some might lack efficiency or require frequent maintenance. Evaluating user reviews and performance data can provide insights into these shortcomings. It's also wise to consider the machine's operational cost. An initial low price may lead to higher operating expenses in the long run. Being aware of these factors helps buyers make well-rounded decisions.

Key Features to Consider in Laser Cleaning Technology

When selecting a large format laser cleaning machine, key features are crucial. Power output is vital for efficiency. A machine with adjustable settings allows you to handle various surfaces, from delicate materials to robust metals. The laser wavelength influences cleaning effectiveness. Ensure it matches the types of contaminants you often encounter.

The cleaning speed is another factor. Faster machines can save time, but may require more monitoring. An ideal model balances speed with precision. Dust and debris management systems are essential too. They protect the laser lens and maintain optimal performance. Consider the machine's ease of use as well. An intuitive interface minimizes training time and reduces operator errors.

Maintenance requirements should not be overlooked. A machine that is easy to service tends to have longer life expectancy. Regular checks are necessary, but overly complex machines can lead to frustration. It's worth weighing costs against features carefully. Ultimately, reflect on what suits your specific needs best.

Different Types of Laser Cleaning Processes Explained

Laser cleaning has become popular for various industries. It utilizes focused laser beams to remove contaminants. This technology can be applied in different ways.

One common method is oxide layer removal. This process is effective for rust or paint on metals. Another technique involves surface preparation. It ensures components are clean before coating or welding. Each method has its strengths and weaknesses.

Some users may find that the laser's intensity needs adjustment. Improper settings can lead to incomplete cleaning. Additionally, not all materials respond well to laser cleaning. Some have a risk of damage. It's essential to consider the specific requirements. Testing is crucial before full implementation.

Evaluating the Efficiency and Speed of Laser Machines

When evaluating the efficiency and speed of large format laser cleaning machines, consider several key factors. Speed is often the most noticeable feature. Machines vary widely in how fast they can process materials. Some models can clean large areas quickly, while others may require more time for detailed work. It's essential to align cleaning speed with your specific tasks.

Efficiency plays a crucial role too. A laser cleaning machine should not only work fast but also effectively. This means producing consistent results without damaging the underlying surfaces. Look for machines that can easily adjust power levels for different materials. However, be cautious; extremely high speeds might lead to errors or inconsistencies.

User feedback often highlights the need for a learning curve. Some operators may struggle with setup initially, affecting overall efficiency. Regular maintenance is also vital to keep machines running at peak performance. It's important to find a balance between speed and effectiveness. This could require trial and error before settling on a machine that meets your needs.

Assessing Cost vs. Benefit in Laser Cleaning Equipment

When assessing the cost versus benefit of large format laser cleaning machines, it’s essential to analyze both operational efficiency and long-term savings. A recent industry report indicates that laser cleaning can reduce labor costs by up to 30%. This is significant, especially for industries where manual cleaning is labor-intensive and time-consuming. The upfront investment might seem high, but the return on investment (ROI) can be realized within a few short months.

Consider the energy consumption of laser cleaning versus traditional methods. Many reports highlight that laser systems can operate at 70% less energy than conventional cleaning methods. This lower energy requirement not only saves money but also reduces the environmental impact. However, not every operation may benefit equally. Some environments may require specialized setups that could drive costs higher than expected.

Additionally, maintenance for laser cleaning machines may sometimes bring unforeseen expenses. Routine checks and replacements might be necessary, impacting the budget. It is crucial to weigh these potential costs against productivity gains. A careful assessment reveals that despite high initial costs, the long-term advantages can be substantial. Being aware of these factors is vital before making a purchase decision.

Cost vs. Benefit Analysis of Large Format Laser Cleaning Machines

Importance of Manufacturer Reputation and Support

Choosing the right large format laser cleaning machine is crucial. One important aspect is the reputation of the manufacturer. A good manufacturer should not only provide reliable machines but also offer excellent customer support. This can make a significant difference when you're facing issues or need maintenance.

Tips: Research customer reviews and testimonials. They provide insight into the manufacturer's reliability. Look for feedback on how quickly and effectively they resolve problems.

A strong manufacturer support system is vital. When your machine breaks down, you want prompt assistance. Delays can lead to project setbacks and increased costs. Connect with other users in forums or online groups, and ask about their support experiences.

Tips: Consider the availability of spare parts. This is often overlooked. Long wait times for parts can halt productivity. If a manufacturer has a good reputation, chances are their spare parts will also be easy to source. Evaluate all options carefully before making your final decision.

Maintenance and Safety Considerations for Laser Machines

When operating a large format laser cleaning machine, maintenance is crucial. Regular checks on lenses and mirrors are essential to ensure optimum performance. Clean components help avoid any distortion in the cleaning process. Ignoring this can lead to subpar results. Filters should also be examined frequently. A clogged filter can reduce the efficiency of the machine.

Safety is paramount. Always use protective eyewear when operating a laser machine. This is often overlooked, leading to potential eye damage. Proper ventilation must be ensured to avoid harmful fumes. Training operators is necessary. They should understand emergency protocols. Inadequate training can lead to accidents or equipment damage. Keeping an organized workspace is essential. A cluttered area increases the risk of accidents.

Regular maintenance and safety reviews can prevent disasters. Remember, staying safe is as important as being effective.

FAQS

: Regular practice is essential for skill enhancement. Set specific goals and track your progress over time.

Aim to get feedback after completing a project. Too much feedback can be overwhelming, so find a balance.

Some skills can be learned quickly, but mastery takes time. Focus on consistent, incremental improvements instead.

Mistakes are a natural part of learning. Embrace them and reflect on how to improve for next time.

Taking a break can help clear your mind. Return with a fresh perspective and revisit your goals.

Online resources are valuable but must be used wisely. Evaluate the credibility of sources to ensure quality learning.

Conclusion

When selecting a Large Format Laser Cleaning Machine, it’s crucial to understand the basics of their operation and the variety of processes available. Key features such as power, speed, and efficiency should be critically evaluated to ensure they meet specific cleaning requirements. Different types of laser cleaning methods, from surface preparation to rust removal, can greatly influence the choice based on the intended application.

Additionally, a thorough assessment of the cost versus the benefits of the equipment is essential. A reputable manufacturer often provides better support and ensures reliable machine performance. Maintenance and safety are also paramount; regular upkeep and adherence to safety protocols can significantly impact the longevity and effectiveness of the laser cleaning machine. Overall, careful consideration of these factors will lead to an informed decision and optimal cleaning results.

Related Posts

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

The Future of Industrial Cleaning with High Power Laser Technology

-

Top 5 Benefits of Using Cw Laser Cleaning Machine for Efficient Surface Cleaning

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

-

Innovative Solutions for Effective Laser Cleaning High Power Technology

-

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine