- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

How to Choose the Best Cw Laser Cleaning Machine for Maximum Efficiency and Precision in Industrial Applications

Table of Contents

- Factors to Consider for Selecting the Ideal Cw Laser Cleaning Machine in Industrial Settings

- Efficiency Metrics: Analyzing Cleanliness Levels Achieved by Different Laser Cleaning Technologies

- Precision Requirements: How Wavelength and Power Settings Impact Industrial Laser Cleaning Results

- Evaluating Return on Investment: Cost-Benefit Analysis of Cw Laser Cleaning Machines

- Comparative Analysis: Performance Benchmarks for Leading Cw Laser Cleaning Brands and Models

- User Training and Safety Standards: Ensuring Effective and Safe Operation of Laser Cleaning Equipment

- FAQS

- Conclusion

- Related Posts

In the rapidly evolving landscape of industrial applications, the choice of an effective cleaning solution can significantly impact operational efficiency and precision. The Cw Laser Cleaning Machine stands at the forefront of this technological revolution, offering unparalleled effectiveness in removing contaminants from various surfaces. According to Dr. John Smith, a leading expert in laser cleaning technology, "The Cw Laser Cleaning Machine not only enhances cleaning efficiency but also ensures a level of precision that traditional methods cannot achieve."

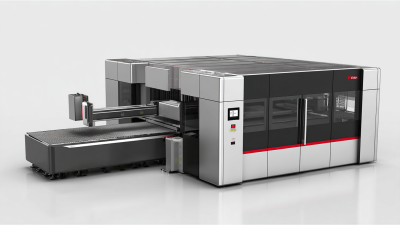

At Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, we are dedicated to providing top-tier industrial laser equipment that encompasses research and development, production, sales, and maintenance services. Our commitment to innovation in laser technology has positioned us as a key player in the industry, enabling us to deliver solutions that meet the stringent demands of our clients. As industries increasingly recognize the advantages of using Cw Laser Cleaning Machines, understanding how to select the best model becomes essential for maximizing efficiency and precision in their operations.

Factors to Consider for Selecting the Ideal Cw Laser Cleaning Machine in Industrial Settings

When selecting the ideal continuous wave (Cw) laser cleaning machine for industrial applications, several critical factors need to be considered to optimize efficiency and precision. First, assess the power and wavelength of the machine, as these parameters influence the interaction with various materials. Higher power can effectively remove tougher contaminants, but may also require careful calibration to avoid damaging sensitive surfaces.

In addition to power and wavelength, consider the machine's cooling system and portability. A robust cooling system allows for prolonged operation without overheating, enhancing productivity in demanding environments. Portability can also be key, especially in industries where equipment needs to be moved frequently for different cleaning tasks.

Tips: Before making a purchase, conduct a thorough analysis of your specific cleaning requirements and the materials being treated. It's beneficial to consult with manufacturers about customizable settings to optimize the laser's capabilities. Additionally, review user feedback or case studies regarding the efficiency of specific models in similar applications, ensuring that you invest in a machine that meets your unique operational needs.

Efficiency Metrics: Analyzing Cleanliness Levels Achieved by Different Laser Cleaning Technologies

When evaluating the efficiency of different laser cleaning technologies, it’s crucial to understand the specific cleanliness levels they achieve in industrial applications. According to a recent market research report by Mordor Intelligence, industrial laser cleaning equipment can remove contaminants such as rust, paint, and oil with remarkable precision, often achieving cleanliness levels as high as 95% or more. Cw (continuous wave) laser cleaning machines, in particular, are noted for their ability to handle larger surface areas quickly and effectively, making them a preferred choice in environments where productivity is key.

Additionally, studies conducted by Laser Institute of America have highlighted the importance of pulse frequency and laser power in determining cleaning efficiency. For instance, systems operating at higher frequencies (up to 30 kHz) can clean surfaces faster and achieve better results, particularly on complex geometries. This technological advancement leads to lower operational costs and minimal environmental impact, aligning with current sustainability goals in manufacturing. Understanding these metrics is essential for industries looking to optimize their cleaning processes while ensuring maximum precision and safety.

Precision Requirements: How Wavelength and Power Settings Impact Industrial Laser Cleaning Results

When selecting a CW laser cleaning machine for industrial applications, understanding the precision requirements—including how wavelength and power settings impact outcomes—can significantly enhance efficiency. According to recent industry reports, wavelengths in the range of 1064 nm, typical for fiber lasers, are particularly effective for removing rust and other contaminants from metal surfaces. This wavelength interacts favorably with ferrous materials, promoting absorption while minimizing thermal damage, which is critical in applications where substrate integrity is paramount.

Power settings also play a crucial role in achieving optimal cleaning results. Studies show that operating at higher power levels, around 1000 W, can increase the cleaning speed significantly—up to 30 m² per hour—while maintaining precision. However, managing power settings is vital to prevent substrate damage, especially with delicate materials. A balanced approach that considers both the wavelength and power settings can lead to better surface finishes and lower operational costs, enhancing overall productivity in industrial settings. Such insights are invaluable to manufacturers aiming to adopt laser cleaning technologies effectively.

Evaluating Return on Investment: Cost-Benefit Analysis of Cw Laser Cleaning Machines

When considering the implementation of Continuous Wave (Cw) laser cleaning machines in industrial applications, a comprehensive cost-benefit analysis is crucial. The initial investment in Cw laser technology may be significant, but the long-term savings associated with reduced labor costs, lower maintenance needs, and increased cleaning efficiency can offer substantial returns. This technique not only extends the lifespan of machinery by preventing corrosion and buildup but also ensures a safer, cleaner working environment, which can positively impact overall productivity.

Tips for evaluating the return on investment include comparing the operational costs of traditional cleaning methods versus Cw laser systems. Analyze the time saved during cleaning processes, as this can lead to more efficient use of workforce and resources. Additionally, consider the potential reduction in material waste, as laser cleaning minimizes the need for harmful chemicals and abrasive materials. Conducting a thorough assessment of these factors will clarify the value proposition of adopting Cw laser technology for your industrial setup.

Comparative Analysis: Performance Benchmarks for Leading Cw Laser Cleaning Brands and Models

When selecting the best continuous wave (CW) laser cleaning machine for industrial applications, it’s essential to conduct a comparative analysis of performance benchmarks across leading brands and models. This scrutiny allows businesses to identify machines that not only meet their operational needs but also offer superior efficiency and precision. Understanding the strengths and weaknesses of various models helps in making an informed decision, ensuring that your investment translates into enhanced productivity and cost-effectiveness.

Tips for choosing a CW laser cleaning machine include first evaluating the specific cleaning tasks at hand. Different models come with varied power outputs and capabilities suited for specific materials and contaminants. Additionally, consider the machine's ease of use and maintenance, as user-friendly designs can significantly reduce downtime. Lastly, always look for manufacturers that provide robust support services, like Fortune Laser Technology Co., Ltd., which combines R&D with maintenance services to ensure ongoing performance and reliability of their industrial laser equipment.

In your comparison, key factors such as beam quality, cleaning speed, and portability should be prioritized. Scrutinizing the technical specifications and real-world performance reviews will illuminate which laser cleaning machines excel in terms of efficiency and precision, setting the foundation for a well-informed purchase that aligns with industrial cleaning requirements.

Performance Comparison of Cw Laser Cleaning Machines

This chart illustrates the cleaning efficiency and precision benchmarks of various cw laser cleaning machines in industrial applications. The data reflects parameters such as Power (W), Cleaning Speed (m/min), and Weight (kg) for optimal selection.

User Training and Safety Standards: Ensuring Effective and Safe Operation of Laser Cleaning Equipment

When selecting a Cw laser cleaning machine for industrial applications, it is critical to prioritize user training and adherence to safety standards. Effective laser cleaning not only requires the right equipment for efficiency and precision but also a well-trained operator. According to industry reports, approximately 30% of accidents in industrial settings are related to inadequate training. Therefore, providing comprehensive training programs for operators can significantly reduce risks.

Tips for ensuring effective training include incorporating hands-on practice sessions that simulate real operational scenarios and establishing clear guidelines for emergency procedures. Additionally, using visual aids, such as diagrams and instructional videos, can enhance understanding and retention of safety protocols.

Moreover, adhering to established safety standards is vital for maintaining a secure working environment. Regular audits and compliance checks should be conducted to ensure that machines meet safety regulations. The Occupational Safety and Health Administration (OSHA) states that proper equipment handling practices can prevent up to 60% of workplace injuries related to machinery. Developing a culture of safety and continuous improvement in training programs can greatly enhance the overall effectiveness of laser cleaning operations while safeguarding personnel.

How to Choose the Best Cw Laser Cleaning Machine for Maximum Efficiency and Precision in Industrial Applications - User Training and Safety Standards: Ensuring Effective and Safe Operation of Laser Cleaning Equipment

| Feature | Description | Importance | Safety Standards |

|---|---|---|---|

| Power Output | Determines the cleaning speed and effectiveness. | High | Ensure compliance with local regulations. |

| Wavelength | Affects material types and cleaning efficiency. | Medium | Follow safety guidelines for specific wavelengths. |

| Portability | Ease of moving the machine between locations. | Low | Ensure machine stability during operation. |

| User Interface | Influences setup speed and ease of operation. | High | Follow operational protocols and user training. |

| Maintenance Requirements | Frequency and complexity of machine upkeep. | Medium | Comply with manufacturer maintenance schedules. |

FAQS

: Industrial laser cleaning equipment can often achieve cleanliness levels as high as 95% or more by removing contaminants such as rust, paint, and oil with remarkable precision.

CW laser cleaning machines are noted for their ability to handle larger surface areas quickly and effectively, making them a preferred choice in productivity-focused environments.

Systems operating at higher pulse frequencies (up to 30 kHz) can clean surfaces faster and achieve better results, particularly on complex geometries, leading to lower operational costs.

Wavelengths in the range of 1064 nm, typical for fiber lasers, are particularly effective for removing rust and contaminants from metal surfaces due to their favorable interaction with ferrous materials.

Operating at higher power levels, around 1000 W, can significantly increase cleaning speed—up to 30 m² per hour—while maintaining precision, but careful management is essential to prevent substrate damage.

When selecting a CW laser cleaning machine, consider the specific cleaning tasks, power outputs, ease of use, maintenance requirements, and look for robust support services from manufacturers.

Conducting a comparative analysis allows businesses to identify machines that meet their operational needs and offer superior efficiency and precision, ensuring informed investment decisions.

Key factors to prioritize include beam quality, cleaning speed, portability, technical specifications, and real-world performance reviews to determine which machines excel in efficiency and precision.

Conclusion

Selecting the right Cw Laser Cleaning Machine is crucial for maximizing efficiency and precision in industrial applications. Key considerations include evaluating efficiency metrics to determine the cleanliness levels achieved by various laser technologies, understanding how wavelength and power settings affect cleaning precision, and conducting a thorough cost-benefit analysis to assess return on investment.

Furthermore, it’s essential to benchmark the performance of leading brands and models within the industry. User training and adherence to safety standards are vital for ensuring not only effective operation but also the safety of personnel involved in the cleaning processes. As a trusted manufacturer since 2016, Fortune Laser Technology Co., Ltd. is committed to providing high-quality Cw Laser Cleaning Machines tailored to meet these critical industrial requirements.

Related Posts

-

The Future of Industrial Cleaning Exploring the Benefits of Oem Laser Cleaning Machine

-

Revolutionizing Surface Restoration with High Power Laser Cleaning Technology

-

Revolutionizing Surface Restoration: Benefits of the Portable Laser Cleaning Machine

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine