- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

How to Choose the Right Fully Enclosed Fiber Laser Cutter for Your Business Needs

Table of Contents

- Understanding the Different Types of Fully Enclosed Fiber Laser Cutters

- Key Specifications to Consider When Selecting a Fiber Laser Cutter

- Assessing Your Business Needs and Production Requirements

- Cost Analysis: Budgeting for a Fully Enclosed Fiber Laser Cutter

- Evaluating the Space and Safety Requirements for Installation

- Maintenance and Support: Ensuring Longevity of Your Laser Cutter

- FAQS

- Related Posts

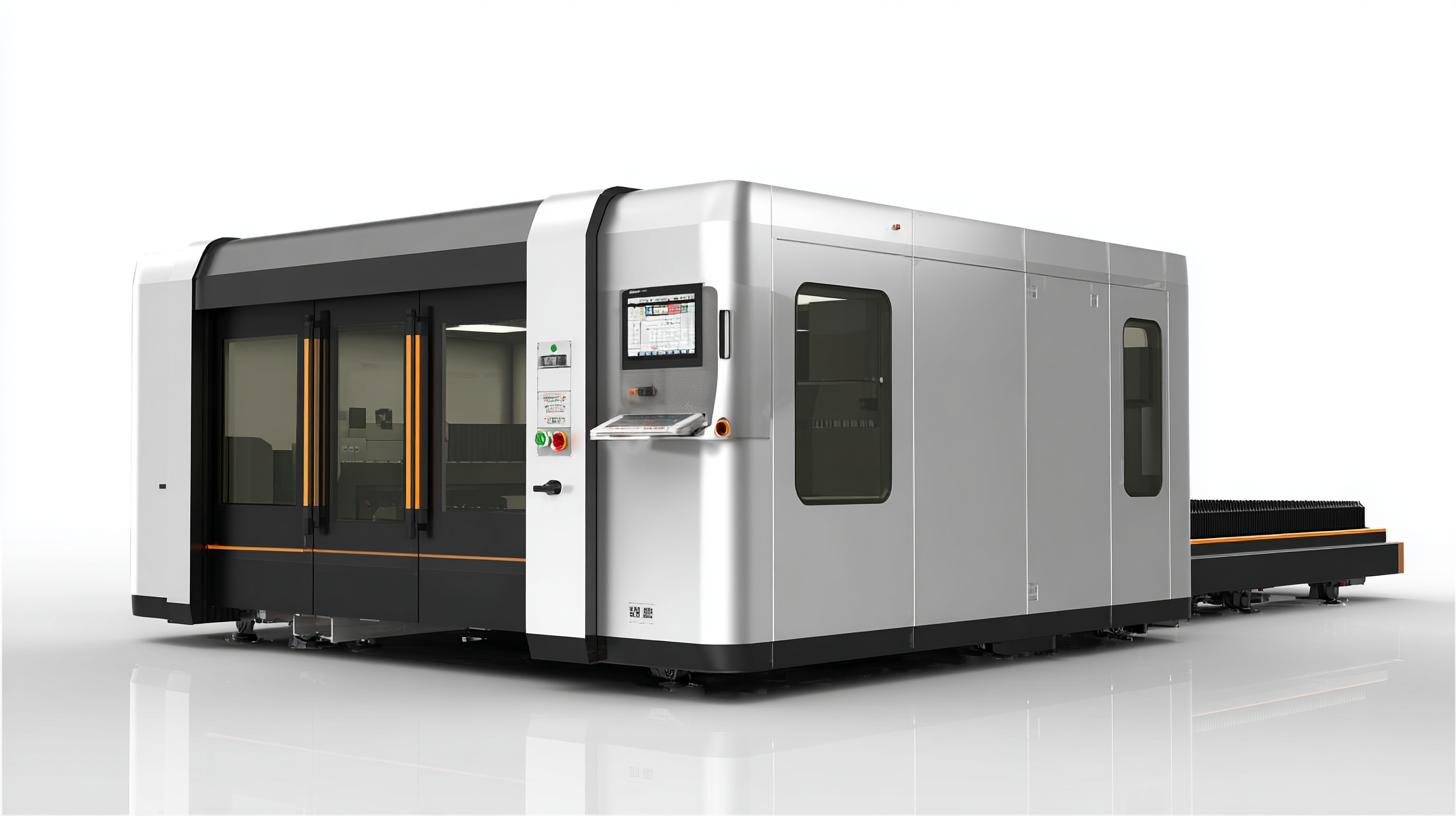

As the manufacturing landscape continues to evolve, businesses are increasingly turning to advanced technologies to enhance their production capabilities. Among these, the Fully Enclosed Fiber Laser Cutter has gained significant traction due to its precision and efficiency. According to a recent report by Mordor Intelligence, the global fiber laser market is expected to grow at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026, driven by the increasing demand for high-performance cutting solutions in various industries. Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen, stands at the forefront of this innovation, offering cutting-edge fiber laser equipment that integrates R&D, production, sales, and comprehensive maintenance services. In this blog, we will explore how to choose the right Fully Enclosed Fiber Laser Cutter tailored to your business needs, ensuring optimal production efficiency and cost-effectiveness.

Understanding the Different Types of Fully Enclosed Fiber Laser Cutters

When selecting the right fully enclosed fiber laser cutter for your business needs, it’s essential to understand the different types available on the market. Fully enclosed fiber laser cutters come in various configurations, each designed to address specific operational requirements. For instance, some models focus on high-speed cutting, making them ideal for businesses that need to process large volumes of materials quickly and efficiently. These machines often feature advanced cooling systems and enhanced optics to maintain cutting quality at elevated speeds.

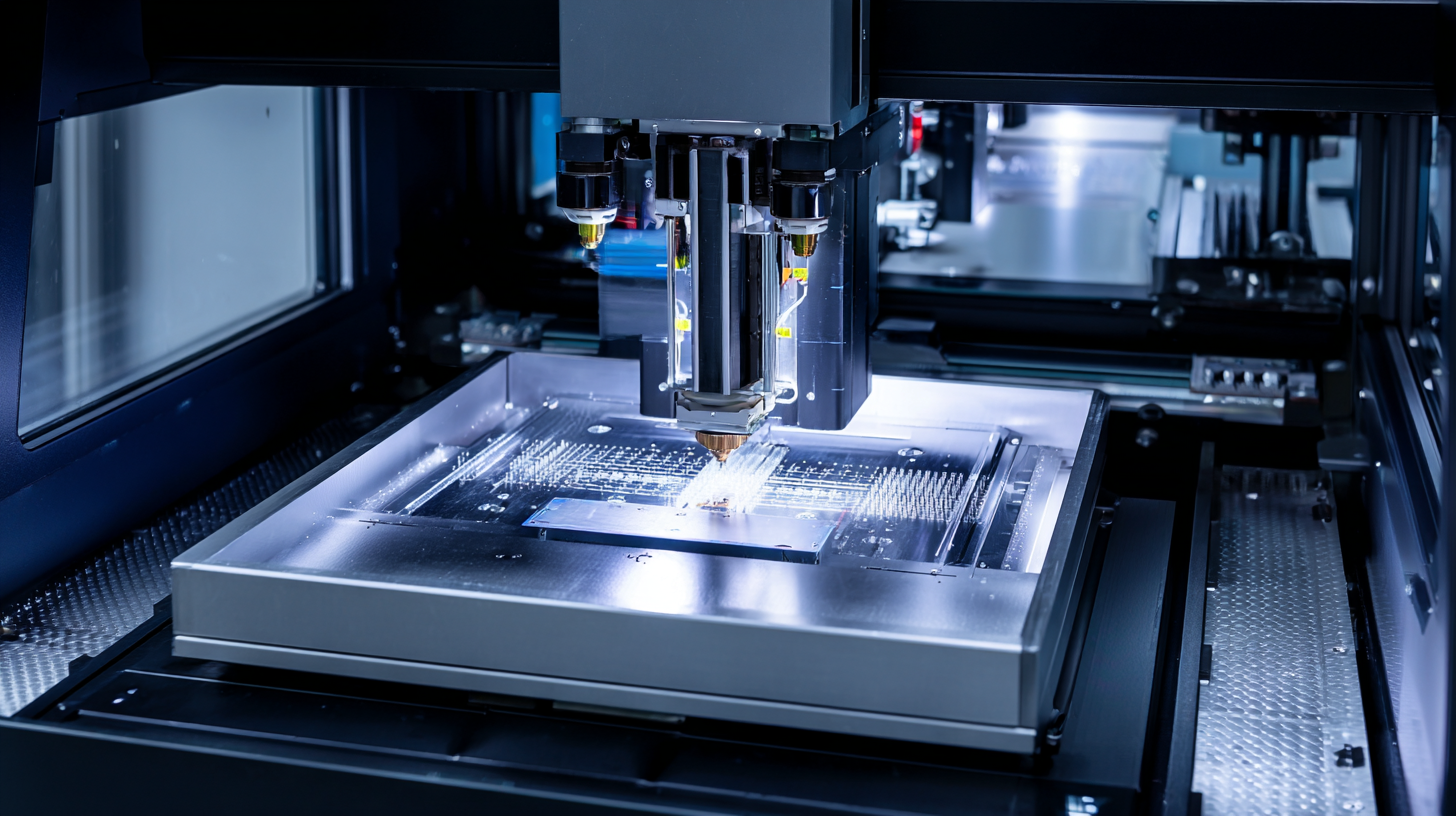

On the other hand, there are laser cutters designed for intricate designs and precision cutting. These machines are equipped with superior software and automation capabilities, allowing for detailed work on a wide array of materials, such as metal, wood, and acrylic. When choosing between these types, consider factors such as the thickness of the materials you typically work with, the level of detail required in your projects, and your production volume. Understanding these distinctions will help you make an informed decision that aligns with your business's operational demands and goals.

Key Specifications to Consider When Selecting a Fiber Laser Cutter

When selecting a fully enclosed fiber laser cutter, there are several key specifications to consider that directly impact your business's operational efficiency and productivity. Firstly, the laser power is crucial; higher wattage, typically ranging from 100W to 2000W, enables faster cutting speeds and the ability to process thicker materials. According to a report by MarketsandMarkets, the global fiber laser market is expected to reach USD 5.94 billion by 2025, underscoring the increasing reliance on these advanced systems for high-precision cutting tasks.

Another significant specification is the cutting speed and precision. Modern fiber laser cutters can achieve cutting speeds up to 60 meters per minute with an accuracy of ±0.05mm. This level of precision is essential for industries like automotive and aerospace, where tolerances are critical. Additionally, consider features such as automated material handling and integrated software compatibility, which can streamline your workflow and reduce operational costs. The versatility of fiber laser technology in cutting various materials, including metals, plastics, and ceramics, further emphasizes the need to analyze your specific business requirements before making a selection.

How to Choose the Right Fully Enclosed Fiber Laser Cutter for Your Business Needs

| Specification | Description | Importance |

|---|---|---|

| Laser Power | Ranges from 500W to 4000W, affecting cutting speed and material thickness. | Crucial for determining the cutter's capability on different materials. |

| Cutting Area | Available sizes typically range from 1300x2500mm to 1500x3000mm. | Important for accommodating large materials and production needs. |

| Speed | Cutting speeds may vary between 10 m/min to 100 m/min based on material type. | Directly impacts productivity and efficiency. |

| Material Compatibility | Can cut metals, plastics, and even wood, depending on the model. | Determines versatility of the laser cutter for various applications. |

| Cooling System | Includes water or air cooling systems to maintain optimal performance. | Essential for sustaining operation under heavy use. |

| Safety Features | Enclosed design, interlocks, and emergency stop functions. | Vital for ensuring operator safety and compliance with regulations. |

| Ease of Use | User-friendly interface and software for design input. | Crucial for reducing training time and increasing operator efficiency. |

| Maintenance Support | Availability of technical support and spare parts. | Important for minimizing downtime and ensuring longevity of the equipment. |

Assessing Your Business Needs and Production Requirements

When selecting the right fully enclosed fiber laser cutter for your business, it's crucial to assess your specific production requirements. Consider the materials you plan to work with, such as metal or plastics, and the thickness of these materials, as different laser cutters are designed for varying capacities. Furthermore, evaluate the precision and speed needed for your operations. For instance, industries that demand high accuracy and fast production cycles, such as electronics or automotive, will require a more advanced machine compared to businesses focused on basic engraving or cutting tasks.

At Fortune Laser Technology Co., Ltd., we understand that each business has unique needs. Since our establishment in 2016, we have provided tailored solutions to meet the diverse demands of our clients. Our fully enclosed fiber laser cutters are engineered with safety, efficiency, and effectiveness in mind, ensuring that they not only meet standard production needs but can also adapt as your business evolves. By investing in the right technology today, you can enhance your production capabilities and drive growth in the long run.

Cost Analysis: Budgeting for a Fully Enclosed Fiber Laser Cutter

When considering the purchase of a fully enclosed fiber laser cutter, a crucial aspect to evaluate is the cost analysis. According to a report by Markets and Markets, the fiber laser market is projected to grow from $1.99 billion in 2020 to $5.68 billion by 2025, highlighting the increasing demand for these efficient cutting solutions. This growth reflects a trend towards investing in machinery that can enhance productivity while ensuring safety and compliance within a work environment. It is essential for businesses to establish a comprehensive budget that not only covers the initial acquisition cost, which can range from $50,000 to over $200,000 depending on the machine's specifications, but also includes operational expenses such as maintenance and consumables.

Additionally, businesses must factor in the potential return on investment (ROI). A study by the Laser Institute of America found that fiber lasers can offer up to a 30% reduction in operational costs when compared to traditional cutting methods. This is due to their higher cutting speeds and lower energy consumption. By analyzing the machine's efficiency and the overall impact on manufacturing processes, companies can make informed financial decisions that align with their operational goals. Investing in technology that bridges the gap between cost and efficiency can significantly facilitate business growth in the competitive manufacturing landscape.

Evaluating the Space and Safety Requirements for Installation

When considering the installation of a fully enclosed fiber laser cutter for your business, it's essential to evaluate the space and safety requirements meticulously. According to a report by MarketsandMarkets, the global fiber laser market is expected to grow from $2.5 billion in 2020 to $5.3 billion by 2025, reflecting the increasing demand for high-precision cutting solutions across various industries. As businesses invest in these advanced technologies, understanding the spatial needs becomes crucial. Typically, a fiber laser cutter requires a dedicated workspace that accommodates not only the machine itself but also necessary utilities, such as ventilation systems and material loading areas. A general guideline is to allocate at least 100 square feet of space for smaller models, while larger cutters may need upwards of 300 square feet.

Safety is another paramount consideration when setting up your laser cutter. The Occupational Safety and Health Administration (OSHA) highlights that laser equipment can pose serious risks if not properly managed, including exposure to hazardous emissions and potential fire risks. Ensuring that the installation area complies with safety regulations involves integrating appropriate safety features, like controlled access points and adequate emergency shut-off systems. The integration of robust safety measures can mitigate risks effectively, thereby fostering a safer working environment while enhancing operational efficiency. Considering both space and safety meticulously will not only align with regulatory standards but will also ensure that your investment in laser cutting technology yields optimal productivity.

Maintenance and Support: Ensuring Longevity of Your Laser Cutter

When selecting a fully enclosed fiber laser cutter for your business, considering maintenance and support is crucial to ensure its longevity. Regular maintenance not only prolongs the life of your equipment but also optimizes performance. Implementing a routine maintenance schedule will help identify potential issues before they escalate, saving you time and money in the long run.

When selecting a fully enclosed fiber laser cutter for your business, considering maintenance and support is crucial to ensure its longevity. Regular maintenance not only prolongs the life of your equipment but also optimizes performance. Implementing a routine maintenance schedule will help identify potential issues before they escalate, saving you time and money in the long run.

Tip 1: Create a maintenance checklist that includes tasks such as cleaning optics, checking alignment, and inspecting the cooling system. Performing these checks routinely can prevent common problems that might arise during operation.

Moreover, having reliable technical support from the manufacturer is invaluable. Ensure that the supplier offers comprehensive customer service and readily accessible support resources. This means not only having skilled technicians available for on-site repairs but also providing remote support for troubleshooting.

Tip 2: Before finalizing your purchase, inquire about the warranty options and any service plans available. Understanding these aspects can give you peace of mind and ensure that help is always just a call away when needed.

FAQS

: You should assess your specific production requirements, including the materials you will work with (metal or plastics), their thickness, and the precision and speed needed for your operations.

Industries that demand high accuracy and fast production cycles, such as electronics or automotive, typically require more advanced laser cutters compared to businesses focused on basic engraving or cutting tasks.

Investing in the right technology can enhance your production capabilities and drive growth in the long run by adapting to your business’s evolving needs.

The initial acquisition cost for a fully enclosed fiber laser cutter can range from $50,000 to over $200,000, depending on the machine's specifications.

In addition to the initial purchase price, you should also factor in maintenance costs and consumables as part of your overall budget.

The fiber laser market is projected to grow from $1.99 billion in 2020 to $5.68 billion by 2025, indicating increasing demand for these cutting solutions.

Fiber lasers can provide up to a 30% reduction in operational costs due to their higher cutting speeds and lower energy consumption compared to traditional methods.

A comprehensive cost analysis helps businesses make informed financial decisions by evaluating both the acquisition costs and the potential return on investment from efficiency and productivity improvements.

Related Posts

-

Exploring the Cutting Edge Alternatives to the Best Fiber Optic Laser Cutting Machine

-

How to Choose the Perfect Laser Cutting Machine for Your Business Needs

-

How to Choose the Best Mini Laser Cutting Machine for 2025 Industry Trends

-

Craftsmanship Meets Technology: Explore the Finest Mini Laser Cutting Machines from China

-

Explore the Advantages of the Best Exchange Table Fiber Laser Cutting Machine: Top Industry Examples and Data Insights

-

Ultimate Guide to Selecting the Best Laser Welders for Global Manufacturing Efficiency