- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Understanding Challenges with Affordable Fiber Laser Cutter Reliability

Table of Contents

- Identifying Common Reliability Issues in Affordable Fiber Laser Cutters

- Technical Factors Impacting Fiber Laser Cutter Performance

- Maintenance Practices to Enhance Laser Cutter Longevity

- Cost-Effective Solutions for Common Laser Cutting Challenges

- User Training for Improved Fiber Laser Cutter Reliability

- Innovative Technologies to Improve Affordable Laser Cutter Performance

- FAQS

- Conclusion

- Related Posts

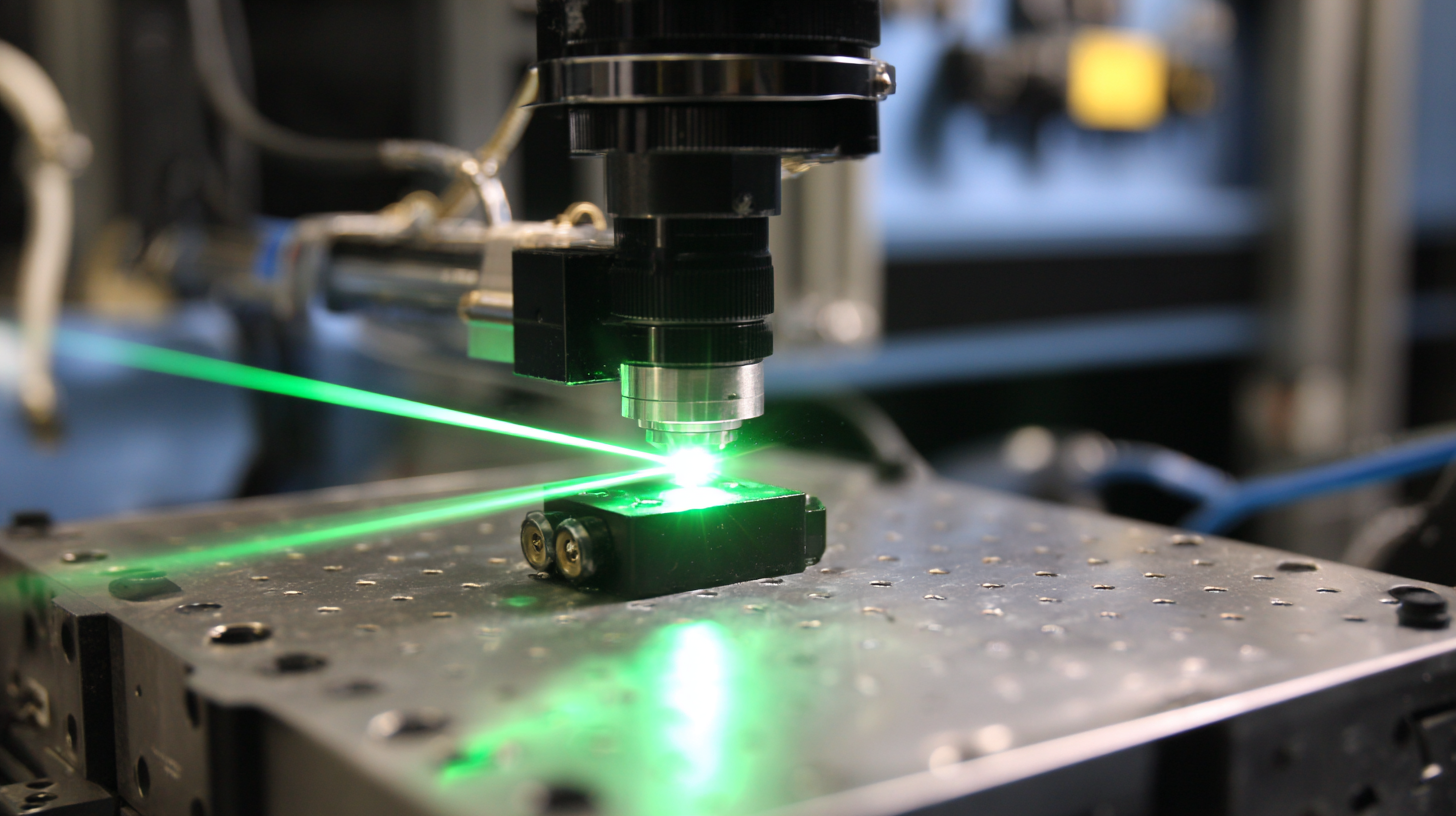

The demand for Affordable Fiber Laser Cutter technology has surged in recent years, driven by the need for precision and efficiency across various industrial applications. According to a report by MarketsandMarkets, the fiber laser market is projected to reach $3.5 billion by 2025, highlighting its significance in sectors such as automotive, aerospace, and electronics.

However, while affordability is an attractive characteristic, the reliability of these cutters remains a significant challenge. In industries that require consistent quality and uptime, issues such as maintenance frequency, operational lifespan, and service response times can dramatically impact production efficiency. Founded in 2016, Fortune Laser Technology Co., Ltd. understands these challenges intimately, as a professional manufacturer of industrial laser equipment based in Shenzhen. By integrating research and development with production and maintenance services, Fortune Laser Technology aims to address reliability concerns and enhance the performance of Affordable Fiber Laser Cutters in demanding environments.

Identifying Common Reliability Issues in Affordable Fiber Laser Cutters

When it comes to affordable fiber laser cutters, reliability often becomes a key concern for businesses looking to maximize efficiency without breaking the bank. A recent report from the Laser Institute of America highlighted that nearly

30% of users experienced frequent downtime with low-cost models, primarily due to inadequate cooling systems and subpar components. These reliability issues can lead to costly interruptions, as the average production lost per hour of downtime can exceed

$10,000 for medium-sized manufacturing operations.

Additionally, the longevity of affordable fiber laser cutters is often compromised by the lack of advanced technologies found in higher-end models. According to a study by the International Society for Manufacturing Engineers, nearly

25% of affordable fiber lasers fail to maintain their cutting quality over time. This degradation can be attributed to inferior optical components and laser diodes, which tend to have shorter operational lifespans. Consequently, businesses that opt for these budget-friendly options may find themselves investing more in

maintenance and repairs than they initially anticipated, impacting their overall profitability.

Technical Factors Impacting Fiber Laser Cutter Performance

When exploring the technical factors that impact fiber laser cutter performance, several critical elements come into play. The reliability of these machines is often influenced by their design and the quality of components used.

According to a report by the International Society of Laser Applications, over 70% of fiber laser cutter failures stem from inadequate thermal management. Effective cooling systems are essential to prevent overheating, which can lead to component degradation and ultimately affect performance.

Another significant factor is the operational environment. A study published by Laser Focus World indicates that dust and moisture can compromise the longevity of fiber laser systems. In fact, environments with high levels of particulate matter can reduce laser optics efficiency by up to 40%, leading to inconsistent cutting quality and increased maintenance costs.

Furthermore, manufacturers also need to consider the importance of using high-quality optical fibers, as low-grade materials can result in a staggering 30% reduction in service life and cutting precision, ultimately affecting the reliability and affordability of the machines.

Maintenance Practices to Enhance Laser Cutter Longevity

When it comes to enhancing the longevity of affordable fiber laser cutters, maintenance practices play a critical role. According to a report by MarketsandMarkets, the global market for laser cutting systems is projected to reach $5.59 billion by 2025, highlighting the increasing reliance on these technologies in various industries.

To ensure that these systems operate at peak performance, regular maintenance routines must be established. This includes routine inspections of optics, check-ups on cooling systems, and alignment adjustments, which collectively ensure that the fiber laser's efficiency remains intact.

Moreover, preventative maintenance can significantly mitigate the risks of unexpected failures. The Laser Institute of America's guidelines suggest that scheduled maintenance can reduce downtime by up to 30%, leading to increased productivity and reduced operating costs. By investing in training for operators to recognize early signs of wear and tear, companies can further enhance the lifespan of their laser cutters. Emphasizing the importance of well-maintained equipment, these practices not only extend the operational life of the machines but also optimize their performance, providing a solid return on investment in the long term.

Cost-Effective Solutions for Common Laser Cutting Challenges

Affordable fiber laser cutters have revolutionized the manufacturing landscape by making high-precision cutting accessible to various industries. However, challenges such as inconsistent performance, maintenance issues, and operational downtime can hinder their reliability. Understanding these challenges is crucial for businesses looking to maximize their investment in laser cutting technology. Key solutions include regular maintenance protocols, utilizing high-quality components, and integrating advanced monitoring systems to preemptively address potential issues.

At Fortune Laser Technology Co., Ltd., we recognize that reliability in laser cutting systems is paramount for productivity. Established in 2016, our experience in R&D and manufacturing allows us to offer cost-effective solutions tailored to common laser cutting challenges. For instance, we focus on improving the durability of our laser heads and optimizing power management to enhance the overall efficiency of our machines. By investing in innovations that prioritize reliability, we aim to empower our clients to achieve exceptional results while minimizing operational costs.

User Training for Improved Fiber Laser Cutter Reliability

User training plays a critical role in enhancing the reliability of fiber laser cutters. Many common issues arise not from the machines themselves but from a lack of understanding of their operation and maintenance. Therefore, investing time in comprehensive training programs can significantly reduce downtime and improve output quality. It’s essential for operators to familiarize themselves not only with the technical aspects of the cutter but also with best practices for its use.

**Tip**: Conduct regular workshops to keep your team updated on the latest techniques and troubleshooting procedures. This approach ensures that all operators are on the same page and can efficiently tackle any problems that arise.

Moreover, practical hands-on training is important. Encouraging operators to engage in practical sessions where they can learn to troubleshoot minor issues can greatly enhance their confidence and skills. This proactive approach can lead to better performance and prolonged machine lifespan.

**Tip**: Create a mentorship system where experienced operators can guide new ones in understanding the nuances of the fiber laser cutter. This knowledge transfer can foster a culture of continuous learning and adaptability within your team.

Challenges with Affordable Fiber Laser Cutter Reliability

This chart illustrates the common challenges faced with affordable fiber laser cutter reliability based on user training feedback.

Innovative Technologies to Improve Affordable Laser Cutter Performance

The push for affordable fiber laser cutters has revolutionized the manufacturing industry, but challenges remain regarding their reliability and performance. Innovative technologies are emerging to address these issues, enhancing the durability and efficiency of budget-friendly laser solutions. According to a report by MarketsandMarkets, the global laser cutting machine market is expected to grow from $3.6 billion in 2020 to $6.8 billion by 2025, underscoring the increasing demand for cutting-edge yet affordable options.

To improve the reliability of these machines, manufacturers are integrating advanced cooling systems and diagnostic software that monitor performance in real-time. Such innovations not only extend the lifespan of laser cutters but also minimize downtime caused by unexpected failures.

Tip: Regular maintenance checks can significantly enhance your fiber laser cutter's performance. Ensure that lenses and mirrors are clean and free from dust, as this can result in improved cutting quality and efficiency.

Moreover, advancements in materials used for laser components are playing a crucial role in elevating performance. For instance, the introduction of robust, high-heat-resistant lenses significantly reduces wear and tear under high-intensity operations.

Tip: Invest in training for operators to better understand the capabilities and limitations of your machine, which can lead to more optimized cutting processes and reduced operational errors.

FAQS

: The key factors include the design and quality of components, effective thermal management to prevent overheating, and the operational environment, such as dust and moisture levels that can compromise system longevity.

Inadequate thermal management can cause overheating, resulting in component degradation, which affects the overall performance and reliability of the fiber laser cutter.

Environments with high particulate matter, dust, and moisture can reduce the efficiency of laser optics by up to 40%, leading to inconsistent cutting quality and increased maintenance costs.

High-quality optical fibers are essential, as low-grade materials can lead to a 30% reduction in service life and cutting precision, adversely affecting the machine’s reliability and affordability.

Regular maintenance practices include routine inspections of optics, check-ups on cooling systems, and alignment adjustments, all of which help maintain peak performance.

Scheduled maintenance can reduce downtime by up to 30%, which increases productivity and lowers operating costs by mitigating unexpected failures.

Operators should be trained to recognize early signs of wear and tear, enabling them to take preventative measures before significant issues arise.

The global market for laser cutting systems is projected to reach $5.59 billion by 2025, indicating an increasing reliance on these technologies across various industries.

Well-maintained fiber laser cutters not only extend operational life but also optimize performance, providing a solid return on investment in the long run.

Conclusion

In the blog "Understanding Challenges with Affordable Fiber Laser Cutter Reliability," we explore the various reliability issues that users encounter with affordable fiber laser cutters. Key topics include identifying common reliability problems, understanding the technical factors that affect performance, and implementing maintenance practices that can significantly enhance the longevity of these machines. We also discuss cost-effective solutions to address prevalent cutting challenges and emphasize the importance of user training in improving operational reliability.

Moreover, the blog highlights innovative technologies that can boost the performance of affordable fiber laser cutters, ensuring they meet the demands of modern industrial applications. As a leading manufacturer in the laser equipment industry, Fortune Laser Technology Co., Ltd. is dedicated to providing comprehensive support, encompassing R&D, production, and maintenance services, to help users maximize the reliability and efficiency of their laser cutting operations.

Related Posts

-

Exploring the Versatile Applications of Best Industrial Laser Cutting Equipment in Aerospace and Automotive Industries

-

Trust in Global Manufacturing Excellence Discover the Best Industrial Laser Cutting Machines from China's Leading Factory

-

Future of Best CNC Laser Cutters in 2025 Embracing Emerging Technologies for Increased Efficiency and Precision

-

Unlocking Efficiency and Precision with the Best Fiber Laser Cutting Machine Benefits to Your Business

-

What is the Best CNC Laser Machine? A Comprehensive Overview with Industry Insights and Data

-

How to Choose the Best Mini Laser Cutting Machine for 2025 Industry Trends