- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Revolutionizing Surface Restoration: Benefits of the Portable Laser Cleaning Machine

Table of Contents

- Benefits of Portable Laser Cleaning Machines in Surface Restoration

- Innovative Technologies Behind Laser Cleaning Techniques

- Comparative Analysis: Portable Laser Machines vs. Traditional Cleaning Methods

- Applications of Laser Cleaning Across Various Industries

- Environmental Advantages of Using Laser Cleaning Solutions

- Cost-Effectiveness and Efficiency of Portable Laser Cleaning Systems

- FAQS

- Conclusion

- Related Posts

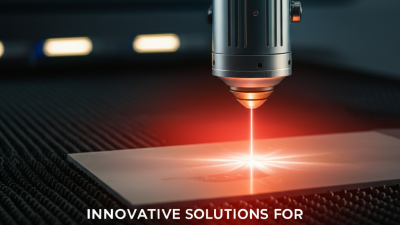

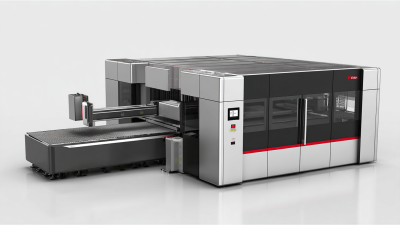

As industries increasingly prioritize efficiency and sustainability, the demand for advanced cleaning technologies has surged, leading to a significant shift in surface restoration methods. Among these innovations, the Portable Laser Cleaning Machine stands out as a game-changer, offering unparalleled precision and versatility in various applications. According to a report from MarketsandMarkets, the global laser cleaning market is projected to reach $1.23 billion by 2026, driven by the growing adoption of eco-friendly solutions in manufacturing and maintenance sectors. Established in 2016, Fortune Laser Technology Co., Ltd., headquartered in Shenzhen, has positioned itself at the forefront of this revolution, combining extensive R&D, production, and service capabilities to deliver state-of-the-art industrial laser equipment. By harnessing the power of laser technology, our Portable Laser Cleaning Machine not only enhances operational efficiency but also minimizes environmental impact, thereby setting new standards in surface restoration and maintenance solutions.

Benefits of Portable Laser Cleaning Machines in Surface Restoration

The rise of portable laser cleaning machines is transforming the surface restoration industry, ushering in a plethora of advantages that enhance efficiency and effectiveness. According to a report by MarketsandMarkets, the global laser cleaning market is expected to reach USD 3.14 billion by 2025, growing at a compound annual growth rate (CAGR) of 27.5% from 2020. This growth is largely attributed to the precision and eco-friendliness of laser cleaning technologies, which significantly reduce the need for harmful chemicals and abrasive materials traditionally used in surface restoration.

One of the standout benefits of portable laser cleaning machines is their versatility. These machines can address a wide range of applications, from removing rust and corrosion on metal surfaces to restoring delicate art and heritage items without causing damage. A study by the International Journal of Advanced Manufacturing Technology highlighted that laser cleaning can achieve removal rates of over 80% for contaminants like paint and grease in mere seconds, thereby streamlining the restoration process. Additionally, their portability allows for on-site applications, thus eliminating the need for transporting materials and potentially lowering operational costs. With these factors in mind, it's clear why industries are increasingly relying on this innovative technology for their surface restoration needs.

Innovative Technologies Behind Laser Cleaning Techniques

The innovative technologies behind laser cleaning techniques have revolutionized surface restoration processes across various industries. Laser cleaning utilizes focused light to remove contaminants from surfaces without causing damage to the underlying materials. Recent advancements in laser configurations, including the utilization of different wavelengths and pulse durations, have shown promising results in effectively cleaning delicate materials such as aged silk fibers. This approach represents a significant improvement over traditional cleaning methods, which often leave residues or can alter the fabric's integrity.

Moreover, the application of online monitoring technologies during the laser cleaning process enhances precision and efficiency. This includes real-time analytics like wave vibration and plasma spectrum analysis, which ensure the cleaning process is both effective and safe for the materials involved. The integration of advanced monitoring systems paves the way for the potential of deeper cleaning capabilities while minimizing environmental impact, contributing to more sustainable practices in surface restoration. As industries seek to adopt greener methods, the innovation behind laser cleaning technologies stands at the forefront, setting new standards for efficiency and effectiveness.

Comparative Analysis: Portable Laser Machines vs. Traditional Cleaning Methods

Portable laser cleaning machines are emerging as a transformative technology in surface restoration, showing significant advantages over traditional cleaning methods. According to a report by Mordor Intelligence, the global laser cleaning market is expected to reach USD 1.5 billion by 2025, reflecting a growing preference for precision and eco-friendliness in surface restoration. Unlike traditional methods such as sandblasting or chemical solvents, which can produce hazardous waste and require extensive setup, portable laser machines offer a sustainable alternative that minimizes material usage and environmental impact.

A comparative analysis reveals that portable laser cleaning is not only more efficient but also more effective on delicate surfaces. A study by Research and Markets indicates that laser cleaning can remove contaminants without causing damage to the substrate—a feat that conventional mechanical or chemical methods often struggle to achieve. Furthermore, laser cleaning can operate at lower costs over time; data shows that it reduces labor and cleanup time by up to 50%, making it a cost-effective solution for industries ranging from automotive to art restoration. As the technology continues to evolve, its role in modern cleaning practices will likely expand, further displacing traditional methods.

Applications of Laser Cleaning Across Various Industries

The growing adoption of portable laser cleaning machines is transforming surface restoration across various industries, including manufacturing, automotive, and conservation. These machines utilize high-intensity laser beams to effectively remove contaminants such as rust, paint, and dirt without damaging the underlying substrate. According to a recent market report, the global laser cleaning market is expected to grow at a CAGR of 21.2% from 2022 to 2030, driven by increasing demand for environmentally-friendly surface treatment solutions.

In the manufacturing sector, laser cleaning is being utilized to prepare surfaces for welding or coating, ensuring superior adhesion and enhanced durability. For the automotive industry, the precision and efficiency of laser cleaning facilitate the maintenance of machinery and restoration of vintage vehicles. Furthermore, in cultural heritage preservation, professionals are increasingly relying on laser technology to gently and effectively clean delicate artifacts without harming their integrity.

Fortune Laser Technology Co., Ltd., based in Shenzhen since 2016, is at the forefront of this technological advancement, providing innovative laser solutions that cater to the specific needs of these diverse fields.

Environmental Advantages of Using Laser Cleaning Solutions

The global laser cleaning market is witnessing significant growth, driven by environmental advantages and the increasing demand for sustainable cleaning solutions. Reports indicate that the market is projected to reach a size of approximately $3 billion by 2025, with a compound annual growth rate (CAGR) of around 5.2% from 2020 to 2025. This growth is largely attributed to the adoption of laser cleaning technologies across various industries, including general manufacturing, automotive, and aerospace. As traditional cleaning methods often involve harmful chemicals, laser cleaning presents a safer and more eco-friendly alternative.

Laser cleaning, especially with solid-state and fiber lasers, minimizes waste and eliminates the need for chemical solvents, making it a preferred choice for businesses committed to sustainability. The technology not only effectively removes contaminants but also reduces the carbon footprint associated with conventional cleaning processes. Industries are increasingly recognizing the value of such solutions, as evidenced by the rising market share of fiber lasers, which accounted for over 40% in recent years.

**Tips:** When considering laser cleaning solutions, assess the specific needs of your industry to choose the appropriate laser type. Additionally, investing in portable laser cleaning machines can enhance operational efficiency while promoting environmental responsibility. Make sure to stay updated on technological advancements that could further improve the effectiveness and sustainability of laser cleaning methods.

Revolutionizing Surface Restoration: Benefits of the Portable Laser Cleaning Machine

| Benefit | Description | Environmental Impact |

|---|---|---|

| Non-Toxic Cleaning | Utilizes no harmful chemicals, ensuring a safe cleaning process. | Reduces chemical waste and pollution. |

| Energy Efficiency | Typically requires less energy compared to traditional methods. | Lowers carbon footprint associated with energy consumption. |

| Water Conservation | Requires minimal to no water for effective cleaning. | Helps preserve water resources. |

| Reduced Waste | Minimizes debris and waste generation during cleaning. | Lessens the burden on landfills and waste management systems. |

| Precision Cleaning | Targets only the material to be removed, preserving surfaces. | Reduces the need for repair and replacement, thereby conserving resources. |

Cost-Effectiveness and Efficiency of Portable Laser Cleaning Systems

The portable laser cleaning machine represents a significant advancement in surface restoration technology, specifically due to its cost-effectiveness and efficiency. Unlike traditional cleaning methods that may require substantial labor and resources, these machines offer a streamlined solution that minimizes both time and expenditure. Their ability to quickly remove contaminants, rust, and coatings without the need for harsh chemicals results in lower operational costs, making them an attractive option for businesses aiming to reduce their environmental footprint while maintaining high standards of cleanliness.

Moreover, portable laser cleaning systems are designed for versatility and ease of use, enabling operators to tackle a variety of surfaces and materials with precision. This flexibility not only enhances efficiency during maintenance tasks but also significantly shortens project timelines. The initial investment in a portable laser cleaning machine is often offset by the long-term savings associated with reduced manpower, less waste disposal, and fewer collateral damages to the surfaces being treated. Consequently, companies can experience improved productivity and return on investment, establishing portable laser cleaning as a modern solution in the field of surface restoration.

FAQS

: Portable laser cleaning machines enhance efficiency and effectiveness in surface restoration by providing precise and eco-friendly solutions that reduce the need for harmful chemicals and abrasive materials.

The global laser cleaning market is expected to reach USD 3.14 billion by 2025, growing at a compound annual growth rate (CAGR) of 27.5% from 2020.

Yes, these machines are versatile and can be used for a wide range of applications, including removing rust and corrosion on metal surfaces and restoring delicate art and heritage items without causing damage.

Laser cleaning can achieve removal rates of over 80% for contaminants like paint and grease in mere seconds, significantly streamlining the restoration process.

Laser cleaning minimizes waste, eliminates the need for chemical solvents, and reduces the carbon footprint associated with conventional cleaning processes, making it a safer and more eco-friendly alternative.

Industries such as general manufacturing, automotive, and aerospace are increasingly adopting laser cleaning technologies due to its environmental advantages.

Solid-state and fiber lasers are preferred for their effectiveness and sustainability, with fiber lasers accounting for over 40% of the market share in recent years.

Investing in portable laser cleaning machines can enhance operational efficiency and promote environmental responsibility by providing effective cleaning solutions on-site.

Businesses should assess their specific industry needs to choose the appropriate laser type and stay updated on technological advancements to improve the effectiveness and sustainability of their cleaning methods.

The growth of the laser cleaning market reflects the increasing demand for sustainable cleaning solutions and the shift away from traditional cleaning methods that use harmful chemicals.

Conclusion

The article titled "Revolutionizing Surface Restoration: Benefits of the Portable Laser Cleaning Machine" highlights the transformative impact of portable laser cleaning technology in surface restoration. These machines offer significant advantages over traditional cleaning methods, including higher efficiency, reduced manual labor, and improved effectiveness in removing contaminants without damaging surfaces. The innovative technologies driving these laser cleaning techniques have led to widespread applications across various industries, effectively addressing cleaning needs while minimizing environmental impact.

Additionally, the comparative analysis between portable laser machines and conventional cleaning solutions underscores their cost-effectiveness and operational efficiency. As a professional manufacturer of industrial laser equipment, Fortune Laser Technology Co., Ltd. is well-positioned to lead in this rapidly evolving field, offering cutting-edge portable laser cleaning machines that cater to diverse industrial requirements.

Related Posts

-

Exploring the 2025 Technological Advancements in Best Pulsed Laser Cleaning Machines and Their Competitive Edge

-

Exploring Laser Cleaning Machine Innovations at 2025 China Import and Export Fair: Industry Trends and Market Growth

-

Innovative Solutions for Effective Laser Cleaning High Power Technology

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

How to Optimize Your Laser Cleaning Device for Maximum Efficiency

-

Exploring ODM Laser Cleaning Machines Industry Trends at the 138th Canton Fair 2025 in China

Blog Tags: