- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Discover the Benefits of Using Metal Mold Laser Cleaner in 2025 Top Technologies

Table of Contents

- Advantages of Metal Mold Laser Cleaners in Modern Manufacturing Environments

- How Metal Mold Laser Cleaning Improves Production Efficiency

- Comparison of Traditional Cleaning Methods vs. Laser Cleaning Technology

- Key Features of Advanced Metal Mold Laser Cleaners in 2025

- Environmental Impact and Sustainability of Laser Cleaning Solutions

- Future Trends in Metal Mold Cleaning Technologies and Their Benefits

- FAQS

- Conclusion

- Related Posts

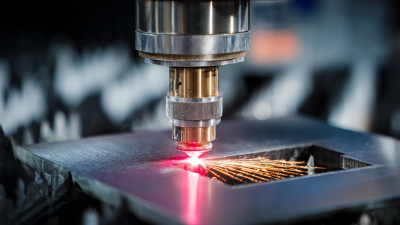

As industries evolve and integrate cutting-edge technologies, the need for efficient and sustainable cleaning solutions has become increasingly critical. The Metal Mold Laser Cleaner emerges as a frontrunner in this transformation, offering a sophisticated approach that aligns with contemporary manufacturing standards. According to a report by MarketsandMarkets, the global laser cleaning market is projected to reach $1.15 billion by 2025, with the metal mold segment driving significant growth due to its effectiveness and eco-friendliness.

The advantages of the Metal Mold Laser Cleaner extend beyond traditional methods, minimizing downtime and improving mold maintenance while ensuring the highest quality of production. With the ability to remove rust, corrosion, and contaminants without the chemical solvents commonly used in conventional cleaning processes, this technology supports not only cost efficiency but also compliance with stringent environmental regulations. In light of these developments, businesses are recognizing the value of incorporating laser cleaning technologies into their operations to enhance productivity and product quality.

With the expected rise in the adoption of automation and intelligent manufacturing practices, integrating the Metal Mold Laser Cleaner into production workflows is not just beneficial but necessary for companies striving to remain competitive in the rapidly advancing industrial landscape.

Advantages of Metal Mold Laser Cleaners in Modern Manufacturing Environments

In modern manufacturing environments, the efficiency and cleanliness of production processes are paramount. One technology that has gained significant traction is the metal mold laser cleaner, which utilizes high-powered lasers to remove contaminants from mold surfaces. According to a report by the International Journal of Advanced Manufacturing Technology, using laser cleaning can enhance mold life by up to 30%, thus reducing replacement costs and downtime. This not only contributes to economic savings but also helps in maintaining consistent product quality by preventing defects caused by mold contamination.

Furthermore, the environmental benefits are noteworthy. Traditional cleaning methods often involve harsh chemicals that can pose health risks and lead to hazardous waste. In contrast, laser cleaning generates no secondary waste and is a more sustainable option. A study by the Environmental Protection Agency highlighted that integrating laser cleaning in manufacturing processes can reduce chemical usage by over 60%, marking a significant step towards greener practices. This alignment with sustainability goals resonates well in today's eco-conscious market, making metal mold laser cleaners not only a practical choice but also a responsible one for manufacturers aiming to innovate while minimizing their ecological footprint.

How Metal Mold Laser Cleaning Improves Production Efficiency

In 2025, the integration of metal mold laser cleaning technology presents significant advantages in enhancing production efficiency within various manufacturing sectors. As the global demand for precision and quality escalates, laser cleaning emerges as a pivotal solution for maintaining metal molds used in additive manufacturing. This process not only eliminates contaminants but also ensures that molds remain in optimal condition, reducing downtime caused by maintenance.

Moreover, the adoption of metal mold laser cleaning translates to faster turnaround times and improved product quality. With the laser cleaning market projected to see substantial growth, manufacturers are increasingly recognizing the value of this technology. By streamlining the cleaning process and minimizing waste, industries can enhance productivity and respond to market demands more effectively. This transformative approach reflects a broader shift towards advanced technologies, which aim to optimize operational workflows and leverage automation for superior results in production efficiency.

Comparison of Traditional Cleaning Methods vs. Laser Cleaning Technology

The comparison between traditional cleaning methods and laser cleaning technology reveals significant advantages that the latter holds in the industrial cleaning sector. Laser cleaning technology offers a non-contact processing method that eliminates mechanical force, preventing damage to the surface of the materials being cleaned. This is particularly beneficial for high-hardness materials, where conventional methods may fail or cause wear and tear. Recent reports indicate that the global market for laser processing will exceed $10 billion, driven by innovations in consumer electronics and the growing demand for efficient cleaning solutions.

One of the key benefits of using metal mold laser cleaners is their eco-friendliness. Unlike traditional chemical cleaning methods that can involve harmful solvents and create hazardous waste, laser cleaning produces minimal residue and uses no chemicals. This not only reduces environmental impact but also improves workplace safety.

Tips: When considering transitioning to laser cleaning technology, assess the specific materials and contaminants in your application to ensure optimal results. Additionally, investing in high-quality laser cleaning equipment can lead to long-term cost savings and efficiency improvements in your production process. Keep an eye on industry trends, as the adoption of laser cleaning solutions is expected to rise steadily.

Key Features of Advanced Metal Mold Laser Cleaners in 2025

As we move into 2025, the advancements in metal mold laser cleaning technology are nothing short of revolutionary. Advanced metal mold laser cleaners now feature higher precision and efficiency, drastically reducing cleaning time while ensuring thorough removal of contaminants. These devices utilize optimized laser wavelengths that target specific materials, allowing for effective removal of rust, grease, and other residues without damaging the mold surface.

When considering the purchase of a metal mold laser cleaner, it’s crucial to look for key features such as adjustable power settings, portability, and user-friendly interfaces. These features not only enhance the cleaning experience but also allow operators to tailor the cleaning process to different types of molds and contaminants.

Tips: Always ensure that the laser cleaner you choose has safety features like automatic shut-off and protective eyewear. Regularly maintaining your equipment will also extend its lifespan and maintain optimal cleaning performance. By investing in advanced technology, businesses can significantly improve productivity and mold longevity, making these laser cleaners an essential tool in modern manufacturing.

Environmental Impact and Sustainability of Laser Cleaning Solutions

The increasing emphasis on environmental impact has led to a shift towards sustainable technologies in various industries. Among these, metal mold laser cleaners are gaining recognition for their eco-friendly attributes. Unlike traditional cleaning methods that often rely on harsh chemicals, laser cleaning solutions utilize high-intensity laser beams to remove contaminants without generating waste or harmful byproducts. This not only minimizes the carbon footprint but also ensures cleaner working conditions and safer operations for employees.

In 2025, several trends in laser technology reflect a broader commitment to sustainability across sectors. Innovations in laser cleaning systems demonstrate enhanced efficiency and versatility, making them pivotal in industries such as manufacturing and automotive. Additionally, the rise of startups focused on laser cleaning technologies indicates a burgeoning market that prioritizes environmental responsibility. These advancements are revolutionizing cleaning practices and aligning with global sustainability goals, ultimately driving better business practices and fostering a cleaner, greener future.

Future Trends in Metal Mold Cleaning Technologies and Their Benefits

As we step into 2025, the landscape of metal mold cleaning technologies is evolving rapidly, with laser cleaning emerging as a front-runner. This innovative method not only enhances efficiency but also minimizes environmental impact. According to a report by Research and Markets, the global laser cleaning market is projected to grow at a CAGR of 22.5% from 2023 to 2028, underscoring the increasing adoption of this technology across various industries.

One of the standout benefits of metal mold laser cleaners is their ability to remove contaminants without abrasive materials or harsh chemicals, which can damage molds and pose health risks. Furthermore, a study from Transparency Market Research highlights that laser cleaning can achieve up to 99% surface cleanliness, significantly improving mold lifespan and production quality. As manufacturers seek to optimize processes and enhance sustainability, the integration of advanced laser cleaning technologies into their operations is set to redefine industry standards in mold maintenance for years to come.

Benefits of Using Metal Mold Laser Cleaner in 2025

This bar chart illustrates the various benefits of using metal mold laser cleaners in 2025. The percentages indicate the perceived improvement in efficiency, cost savings, environmental impact, time savings, and surface quality enhancement.

FAQS

: Laser cleaning technology is a non-contact processing method that uses high-intensity laser beams to remove contaminants from surfaces without mechanical force, thereby preventing damage to the materials.

Unlike traditional cleaning methods that may involve harmful chemicals and mechanical abrasion, laser cleaning is eco-friendly, produces minimal residue, and is less likely to damage surfaces, especially those made of high-hardness materials.

Laser cleaning reduces environmental impact by minimizing waste and harmful byproducts, eliminating the need for harsh chemicals, and improving workplace safety for employees.

The global market for laser processing is expected to exceed $10 billion, driven by innovations in consumer electronics and the growing need for efficient, sustainable cleaning solutions in various industries.

Companies should assess the specific materials and contaminants in their applications to ensure optimal cleaning results and consider investing in high-quality laser cleaning equipment for long-term cost savings and efficiency improvements.

The rise of startups focused on laser cleaning technologies indicates a growing market that prioritizes environmental responsibility and innovation, aligning with global sustainability goals and revolutionizing cleaning practices.

Key industries benefiting from laser cleaning include manufacturing and automotive, where enhanced efficiency and sustainability are critical.

Trends in laser technology by 2025 include enhanced efficiency, versatility in applications, and a stronger commitment to sustainability across various sectors, reflecting a shift towards more responsible business practices.

Conclusion

The article "Discover the Benefits of Using Metal Mold Laser Cleaner in 2025 Top Technologies" highlights the significant advantages of Metal Mold Laser Cleaners in contemporary manufacturing settings. These advanced cleaning solutions enhance production efficiency by effectively removing contaminants, thereby minimizing downtime and optimizing workflow. In comparison to traditional cleaning methods, laser cleaning technology offers a more sustainable approach, with less environmental impact and reduced waste.

Key features of the latest Metal Mold Laser Cleaners include precision cleaning capabilities and versatility, making them essential for modern manufacturing needs. The ongoing trends in metal mold cleaning technologies suggest an increasing integration of automation and intelligent systems, promising further benefits for manufacturers seeking efficiency and sustainability. As a leading manufacturer in the industrial laser equipment sector, Fortune Laser Technology Co., Ltd. is poised to support these advancements, solidifying its role in shaping the future of cleaning solutions.

Related Posts

-

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine

-

Revolutionizing Surface Restoration with Laser Cleaner Rust Removal for Industrial Applications

-

Revolutionize Your Surface Restoration with Laser Cleaner for Efficient Rust Removal

-

Top 5 Benefits of Using ODM Laser Cleaning Machines in Industrial Applications

-

The Future of Precision in Metal Sheet Laser Cutting Technology

-

The Future of Precision Engineering with the Best Laser Cutting Device

Blog Tags: