- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Top Benefits of Large Format Laser Cleaning Machines for Industrial Application

Table of Contents

- Overview of Large Format Laser Cleaning Machines

- Key Features of Industrial Laser Cleaning Technology

- Advantages of Laser Cleaning over Traditional Methods

- Applications of Large Format Laser Cleaning in Various Industries

- Cost Efficiency and Environmental Benefits of Laser Cleaning

- Case Studies: Successful Implementations of Laser Cleaning Solutions

- Future Trends in Large Format Laser Cleaning Technology

- FAQS

- Conclusion

- Related Posts

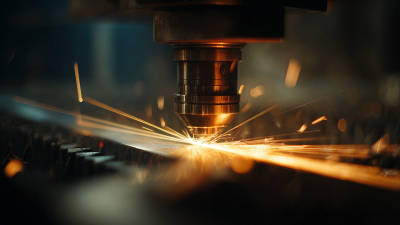

In the realm of industrial applications, the adoption of advanced technologies has become essential for enhancing efficiency and sustainability. One such groundbreaking advancement is the Large Format Laser Cleaning Machine, which has revolutionized the way industries approach surface cleaning and maintenance. Traditional cleaning methods often involve harsh chemicals and intensive labor, leading to increased costs and environmental concerns. In contrast, large format laser cleaning technology offers a precise, eco-friendly solution that reduces material waste and minimizes health risks associated with chemical exposure.

The benefits of employing Large Format Laser Cleaning Machines are multifaceted, ranging from their ability to clean intricate surfaces to their effectiveness in removing coatings, rust, and contaminants without causing damage to the underlying material. As industries strive to comply with stringent environmental regulations and seek cost-effective maintenance solutions, the integration of this technology presents a formidable advantage. By harnessing the power of laser cleaning, companies can not only improve operational efficiency but also contribute to a greener and safer industrial environment. Through this exploration, we will delve into the top benefits that these machines bring to various industrial sectors, highlighting their transformative impact on contemporary cleaning processes.

Overview of Large Format Laser Cleaning Machines

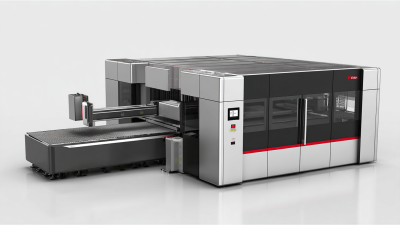

Large format laser cleaning machines represent a significant advancement in industrial cleaning technology, revolutionizing the way large surfaces and heavy machinery are maintained. These machines utilize high-intensity laser beams to effectively remove contaminants such as rust, paint, and other substances from a variety of materials without the need for harsh chemicals or abrasive methods. According to a recent industry report, the global laser cleaning market is projected to grow at a compound annual growth rate (CAGR) of over 25% from 2023 to 2030, highlighting the growing adoption of this technology in sectors like manufacturing, maritime, and aerospace.

One of the key advantages of large format laser cleaning machines is their precision and control. The focused energy of the laser can be adjusted to accommodate different materials and contaminants, providing a tailored cleaning solution that minimizes damage to the underlying substrate. This capacitated efficiency not only enhances productivity but also reduces operational costs; studies have shown that laser cleaning can reduce labor time by up to 80% compared to traditional methods. Additionally, the eco-friendly nature of laser cleaning, which produces no harmful waste or chemical run-off, aligns with the increasing industry shift towards sustainable practices. As companies seek to improve their environmental footprint, large format laser cleaning machines are becoming an essential tool in their maintenance arsenal.

Top Benefits of Large Format Laser Cleaning Machines for Industrial Applications

Key Features of Industrial Laser Cleaning Technology

Industrial laser cleaning technology has emerged as a cutting-edge solution for various surface preparation tasks, greatly enhancing the efficiency and effectiveness of cleaning processes across multiple sectors. One of the key features of this technology is its precision. Laser cleaning machines can target specific areas without affecting adjacent surfaces, making them ideal for applications where delicate components or intricate designs are involved. The ability to adjust laser parameters such as intensity and frequency further allows operators to customize the cleaning process to suit different materials and contaminant types.

Another notable feature is the environmental friendliness of laser cleaning technology. Unlike traditional cleaning methods that often rely on harsh chemicals or abrasive materials, laser cleaning uses high-powered beams of light to remove contaminants. This not only minimizes waste but also reduces the potential for chemical exposure to workers and the environment. Furthermore, many modern laser systems are designed with energy efficiency in mind, contributing to lower operational costs while maintaining high cleaning performance. Overall, the advancements in industrial laser cleaning technology have revolutionized the way industries approach surface cleaning, offering precision, safety, and sustainability.

Advantages of Laser Cleaning over Traditional Methods

Laser cleaning technology is revolutionizing the way industries approach surface preparation and material restoration. Unlike traditional cleaning methods that typically rely on harsh chemicals or abrasive techniques, laser cleaning offers a non-contact approach that minimizes surface damage. According to industry reports, laser cleaning can achieve removal rates of up to 90% faster than conventional methods, significantly enhancing productivity in manufacturing environments. Additionally, a study by the International Journal of Advanced Manufacturing Technology noted that laser systems can effectively clean various materials, including metals and plastics, without the need for consumables, leading to substantial cost savings over time.

One of the standout advantages of laser cleaning is its precision. Laser systems can selectively target contaminants, such as rust or paint, without affecting the underlying substrate. This precision results in minimal waste and lower environmental impact, as laser cleaning is typically associated with fewer hazardous byproducts compared to chemical-based cleaning processes. Reports indicate that industries utilizing laser technology for cleaning see a reduction in chemical use by as much as 70%, contributing to more sustainable practices.

Tips for maximizing the benefits of laser cleaning include conducting thorough surface analysis before initiating the cleaning process to determine the right laser settings and parameters, ensuring optimal results. It's also advisable to keep maintenance records of the equipment to track its efficiency and performance over time. Periodically updating the software that controls the laser technology can lead to better operational capabilities and enhanced cleaning outcomes.

Applications of Large Format Laser Cleaning in Various Industries

Large format laser cleaning machines have revolutionized the industrial cleaning landscape across various sectors. In manufacturing, these machines are employed to remove paint, rust, and other contaminants from large metal surfaces, enhancing the quality and longevity of machinery and structures. The precision of laser cleaning allows for targeted applications without damaging the underlying material, making it an ideal choice for restoring heavy equipment and facilitating routine maintenance.

In the automotive industry, laser cleaning is utilized for the restoration of molds and tools, ensuring high standards of cleanliness that are crucial for production efficiency. This method effectively eliminates residues without the need for harsh chemicals or extensive downtime, thereby streamlining operations. Moreover, in the restoration of heritage structures, large format laser systems offer an environmentally friendly solution to remove layers of dirt and paint, preserving the integrity of historical materials while improving aesthetics. The versatility of these machines enables them to adapt to different surfaces and contaminants, establishing their place as essential tools in modern industrial processes.

Cost Efficiency and Environmental Benefits of Laser Cleaning

Laser cleaning technology has emerged as a highly efficient alternative to conventional cleaning methods in industrial applications. One of the foremost advantages of utilizing large format laser cleaning machines is their cost efficiency. These machines significantly reduce the need for harmful chemicals and costly waste disposal processes. In traditional cleaning practices, chemical agents not only add to the operating expenses but also pose storage and handling challenges. In stark contrast, laser cleaning operates using focused light energy, which targets contaminants accurately without the risk of secondary waste. This capability allows industries to minimize costs associated with both materials and labor, contributing to a more streamlined operational budget.

Moreover, the environmental benefits of laser cleaning cannot be overstated. By eliminating the reliance on chemical solvents, laser cleaning machines promote a healthier workplace and reduce the ecological footprint of industrial operations. The process generates minimal waste, which means fewer pollutants are released into the environment. As industries increasingly commit to sustainable practices, the adoption of laser cleaning technology aligns with these values, paving the way for a greener future. Furthermore, the potential for reduced energy consumption during the cleaning process compared to traditional methods enhances the overall environmental appeal of laser cleaning solutions, making them a forward-thinking choice for modern industrial applications.

Case Studies: Successful Implementations of Laser Cleaning Solutions

The implementation of large format laser cleaning machines in industrial applications has led to significant advancements in efficiency and effectiveness. Numerous case studies highlight the successful adoption of these solutions across various sectors, showcasing their ability to significantly reduce downtime and improve asset longevity. For instance, a leading aerospace manufacturer employed laser cleaning technology to remove paint and contaminants from aircraft components, resulting in a 70% decrease in cleaning time compared to traditional methods. Additionally, the elimination of harmful chemicals not only enhanced worker safety but also contributed to a more sustainable manufacturing process.

In another noteworthy case, a major automotive manufacturer integrated laser cleaning machines into their assembly line to prepare surfaces for welding. This application demonstrated how laser technology could achieve precise cleaning without damaging underlying materials, ultimately reducing the need for rework. Such implementations not only optimize production time but also ensure higher quality outcomes, reaffirming the value of laser cleaning solutions in today's industrial landscape.

**Tips:** When considering laser cleaning for your facility, assess the size and complexity of the surfaces to be cleaned, as this will affect the choice of equipment and process. Additionally, training personnel on the operation and safety procedures related to laser machines is crucial for maximizing their benefits and ensuring a safe working environment.

Top Benefits of Large Format Laser Cleaning Machines for Industrial Application - Case Studies: Successful Implementations of Laser Cleaning Solutions

| Application Area | Before Laser Cleaning (Time/Cost) | After Laser Cleaning (Time/Cost) | Efficiency Improvement (%) | Environmental Impact |

|---|---|---|---|---|

| Metal Surface Restoration | 30 hours / $500 | 10 hours / $200 | 67% | Reduced chemical usage |

| Marine Vessel Maintenance | 40 hours / $800 | 15 hours / $300 | 62.5% | No toxic waste produced |

| Industrial Equipment Cleaning | 25 hours / $400 | 8 hours / $150 | 68% | Lower emissions |

| Historic Building Restoration | 35 hours / $700 | 12 hours / $250 | 65% | Preservation of original materials |

Future Trends in Large Format Laser Cleaning Technology

The future of large format laser cleaning technology is poised for significant advancements, driven by innovations in materials and automation. As industries increasingly focus on sustainability and efficiency, laser cleaning machines are becoming integral in reducing waste and energy consumption. One promising trend is the development of advanced AI algorithms that optimize the cleaning process, allowing machines to adapt to various surfaces and contaminants dynamically. This not only enhances cleaning efficacy but also minimizes the risk of damage to sensitive components, making laser cleaning a more versatile solution across different sectors.

In addition to automation, the integration of IoT (Internet of Things) technology is set to revolutionize large format laser cleaning. By connecting machines to a network, operators can monitor performance in real-time, predict maintenance needs, and analyze cleaning outcomes through data analytics. This predictive approach empowers companies to maintain high operational standards while reducing downtime and operational costs.

Tips: When considering the adoption of large format laser cleaning technology, it’s essential to assess the specific requirements of your industrial application. Ensure the equipment is compatible with the surfaces you intend to clean and evaluate the potential return on investment based on reduced labor and material costs. Regular training for operators can also enhance the effectiveness and safety of the cleaning process, maximizing the benefits of this modern technology.

FAQS

: Industrial laser cleaning technology uses high-powered beams of light to remove contaminants from surfaces, enhancing efficiency and effectiveness in various surface preparation tasks.

Laser cleaning allows for targeted area cleaning without affecting adjacent surfaces, making it suitable for delicate components and intricate designs.

Laser cleaning minimizes waste and reduces the use of harsh chemicals, making it a safer option for both workers and the environment.

Laser cleaning can achieve removal rates that are up to 90% faster than traditional methods, significantly enhancing productivity in manufacturing.

Since laser systems do not require consumables and reduce chemical use, they lead to substantial cost savings over time.

It's important to conduct thorough surface analysis to determine the right laser settings and parameters for optimal results.

Innovations in AI and IoT are expected to improve cleaning efficacy, automate processes, and enable real-time performance monitoring and predictive maintenance.

Laser cleaning is associated with a reduction in chemical use by up to 70%, contributing to more sustainable industrial practices.

Regular equipment maintenance, software updates, and operator training can enhance the effectiveness and safety of the cleaning process.

Automation will allow for dynamic adjustments in the cleaning process based on surface and contaminant types, enhancing versatility and reducing damage risk.

Conclusion

Large Format Laser Cleaning Machines have emerged as a revolutionary technology in industrial applications, offering numerous advantages over traditional cleaning methods. These machines utilize advanced laser technology that delivers precise, efficient, and environmentally friendly cleaning solutions. Key features of large format laser cleaning technology include its ability to remove contaminants without damaging surfaces, making it suitable for a wide range of industrial materials.

The benefits of laser cleaning extend beyond just effectiveness; it also provides significant cost efficiencies and environmental advantages. Industries from manufacturing to restoration are increasingly adopting these machines for their ability to enhance operational efficiency while reducing harmful waste. Case studies demonstrate successful implementations that highlight the transformative impact of Large Format Laser Cleaning Machines across various sectors. Future trends indicate further advancements in technology, promising even greater potential for industrial applications.

Related Posts

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

-

How to Maximize Efficiency with a 100 Watt Fiber Laser Cleaning Machine

-

5 Essential Tips for Using a Laser Rust Removal Machine Effectively

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

Revolutionizing Surface Restoration with High Power Laser Cleaning Technology

-

The Future of Industrial Cleaning with High Power Laser Technology