- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

5 Reasons Why the 3015 Fiber Laser Cutter is the Best Investment for Your Manufacturing Efficiency

Table of Contents

- Benefits of the 3015 Fiber Laser Cutter for Modern Manufacturing

- Comparative Analysis: 3015 Fiber Laser Cutter vs. Traditional Cutting Methods

- Cost-Effectiveness: Long-Term Savings with the 3015 Fiber Laser Cutter

- Enhancing Precision: How the 3015 Fiber Laser Cutter Outperforms Alternatives

- Versatility in Materials: The 3015 Fiber Laser Cutter's Range Compared to Competitors

- User-Friendly Technology: Simplifying Operations with the 3015 Fiber Laser Cutter

- FAQS

- Conclusion

- Related Posts

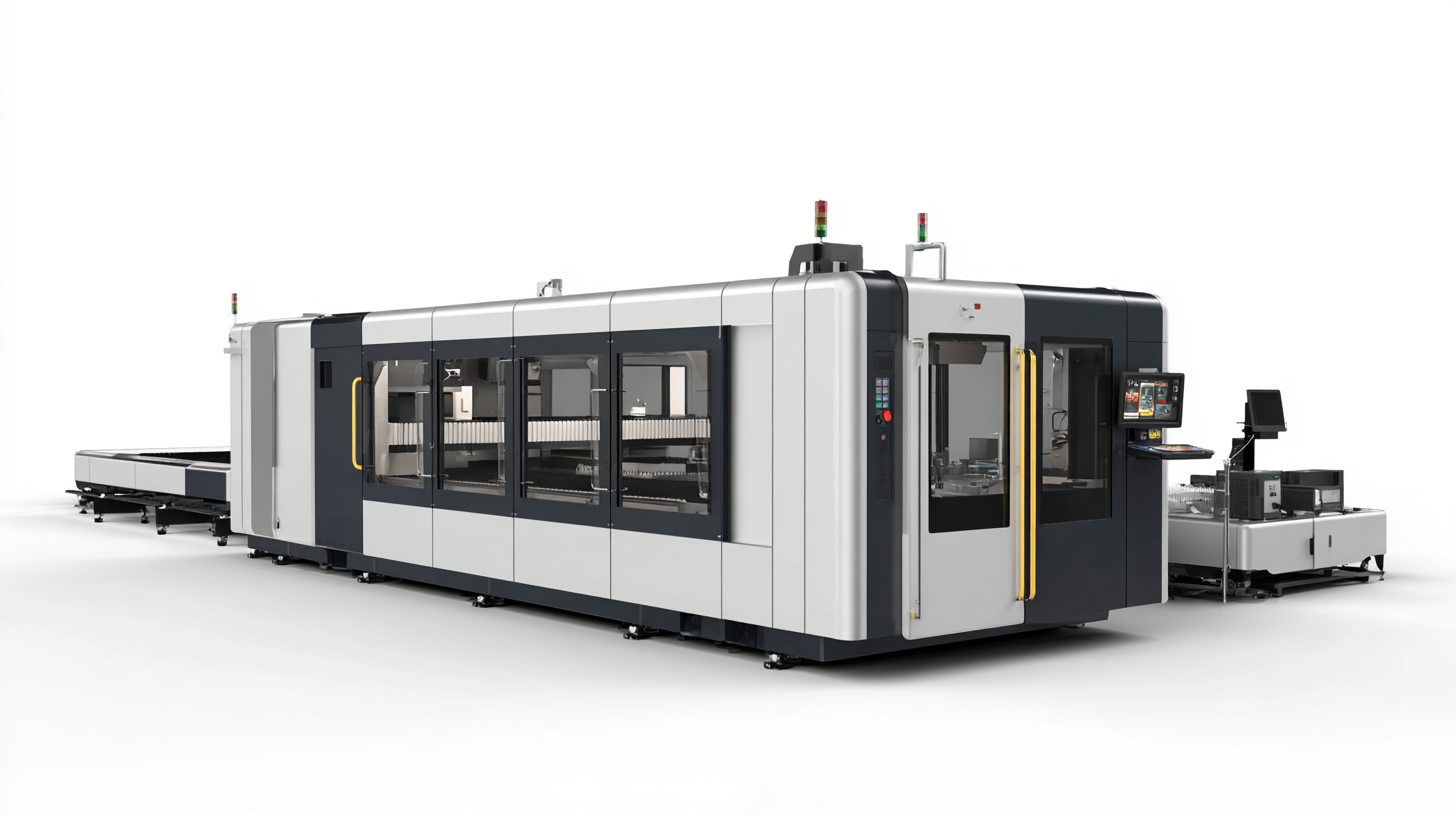

In today's competitive manufacturing landscape, efficiency and precision are paramount, making the 3015 Fiber Laser Cutter an exceptional investment for businesses looking to enhance their operational capabilities. According to a report by Markets and Markets, the global laser cutting market is projected to reach $6.2 billion by 2025, driven by advancements in laser technology and increasing demand for high-precision fabrication across various industries. As a leading manufacturer in this field, Fortune Laser Technology Co., Ltd. has been at the forefront of innovation since its inception in 2016, providing advanced laser solutions that integrate research and development, production, sales, and maintenance services. The 3015 Fiber Laser Cutter stands out not only for its cutting speed and accuracy but also for its cost-effectiveness and versatility, making it a top choice for manufacturers aiming to optimize their processes and stay ahead in a rapidly evolving market.

Benefits of the 3015 Fiber Laser Cutter for Modern Manufacturing

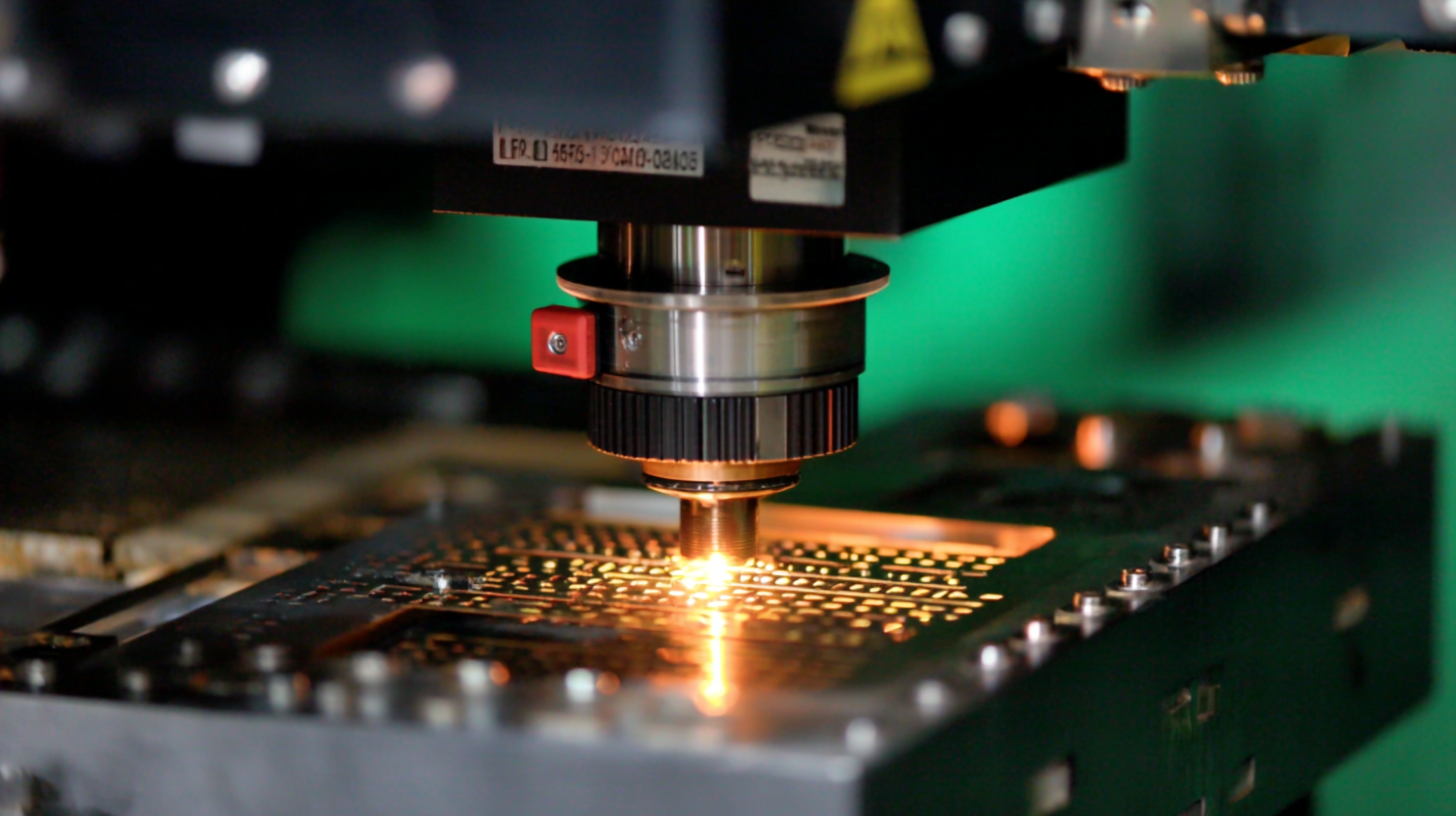

The 3015 Fiber Laser Cutter stands out as a pivotal tool in modern manufacturing, enhancing efficiency and precision. With its ability to cut through a variety of materials, including steel, aluminum, and brass, this machine offers versatility that is crucial for any production environment. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach $5.18 billion by 2024, driven by the increasing demand for laser cutting technologies. This trend emphasizes the importance of adopting advanced machinery like the 3015 to remain competitive in the industry.

Moreover, the operational efficiency of the 3015 Fiber Laser Cutter is supported by its low power consumption and high cutting speeds. Studies show that fiber laser technology can achieve cutting speeds of up to 80% faster than traditional CO2 lasers, leading to significant reductions in cycle times. Additionally, the improved energy efficiency results in lower operational costs and reduced environmental impact. As manufacturers strive for sustainability, the 3015 Fiber Laser Cutter emerges as a preferred choice, combining performance with eco-conscious advantages that are increasingly sought after in today's market.

Comparative Analysis: 3015 Fiber Laser Cutter vs. Traditional Cutting Methods

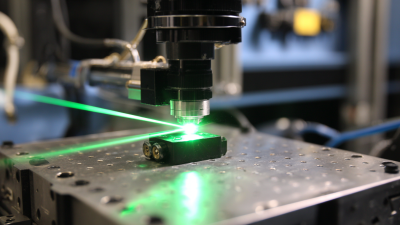

The 3015 fiber laser cutter represents a significant advancement over traditional cutting methods, particularly when considering efficiency and productivity. With China's laser equipment market projected to reach ¥910 billion in sales revenue by 2024, the growth indicates a shift towards more innovative technologies. Specifically, the fiber laser cutting market alone is expected to hit ¥368.5 billion, highlighting the demand for precision and performance that traditional cutting methods may struggle to meet.

One of the primary advantages of the 3015 fiber laser cutter is its speed. Traditional methods often lag due to slower processing times; however, fiber laser technology can achieve cuts at remarkable speeds, contributing to enhanced manufacturing efficiency. Furthermore, these machines offer improved accuracy and reduced material wastage, which can lead to significant cost savings in the long run.

**Tips**:

- When considering a transition to fiber laser cutting, evaluate your current production processes and identify areas where you can benefit from increased speed and precision.

- Keep an eye on the evolving market trends, as advancements in fiber laser technology could offer even greater improvements in efficiency, especially with the ongoing developments in materials processing and laser sources.

Investing in a 3015 fiber laser cutter not only ensures a competitive advantage today but also aligns with the future trajectory of the manufacturing industry towards automation and efficiency optimization.

5 Reasons Why the 3015 Fiber Laser Cutter is the Best Investment for Your Manufacturing Efficiency

| Feature | 3015 Fiber Laser Cutter | Traditional Cutting Method |

|---|---|---|

| Cutting Speed | Up to 30 m/min | 5-15 m/min |

| Precision | ±0.05 mm | ±0.1 mm |

| Material Versatility | Metals, Plastic, Wood | Metals Only |

| Maintenance Cost | Low | High |

| Energy Efficiency | 30% less energy | Higher energy consumption |

Cost-Effectiveness: Long-Term Savings with the 3015 Fiber Laser Cutter

In today’s competitive manufacturing landscape, choosing the right equipment can make all the difference in operational efficiency and cost management. The 3015 Fiber Laser Cutter stands out as a top-tier investment primarily due to its exceptional cost-effectiveness. One of the key advantages of this system is its low operational costs. Unlike traditional cutting methods that often involve high maintenance and consumable expenses, the fiber laser utilizes a more efficient energy source, translating to significant reductions in electricity bills and upkeep.

Moreover, the durability and longevity of the 3015 Fiber Laser Cutter further enhance its value proposition. With minimal wear and tear, these machines require less frequent replacement and upkeep compared to their counterparts, leading to long-term savings for manufacturers. Additionally, the precision and speed of the fiber laser technology minimize material waste, ensuring that every cut is not only accurate but also economically advantageous. This combination of lower operational costs, reduced maintenance, and optimized material usage makes the 3015 Fiber Laser Cutter a smart choice for businesses looking to bolster their manufacturing efficiency while achieving considerable cost savings over time.

Enhancing Precision: How the 3015 Fiber Laser Cutter Outperforms Alternatives

The 3015 Fiber Laser Cutter stands out in the manufacturing sector due to its exceptional precision, revolutionizing how companies approach metal fabrication. Unlike traditional cutting methods, which often leave behind jagged edges and inconsistent shapes, the fiber laser cutter utilizes advanced beam technology to produce smooth, clean cuts that meet stringent design specifications. This level of accuracy not only enhances the quality of the final product but also reduces the need for extensive secondary processes, saving time and resources.

Moreover, the 3015 model is uniquely designed to handle diverse materials, including steel, aluminum, and brass, with remarkable finesse. Its adaptability ensures that businesses can pivot quickly to meet changing market demands without compromising on quality. This multifaceted capability, paired with high-speed cutting, positions the 3015 Fiber Laser Cutter as an invaluable asset for manufacturers looking to boost their production efficiency while maintaining outstanding operational standards. As a result, investing in this cutting-edge technology proves to be a strategic move for companies aiming to stay competitive in a fast-evolving landscape.

Versatility in Materials: The 3015 Fiber Laser Cutter's Range Compared to Competitors

When it comes to maximizing manufacturing efficiency, the versatility of the 3015 Fiber Laser Cutter from Fortune Laser Technology Co., Ltd. stands out in the industry. This advanced machine can cut a wide range of materials, including stainless steel, aluminum, brass, and even plastics, providing manufacturers with the flexibility needed to take on various projects.

According to a report by Allied Market Research, the global fiber laser market is anticipated to reach $8 billion by 2025, driven by the increasing demand for high-precision cutting and the ability to work with diverse materials.

What truly distinguishes the 3015 Fiber Laser Cutter from its competitors is not just its material compatibility but also its superior cutting speeds and efficiency. With advancements in laser technology, this cutter can operate at speeds that are 2-3 times faster than traditional methods. A study from Research and Markets indicates that manufacturers who adopt fiber laser cutting technology can reduce operational costs by up to 30%. This enables companies to enhance their production throughput while maintaining high-quality standards, solidifying the 3015 as a strategic investment for any manufacturing operation.

User-Friendly Technology: Simplifying Operations with the 3015 Fiber Laser Cutter

The 3015 Fiber Laser Cutter stands out as a premier choice for manufacturers seeking to enhance their operational efficiency through user-friendly technology. With cutting-edge features designed for ease of use, this machine simplifies complex cutting operations, making it accessible even for operators with minimal training. According to a recent report by the Fabricators & Manufacturers Association, companies that implement advanced cutting technology like fiber lasers can increase their production efficiency by up to 30%, significantly impacting their bottom line.

Moreover, the intuitive software interface of the 3015 Fiber Laser Cutter reduces setup times and operational errors. With a focus on streamlining production processes, this technology enables manufacturers to quickly adapt to production changes while maintaining precision. A study published in the Journal of Manufacturing Science and Engineering noted that user-friendly equipment can boost employee productivity by over 20%, as workers spend less time troubleshooting and more time focused on output. As manufacturers continue to prioritize efficiency, investing in manageable yet powerful technologies like the 3015 Fiber Laser Cutter is more critical than ever.

5 Reasons Why the 3015 Fiber Laser Cutter is the Best Investment for Your Manufacturing Efficiency

This bar chart represents the efficiency ratings of the 3015 Fiber Laser Cutter across five key factors: Speed, Precision, Cost-Effectiveness, Versatility, and User-Friendliness. Each factor highlights why the 3015 Fiber Laser Cutter is an excellent investment for enhancing manufacturing efficiency.

FAQS

: The 3015 Fiber Laser Cutter can cut a variety of materials, including steel, aluminum, and brass.

The 3015 Fiber Laser Cutter can achieve cutting speeds that are up to 80% faster than traditional CO2 lasers.

The 3015 Fiber Laser Cutter has low power consumption and high cutting speeds, which lead to lower operational costs and reduced environmental impact.

Manufacturers are adopting fiber laser cutting technologies due to their enhanced efficiency, precision, and the increasing demand for sustainable production methods.

The projected growth in the laser equipment market indicates a shift towards innovative technologies that offer improved precision and performance, which traditional methods may struggle to provide.

Advantages include faster processing times, improved accuracy, and reduced material wastage, leading to significant cost savings in the long term.

Manufacturers should evaluate their current production processes and identify areas where they can benefit from increased speed and precision.

The global fiber laser market is projected to reach $5.18 billion by 2024.

Its improved energy efficiency leads to lower operational costs and a reduced environmental impact, making it a more eco-conscious choice.

Manufacturers should keep an eye on evolving market trends and advancements in fiber laser technology, which could offer further improvements in efficiency and automation.

Conclusion

The 3015 Fiber Laser Cutter stands out as a superior investment for modern manufacturing due to its remarkable benefits and advanced technology. Unlike traditional cutting methods, the 3015 Fiber Laser Cutter enhances precision, offering superior cutting capabilities while significantly reducing operational costs over time. Its versatility allows it to handle a wide range of materials, making it an invaluable asset for diverse manufacturing needs.

Additionally, the user-friendly technology integrated into the 3015 Fiber Laser Cutter simplifies operations, enabling manufacturers to optimize their processes with ease. As a professional manufacturer of industrial laser equipment since 2016, Fortune Laser Technology Co., Ltd. ensures that businesses can maximize their efficiency and productivity through the innovative features of the 3015 Fiber Laser Cutter. Investing in this technology not only boosts manufacturing performance but also paves the way for significant long-term savings.

Related Posts

-

Understanding Challenges with Affordable Fiber Laser Cutter Reliability

-

Trust in Global Manufacturing Excellence Discover the Best Industrial Laser Cutting Machines from China's Leading Factory

-

Unlocking Efficiency and Precision with the Best Fiber Laser Cutting Machine Benefits to Your Business

-

Finding Top Suppliers for Best 3015 Fiber Laser Cutter Your Essential Checklist Guide

-

Exploring the Cutting Edge Alternatives to the Best Fiber Optic Laser Cutting Machine

-

5 Best Pulsed Laser Cleaning Machines for Global Buyers in 2023