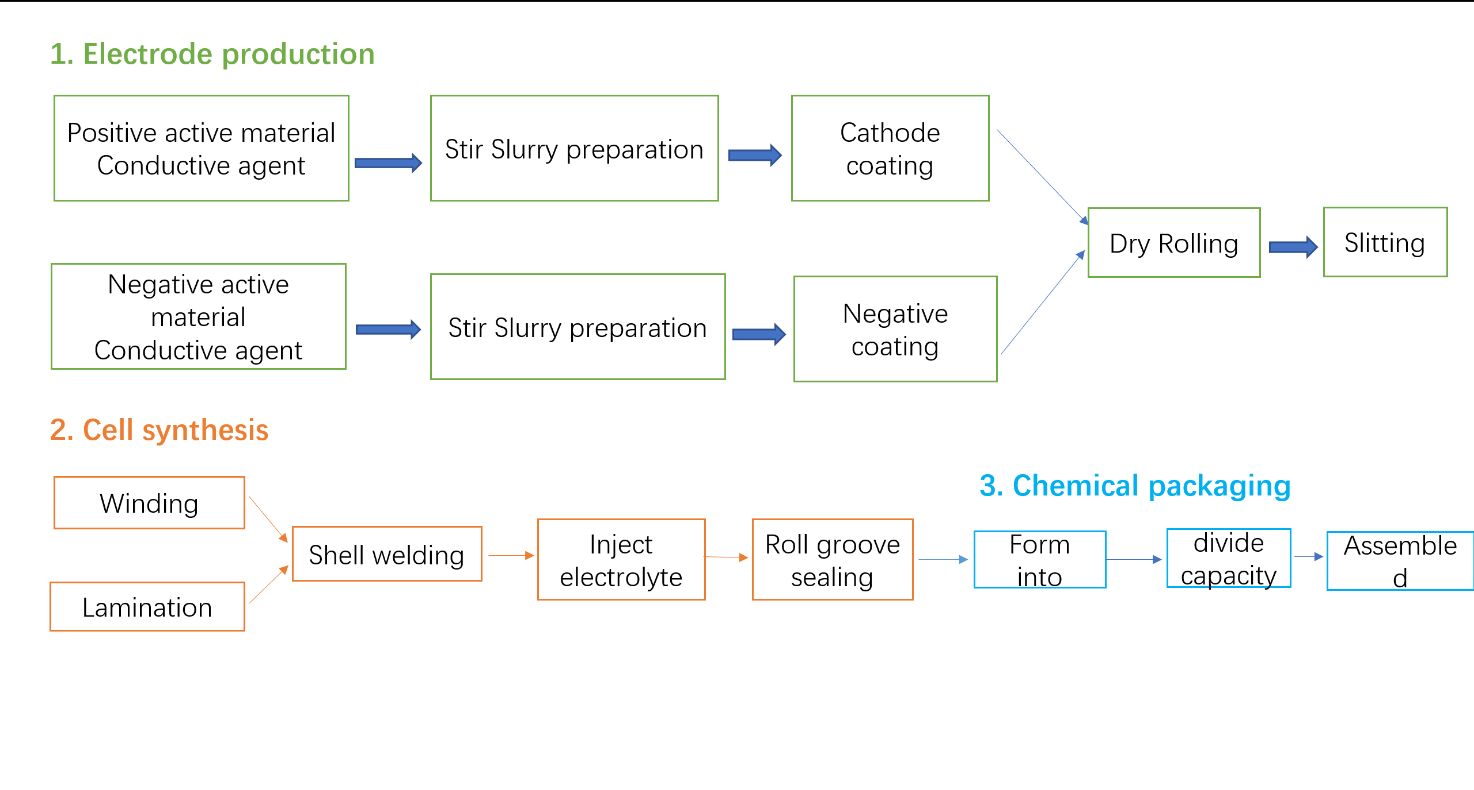

Ukukhiqizwa kweamabhethri e-lithiumkuyinqubo "yokugoqa-kuya-roll".Kungakhathaliseki ukuthi ibhethri ye-lithium iron phosphate, ibhethri ye-sodium-ion noma ibhethri le-ternary, idinga ukudlula inqubo yokucubungula isuka kufilimu elincanyana iye kwibhethri elilodwa, bese iye ohlelweni lwebhethri.Inqubo yokulungiselela amabhethri e-lithium ingahlukaniswa cishe izigaba ezintathu: ukukhiqizwa kweshidi le-electrode, ukuhlanganiswa kwamaseli, kanye nokupakishwa kwamakhemikhali.

Kunezinqubo ezimbalwa ezibalulekile kulezi zinqubo ezintathu ezinkulu, ezizothinta ngokuqondile umthamo wokugcina amandla ebhethri, ukuphepha komkhiqizo kanye nempilo yesevisi.Ngakho-ke, ukusebenza kwamabhethri akhiqizwa izinqubo ezahlukene zokukhiqiza kuyahluka kakhulu.Kulezi zixhumanisi,ukuhlanza laserokwamanje ingabamba iqhaza ezinqubweni zokulungiselela ezingaphezu kweshumi nambili, ezingathuthukisa kakhulu izinga lekhwalithi yamabhethri e-lithium.

| Uhlelo lokusebenza lokuhlanza i-laser kubhethri lamandla | |||

| Ingxenye yangaphambili yebhethri | Ingxenye yeseli | Ingxenye yemojuli | PACK ibhethri iphakethe |

| Ukuhlanza isigxobo | Ukuhlanza izinzipho | Ukuhlanza isigxobo | I-Pallet CMT Weld Seam Cleaning |

| Ukuhlanza ngaphambi kokugoqa | Ukuhlanza amathebhu ngaphambi kokuhlanganisa | Ukuhlanza ifilimu eliluhlaza okwesibhakabhaka | Cover plate electrophoretic paint yokuhlanza |

| Ukuhlanza ngemva kokugoqa | I-Cell Silicone Cleaning | Ukuhlanza ungqimba lwekhabhinethi ye-sealant oxide | |

| Ukuhlanzwa kwe-cell coating | Ukuhlanzwa kwe-oksidi kwepuleti elingaphansi elivikelayo ngaphambi kokushisela | ||

| Ukuhlanza imbobo yomjovo | Ukuhlanza ilebula ye-Foil | ||

| ukuhlanza ibha yebhasi | |||

Njengoba isidingo samabhethri kagesi siqhubeka nokwanda, isidingo seukuhlanza laserimishini nayo izokwanda.Okulandelayo, sizogxila kwezinye zezinqubo zohlelo lokusebenza kanye nezinzuzo zokuqhathanisa.

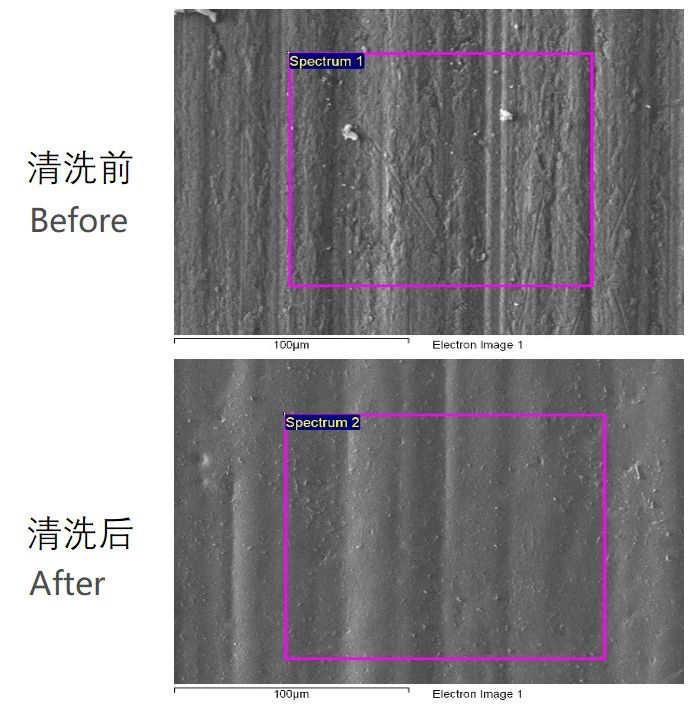

1. Ukuhlanzwa kwe-laser kwe-copper ne-aluminium foil ngaphambi kokumbozwa kwesiqephu sesigxobo

Ama-electrode aqondile noma angalungile ebhethri ye-lithium enziwa ngokumboza ama-electrode aqondile noma angalungile ebhethri ye-lithium kucwecwe lwe-aluminium kanye necwecwe lethusi.Uma izinhlayiya, imfucumfucu, uthuli kanye neminye imidiya ixubene enqubweni yokumboza, izobangela i-micro-short circuit ngaphakathi kwebhethri, futhi ezimweni ezinzima, ibhethri izobamba umlilo futhi iqhume.

Ngakho-ke, i-foil idinga ukuhlanzwa ngaphambi kokumbozwa ukuze kutholakale indawo ehlanzekile ngokuphelele, engena-oxide.

Izingcezu zezigxobo zebhethri ezikhona ngokuvamile zihlanzwa ngamagagasi e-ultrasonic, futhi isisombululo se-ethanol sisetshenziswa njenge-ejenti yokuhlanza njengenqubo yokuhlanza ngaphambi kokumbozwa.Le ndlela inamaphutha alandelayo:

1. Lapho i-ultrasonically ihlanza izingxenye ze-foil zensimbi, ikakhulukazi i-aluminium alloy workpieces, ezithintekayo imvamisa, isikhathi sokuhlanza namandla, umphumela we-cavitation wamagagasi e-ultrasonic ungagqwala kalula ucwecwe lwe-aluminium, okuholela kuma-pores amahle.Uma isikhathi sesenzo siqhubeka, ama-pores amakhulu.

I-foil esetshenziselwa ucezu lwesigxobo sebhethri ye-lithium ngokuvamile i-foil eyodwa enguziro enogqinsi luka-10 μm, ethambekele kakhulu ekubhobozeni izimbobo ngenxa yezinkinga zenqubo yokuhlanza.

2. Ukusetshenziswa kwesisombululo se-ethanol njenge-ejenti yokuhlanza akulula nje ukudala umonakalo kwezinye izingxenye zebhethri ye-lithium, kodwa futhi kujwayele "i-hydrogen embrittlement", ethinta izakhiwo zemishini ye-aluminium foil.

3. Nakuba umphumela wokuhlanza mubi kakhulu kunowokuhlanzwa kwamakhemikhali amanzi ngokwesiko, ukuhlanzeka akukabi kuhle njengalokho okuhlanzwa nge-laser.Ngezinye izikhathi kusekhona ukungcola ebusweni, okuzokwenza ukuthi ukumboza kuhlukane ne-foil noma kukhiqize izimbobo zokuncipha.

Njengokuhlanza okomile ngaphandle kwezinto ezisetshenziswayo, ukuhlanzwa nge-laser kusondele ku-zero amaphutha ngokuya ngenhlanzeko kanye ne-hydrophilicity yokwelashwa okungaphezulu kwe-aluminium foil, okuqinisekisa umphumela wokulinganisa nokumboza esiqeshini sesigxobo ngezinga elikhulu kakhulu.

Ukusetshenziswa kwe-laser yokuhlanza insimbi yensimbi akukwazi nje ukuthuthukisa ukusebenza kahle kwenqubo yokuhlanza futhi kulondoloze izinsiza zokuhlanza, kodwa futhi kusungule ukuqapha kwesikhathi sangempela kwedatha yenqubo yokuhlanza kanye nokunqunywa kwenani lemiphumela yokuhlanza, engathuthukisa ngempumelelo ukuvumelana kokukhiqizwa kwe-batch. izingcezu zesigxobo.

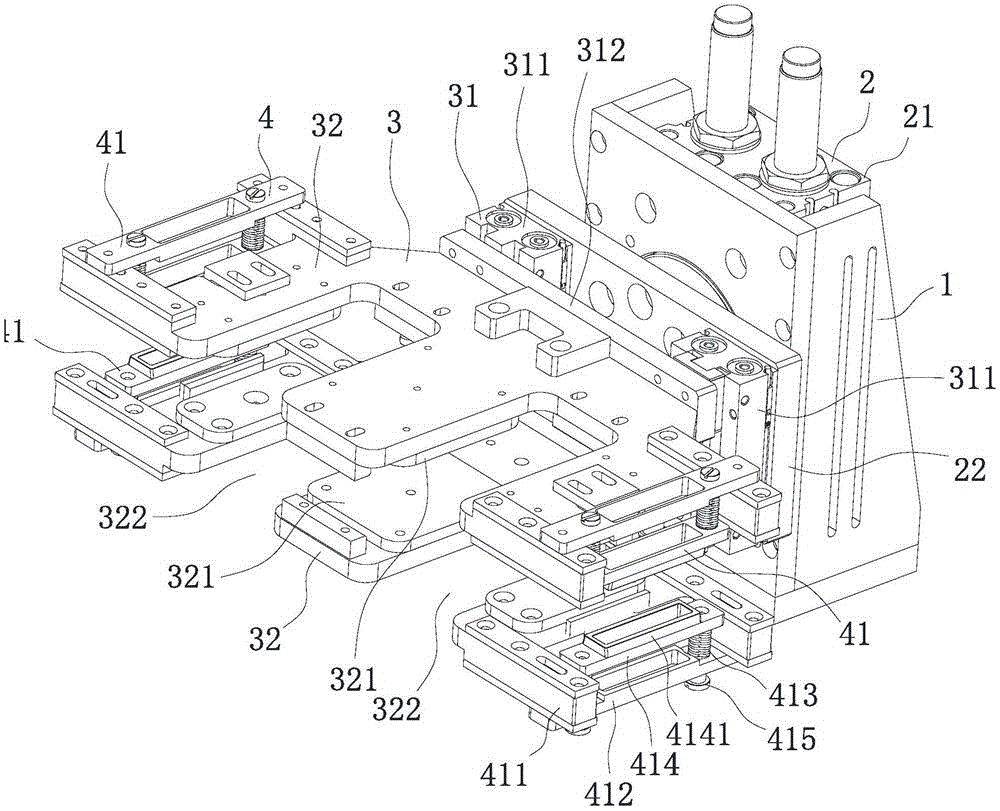

2. Ukuhlanzwa nge-laser kwamathebhu ebhethri ngaphambi kokushisela

Amathebhu ayizicucu zensimbi eziholela ngaphandle kwama-electrode ephozithivu nenegethivu kuseli yebhethri, futhi ayizindawo zokuxhumana lapho ibhethri lishajwa futhi likhishwa.Ukungcola okungaphezulu okunjengamafutha, ama-corrosion inhibitors nezinye izinhlanganisela enqubweni kungabangela izinkinga ezifana nokushisela okubi, ukuqhekeka kanye ne-porosity ekushiseleni.

Ukuhlanzeka kwendawo yokuxhumana kungathinta kakhulu ukuthembeka nokuqina kokuxhumeka kukagesi.

Ukuhlanza okukhona kwe-electrode ikakhulukazi kusebenzisa ukuhlanzwa ngesandla, ukuhlanzwa kwamakhemikhali amanzi noma ukuhlanzwa kwe-plasma:

● Ukuhlanza mathupha akuphumelelanga futhi kubiza;

● Nakuba umugqa wokuhlanza amanzi wenqubo emanzi uthuthukisa ukusebenza kahle, ubude bomugqa bude, buthatha indawo enkulu yefektri, futhi i-ejenti yamakhemikhali nayo kulula ukulimaza ezinye izingxenye zebhethri ye-lithium;

● Nakuba ukuhlanzwa kwe-plasma kungadingi i-liquid medium, kudinga futhi igesi yenqubo njengento esebenzisekayo, futhi i-ionization yegesi izobangela ukuthi ama-electrode aqondile noma angalungile ebhethri avulwe kalula.Uma ufaka isicelo, kuvame ukudingekile ukuba uphenye ibhethri izikhathi ezimbalwa ukuze uhlukanise ama-electrode aqondile noma angalungile ukuze ahlanzwe.Ukusebenza kwangempela Hhayi phezulu.

Ukuhlanza i-laser kungasusa ngempumelelo ukungcola, uthuli, njll. ekupheleni kwesigxobo sebhethri, futhi ulungiselele ukushiselwa kwebhethri kusengaphambili.

Ngenxa yokuthi ukuhlanza nge-laser akudingi izinto ezisetshenziswayo ezifana nokuqinile, uketshezi kanye negesi, isakhiwo sihlangene, indawo ehlala kuyo incane, futhi umphumela wokuhlanza uyamangalisa, ongathuthukisa kakhulu umjikelezo wokukhiqiza futhi unciphise izindleko zokukhiqiza;

Ingaqinisa indawo yokushisela ngesisekelo sokususa ngokuphelele izinto eziphilayo kanye nezinhlayiya ezincane, futhi ithuthukise ukwethembeka kokushisela kwe-laser okulandelayo.Kungenye yezinketho ezingcono kakhulu zokuhlanza amathebhu.

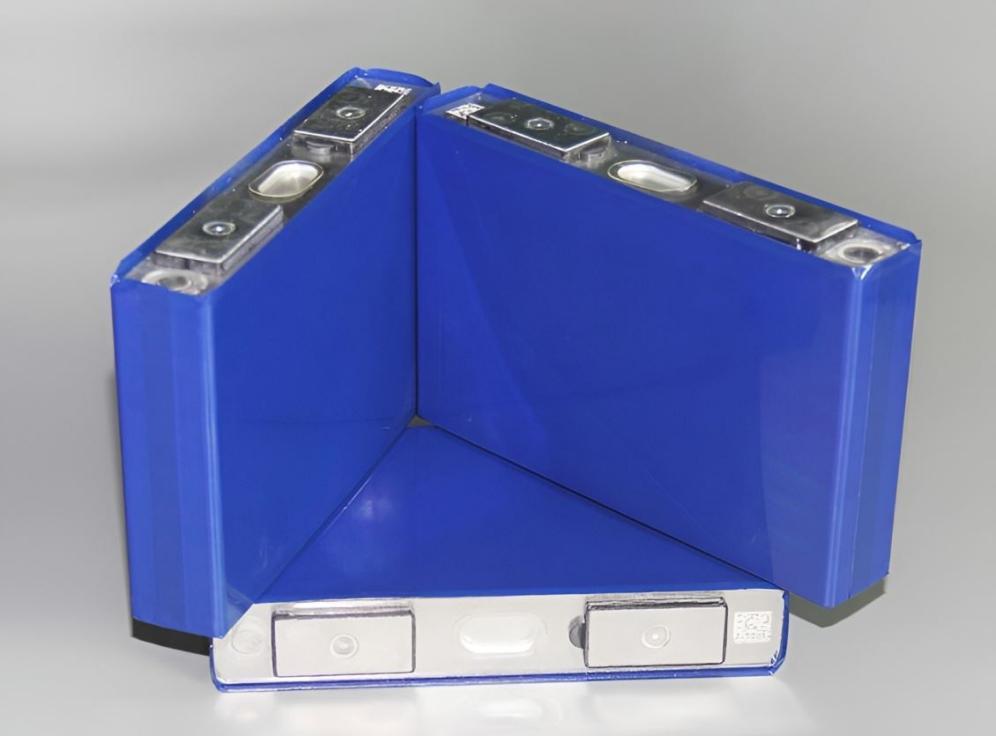

3. Ukuhlanzwa kwe-adhesive yangaphandle ngesikhathi somhlangano

Ukuze uvimbele izingozi zokuphepha zamabhethri e-lithium, ngokuvamile kuyadingeka ukufaka iglue kumaseli ebhethri ye-lithium ukuze udlale indima yokuvikela, ukuvimbela ama-circuits amafushane, ukuvikela amasekhethi, nokuvimbela imihuzuko.

Lapho ifilimu yangaphandle yeseli engcolile ihlolwe yi-CCD, kuyoba khona imibimbi, ama-bubbles emoyeni, imihuzuko nezinye iziphambeko ekubukeni, futhi ama-bubbles emoyeni ane-diameter ye-≥ 0.3mm ngokuvamile angatholakala.Kukhona ithuba lokuvuza nokugqwala, okunciphisa impilo yebhethri futhi kube nezingozi ezingaba khona zokuphepha.

Ukuhlanza i-laseringafinyelela izinga le-Sa3 ekhonweni lokuhlanza lendawo yeseli, futhi izinga lokususa lingaphezu kuka-99.9%;futhi akukho ukucindezeleka ebusweni beseli.Uma kuqhathaniswa nezinye izindlela zokuhlanza ezifana nokuhlanza i-ultrasonic noma ukugaya ngomshini, kungaqinisekisa ukuthi izinkomba ezingokwenyama namakhemikhali ezifana nokuqina kobuso bamaseli ebhethri akuguquki ngezinga elikhulu kakhulu. , futhi andise impilo yesevisi yebhethri.

Ngaphezu kwalezi zibonelo ezishiwo ngenhla, ukuhlanzwa nge-laser nakho kunezinzuzo ezinhle ezihlukile kwezinye izinqubo eziyishumi nambili ezifana nokususwa kopende wekhava yebhethri ye-electrophoretic kanye nokuhlanza ilebula le-foil.

Uma ufuna ukufunda okwengeziwe mayelana nokuhlanza i-laser, noma ufuna ukukuthengela umshini wokuhlanza we-laser ongcono kakhulu, sicela ushiye umlayezo kuwebhusayithi yethu futhi usithumele i-imeyili ngokuqondile!

Isikhathi sokuthumela: Oct-19-2022