Fortune Laser Handheld Fiber Laser Welding Machine

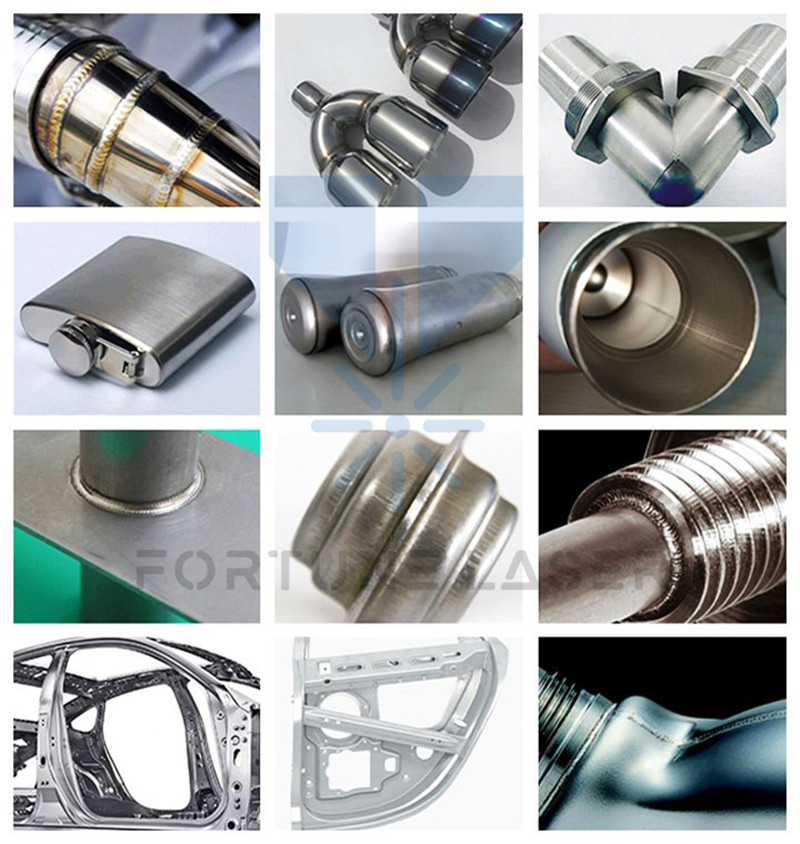

Umshini wokushisela we-laser ophathwa ngesandla, obizwa nangokuthi i-Portable Handheld Laser Welder, iyisizukulwane esisha semishini yokushisela i-laser, okungeye-non-contact welding. Inqubo yokusebenza ayidingi ingcindezi. Umgomo wokusebenza uwukukhanyisa ngokuqondile isigxobo se-laser esinamandla amakhulu phezu kwezinto ezibonakalayo ngokusebenzisana kwe-laser nezinto ezibonakalayo. Impahla iyancibilika ngaphakathi, bese ipholiswa futhi ifakwe ngamakristalu ukwenza i-weld.

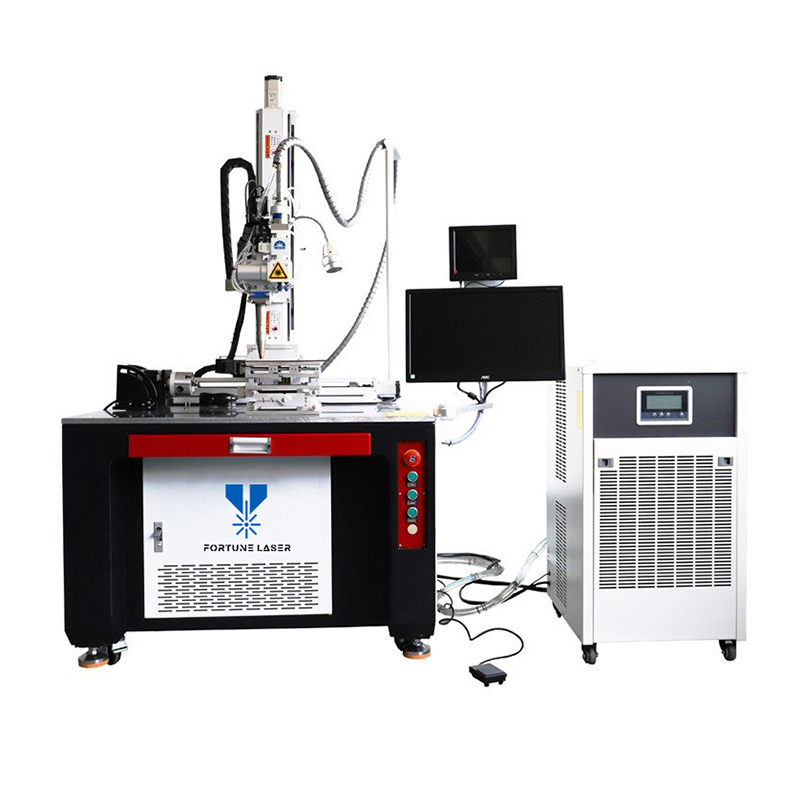

Umshini wokushisela we-Laser oqhubekayo

I-Fortune Laser eqhubekayo yomshini wokushisela i-fiber CW laser welding ihlanganisa umzimba wokushisela, ithebula elisebenzayo lokushisela, i-chiller yamanzi kanye nesistimu yesilawuli njll. Lolu chungechunge lwemishini luyizikhathi ezingu-3-5 zejubane kunomshini wokushisela we-laser optical optical transmission wendabuko. Ingakwazi ukushisela ngokunembile isicaba, isiyingi, imikhiqizo yohlobo lomugqa kanye nemigqa yokukhiqiza eyenziwe ngokwezifiso engajwayelekile.

Ubucwebe be-Mini Spot Laser Welder 60W 100W

Le 60W 100W YAG mini spot laser welder, ebuye yaziwa njengomshini ophathwayo we-laser soldering wobucwebe, ithuthukiswe ngokukhethekile ukushisela ubucwebe nge-laser, futhi isetshenziswa kakhulu ekubhobozeni nasekushiseleni amabala ubucwebe begolide nobusiliva. I-laser spot welding iyisici esibalulekile sohlelo lokusebenza lobuchwepheshe be-laser.

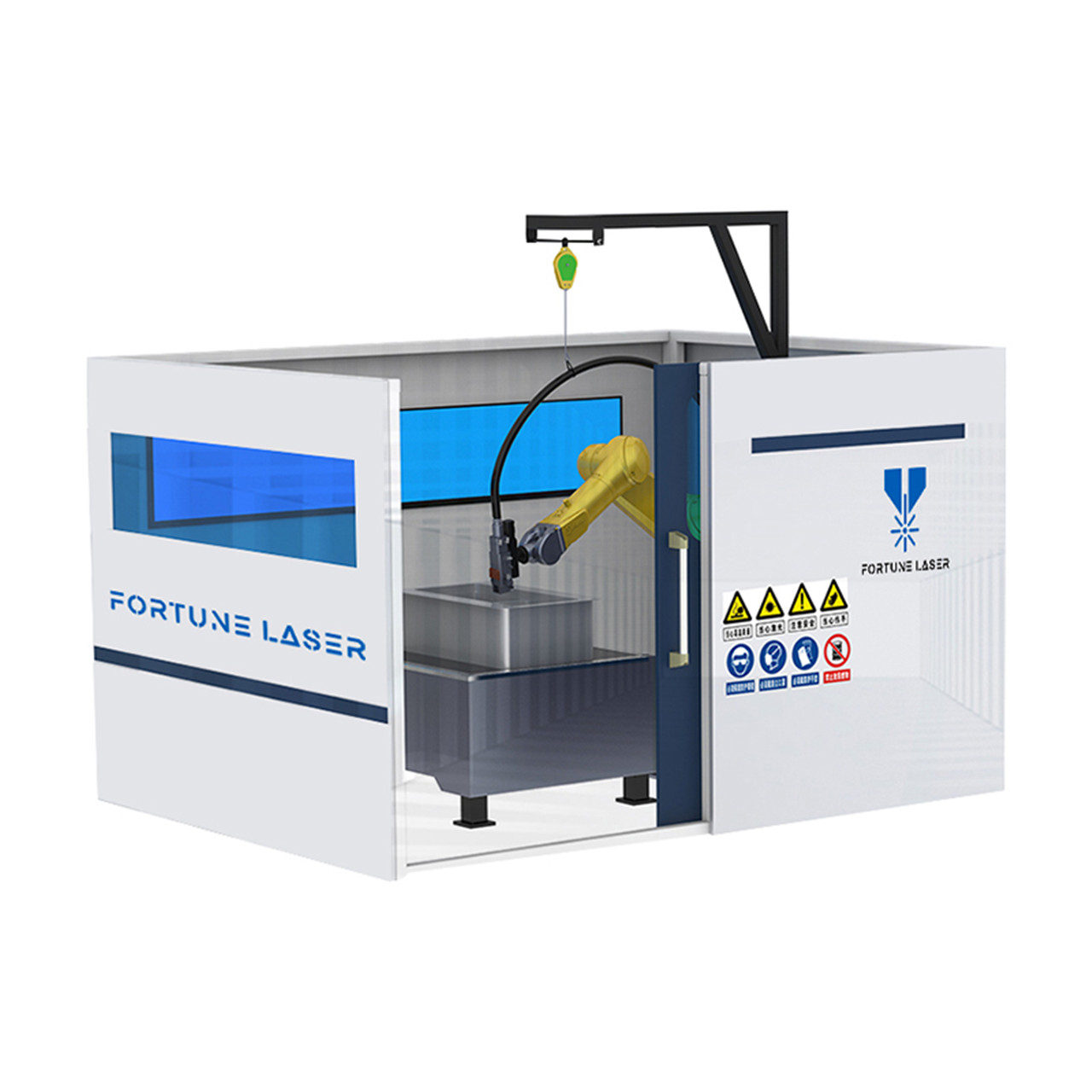

I-Robotic Fiber Laser Welding Machine

Umshini wokushisela i-Fortune Laser irobhothi we-laser wakhiwe ngekhanda elizinikele le-fiber laser, uhlelo lokulandela umthamo olunembe kakhulu, i-fiber laser kanye nesistimu yerobhothi yezimboni. Kuyimishini ethuthukisiwe yokushisela okuguquguqukayo kwamashidi ensimbi anobukhulu obuhlukahlukene ukusuka kuma-engeli amaningi kanye nezinkomba eziningi.

Inhlanganisela ye-laser welding namarobhothi inezinzuzo zokuzenzakalela, ubuhlakani, kanye nokuguquguquka okuphezulu, futhi ingasetshenziselwa ukushisela izinto ezingaphezulu eziyinkimbinkimbi.