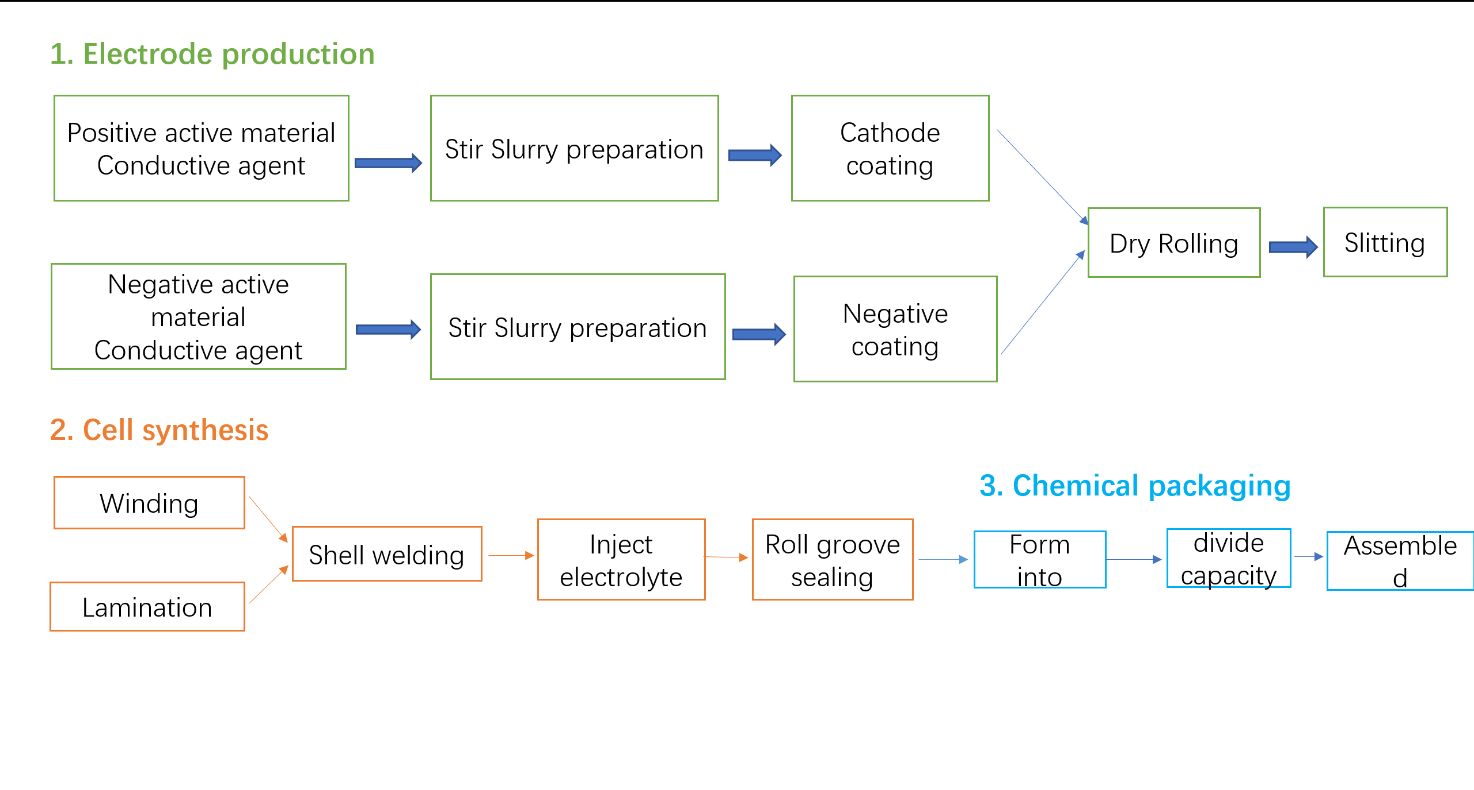

Imveliso yeiibhetri ze-lithiumyinkqubo “yokuqengqeleka”.Nokuba ibhetri ye-lithium ye-iron phosphate, ibhetri ye-sodium-ion okanye ibhetri ye-ternary, kufuneka ihambe ngenkqubo yokucubungula ukusuka kwifilimu encinci ukuya kwibhetri enye, kwaye emva koko iye kwinkqubo yebhetri.Inkqubo yokulungiswa kweebhetri ze-lithium inokwahlulwa ngokufanelekileyo ngokwezigaba ezintathu: ukuveliswa kweshidi le-electrode, i-cell synthesis, kunye nokupakishwa kweekhemikhali.

Kukho iinkqubo ezininzi eziphambili kwezi zintathu iinkqubo ezinkulu, eziza kuchaphazela ngqo amandla okugcina amandla ebhetri, ukhuseleko lwemveliso kunye nobomi benkonzo.Ke ngoko, ukusebenza kweebhetri eziveliswe ziinkqubo ezahlukeneyo zokuvelisa ziyahluka kakhulu.Kwezi linki,ukucoca ngelaserngoku unokuthatha inxaxheba kwiinkqubo ezingaphezu kweshumi elinesibini zokulungiselela, ezinokuthi ziphucule kakhulu izinga lomgangatho weebhetri ze-lithium.

| Inkqubo yokusetyenziswa kwe-laser yokucoca kwibhetri yamandla | |||

| Icandelo langaphambili lebhetri | Icandelo leseli | Icandelo lemodyuli | PACK ibhetri pack |

| Ukucoca ipali | Ukutywinwa kokucoca iinzipho | Ukucoca ipali | I-Pallet CMT Weld Seam Cleaning |

| Ukucoca ngaphambi kokuqengqeleka | Ukucoca iithebhu ngaphambi kokuba i-soldering | Ukucoca ifilimu yeseli eluhlaza | Ukugubungela ipleyiti yokucoca ipeyinti ye-electrophoretic |

| Ukucoca emva kokuqengqeleka | Ukucoca iSeli yeSilicone | IKhabhinethi sealant oxide umaleko ukucoca | |

| Ukucocwa kokwaleka kweeseli | Ukucocwa kwe-oxide yepleyiti esezantsi ekhuselayo phambi kwe-welding | ||

| Ukucoca umngxuma wokutofa | I-Foil Label Cleaning | ||

| ukucocwa kwebhasi | |||

Njengoko imfuno yeebhetri zamandla iqhubeka ukwanda, imfuno yeukucoca ngelaserizixhobo nazo ziya kwanda.Emva koko, siya kugxininisa kwezinye iinkqubo zesicelo kunye neenzuzo zokuthelekisa.

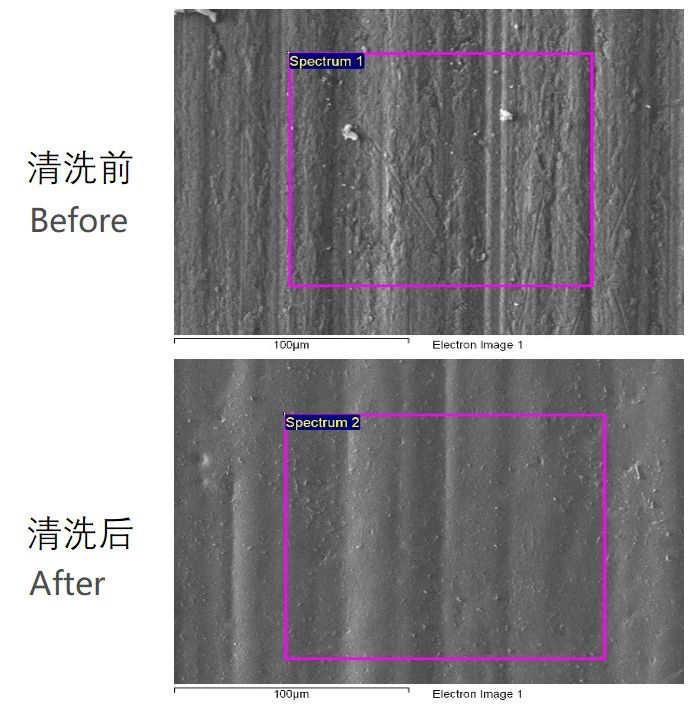

1. Ukucocwa kwelaser yobhedu kunye nefoyile yealuminiyam phambi kokwalekwa kwesiqwenga sepali

I-electrodes efanelekileyo kunye ne-negative yebhetri ye-lithium yenziwa ngokugubungela i-electrodes efanelekileyo kunye ne-negative ye-lithium ibhetri kwi-aluminium foil kunye ne-copper foil.Ukuba iinqununu, i-debris, uthuli kunye nezinye imidiya zixutywe kwinkqubo yokugqoka, iya kubangela i-micro-short circuit ngaphakathi kwebhetri, kwaye kwiimeko ezinzima, ibhetri iya kubamba umlilo kwaye iqhume.

Ngoko ke, i-foil idinga ukucocwa ngaphambi kokuba ifakwe ukuze ifumane indawo ecocekileyo, engena-oxide.

Iziqwenga ezisele zikhona zebhetri zicocwa ngokubanzi ngamaza e-ultrasonic, kwaye isisombululo se-ethanol sisetyenziselwa ukucoca njengenkqubo yokucoca ngaphambi kokugubungela.Le ndlela ineziphene zilandelayo:

1. Xa i-ultrasonically ihlambulula iinxalenye ze-foil zetsimbi, ngokukodwa i-aluminium alloy workpieces, echaphazelekayo ngokuphindaphindiweyo, ixesha lokucoca kunye namandla, i-cavitation effect yamaza e-ultrasonic angakwazi ukugqwesa ngokulula i-aluminium foil, ebangela ukuba iipores ezintle.Ixesha elide lesenzo, i-pores inkulu.

I-foil esetyenziselwa i-lithium ibhetri ye-pole piece ngokubanzi i-foil ye-zero enye kunye nobukhulu be-10 μm, ethandwa kakhulu ukukrazula kwimingxuma ngenxa yeengxaki zenkqubo yokucoca.

2. Ukusetyenziswa kwesisombululo se-ethanol njenge-ejenti yokucoca akulula nje ukwenza umonakalo kwezinye iindawo zebhetri ye-lithium, kodwa kwakhona kuxhomekeke "kwi-hydrogen embrittlement", echaphazela iimpawu zomatshini we-aluminium foil.

3. Nangona umphumo wokucoca ubi kakhulu kunokucoca iikhemikhali ezimanzi zendabuko, ukucoceka akukabi kuhle njengokucoca nge-laser.Ngamanye amaxesha kusekho ukungcola phezu komhlaba, okuya kubangela ukuba i-coating ihluke kwi-foil okanye ivelise imingxuma yokunciphisa.

Njengokucoca okomileyo ngaphandle kwezinto ezisetyenziswayo, ukucocwa kwelaser kusondele kwiziphene zero malunga nokucoceka kunye ne-hydrophilicity yonyango lomphezulu wefoyile ye-aluminium, iqinisekisa isiphumo sokulinganisa kunye nokugquma kwisiqwenga sepali ukuya kuthi ga kwinqanaba elikhulu.

Ukusetyenziswa kwe-laser yokucoca i-foil yensimbi ayinakuphucula kuphela ukusebenza kwenkqubo yokucoca kunye nokugcina izixhobo zokucoca, kodwa kwakhona ukuseka iliso lexesha langempela ledatha yenkqubo yokucoca kunye nokuzimisela kobungakanani beziphumo zokucoca, ezinokuphucula ngokufanelekileyo ukuhambelana kwemveliso yebhetshi. iziqwenga zepali.

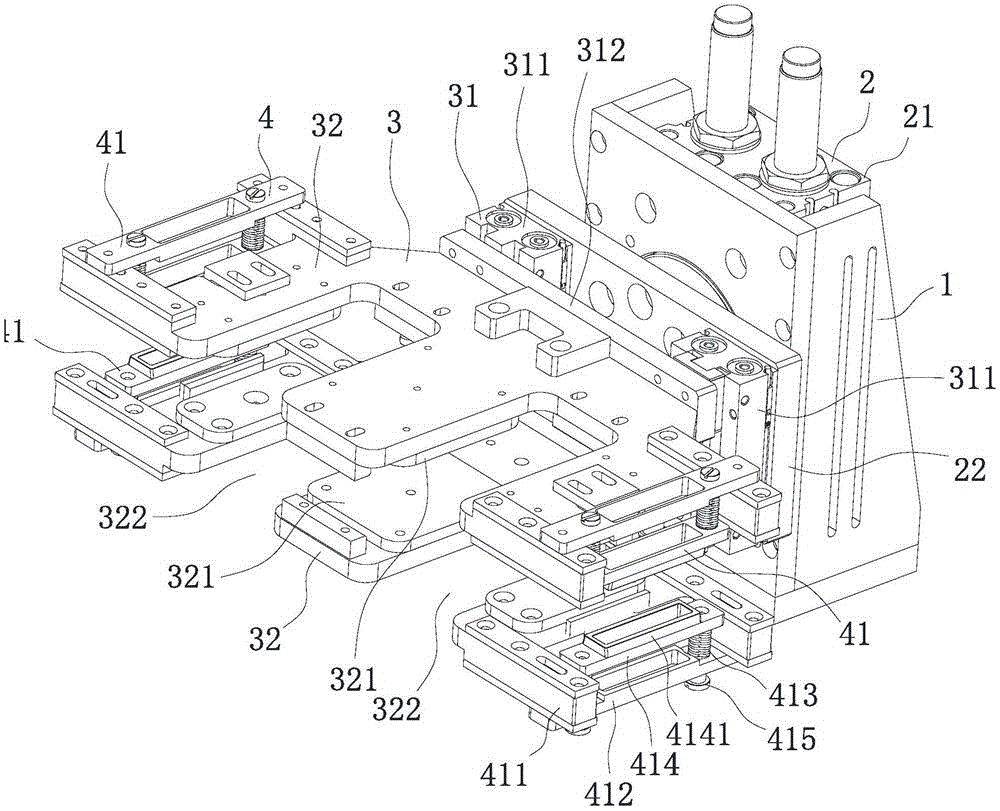

2. Ukucocwa kwelaser kwiithebhu zebhetri phambi kwewelding

Iithebhu zizicwe zentsimbi ezikhokelela ngaphandle kwe-electrode ekhayo kunye ne-negative kwiseli yebhetri, kwaye ziindawo zoqhagamshelwano xa ibhetri itshajiwe kwaye ikhutshwa.Ungcoliseko oluphezulu olufana negrisi, i-corrosion inhibitors kunye nezinye iikhompawundi kwinkqubo zinokubangela iingxaki ezinjenge-welds embi, ii-cracks kunye ne-porosity kwi-weld.

Ukucoceka kwendawo yokudibanisa kunokuchaphazela kakhulu ukuthembeka kunye nokuqina koxhumo lombane.

Ukucocwa kwe-electrode ekhoyo kusetyenziswa ukucoca ngesandla, ukucocwa kweekhemikhali ezimanzi okanye ukucocwa kweplasma:

● Ukucoca ngesandla akuphumelelanga kwaye kuyabiza;

● Nangona inkqubo emanzi yokucoca umgca wokucoca amanzi iphucula ukusebenza kakuhle, ubude bomgca bude, buhlala kwindawo enkulu yefektri, kwaye i-agent yekhemikhali nayo ilula ukuyonakalisa ezinye iindawo zebhetri ze-lithium;

● Nangona ukucocwa kweplasma kungafuneki i-medium liquid, ifuna kwakhona i-gas yenkqubo njengento esetyenziswayo, kunye ne-ionization yegesi iya kubangela ukuba i-electrode efanelekileyo kunye ne-negative yebhetri ivuleke ngokulula.Xa ufaka isicelo, kuye kufuneke ukuba ujike ibhetri amaxesha amaninzi ukwahlula ii-electrode ezilungileyo nezingalunganga zokucoca.Obona buchule Abukho phezulu.

Ukucocwa kweLaser kunokususa ngokufanelekileyo ukungcola, uthuli, njl njl kwisiphelo sobuso bepali yebhetri, kwaye ulungiselele ukuwelda ibhetri kwangaphambili.

Ngenxa yokuba ukucocwa kwe-laser akufuni naziphi na izinto ezisetyenziswayo ezinjengokuqina, ulwelo kunye negesi, isakhiwo sinobumbano, indawo ehlala kuyo incinci, kwaye umphumo wokucoca uyamangalisa, unokuphucula kakhulu umjikelezo wemveliso kunye nokunciphisa iindleko zokuvelisa;

Iyakwazi ukwenza i-roughen ye-welding surface ngesiseko sokususa ngokucokisekileyo i-organic matter kunye namasuntswana amancinci, kunye nokuphucula ukuthembeka kwe-laser welding elandelayo.Ngolunye ukhetho olungcono lokucoca ithebhu.

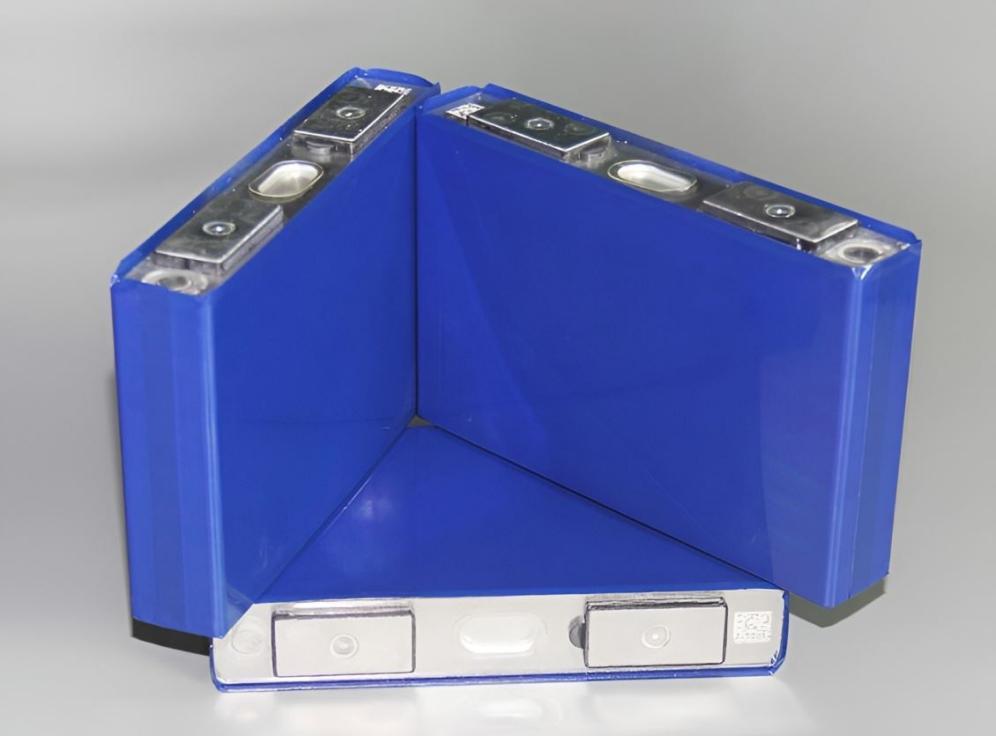

3. Ukucocwa kwe-adhesive yangaphandle ngexesha lokuhlanganisa

Ukuze kuthintelwe iingozi zokhuseleko lweebhetri ze-lithium, ngokuqhelekileyo kuyimfuneko ukusebenzisa i-glue kwiiseli zebhetri ze-lithium ukuze zidlale indima yokukhusela, ukukhusela imijikelezo emfutshane, ukukhusela iisekethe, kunye nokuthintela imikrwelo.

Xa ifilimu yangaphandle yeseli engahlambulukanga ivavanywa yiCCD, kuya kubakho imibimbi, iibhubhu zomoya, imikrwelo kunye nezinye iziphene ngokubonakala, kunye neebhubhu zomoya ezinobubanzi be-≥ 0.3mm zihlala zibonwa.Kukho ithuba lokuvuza kunye nomhlwa, okunciphisa ubomi bebhetri kwaye kunobungozi obunokubakho bokhuseleko.

Ukucocwa kweLaserinokufikelela kwinqanaba le-Sa3 kwikhono lokucoca indawo yeseli, kwaye izinga lokususa lingaphezulu kwe-99.9%;kwaye akukho xinzelelo kumphezulu weseli.Xa kuthelekiswa nezinye iindlela zokucoca ezifana nokucocwa kwe-ultrasonic okanye ukugaya ngomatshini, kunokuqinisekisa ukuba izibonakaliso ezibonakalayo kunye neekhemikhali ezifana nobunzima bomhlaba weeseli zebhetri azitshintshi ukuya kwinqanaba elikhulu. , kunye nokwandisa ubomi benkonzo yebhetri.

Ukongeza kule mizekelo ikhankanyiweyo ngasentla, ukucocwa kwelaser kukwanoncedo olukhulu kwezinye iinkqubo ezilishumi elinesibini ezinje ngebhetri ukususwa kwepeyinti ye-electrophoretic kunye nokucoca iileyibhile.

Ukuba ufuna ukufunda ngakumbi malunga nokucoca i-laser, okanye ufuna ukukuthengela umatshini wokucoca i-laser, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngqo!

Ixesha lokuposa: Oct-19-2022