I-Fortune Laser Mini 1000W/1500W/2000W 3 Kumshini wokushisela we-Fiber Handheld Laser Welding

I-Fortune Laser Mini 1000W/1500W/2000W 3 Kumshini wokushisela we-Fiber Handheld Laser Welding

Ngesikhathi esifanayo, lo mshini omncane we-laser welding wesandla usekela ukusika nokushisela ngesikhathi esifanayo kanye nomshini wokusabalalisa ucingo olujwayelekile, onganciphisa izidingo zokuvunyelwa kwezingxenye futhi uthuthukise ikhwalithi yokushisela. Ingase futhi isetshenziswe ngokuhlanganyela nerobhothi elihlanganyelwe ukulungisa ithoshi yokushisela irobhothi elihlanganyelwe, ukunciphisa amandla okusebenza komsebenzisi kanye nokuthuthukisa ikhwalithi yokushisela ye-weld.

1000W 1500w 2000w 3000W Mini Laser Welding Machine Inzuzo

Umklamo we-chassis we-in-one ulungile

Umshini wokushisela i-fiber laser we-Fortunelaser ophethwe ngesandla usebenzisa ukwakheka kwekhabhinethi edidiyelwe, ehlanganisa i-laser, i-chiller, isilawuli sesofthiwe, njll., futhi inezinzuzo zonyawo oluncane, ukunyakaza okulula, nokusebenza okuqinile.

Esikhundleni sokuthi "indlela yokubona engaguquki", ukusebenza kulula kakhulu.

Manje i-welding ebanjwe ngesandla, isebenzisa isibhamu sokushisela esibanjwe ngesandla ukuze sithathe indawo yendlela engaguquki ye-optical, ukusebenza kulula kakhulu, ukuphula imingcele ye-workbench, ukuhlangabezana nokushiswa kwama-engeli ahlukahlukene kanye nezikhundla. Ngaphezu kwalokho, indawo ye-infrared isetshenziselwa ukubeka okunembe kakhudlwana nokulinganisa indawo yokushisela ukuze kuqinisekiswe ukushisela okuhle kakhulu.

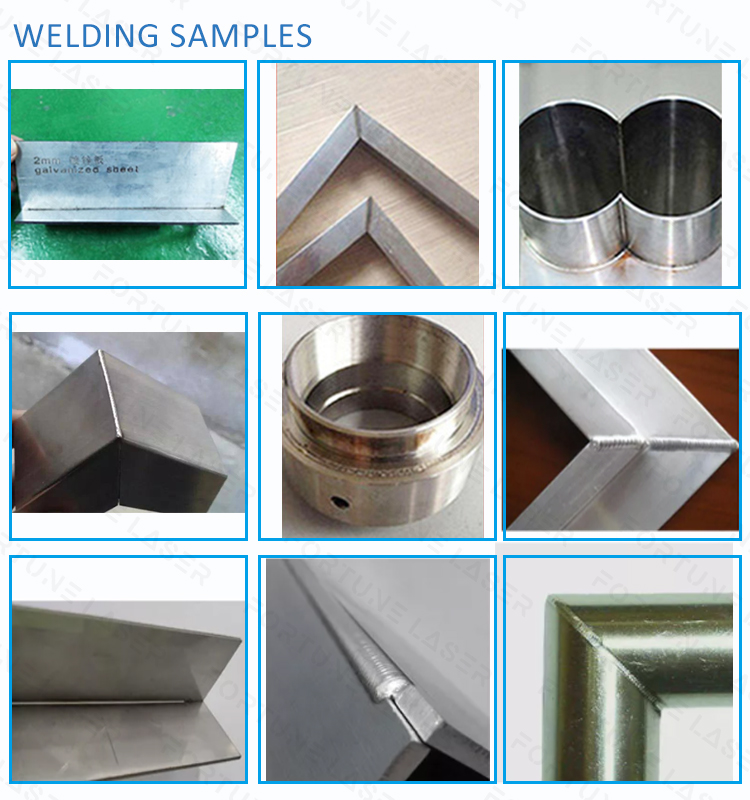

I-deformation encane yokushisa, i-weld ebushelelezi futhi enhle

Siyabona ukuthi umthungo wokushisela womshini wokushisela we-laser ophethwe ngesandla ushelela futhi muhle, i-welding workpiece ayinakho ukuguquguquka, asikho isibazi sokushisela, futhi ukushisela kuqinile, kunciphisa inqubo yokugaya elandelayo, ukonga isikhathi nezindleko. I-welding yendabuko inzima ukufeza ubuhle be-welding ye-workpieces eyinkimbinkimbi, kuyilapho i-welding ebanjwe ngesandla ingafinyelela ama-engeli alungile, amakhona ayindilinga kanye nezindlela eziningi zokushisela, okwenza ukushisela kube lula.

Ukujula kokushisela kukhulu futhi ukushisela kuqinile

Umshini wokushisela we-laser ophethwe ngesandla usetshenziselwa ikakhulukazi ukushisela i-laser yezindawo ezikude nezinkulu zokusebenza. Indawo ethinteke ukushisa ngesikhathi sokushisela incane, engeke ibangele ukuguqulwa komsebenzi, i-blackening, kanye nemikhondo ngemuva. Ukujula kwe-welding kukhulu, i-welding iqinile, futhi ukuncibilika kwanele.

Umshini owodwa usekela imisebenzi emithathu yokushisela, ukusika nokuhlanza

Ukuguqulwa kwemisebenzi emi-3 kungenziwa kuphela ngekhanda le-laser.

I-Fortune Laser Mini Laser Welding Machine Imingcele Yezobuchwepheshe

| Imodeli | FL-HW1000M | FL-HW1500M | FL-HW2000M |

| Laser Amandla | 1000W | 1500W | 2000W |

| Indlela Yokupholisa | Ukupholisa Amanzi | Ukupholisa Amanzi | Ukupholisa Amanzi |

| I-LaserWubude | 1080nm | 1080nm | 1080nm |

| Way Yokusebenza | Cokuqhubekayo/ Ukuguquguquka | ||

| Ubude be-Fiber | U-10m ojwayelekile, ubude obenziwe ngezifiso ubude bungu-15m | ||

| Ubukhulu | 100*68*45cm | ||

| Wayisishiyagalombili | 165kg | ||

| Izinketho | Iyaphatheka | ||

| Ububanzi besivinini se-welder | 0-120mm/s | ||

| Izinga lokushisa | 15-35 ℃ | ||

| I-Voltage yokusebenza | I-AV 220V | ||

| I-Focal Spot Diameter | 0.5mm | ||

| Welding ukujiya | 0.5-5mm | ||

Izici

l Izici eziyisisekelo: isistimu yokulawula emithathu-in-one eyakhiwe ngokwayo, ukushintsha okuguquguqukayo kwe-welding, ukuhlanza, nokusika, ama-alamu amaningi okuphepha, ukusebenza okulula nokuguquguqukayo.

l Ukuzinza okwengeziwe: Yonke imingcele iyabonakala, ukuqapha ngesikhathi sangempela isimo somshini wonke, ukugwema izinkinga kusengaphambili, ukwenza lula ukuxazulula izinkinga nokuxazulula izinkinga, nokuqinisekisa ukusebenza okuzinzile kwesistimu.

l Inqubo: Amapharamitha wenqubo angasethwa, futhi imiphumela ehlukahlukene yenqubo ingazanywa ngokuguquguquka.

l Amapharamitha azinzile nokuphindaphinda okuphezulu: Ingcindezi yomoya ye-nozzle enqunyiwe kanye nesimo se-lens, inqobo nje uma amandla e-laser ezinzile, imingcele yenqubo kufanele iphindwe, okuthuthukisa kakhulu ukusebenza kahle.

| I-voltage yokuhlinzeka (V) | 220V±10% AC 50/60Hz |

| Beka imvelo | Iphansi, akukho ukudlidliza nokushaqeka |

| Izinga lokushisa lendawo yokusebenza (℃) | 10 - 40 |

| Umswakama wendawo yokusebenza(%) | <70 |

| Indlela yokupholisa | Ukupholisa amanzi |

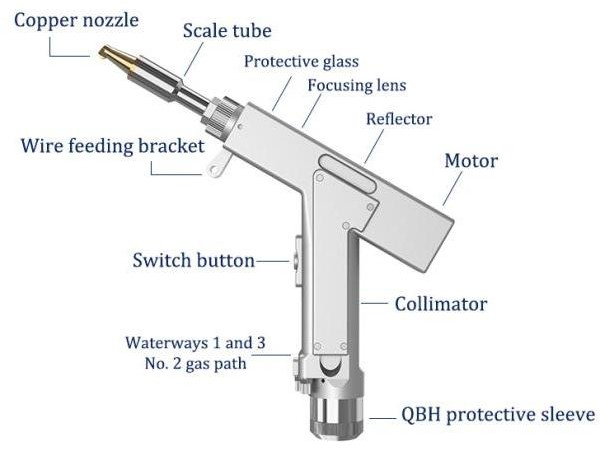

| Ukuhlanganisa | D20*5/F60 |

| Ukugxila (imodi yokushisela ephathwayo) | D20*4.5/F150 |

| Gxila (imodi yokuhlanza) | D20*4.5/F400 |

| Ukuzindla | 30*14 T2 |

| Imininingwane yelensi yokuvikela | 18*2 |

| Umfutho womoya ophezulu osekelwe | 10Ibha |

| Gxila kububanzi bokulungisa obuqondile | ±10mm |

| Ibanga lokulungiswa kwendawo (imodi yokubamba ngesandla) | 0; 6mm |

| Ibanga lokulungiswa kwendawo (imodi yokuhlanza) | 0 ~ 50mm |