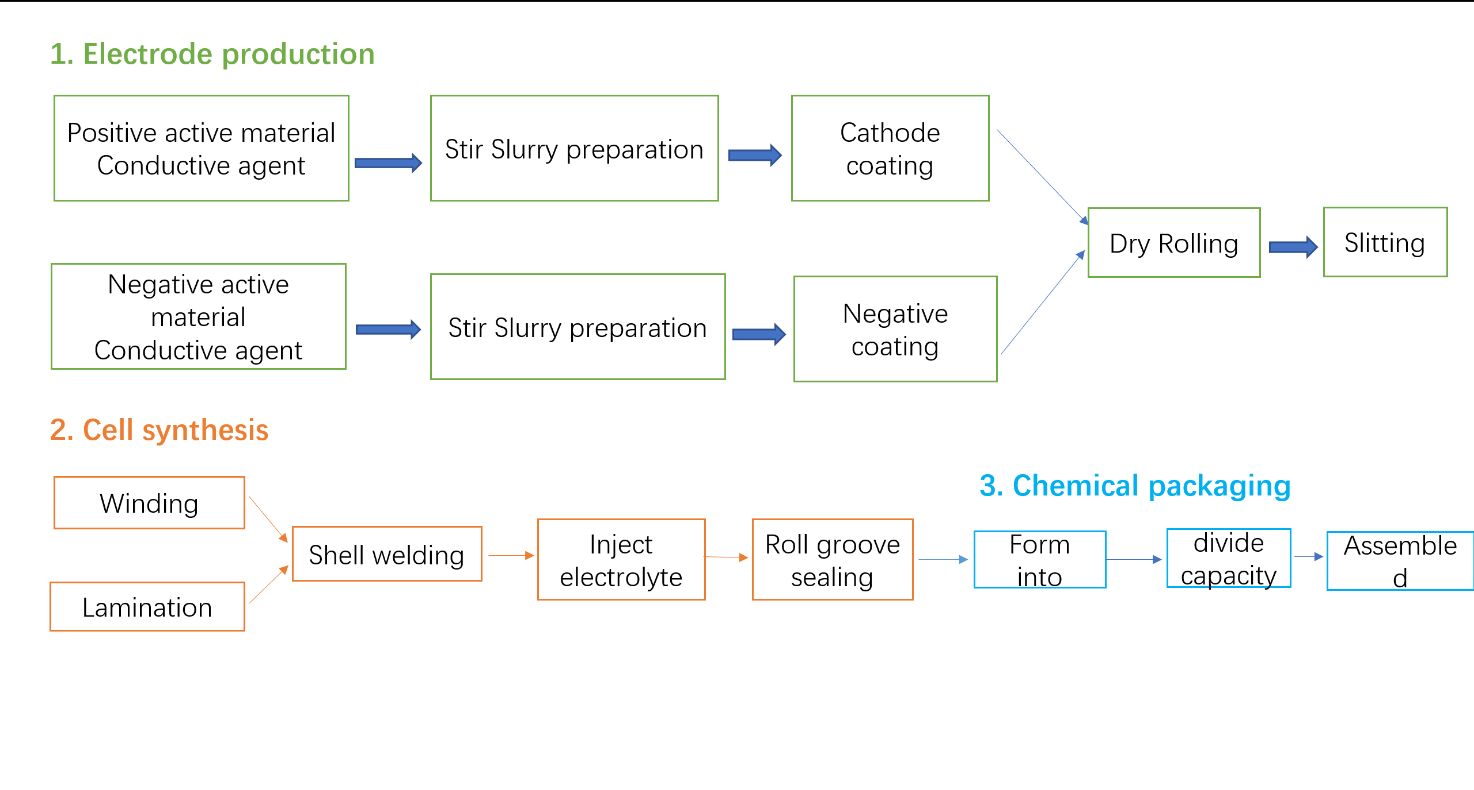

Ukukhiqizwa kweamabhethri e-lithiumkuyinqubo "yokugoqa-ukugoqa". Kungakhathaliseki ukuthi ibhethri le-lithium iron phosphate, ibhethri le-sodium-ion noma ibhethri le-ternary, idinga ukudlula enkambisweni yokucubungula kusukela kufilimu encane kuya kubhethri elilodwa, bese kuba uhlelo lwebhethri. Inqubo yokulungiselela amabhethri e-lithium ingahlukaniswa cishe ngezigaba ezintathu: ukukhiqizwa kweshidi le-electrode, ukwenziwa kwamaseli, kanye nokupakishwa kwamakhemikhali.

Kunezinqubo eziningana ezibalulekile kulezi zinqubo ezintathu ezinkulu, ezizothinta ngqo amandla okugcina amandla ebhethri, ukuphepha komkhiqizo kanye nempilo yesevisi. Ngakho-ke, ukusebenza kwamabhethri akhiqizwa yizinqubo ezahlukene zokukhiqiza kuyahlukahluka kakhulu. Kulezi zixhumanisi,ukuhlanzwa nge-laserokwamanje ingahlanganyela ezinqubweni zokulungiselela ezingaphezu kweshumi nambili, okungathuthukisa kakhulu izinga lekhwalithi yamabhethri e-lithium.

| Inqubo yokufaka isicelo sokuhlanza nge-laser kubhethri lamandla | |||

| Ingxenye engaphambili yebhethri | Ingxenye yeseli | Ingxenye yemojuli | Iphakethe lebhethri |

| Ukuhlanza izinsika | Ukuhlanza izinzipho ngokuvala | Ukuhlanza izinsika | Ukuhlanzwa Komthungo Weld Weld wePallet CMT |

| Ukuhlanza ngaphambi kokugingqa | Ukuhlanza amathebhu ngaphambi kokunamathisela nge-solder | Ukuhlanzwa kwefilimu eluhlaza okwesibhakabhaka kweseli | Ukuhlanza upende nge-electrophoretic plate |

| Ukuhlanza ngemva kokugoqa | Ukuhlanzwa kwe-Silicone Yeseli | Ukuhlanza ungqimba lwe-oxide lwekhabhinethi oluvala amakhabhinethi | |

| Ukuhlanzwa kwesembozo seseli | Ukuhlanzwa kwe-oxide kwepuleti elingaphansi elivikelayo ngaphambi kokushisela | ||

| Ukuhlanza imigodi ngomjovo | Ukuhlanzwa Kwelebula Le-foil | ||

| ukuhlanza ibha yebhasi | |||

Njengoba isidingo samabhethri kagesi siqhubeka nokukhula, isidingoukuhlanzwa nge-laserimishini nayo izokhula. Okulandelayo, sizogxila kwezinye zezinqubo zokufaka isicelo kanye nezinzuzo zokuqhathanisa.

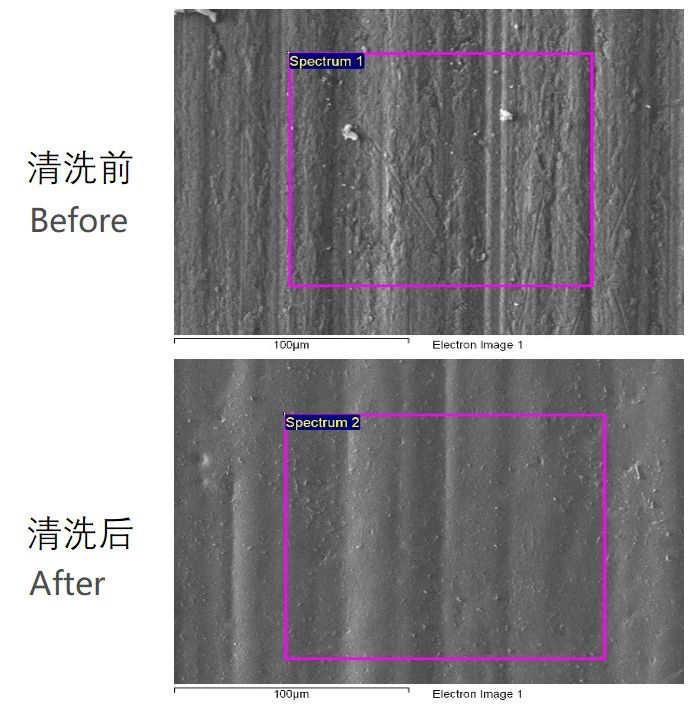

1. Ukuhlanzwa nge-laser kwe-copper kanye ne-aluminium foil ngaphambi kokumbozwa kwezingcezu ze-pole

Ama-electrode amahle nangalungile ebhethri le-lithium enziwa ngokumboza ama-electrode amahle nangalungile ebhethri le-lithium ku-aluminium foil kanye ne-copper foil. Uma izinhlayiya, udoti, uthuli kanye nezinye izinto zixutshwa enkambisweni yokumboza, kuzobangela i-micro-short circuit ngaphakathi kwebhethri, futhi ezimweni ezimbi kakhulu, ibhethri lizosha umlilo liqhume.

Ngakho-ke, i-foil idinga ukuhlanzwa ngaphambi kokumboza ukuze kutholakale indawo ehlanzekile ngokuphelele, engena-oxide.

Izingcezu ze-battery pole ezikhona ngokuvamile zihlanzwa ngamagagasi e-ultrasonic, futhi isixazululo se-ethanol sisetshenziswa njenge-ejenti yokuhlanza njengenqubo yokuhlanza ngaphambi kokumboza. Le ndlela inamaphutha alandelayo:

1. Lapho kuhlanza izingxenye ze-foil yensimbi nge-ultrasonic, ikakhulukazi izingcezu zomsebenzi ze-aluminium alloy, ezithintwa yimvamisa, isikhathi sokuhlanza kanye namandla, umphumela we-cavitation wamagagasi e-ultrasonic ungalimaza kalula i-foil ye-aluminium, okuholela ezimbotsheni ezincane. Uma isikhathi sokusebenza side, kulapho izimbotshana zikhulu khona.

I-foil esetshenziselwa ingxenye ye-lithium battery pole ngokuvamile iyi-foil eyodwa engenalutho enobukhulu obungu-10 μm, okuvame kakhulu ukuqhekeka ibe yimigodi ngenxa yezinkinga zenqubo yokuhlanza.

2. Ukusetshenziswa kwesisombululo se-ethanol njengesihlanzi akugcini nje ngokubanga umonakalo kwezinye izingxenye zebhethri le-lithium, kodwa futhi kuthambekele “ekubhidlikeni kwe-hydrogen”, okuthinta izakhiwo zemishini ze-aluminium foil.

3. Nakuba umphumela wokuhlanza umubi kakhulu kunowokuhlanza amakhemikhali ajwayelekile, ukuhlanzeka akukabi kuhle njengokuhlanza nge-laser. Ngezinye izikhathi kusekhona ukungcola ebusweni, okuzobangela ukuthi ungqimba luhlukane ne-foil noma lukhiqize izimbobo zokuncibilika.

Njengokuhlanza okomile ngaphandle kwezinto ezidliwayo, ukuhlanza nge-laser kucishe kungabi namaphutha maqondana nokuhlanzeka kanye nokunamathela kwamanzi kokwelashwa kobuso be-aluminium foil, okuqinisekisa umphumela wosayizi kanye nokugqoka engxenyeni yesigxobo ngezinga elikhulu.

Ukusetshenziswa kwe-laser cleaning metal foil akugcini nje ngokuthuthukisa ukusebenza kahle kwenqubo yokuhlanza nokusindisa izinsiza zokuhlanza, kodwa futhi kusungula ukuqapha ngesikhathi sangempela kwedatha yenqubo yokuhlanza kanye nokunqunywa kwemiphumela yokuhlanza, okungathuthukisa ngempumelelo ukuhambisana kokukhiqizwa kwenqwaba yezingcezu zezigxobo.

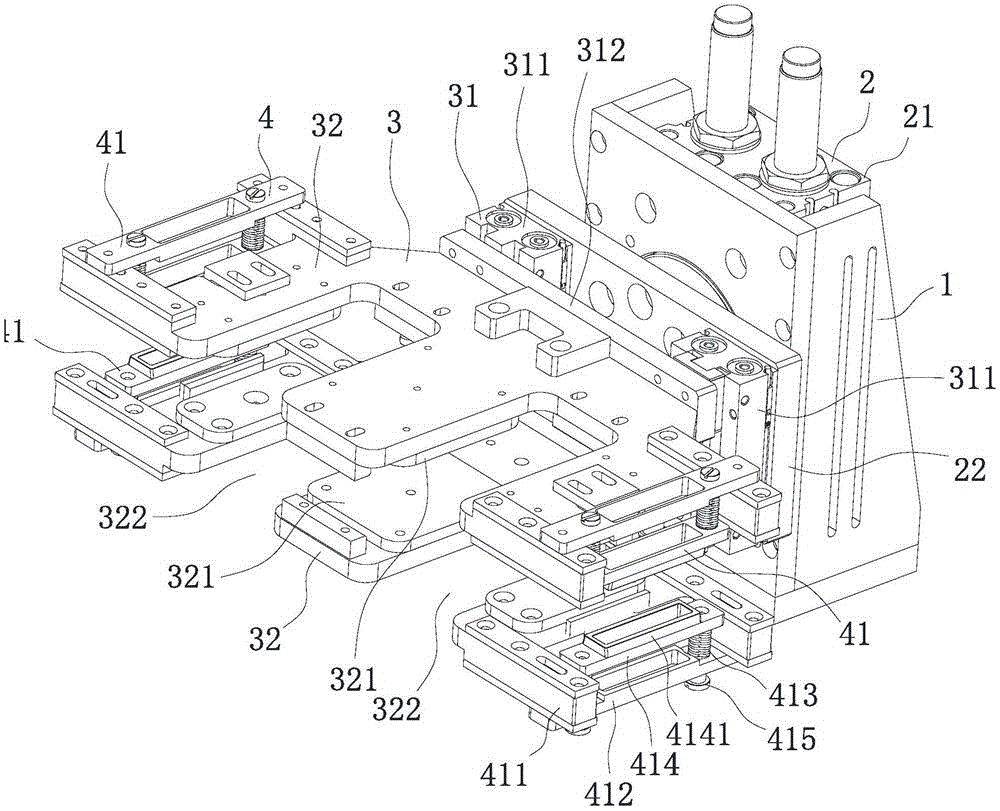

2. Ukuhlanzwa kwamathebhu ebhethri nge-laser ngaphambi kokushisela

Amathebhu ayizicucu zensimbi ezikhipha ama-electrode amahle nangalungile avela kuseli yebhethri, futhi ayizindawo zokuxhumana lapho ibhethri lishajwa futhi likhishwa. Izinto ezingcolisayo ezingaphandle njengegrisi, izithibi zokugqwala kanye nezinye izinto ezisetshenziswayo kule nqubo zingabangela izinkinga ezifana nokushintshwa okungekuhle, imifantu kanye nokuvuleka kwe-weld.

Ukuhlanzeka kwendawo yokuxhumana kungathinta kakhulu ukuthembeka nokuqina koxhumano lukagesi.

Ukuhlanza ama-electrode akhona kusebenzisa kakhulu ukuhlanza ngesandla, ukuhlanza ngamakhemikhali amanzi noma ukuhlanza nge-plasma:

● Ukuhlanza ngezandla akusebenzi kahle futhi kuyabiza;

● Nakuba umugqa wokuhlanza amanzi osebenza ngokumanzi uthuthukisa ukusebenza kahle, ubude bomugqa bude, uhlala endaweni enkulu efektri, futhi i-chemical agent nayo kulula ukuyonakalisa ezinye izingxenye zebhethri le-lithium;

● Nakuba ukuhlanzwa kwe-plasma kungadingi indawo yoketshezi, kudinga negesi yokucubungula njengento esetshenziswayo, futhi i-ionization yegesi izokwenza ukuthi ama-electrode amahle nangalungile ebhethri avulwe kalula. Uma ufaka isicelo, ngokuvamile kuyadingeka ukujika ibhethri izikhathi eziningana ukuze uhlukanise ama-electrode amahle nangalungile okuhlanza. Ukusebenza kahle kwangempela Akuphezulu.

Ukuhlanza nge-laser kungasusa ngempumelelo ukungcola nothuli, njll. ekugcineni kwesigxobo sebhethri, bese ulungiselela ukushisela ibhethri kusenesikhathi.

Ngenxa yokuthi ukuhlanzwa nge-laser akudingi noma yiziphi izinto ezisetshenziswayo njengezinto eziqinile, uketshezi kanye negesi, isakhiwo sincane, isikhala esisetshenziswayo sincane, futhi umphumela wokuhlanza uyamangalisa, okungathuthukisa kakhulu umjikelezo wokukhiqiza futhi kunciphise izindleko zokukhiqiza;

Kungalungisa ubuso bokushisela ngesisekelo sokususa ngokuphelele izinto eziphilayo nezinhlayiya ezincane, futhi kuthuthukise ukuthembeka kokushisela nge-laser okulandelayo. Kungenye yezinketho ezinhle kakhulu zokuhlanza amathebhu.

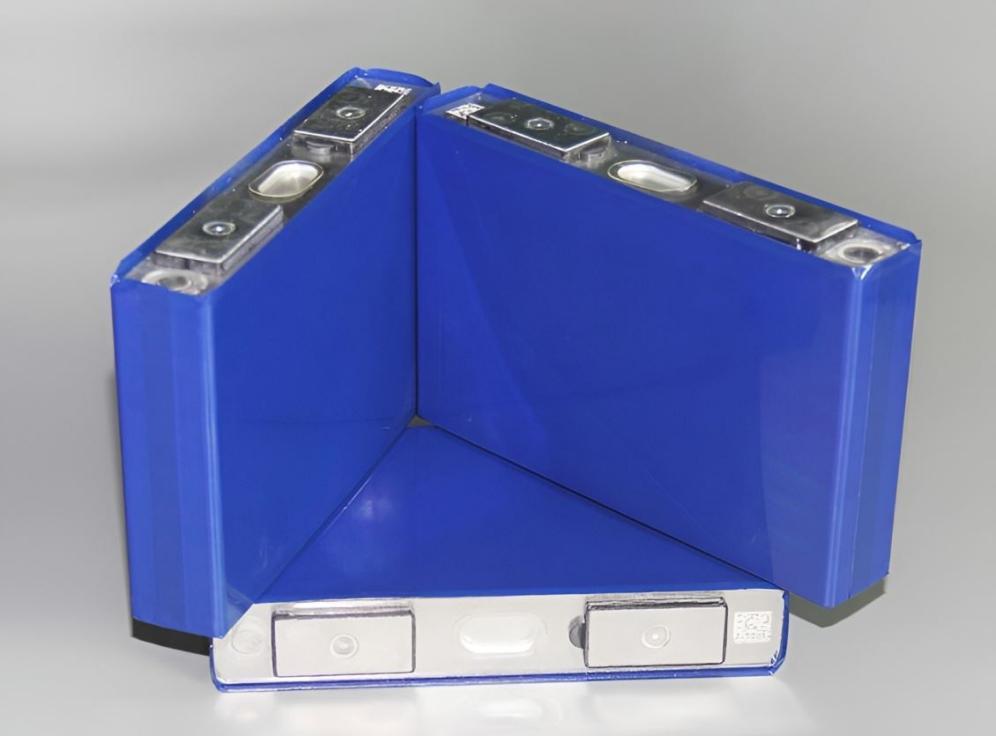

3. Ukuhlanzwa kwe-glue yangaphandle ngesikhathi sokuhlanganiswa

Ukuze kuvinjelwe izingozi zokuphepha kwamabhethri e-lithium, ngokuvamile kuyadingeka ukufaka inhlaka kumaseli ebhethri le-lithium ukuze kudlale indima yokuvikela ukufudumala, kuvinjelwe ama-short circuits, kuvikelwe ama-circuits, futhi kuvikelwe imihuzuko.

Uma ifilimu yangaphandle yeseli elingahlanzekile ihlolwa yi-CCD, kuzoba nemibimbi, amabhamuza omoya, imihuzuko kanye nezinye izinkinga ngokubukeka, futhi amabhamuza omoya anobubanzi obungu-≥ 0.3mm angavame ukutholakala. Kukhona ithuba lokuvuza nokugqwala, okunciphisa impilo yebhethri futhi kube nezingozi zokuphepha ezingaba khona.

Ukuhlanzwa nge-laseringafinyelela ezingeni le-Sa3 ekhonweni lokuhlanza ubuso beseli, futhi izinga lokususa lingaphezu kuka-99.9%; futhi akukho ukucindezeleka ebusweni beseli. Uma kuqhathaniswa nezinye izindlela zokuhlanza njengokuhlanza nge-ultrasound noma ukugaya ngomshini, ingaqinisekisa ukuthi izinkomba zomzimba nezamakhemikhali ezifana nokuqina kobuso bamaseli ebhethri azishintshi kakhulu, futhi zandise impilo yebhethri.

Ngaphezu kwezibonelo ezishiwo ngenhla, ukuhlanzwa nge-laser kunezinzuzo ezinhle kwezinye izinqubo eziyishumi nambili njengokususwa kopende nge-electrophoretic cover kanye nokuhlanzwa kwelebula le-foil.

Uma ufuna ukufunda kabanzi ngokuhlanzwa nge-laser, noma ufuna ukuthenga umshini wokuhlanza nge-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Okthoba-19-2022