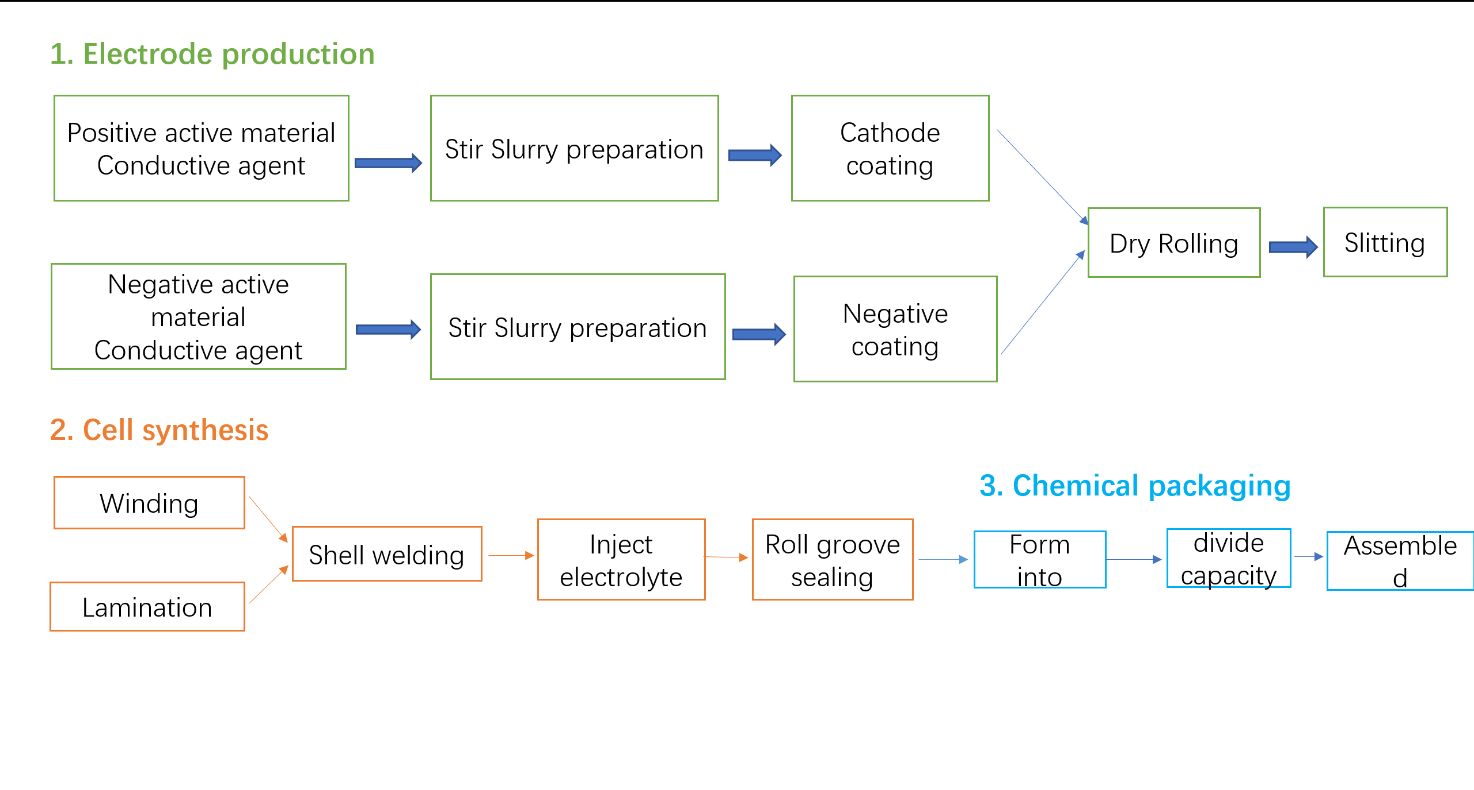

Samar dabatirin lithiumtsari ne na "roll-to-roll". Ko dai batirin lithium iron phosphate ne, batirin sodium-ion ko baturi na ternary, yana buƙatar ya bi ta hanyar sarrafawa daga siririn fim zuwa baturi ɗaya, sannan zuwa tsarin baturi. Tsarin shirya batirin lithium za a iya raba shi kusan zuwa matakai uku: samar da takardar lantarki, haɗa ƙwayoyin halitta, da marufi na sinadarai.

Akwai muhimman matakai da dama a cikin waɗannan manyan matakai guda uku, waɗanda za su shafi ƙarfin ajiyar wutar lantarki na batirin kai tsaye, amincin samfura da tsawon lokacin sabis. Saboda haka, aikin batirin da aka samar ta hanyoyi daban-daban ya bambanta sosai. A cikin waɗannan hanyoyin haɗin yanar gizo,tsaftacewar lasera halin yanzu za iya shiga cikin fiye da dozin hanyoyin shiri, wanda zai iya inganta ingancin batirin lithium sosai.

| Tsarin aikace-aikacen tsaftacewar laser akan batirin wutar lantarki | |||

| Sashen gaba na batirin | Sashen tantanin halitta | Sashen module | Fakitin batirin FAKITI |

| Tsaftace sanda | Tsaftace ƙusa da ƙusa | Tsaftace sanda | Tsaftace Kaya na Pallet CMT Weld |

| Tsaftacewa kafin mirgina | Tsaftace shafuka kafin soldering | Tsaftace fim ɗin shuɗi na tantanin halitta | Tsaftace fenti mai amfani da wutar lantarki a farantin murfi |

| Tsaftacewa bayan birgima | Tsaftace Silikon tantanin halitta | Tsaftace Layer ɗin sealant na kabad mai rufewa oxide | |

| Tsaftace rufin sel | Tsaftace Oxide na farantin kariya na ƙasa kafin walda | ||

| Tsaftace ramin allura | Tsaftace Lakabin Tsaftace | ||

| tsaftace wurin bas | |||

Yayin da buƙatar batura masu amfani da wutar lantarki ke ci gaba da ƙaruwa, buƙatar batura masu amfani da wutar lantarki na ci gaba da ƙaruwatsaftacewar laserKayan aiki kuma za su ƙaru. Na gaba, za mu mayar da hankali kan wasu hanyoyin aikace-aikace da fa'idodin kwatantawa.

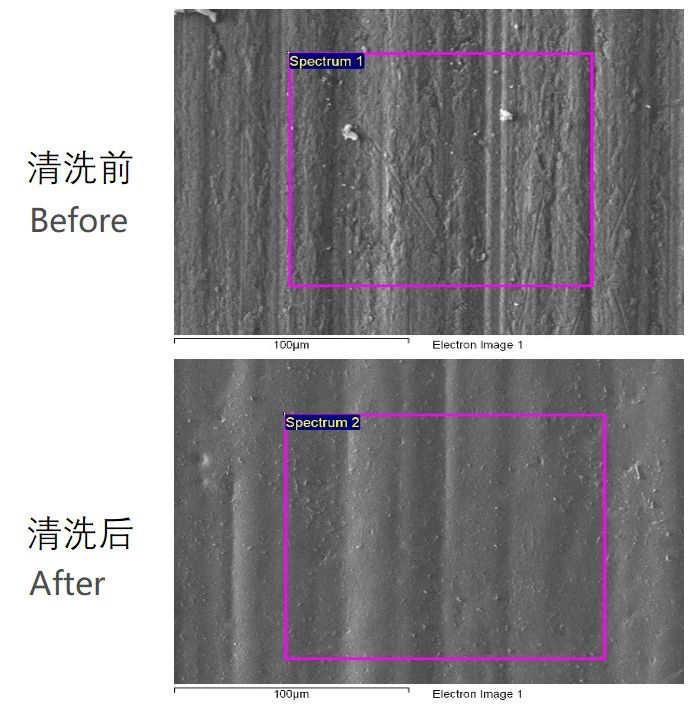

1. Laser tsaftacewa na jan ƙarfe da aluminum foil kafin shafi yanki na sanda

Ana yin electrodes masu kyau da marasa kyau na batirin lithium ta hanyar shafa electrodes masu kyau da marasa kyau na batirin lithium akan foil ɗin aluminum da foil ɗin jan ƙarfe. Idan aka gauraya barbashi, tarkace, ƙura da sauran hanyoyin sadarwa a cikin tsarin shafa, zai haifar da ƙaramin zagaye a cikin batirin, kuma a cikin mawuyacin hali, batirin zai kama wuta ya fashe.

Saboda haka, ana buƙatar a tsaftace foil ɗin kafin a shafa shi don samun saman da ba shi da sinadarin oxide gaba ɗaya.

Galibi ana tsaftace sassan sandar batirin da ke akwai ta hanyar amfani da fasahar ultrasonic, kuma ana amfani da maganin ethanol a matsayin maganin tsaftacewa kafin a shafa. Wannan hanyar tana da waɗannan kurakuran:

1. Lokacin da aka yi amfani da ultrasonic wajen tsaftace sassan ƙarfe na ƙarfe, musamman kayan aikin ƙarfe na aluminum, waɗanda mita, lokacin tsaftacewa da ƙarfi suka shafa, tasirin cavitation na raƙuman ultrasonic na iya lalata foil ɗin aluminum cikin sauƙi, wanda ke haifar da ƙananan ramuka. Tsawon lokacin aiki, haka nan girman ramukan.

Faifan da ake amfani da shi don aikin ginin batirin lithium gabaɗaya foil ɗaya ne mai kauri na 10 μm, wanda ya fi saurin tsagewa cikin ramuka saboda matsalolin aikin tsaftacewa.

2. Amfani da maganin ethanol a matsayin maganin tsaftacewa ba wai kawai yana da sauƙin haifar da lalacewa ga wasu sassan batirin lithium ba, har ma yana iya haifar da "hasken hydrogen", wanda ke shafar halayen injinan foil ɗin aluminum.

3. Duk da cewa tasirin tsaftacewa ya fi na gargajiya na tsabtace sinadarai masu danshi muni, tsaftar har yanzu ba ta yi kyau kamar ta tsaftacewar laser ba. A wasu lokutan har yanzu akwai gurɓatattun abubuwa a saman, wanda zai sa murfin ya rabu da foil ko kuma ya haifar da ramuka masu raguwa.

A matsayin busasshen tsaftacewa ba tare da abubuwan amfani ba, tsaftacewar laser kusan babu lahani dangane da tsafta da kuma hydrophilicity na maganin saman aluminum foil, yana tabbatar da tasirin girma da shafi akan guntun sandar har zuwa mafi girman matsayi.

Amfani da takardar ƙarfe ta laser ba wai kawai zai iya inganta ingancin aikin tsaftacewa da kuma adana albarkatun tsaftacewa ba, har ma zai iya kafa sa ido a ainihin lokaci kan bayanan tsarin tsaftacewa da kuma tantance sakamakon tsaftacewa, wanda zai iya inganta daidaiton samar da guntu na sandunan.

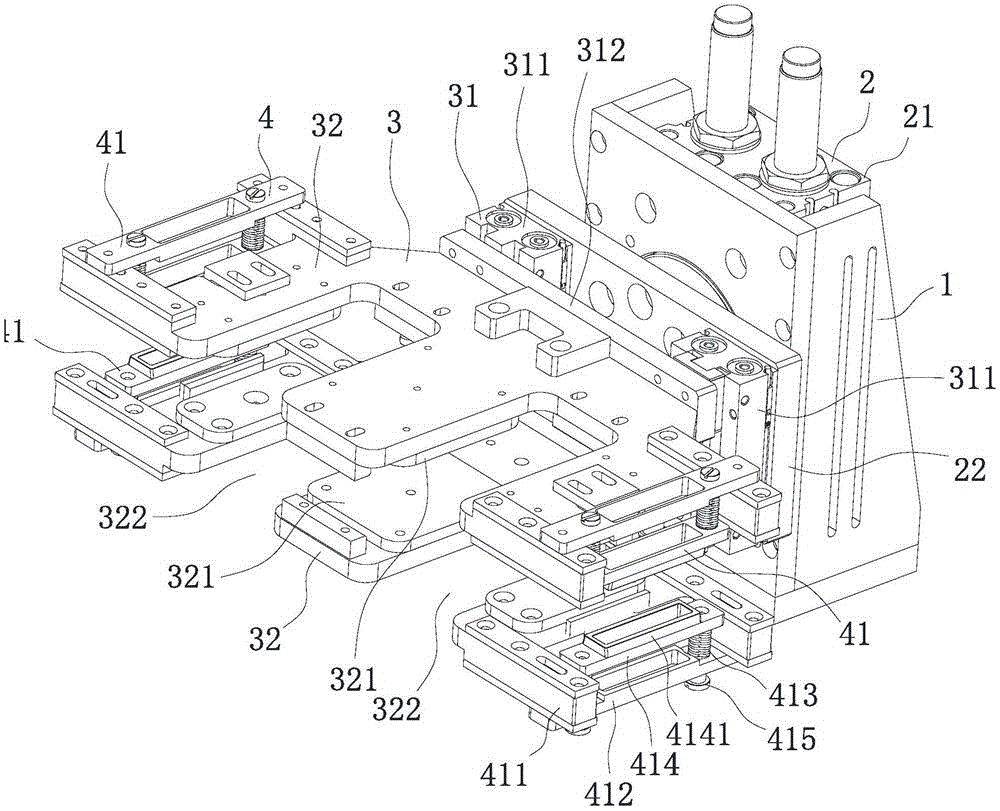

2. Tsaftace batura ta hanyar laser kafin walda

Shafukan ƙarfe ne waɗanda ke fitar da na'urori masu kyau da marasa kyau daga cikin batirin, kuma su ne wuraren da za a iya haɗuwa da su lokacin da aka caji da kuma fitar da batirin. Gurɓatattun abubuwa kamar man shafawa, masu hana tsatsa da sauran mahaɗan da ke cikin aikin na iya haifar da matsaloli kamar rashin kyawun walda, tsagewa da kuma porosity a cikin walda.

Tsaftar saman da aka taɓa zai iya yin tasiri sosai ga aminci da dorewar haɗin wutar lantarki.

Tsaftace wutar lantarki da ake da shi a yanzu galibi yana amfani da tsaftacewa da hannu, tsaftacewar sinadarai ko tsaftacewar plasma:

● Tsaftace hannu ba shi da inganci kuma yana da tsada;

● Duk da cewa layin tsaftace ruwa mai ruwa yana inganta inganci, tsawon layin yana da tsawo, yana mamaye babban yanki na masana'antar, kuma sinadarin yana da sauƙin lalata sauran sassan batirin lithium;

● Duk da cewa tsaftace plasma ba ya buƙatar ruwa mai tsafta, yana kuma buƙatar iskar gas mai sarrafawa a matsayin kayan da ake amfani da su, kuma ionization na gas zai sa a kunna electrodes masu kyau da marasa kyau na batirin cikin sauƙi. Lokacin amfani da shi, sau da yawa yana da mahimmanci a juya batirin sau da yawa don raba electrodes masu kyau da marasa kyau don tsaftacewa. Ingancin gaske Ba shi da yawa.

Tsaftace Laser na iya cire datti, ƙura yadda ya kamatada sauransu a ƙarshen fuskar sandar batirin, kuma a shirya don walda baturi a gaba.

Saboda tsaftacewar laser ba ta buƙatar wani abu da za a iya amfani da shi kamar su daskararru, ruwa da iskar gas, tsarin yana da ƙanƙanta, sararin da ake amfani da shi ƙarami ne, kuma tasirin tsaftacewa abin mamaki ne, wanda zai iya inganta zagayowar samarwa sosai da rage farashin masana'antu;

Zai iya taurare saman walda ta hanyar cire abubuwa masu rai da ƙananan ƙwayoyin cuta, da kuma inganta ingancin walda ta laser da ke tafe. Yana ɗaya daga cikin mafi kyawun zaɓuɓɓuka don tsaftace shafi.

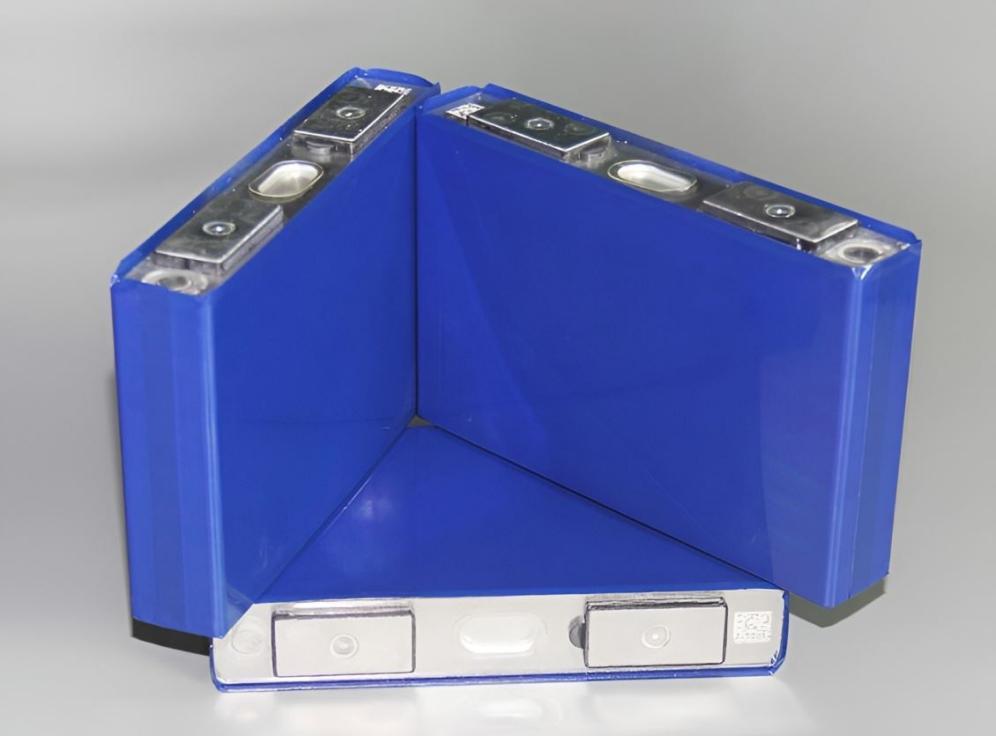

3. Tsaftace manne na waje yayin haɗawa

Domin hana haɗarin aminci na batirin lithium, gabaɗaya yana da mahimmanci a shafa manne a jikin ƙwayoyin batirin lithium don taka rawar kariya, hana gajerun da'irori, kare da'irori, da kuma hana karce.

Idan aka gwada fim ɗin waje na ƙwayar da aka ƙazanta ta hanyar CCD, za a sami wrinkles, kumfa iska, ƙaiƙayi da sauran lahani a bayyanar, kuma sau da yawa ana iya gano kumfa iska mai diamita na ≥ 0.3mm. Akwai yiwuwar zubewa da tsatsa, wanda ke rage tsawon rayuwar batirin kuma yana da yuwuwar haɗarin aminci.

Tsaftace Laserzai iya kaiwa matakin Sa3 a cikin ikon tsaftacewa na saman tantanin halitta, kuma ƙimar cirewa ta fi 99.9%; kuma babu damuwa a saman tantanin halitta. Idan aka kwatanta da sauran hanyoyin tsaftacewa kamar tsaftacewar ultrasonic ko niƙa na inji, yana iya tabbatar da cewa alamun zahiri da sinadarai kamar taurin saman tantanin batirin ba sa canzawa zuwa mafi girman matsayi, kuma yana tsawaita rayuwar sabis na baturin.

Baya ga misalan da aka ambata a sama, tsaftace laser yana da fa'idodi masu kyau a wasu hanyoyi da dama kamar cire fenti na electrophoretic na murfin batir da kuma tsaftace lakabin foil.

Idan kana son ƙarin koyo game da tsaftace laser, ko kuma kana son siyan mafi kyawun injin tsabtace laser a gare ka, da fatan za a bar saƙo a gidan yanar gizon mu kuma a aiko mana da imel kai tsaye!

Lokacin Saƙo: Oktoba-19-2022