Fortune Laser Handheld Fiber Laser Welding Machine

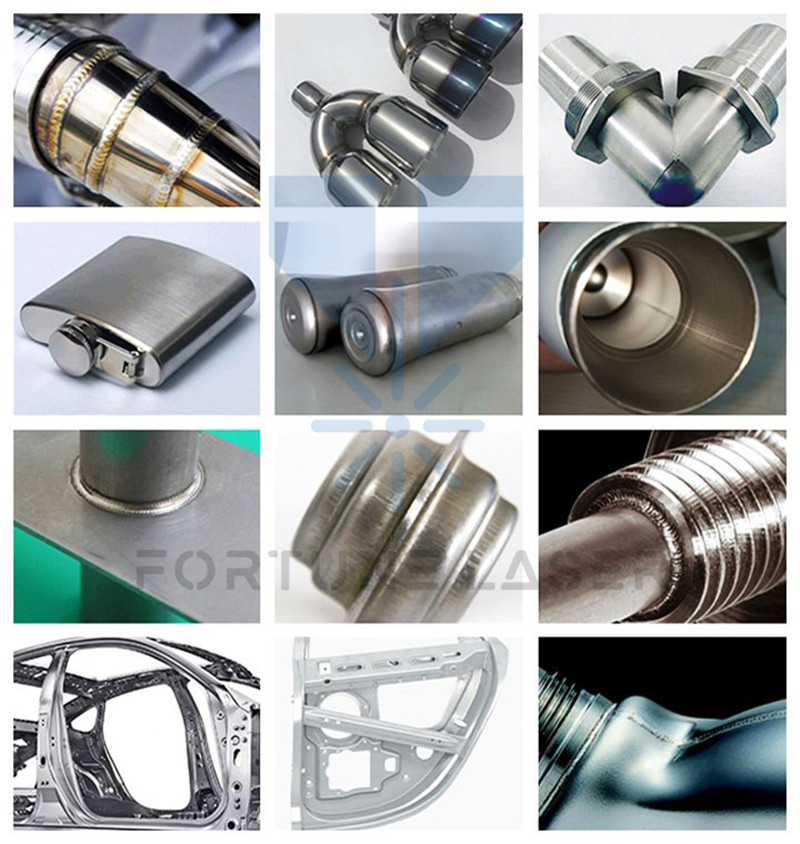

Na'urar walda fiber Laser na hannu, wanda kuma ake kira Portable Handheld Laser Welder, sabon ƙarni ne na kayan walda na Laser, wanda ke cikin walƙiya mara lamba. Tsarin aiki baya buƙatar matsa lamba. Ka'idar aiki ita ce kai tsaye ba da wutar lantarki mai ƙarfi mai ƙarfi Laser katako a saman kayan ta hanyar hulɗar laser da kayan. Ana narkar da kayan a ciki, sannan a sanyaya kuma a sanya crystallized don samar da walda.

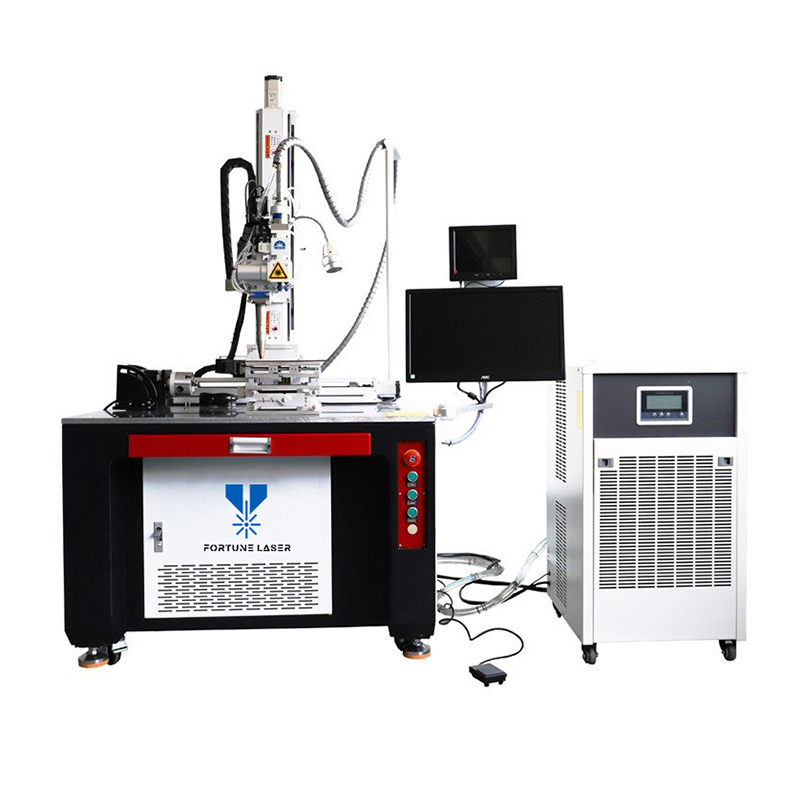

Na'urar Welding Laser mai Ci gaba

The Fortune Laser ci gaba Tantancewar fiber CW Laser waldi inji shi ne kunshi waldi jiki, waldi aiki tebur, ruwa chiller da mai kula da tsarin da dai sauransu Wannan jerin kayan aiki ne 3-5 sau na gudun fiye da gargajiya Tantancewar fiber watsa Laser waldi inji. Yana iya daidai weld lebur, kewaye, layi irin kayayyakin da kuma wadanda ba misali musamman samar Lines.

Kayan ado Mini Spot Laser Welder 60W 100W

Wannan 60W 100W YAG mini tabo Laser welder, wanda kuma aka sani da šaukuwa kayan adon Laser soldering inji, an ƙera musamman don Laser waldi na kayan ado, kuma yafi amfani a perforating da tabo waldi na zinariya da azurfa kayan ado. A Laser tabo waldi ne wani muhimmin al'amari na Laser aiwatar fasaha aikace-aikace.

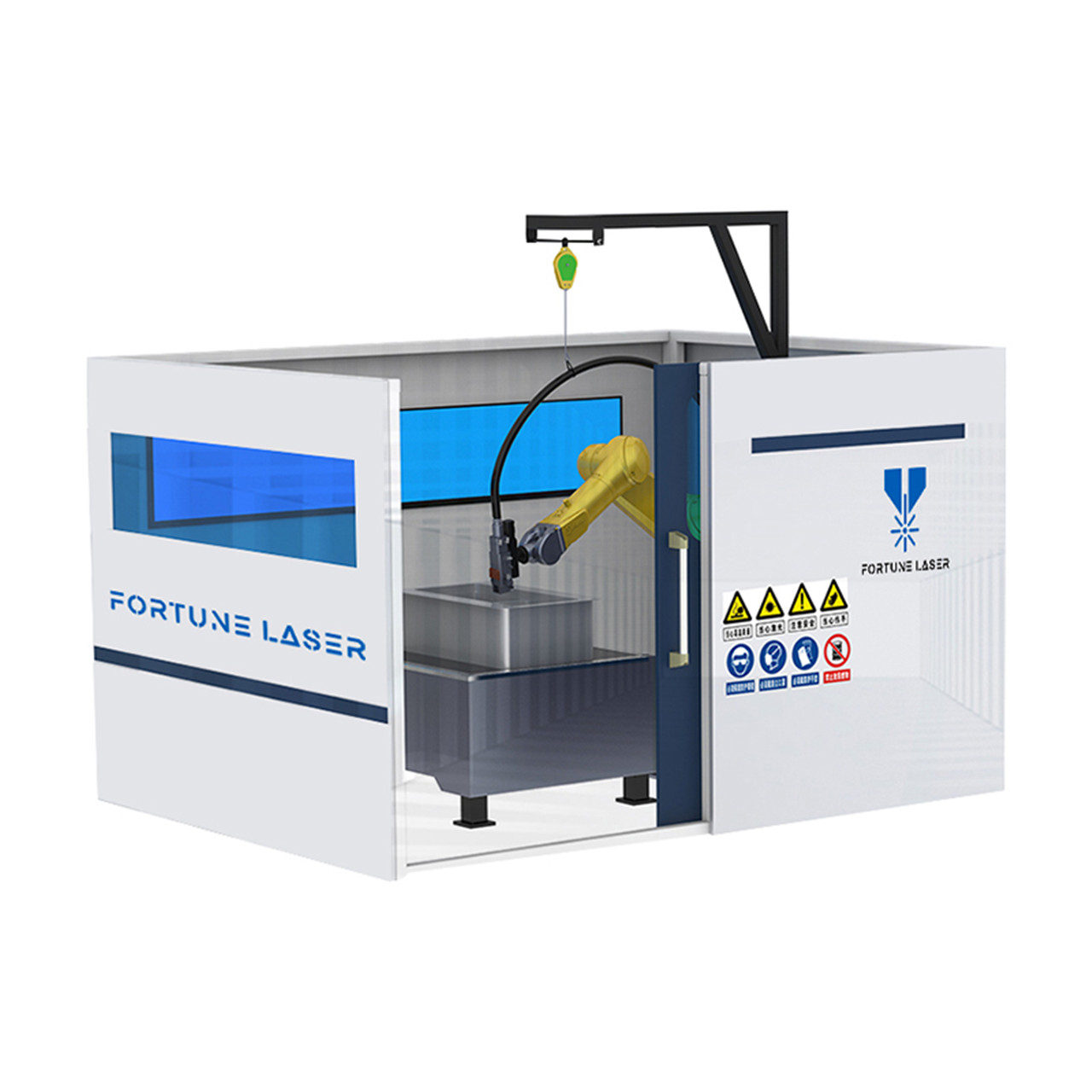

Robotic Fiber Laser Welding Machine

Fortune Laser robot Laser waldi inji an hada da wani kwazo fiber Laser shugaban, a high-daidaici capacitance tracking tsarin, fiber Laser da kuma masana'antu robot tsarin. Yana da wani ci-gaba kayan aiki ga m waldi na karfe zanen gado na daban-daban kauri daga mahara kwana da mahara kwatance.

Haɗin walda na Laser da mutummutumi yana da fa'idodin aiki da kai, hankali, da sassauci mai girma, kuma ana iya amfani da su don walda hadaddun kayan saman.