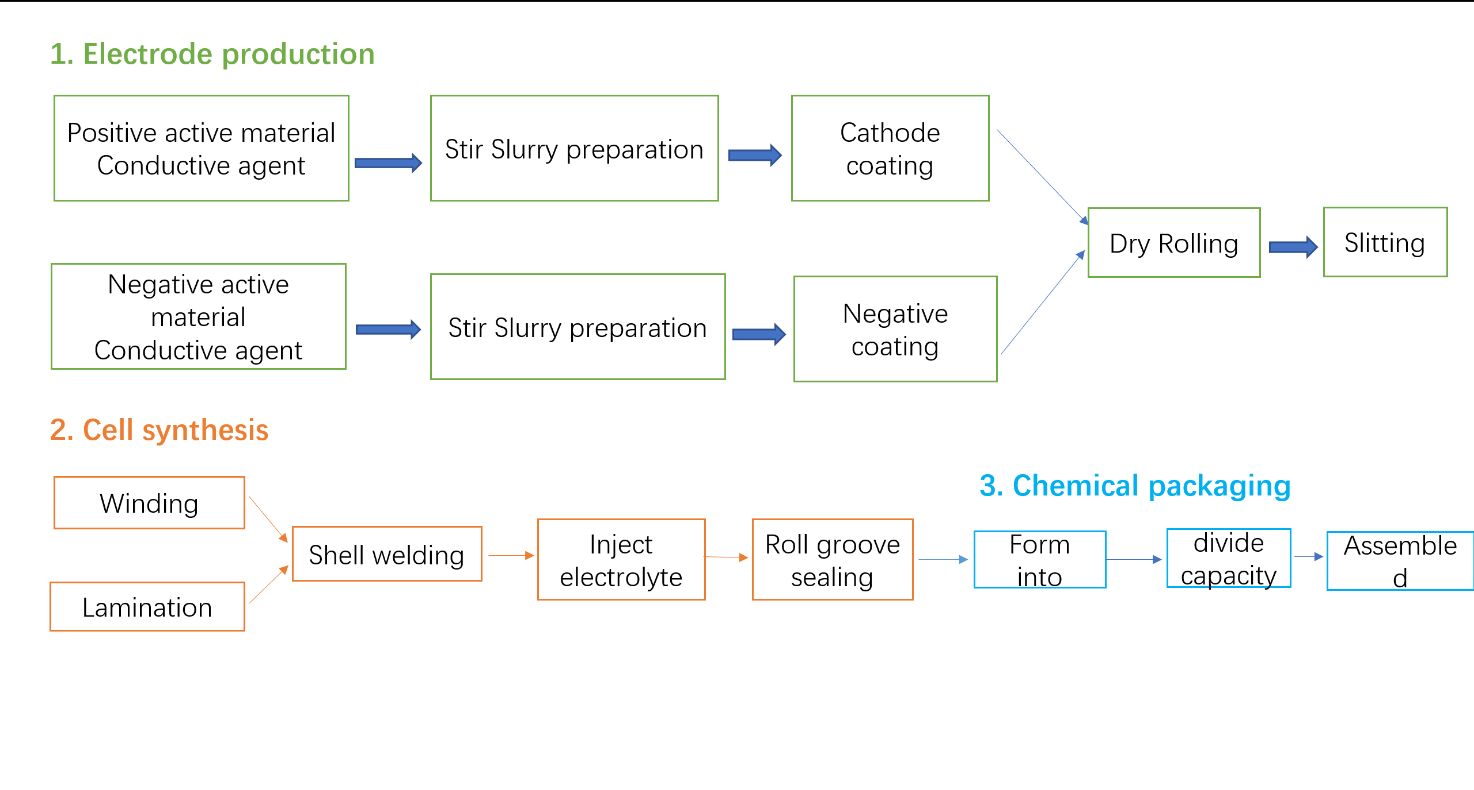

Imveliso yeiibhetri ze-lithiumyinkqubo "yokuqengqeleka ukuya ekuqengqelekeni". Nokuba yibhetri ye-lithium iron phosphate, ibhetri ye-sodium-ion okanye ibhetri ye-ternary, kufuneka idlule kwinkqubo yokucubungula ukusuka kwifilimu encinci ukuya kwibhetri enye, ize emva koko iye kwinkqubo yebhetri. Inkqubo yokulungiselela iibhetri ze-lithium inokwahlulwahlulwa ngokwamanqanaba amathathu: ukuveliswa kwephepha le-electrode, ukwenziwa kweeseli, kunye nokupakishwa kweekhemikhali.

Kukho iinkqubo ezibalulekileyo kwezi nkqubo zintathu ziphambili, eziya kuchaphazela ngokuthe ngqo amandla okugcina amandla ebhetri, ukhuseleko lwemveliso kunye nobomi benkonzo. Ke ngoko, ukusebenza kweebhetri eziveliswa ziinkqubo ezahlukeneyo zemveliso kwahluka kakhulu. Kule miqhagamshelo,ukucoca nge-laserokwangoku banokuthatha inxaxheba kwiinkqubo zokulungiselela ezingaphezu kweshumi elinesibini, nto leyo enokuphucula kakhulu umgangatho weebhetri ze-lithium.

| Inkqubo yokucoca nge-laser kwibhetri yamandla | |||

| Icandelo elingaphambili lebhetri | Icandelo leseli | Icandelo leModyuli | IPHEKI ibhetri |

| Ukucoca iipali | Ukucoca iinzipho ngokuzitywina | Ukucoca iipali | Ukucoca umthungo wePallet CMT Weld |

| Ukucoca phambi kokuqengqeleka | Ukucoca iithebhu ngaphambi kokugalela nge-solder | Ukucoca ifilimu eluhlaza okwesibhakabhaka | Ukucoca ipeyinti nge-electrophoretic plate |

| Ukucoca emva kokuqengqeleka | Ukucoca iSilicone yeSeli | Ukucoca umaleko we-oxide we-sealant yekhabhinethi | |

| Ukucoca i-cell coating | Ukucocwa kwe-oxide kwipleyiti esezantsi ekhuselayo ngaphambi kokuwelda | ||

| Ukucoca imingxunya ngenaliti | Ukucocwa kweleyibhile yefoyile | ||

| ukucoca ibhasi | |||

Njengoko imfuno yeebhetri zamandla iqhubeka isanda, imfunoukucoca nge-laserIzixhobo nazo ziya kwanda. Okulandelayo, siza kugxila kwezinye zeenkqubo zokusetyenziswa kunye neenzuzo zokuthelekisa.

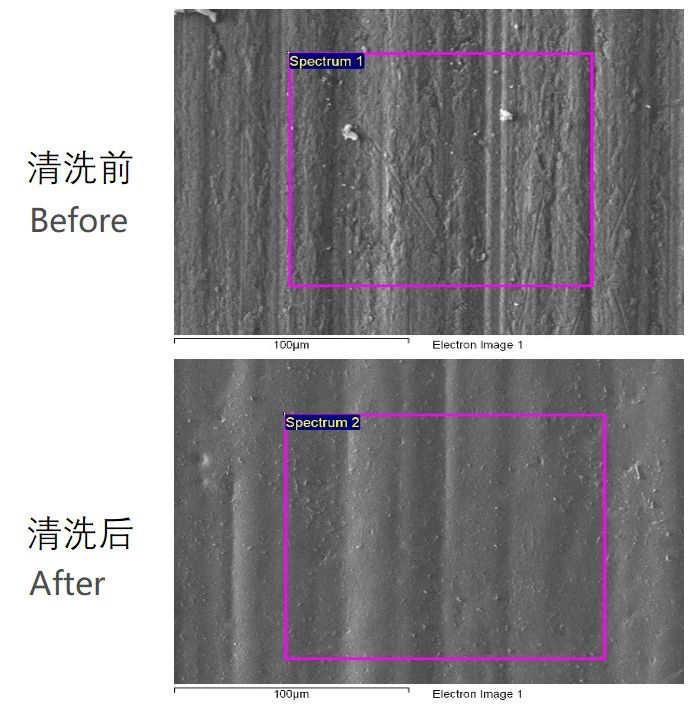

1. Ukucocwa nge-laser kwe-copper kunye ne-aluminium foil ngaphambi kokugqunywa kweepali

Ii-electrode ezilungileyo nezingalunganga zebhetri ye-lithium zenziwa ngokugquma ii-electrode ezilungileyo nezingalunganga zebhetri ye-lithium kwi-foil ye-aluminium kunye ne-foil yobhedu. Ukuba amasuntswana, ukungcola, uthuli kunye nezinye izinto zixutyiwe kwinkqubo yokugquma, kuya kubangela i-micro-short circuit ngaphakathi kwebhetri, kwaye kwiimeko ezinzima, ibhetri iya kutsha kwaye iqhume.

Ngoko ke, ifoyile kufuneka icocwe ngaphambi kokuba igqunywe ukuze kufunyanwe umphezulu ococekileyo nongena-oxide.

Iziqwenga zeepali zebhetri ezikhoyo zihlala zicocwa ngamaza e-ultrasonic, kwaye isisombululo se-ethanol sisetyenziswa njengesixhobo sokucoca njengenkqubo yokucoca ngaphambi kokugquma. Le ndlela ineziphene ezilandelayo:

1. Xa kucocwa iindawo zefoyile yesinyithi nge-ultrasonic, ingakumbi izinto zokusebenza ze-aluminium alloy, ezichaphazeleka yi-frequency, ixesha lokucoca kunye namandla, isiphumo se-cavitation samaza e-ultrasonic sinokuyidla ngokulula ifoyile ye-aluminium, nto leyo ebangela ii-pores ezincinci. Okukhona ixesha lesenzo lide, kokukhona ii-pores zinkulu.

Ifoyile esetyenziselwa ipali yebhetri ye-lithium ngokubanzi yifoyile enye engenalo ulusu enobukhulu obuyi-10 μm, enokukrazulwa ibe yimingxunya ngenxa yeengxaki zenkqubo yokucoca.

2. Ukusetyenziswa kwesisombululo se-ethanol njengesixhobo sokucoca akulula nje kuphela ukubangela umonakalo kwezinye iindawo zebhetri ye-lithium, kodwa kukwanokubangela "ukubhitya kwe-hydrogen", okuchaphazela iimpawu zoomatshini zefoyile ye-aluminium.

3. Nangona isiphumo sokucoca sibi kakhulu kunesokucoca ngekhemikhali emanzi yesiqhelo, ucoceko alukabi luhle njengokucoca nge-laser. Ngamanye amaxesha kusekho izinto ezingcolisayo kumphezulu, eziya kubangela ukuba i-coating yahlulwe kwi-foil okanye ivelise imingxunya yokuncitshiswa.

Njengokucoca okomileyo ngaphandle kwezinto ezisetyenziswayo, ukucoca nge-laser akunaziphene ngokubhekiselele kucoceko kunye nokuphiliswa kwamanzi kwindlela yokunyanga umphezulu we-aluminium foil, okuqinisekisa impembelelo yobukhulu kunye nokugquma kwinxalenye yepali ngokubanzi.

Ukusetyenziswa kwe-laser cleaning metal foil akunakuphucula kuphela ukusebenza kakuhle kwenkqubo yokucoca nokugcina izixhobo zokucoca, kodwa kukwamisela nokubeka esweni idatha yenkqubo yokucoca ngexesha langempela kunye nokuqinisekiswa kobungakanani beziphumo zokucoca, nto leyo enokuphucula ngempumelelo ukuhambelana kokuveliswa kweepali.

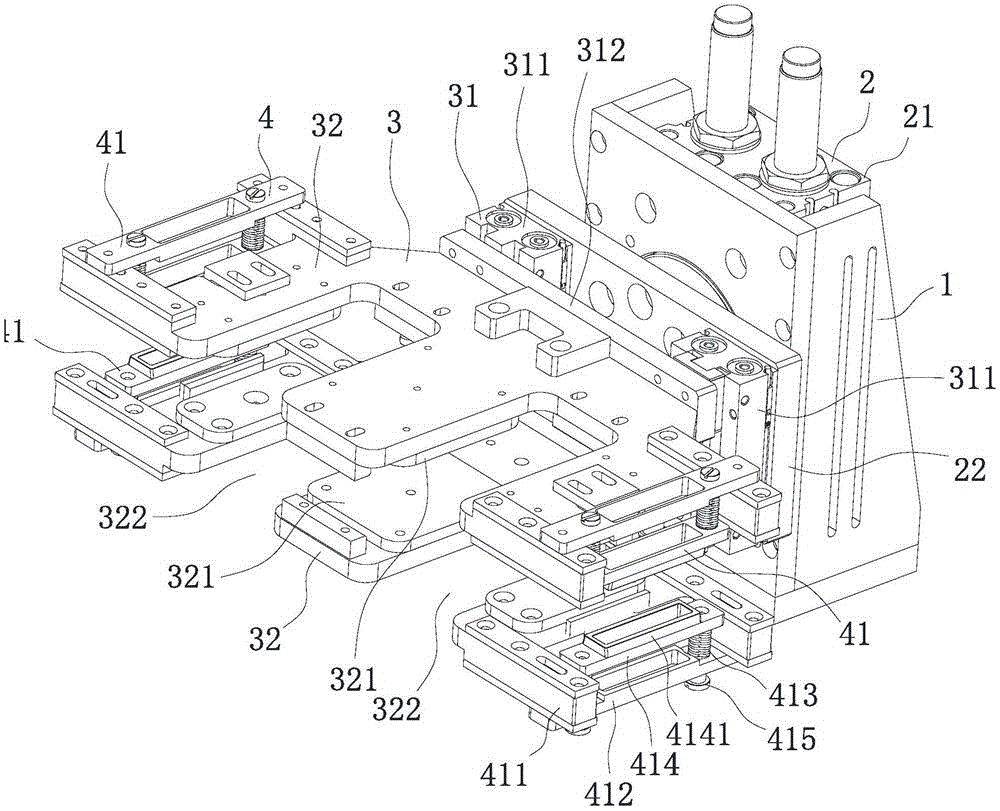

2. Ukucocwa kweebhetri nge-laser ngaphambi kokuwelda

Iithebhu ziingceba zesinyithi ezikhupha ii-electrode ezilungileyo nezingalunganga kwiseli yebhetri, kwaye ziindawo zokunxibelelana xa ibhetri itshajwa kwaye ikhutshwa. Izinto ezingcolisayo ezinje ngamafutha, izithinteli zokugqwala kunye nezinye izinto ezisetyenziswayo kule nkqubo zinokubangela iingxaki ezifana nokugqwala okungahambi kakuhle, ukuqhekeka kunye nokuqhekeka kwe-weld.

Ukucoceka komphezulu woqhagamshelwano kunokuchaphazela kakhulu ukuthembeka kunye nokuqina koqhagamshelo lombane.

Ukucoca i-electrode ekhoyo kusetyenziswa ikakhulu ukucoca ngesandla, ukucoca ngeekhemikhali ezimanzi okanye ukucoca ngeplasma:

● Ukucoca ngesandla akusebenzi kakuhle kwaye kubiza imali eninzi;

● Nangona umgca wokucoca amanzi omanzi uphucula ukusebenza kakuhle, ubude bomgca bude, uthatha indawo enkulu yefektri, kwaye iarhente yamakhemikhali kulula ukuyonakalisa ezinye iindawo zebhetri ye-lithium;

● Nangona ukucoca i-plasma kungadingi medium engamanzi, kukwafuna negesi yenkqubo njengento esetyenziswayo, kwaye i-ionization yegesi iya kubangela ukuba ii-electrode ezilungileyo nezingalunganga zebhetri zivulwe ngokulula. Xa ufaka isicelo, kudla ngokufuneka ujike ibhetri izihlandlo ezininzi ukuze wahlukanise ii-electrode ezilungileyo nezingalunganga zokucoca. Ukusebenza kakuhle Akulunganga.

Ukucocwa nge-laser kunokususa ukungcola nothuli ngempumelelo, njl. ecaleni kwepali yebhetri, kwaye ulungiselele ukuwelda iibhetri kwangaphambili.

Ngenxa yokuba ukucoca nge-laser akudingi zinto zisetyenziswayo ezifana nezinto eziqinileyo, ezingamanzi kunye negesi, isakhiwo sincinci, indawo esetyenziswayo incinci, kwaye isiphumo sokucoca siyamangalisa, nto leyo enokuphucula kakhulu umjikelo wemveliso kwaye inciphise iindleko zokuvelisa;

Ingalungisa umphezulu wokuwelda ngokususa ngokupheleleyo izinto eziphilayo kunye namasuntswana amancinci, kwaye iphucule ukuthembeka kokuwelda nge-laser okulandelayo. Yenye yezona ndlela zilungileyo zokucoca iithebhu.

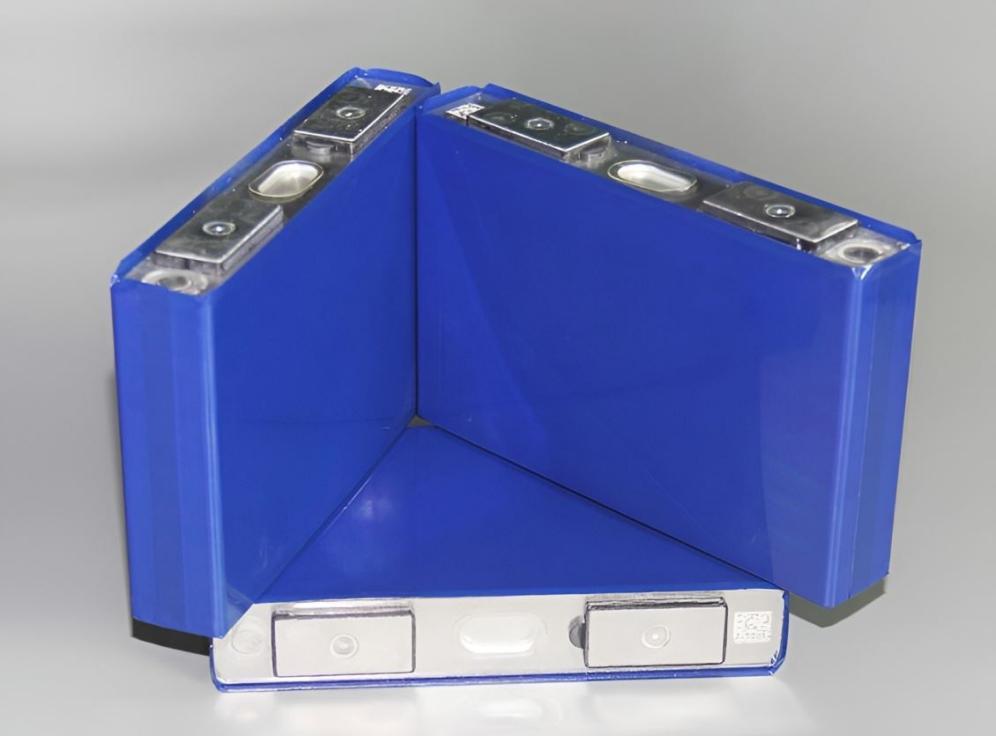

3. Ukucocwa kweglu yangaphandle ngexesha lokuhlanganiswa

Ukuze kuthintelwe iingozi zokhuseleko lweebhetri ze-lithium, ngokuqhelekileyo kuyimfuneko ukufaka iglu kwiiseli zebhetri ze-lithium ukuze zidlale indima yokukhusela, zithintele ii-short circuits, zikhusele ii-circuits, kwaye zithintele imikrwelo.

Xa ifilimu yangaphandle yeseli engacocwanga ivavanywa yi-CCD, kuya kubakho imibimbi, amaqamza omoya, imikrwelo kunye nezinye iziphene ezibonakalayo, kwaye amaqamza omoya anobubanzi obuyi-≥ 0.3mm anokufunyanwa rhoqo. Kukho ithuba lokuvuza kunye nokugqwala komhlwa, okunciphisa ubomi bebhetri kwaye kukwanobungozi obunokubakho bokhuseleko.

Ukucoca nge-laserinokufikelela kwinqanaba le-Sa3 kumandla okucoca umphezulu weseli, kwaye izinga lokususa lingaphezulu kwe-99.9%; kwaye akukho xinzelelo kumphezulu weseli. Xa kuthelekiswa nezinye iindlela zokucoca ezifana nokucoca nge-ultrasound okanye ukugaya ngoomatshini, inokuqinisekisa ukuba izalathisi zomzimba nezekhemikhali ezifana nobunzima bomphezulu weeseli zebhetri azitshintshi kakhulu, kwaye zandise ubomi benkonzo yebhetri.

Ukongeza kwimizekelo ekhankanyiweyo apha ngasentla, ukucoca nge-laser kukwaneengenelo ezinkulu kwezinye iinkqubo ezilishumi elinambini ezifana nokususwa kwepeyinti ye-electrophoretic cover yebhetri kunye nokucoca ilebhile yefoyile.

Ukuba ufuna ukufunda okungakumbi malunga nokucoca nge-laser, okanye ufuna ukuthenga umatshini wokucoca nge-laser ongcono kuwe, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngokuthe ngqo!

Ixesha lokuthumela: Okthobha-19-2022