Insimbi engagqwali isetshenziswa kabanzi ezimbonini ezahlukahlukene ngenxa yezakhiwo zayo ezihlukile njengokumelana nokugqwala kanye nokwakheka kalula. Ngokuthuthuka kobuchwepheshe, ukushisela nge-laser sekuyindlela entsha yokushisela, enezinzuzo eziningi uma kuqhathaniswa namasu okushisela endabuko. Kodwa-ke, enye yezinselele zeukushisela nge-laserukuguquka kwensimbi engagqwali. Kulesi sihloko, sizoxoxa ngendlela yokugwema ukuguqulwa kokushiswa kwensimbi engagqwali nge-laser bese sihlola izici ezihlobene kakhulu nakho.

Okokuqala, kubalulekile ukuqonda ukuthi kungani ukushisela nge-laser kubangela ukushisela kwensimbi engagqwali. Ukushisela nge-laser kuhilela ukusebenzisa umsebe we-laser onamandla aphezulu ukuncibilikisa nokuhlanganisa ubuso bezingcezu ezimbili zensimbi ndawonye. Phakathi nale nqubo, ukushisa nokupholisa okusheshayo kubangela ukushisela kokushisa, okubangela ukushisela kwendawo eshisele. Nakuba lokhu kubonakala kungenakugwenywa, kunezinyathelo eziningana ezingathathwa ukunciphisa noma ngisho nokuqeda ukushisela.

Esinye sezinyathelo zokuqala zokugwemaukushisela nge-laserUkuhlanekezela kuwukukhetha ngokucophelela amapharamitha okushisela nge-laser afanele. Izici ezifana namandla e-laser, isivinini sokushisela, kanye nokugxila kwe-beam kufanele kulungiselelwe ukuze kufezwe ikhwalithi yokushisela oyifunayo. Ngokulungisa la mapharamitha, ukufakwa kokushisa kungalawulwa futhi ukuguqulwa kokushisa okubangela ukuhlanekezela kungancishiswa. Ngaphezu kwalokho, ukusebenzisa imodi ye-pulsed kunemodi yamagagasi aqhubekayo kusiza ukunciphisa indawo ethintekile ekushiseni kanye nokuguqulwa okulandelayo.

Okunye okubalulekile okufanele kucatshangelwe ukwakheka kwesixhumi ngokwaso. Ukuma, usayizi kanye nokuma kwesihlanganisi kungathinta kakhulu inani lokuguquguquka okwenzeka ngesikhathiukushisela nge-laserUkuze kuncishiswe ukusonteka, kunconywa ukusebenzisa ama-weld abanzi futhi kugwenywe amakhona abukhali noma abukhali. Lokhu kusabalalisa ukushisa ngokulinganayo futhi kunciphisa ukucindezeleka kokushisa. Ngaphezu kwalokho, ukusetshenziswa kwama-weld e-fillet (ama-weld anezimo ze-concave noma ze-convex curve) nakho kusiza ekunciphiseni ukusonteka.

Ngaphezu kwemingcele yokushisela kanye nokwakheka kwamalunga, ukukhetha ubukhulu bezinto nakho kudlala indima ebalulekile ekugwemeni ukuphambuka. Amashidi ensimbi engagqwali aqinile athambekele kakhulu ekuguquguqukeni ngenxa yokushisa kwawo okuphezulu. Ukuze kuncishiswe lokhu, kunconywa ukusebenzisa amashidi ensimbi engagqwali aqinile noma usebenzise isinki yokushisa noma uhlelo lokupholisa ngesikhathi senqubo yokunamathisela. Lezi zindlela zokupholisa zisiza ekuqedeni ukushisa okweqile futhi zinciphise ukuphambuka kokushisa, zinciphise ukuphambuka.

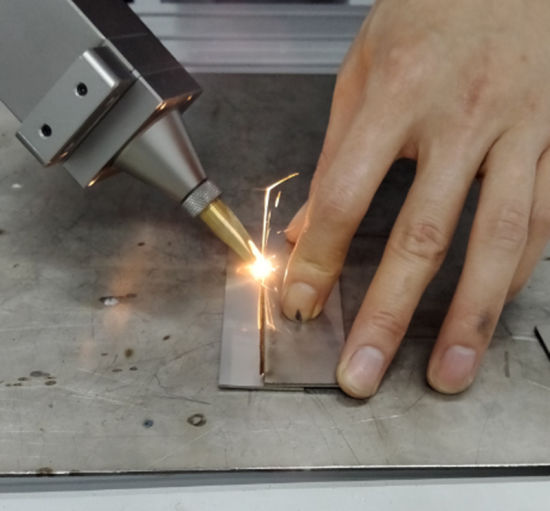

Ngaphezu kwalokho, ukusebenzisa amasu okulungisa nokubopha afanele kungasiza kakhulu ekugwemeni ukuphambuka kokushibilika nge-laser. I-fixture ibhekisela ekubekweni nasekulungisweni kwe-workpiece ngesikhathi senqubo yokushibilika. Kubalulekile ukuqinisekisa ukuthi i-workpiece isekelwe futhi iqondaniswe ngokwanele ukuze kuvinjelwe noma yikuphi ukunyakaza noma ukugoba ngesikhathi sokushibilika. I-clamping, ngakolunye uhlangothi, ihilela ukubamba i-workpiece endaweni yayo kusetshenziswa ama-jig noma ama-fixtures aklanywe ngokukhethekile. I-clamping efanele isiza ukugcina izinga elifunekayo lokuhambisana futhi kunciphisa amathuba okugoba.

Okokugcina, ukwelashwa kokushisa ngemva kokushiswa kungasetshenziswa ukunciphisa ukucindezeleka okusele nokunciphisa ukuphambuka. Ukuhlanganisa, ukunciphisa ukucindezeleka, ngisho nezinqubo ezilula zokupholisa umoya kusiza ekuqiniseni izakhiwo ezishisiwe nokunciphisa ukuphambuka. Ukusetshenziswa kwemishini ekhethekile yokwelapha ukushisa kungahlinzeka ngokujikeleza kokushisa okudingekayo ukuqinisekisa ukuthi insimbi engagqwali eshisiwe ihlala izinzile futhi ingenaso isiphazamiso.

Ngokufigqiwe,ukushisela nge-laserinikeza izinzuzo eziningi kunezindlela zokushisela zendabuko maqondana nesivinini, ukunemba kanye nekhwalithi. Kodwa-ke, ukuguquka kwensimbi engagqwali kuletha izinselele enqubweni yokushisela nge-laser. Ukuphambuka kokushisela nge-laser yensimbi engagqwali kungaphathwa ngempumelelo ngokukhetha ngokucophelela nokwenza ngcono amapharamitha okushisela, ukwakheka kokulungiswa okufanele kwamalunga, ukucatshangelwa kobukhulu bezinto, ukusetshenziswa kokulungiswa okufanele kanye namasu okubamba, kanye nokusetshenziswa kokwelashwa kokushisa ngemuva kokushisela. Lezi zinyathelo, ezihlanganiswe nezakhiwo ezingokwemvelo zensimbi engagqwali, zinegalelo ekushiseni kwekhwalithi ephezulu okunokuphambuka okuncane.

Uma ufuna ukufunda kabanzi ngokushisela nge-laser, noma ufuna ukuthenga umshini wokushisela nge-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Julayi-18-2023