Stainless hlau yog dav siv nyob rau hauv ntau yam lag luam vim nws cov khoom tshwj xeeb xws li corrosion kuj thiab formability.Nrog rau kev nce qib ntawm kev siv tshuab, laser vuam tau dhau los ua txoj kev vuam tshiab, uas muaj ntau yam zoo piv nrog cov txheej txheem vuam tsoos.Txawm li cas los xij, ib qho kev sib tw ntawmlaser vuamyog qhov deformation ntawm stainless hlau.Nyob rau hauv tsab xov xwm no, peb yuav tham txog yuav ua li cas kom tsis txhob stainless hlau laser vuam deformation thiab delve rau hauv cov yam uas ze ze rau nws.

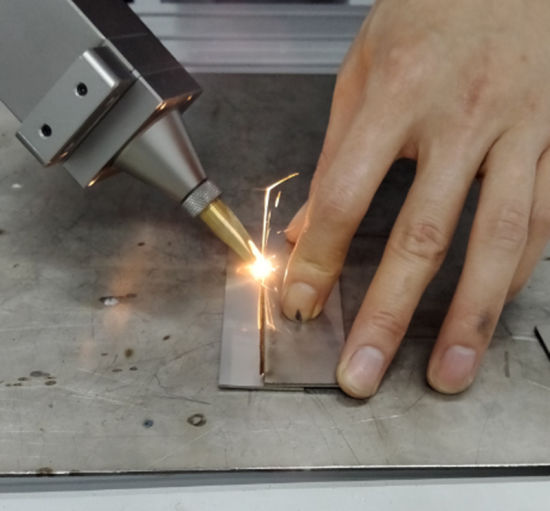

Ua ntej, nws yuav tsum nkag siab tias vim li cas laser vuam ua rau deformation ntawm stainless hlau.Laser vuam siv lub tshuab hluav taws xob siab laser kom yaj thiab fuse qhov chaw ntawm ob daim hlau ua ke.Thaum lub sij hawm tus txheej txheem no, cua kub ceev thiab txias ua rau thermal distortion, uas ua rau deformation ntawm welded cheeb tsam.Thaum qhov no zoo li tsis muaj kev zam, muaj ntau cov kauj ruam uas tuaj yeem ua kom txo qis lossis txawm tias tshem tawm kev cuam tshuam.

Ib qho ntawm thawj kauj ruam hauv kev zamlaser vuamdistortion yog ceev faj xaiv qhov tsim nyog laser vuam tsis.Tej yam xws li laser fais fab, vuam ceev, thiab beam tsom xam yuav tsum tau optimized kom ua tau raws li qhov xav tau weld zoo.Los ntawm kev kho cov kev txwv no, cov khoom siv hluav taws xob tuaj yeem tswj tau thiab thermal deformation ua rau muaj kev cuam tshuam tuaj yeem txo qis.Tsis tas li ntawd, siv hom pulsed es tsis yog hom nthwv dej txuas ntxiv yuav pab txo qhov kub ntawm thaj chaw cuam tshuam thiab tom qab deformation.

Lwm qhov kev txiav txim siab tseem ceeb yog qhov tsim ntawm lub connector nws tus kheej.Cov duab, qhov loj me thiab kev teeb tsa ntawm kev sib koom ua ke tuaj yeem cuam tshuam rau tus nqi deformation uas tshwm sim thaum lub sijhawmlaser vuam.Yuav kom txo qis distortion, nws raug nquahu kom siv cov welds dav thiab tsis txhob ntse los yog ntse.Qhov no faib cov cua sov kom sib npaug thiab txo cov thermal stress concentrations.Tsis tas li ntawd, kev siv cov fillet welds (welds nrog concave los yog convex nkhaus duab) kuj yuav pab txo qis distortion.

Ntxiv nrog rau qhov tsis sib xws thiab kev sib koom ua ke, kev xaiv ntawm cov khoom tuab kuj tseem ua lub luag haujlwm tseem ceeb hauv kev zam kom tsis txhob muaj kev cuam tshuam.Thicker stainless hlau nplooj ntawv muaj ntau dua rau deformation vim lawv cov thermal conductivity ntau dua.Txhawm rau txo qhov no, nws raug nquahu kom siv cov ntawv nyias nyias los yog siv lub dab dej kub lossis cua txias thaum lub sijhawm ua haujlwm.Cov txheej txheem cua txias no pab kom cov cua sov ntau dhau thiab txo cov thermal gradients, txo qis kev cuam tshuam.

Tsis tas li ntawd, siv cov txheej txheem kho kom raug thiab clamping yuav pab tau kom tsis txhob laser vuam distortion.Lub fixture yog hais txog qhov chaw thiab kho ntawm lub workpiece thaum lub sij hawm vuam txheej txheem.Nws yog ib qho tseem ceeb los xyuas kom meej tias lub workpiece tau txais kev txhawb nqa txaus thiab ua kom zoo kom tsis txhob muaj kev txav los yog kev sib tsoo thaum lub sij hawm vuam.Clamping, ntawm qhov tod tes, koom nrog tuav lub workpiece nyob rau hauv qhov chaw siv tshwj xeeb tsim jigs los yog fixtures.Kev clamping kom zoo pab tswj cov qib xav tau ntawm kev sib dhos thiab txo txoj hauv kev ntawm warping.

Thaum kawg, kev kho cua sov tom qab vuam tuaj yeem siv los txo qis kev ntxhov siab thiab txo qhov cuam tshuam.Annealing, txo kev ntxhov siab, thiab txawm tias cov txheej txheem cua txias yooj yim pab kom ruaj khov cov qauv welded thiab txo qis kev cuam tshuam.Kev siv cov cuab yeej kho cua sov tshwj xeeb thiab cov tswv yim tuaj yeem muab cov kev tsim nyog thermal cycling kom ntseeg tau tias cov hlau tsis muaj steel hlau ruaj khov thiab tsis muaj deformation.

Hauv cov ntsiab lus,laser vuammuaj ntau yam zoo dua li cov txheej txheem vuam ib txwm nyob rau hauv cov nqe lus ntawm kev ceev, precision thiab zoo.Txawm li cas los xij, deformation ntawm stainless hlau ua rau muaj teeb meem rau cov txheej txheem laser vuam.Stainless hlau laser vuam distortions tuaj yeem ua tau zoo los ntawm kev ua tib zoo xaiv thiab kev ua kom zoo ntawm cov vuam tsis zoo, tsim cov kev sib koom ua ke tsim nyog, xav txog cov khoom tuab, kev siv cov txheej txheem kho kom haum thiab clamping, thiab siv cov kev kho cua sov tom qab vuam.Cov kev ntsuas no, ua ke nrog cov khoom muaj txiaj ntsig ntawm cov hlau tsis muaj steel, ua rau cov khoom zoo welds nrog tsawg distortion.

Yog tias koj xav paub ntau ntxiv txog laser vuam, lossis xav yuav qhov zoo tshaj plaws laser vuam tshuab rau koj, thov tawm lus rau peb lub vev xaib thiab xa email ncaj qha rau peb!

Post lub sij hawm: Lub Xya hli ntuj-18-2023