Simbi isina tsvina inoshandiswa zvakanyanya mumaindasitiri akasiyana siyana nekuda kweiyo yakasarudzika midziyo senge corrosion resistance uye formability.Nekufambira mberi kwetekinoroji, laser welding yave nzira nyowani yewelding, ine zvakawanda zvakanaka zvichienzaniswa nemaitiro echinyakare welding.Zvisinei, rimwe rematambudziko elaser weldingndiko deformation yesimbi isina tsvina.Munyaya ino, isu tichakurukura nzira yekudzivirira Stainless simbi laser welding deformation uye kunyura muzvinhu zvine hukama nazvo.

Kutanga, zvinodikanwa kuti unzwisise kuti sei laser welding ichikonzera deformation yesimbi isina tsvina.Laser welding kunosanganisira kushandisa high-energy laser danda kunyungudusa uye kusanganisa nzvimbo dzezvidimbu zviviri zvesimbi pamwechete.Munguva iyi, kupisa nekukurumidza uye kutonhora kunokonzera kupisa kunokanganisa, izvo zvinokonzera deformation yenzvimbo yakashongedzwa.Kunyange zvazvo izvi zvichiita sezvisingadzivisiki, pane matanho akawanda anogona kutorwa kuderedza kana kuti kubvisa kukanganisa.

Imwe yematanho ekutanga mukunzvengalaser weldingkukanganisa ndiko kusarudzwa kwekungwarira kweakakodzera laser welding paramita.Zvinhu zvakadai sesimba relaser, welding kumhanya, uye danda kutariswa kunofanirwa kuvandudzwa kuti uwane inodiwa weld mhando.Nekugadzirisa aya ma paramita, kupisa kwekuisa kunogona kudzorwa uye deformation yekupisa inokonzera kukanganisa inogona kuderedzwa.Pamusoro pezvo, kushandisa pulsed modhi kwete kuenderera mberi wave mode kunobatsira kuderedza kupisa kwakakanganisika nzvimbo uye kunotevera deformation.

Imwe fungidziro yakakosha ndeye dhizaini yekubatanidza pachayo.Chimiro, saizi uye kumisikidzwa kwejoinhi inogona kukanganisa zvakanyanya kuwanda kwe deformation inoitika panguvalaser welding.Kuti uderedze kukanganisa, zvinokurudzirwa kushandisa hupamhi welds uye kudzivirira makona akapinza kana akapinza.Izvi zvinogovera kupisa zvakanyanya zvakaenzana uye zvinoderedza kupisa kwekunetseka kwekupisa.Pamusoro pezvo, kushandiswa kwemafillet welds (welds ane concave kana convex curve maumbirwo) inobatsirawo kuderedza kukanganisa.

Kuwedzera kune welding maparamendi uye dhizaini yekubatana, kusarudzwa kwekukora kwezvinhu kunoitawo basa rakakosha mukudzivirira kukanganisa.Mashizha akakora esimbi asina kusimba anonyanya kukonzeresa deformation nekuda kwekukwirira kwawo kwekupisa kwekushisa.Kuti uderedze izvi, zvinokurudzirwa kushandisa matete masimbi asina tsvina kana kushandisa sink yekupisa kana kutonhora system panguva yekushambadzira.Aya maitiro ekutonhodza anobatsira kubvisa kupisa kwakanyanya uye kuderedza kupisa kwemagetsi, kuderedza kukanganisa.

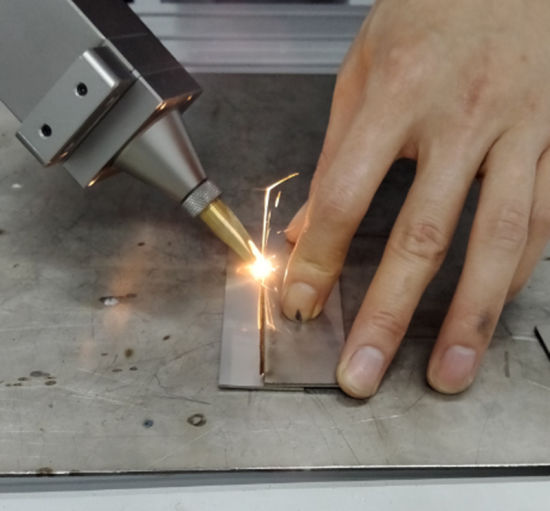

Pamusoro pezvo, kushandisa kwakaringana gadziriso uye clamping matekiniki anogona kubatsira zvakanyanya kudzivirira laser welding kukanganisa.Iyo gadziriso inoreva kumisikidzwa uye kugadzirisa kweiyo workpiece panguva yewelding process.Izvo zvakakosha kuve nechokwadi chekuti workpiece inotsigirwa zvakaringana uye yakarongedzerwa kudzivirira chero kufamba kana warping panguva yewelding.Kurovera, kune rumwe rutivi, kunosanganisira kubata workpiece panzvimbo uchishandisa zvakagadzirirwa jigs kana zvigadziriso.Kurovera kwakaringana kunobatsira kuchengetedza nhanho inodiwa yekurongeka uye inoderedza mukana wekurwa.

Chekupedzisira, post-weld kupisa kurapwa kunogona kushandiswa kudzoreredza kusara kunetseka uye kuderedza kukanganisa.Anealing, kudzoreredza kushushikana, uye kunyange nyore kutonhora kwemhepo maitiro anobatsira kudzikamisa zvivakwa zvakakanyiwa uye kuderedza kukanganisa.Iko kushandiswa kwehunyanzvi hwekupisa kupisa michina uye matekiniki anogona kupa inodiwa yekupisa bhasikoro kuti ive nechokwadi cheWelded Stainless simbi inoramba yakagadzikana uye isina deformation.

Muchidimbu,laser weldinginopa akawanda mabhenefiti pamusoro pechinyakare welding nzira maererano nekumhanya, chaiyo uye mhando.Nekudaro, deformation yesimbi isina simbi inoisa matambudziko kune iyo laser welding process.Stainless simbi laser welding distortions inogona kunyatsobatwa nekunyatso kusarudzwa uye optimization yewelding paramita, dhizaini yeakakodzera majoini masisitimu, kufunga nezvehukobvu hwezvinhu, kuita kwakakodzera kugadzirisa uye clamping matekiniki, uye kushandiswa kwemashure-weld kupisa kurapwa.Aya matanho, akasanganiswa neakasikwa zvimiro zvesimbi isina tsvina, anobatsira kune emhando yepamusoro welds nekukanganisa kushoma.

Kana iwe uchida kudzidza zvakawanda nezve laser welding, kana kuti uchida kutenga yakanakisa laser welding muchina wako, ndapota siya meseji pane yedu webhusaiti uye titumire email zvakananga!

Nguva yekutumira: Jul-18-2023