Ukushisela nge-laseringenye yezici ezibalulekile zokusetshenziswa kobuchwepheshe bokucubungula izinto zokucubungula i-laser. Isetshenziswa kakhulu ekushiseni izinto ezicijile kanye nokushiseni ngesivinini esiphansi. Inqubo yokushisisa ingeyehlobo lokuqhuba ukushisa, okungukuthi, imisebe ye-laser ishisa ubuso bento yokusebenza, futhi ukushisa kobuso kuyasakazeka ngaphakathi ngokushisisa ukushisa. Ngokulawula amapharamitha afana nobubanzi, amandla, amandla aphezulu kanye nemvamisa yokuphindaphinda kwe-laser pulse, i-workpiece iyancibilika ukuze yakhe ichibi elithile elincibilikisiwe. Isetshenziswa kabanzi ekukhiqizeni imishini, ezindizayo, embonini yezimoto, ensimbini yempuphu, embonini ye-biomedical microelectronics kanye neminye imikhakha.

Ngokukhula okukhulu kwezimoto ezintsha zamandla, ukwanda kokukhiqizwa kwamabhethri kagesi kuholele ekukhuleni kokushiswa kwe-laser. Kusukela engxenyeni yesibili ka-2018, ukushiswa kwe-laser okuphethwe ngesandla kuye kwathola ukuthandwa kancane kancane, futhi kuye kwaba yindawo ekhanyayo emakethe yokushiswa kwe-laser engxenyeni yokuqala yalo nyaka. Ngezinga lobuchwepheshe lamanje kanye nezimo zokusetshenziswa kwe-ukushisela nge-laser okuphathwa ngesandla, kungenzeka kakhulu ukuthi ithathe indawo yemakethe yendabuko yomshini wokushisela we-TIG (i-argon arc welding).

Eminyakeni yakamuva,ama-laser efayibhabenze intuthuko enkulu, futhi izinzuzo zabo zifaka phakathi: izinga eliphezulu lokuguqulwa kwe-photoelectric, ukushabalalisa ukushisa okusheshayo, ukuguquguquka okuhle, ikhono eliqinile lokulwa nokuphazamiseka, izindleko eziphansi, impilo ende, akukho ukulungiswa, akukho ukunakekelwa, ukuzinza okuphezulu, usayizi omncane, Imishini yokushisela ye-laser ephathwa ngesandla esebenzisa i-fiber lasers nayo ithuthuke kancane kancane.

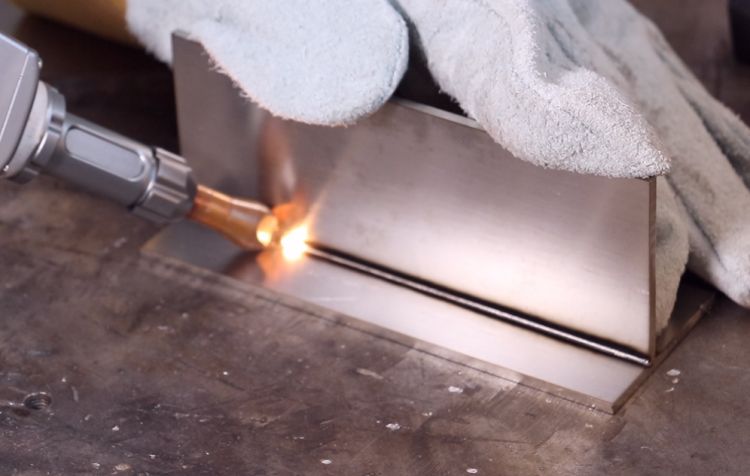

Ukushisela nge-laserKudinga ukunemba okuphezulu kokuhlanganiswa kwento yokusebenza, futhi umthungo wokushisela uthambekele ekuphazamisekeni. Ukuze axazulule le nkinga, umklami ubhekisela emishinini yokushisela yelaser yendiza ekhethekile ukuthuthukisa imishini yokushisela yelaser ephathwa ngesandla enendawo yokujikajika. I-laser isesimweni se-"8" noma "0" uhlobo lokujika lunganciphisa ukunemba kokuhlanganiswa kwento yokusebenza futhi kwandise ukungena kokushisela. Ngemva kochungechunge lokwenziwa ngcono nokuthuthukiswa, imishini yokushisela yelaser ephathwayo yamanje inamandla angu-0.5-1.5KW, futhi ubukhulu nesisindo semishini silingana nemishini yokushisela ye-argon arc, engashisela amapuleti ensimbi angu-3mm noma ngaphansi. Ukuze kuxazululwe ukushiyeka kwamandla anganele okushisela ezakhiwo zokushisela zelaser, eminyakeni yamuva nje, abakhiqizi bemishini bahlanganise amadivayisi okunika izintambo ngokuzenzakalela ngokusekelwe ekushiseni kwelaser, futhi bathuthukise imishini yokushisela yelaser ephethwe ngesandla engondla izintambo ngokuzenzakalela, okuhlangabezana nezidingo zamapuleti ensimbi amancane angaphansi kuka-4m. Ukushisela kungathatha indawo futhi kudlule ukushisela kwe-argon arc, kufinyelele isivinini esiphezulu, ukufakwa kokushisa okuphansi, ukuguqulwa okuncane, ukushisela ukuvikelwa kwemvelo okungabizi kakhulu, futhi izindleko zokukhiqiza ziphansi kunezokushisela kwe-argon arc ngaphansi kwezimo ezifanayo.

Uma isebenza, ikhanda lomshini wokushisela elibanjwe ngesandla linobubanzi bokuskena, futhi ububanzi balo buncane, ngakho-ke uma lishisela, liskena lisuka kwelinye iphuzu liye kwelinye umugqa nomugqa, ngaleyo ndlela lakha ubuhlalu bokushisela. Uma kuqhathaniswa nomshini wokushisela obandayo wendabuko, isivinini sokushisela sokushisela kwe-laser esibanjwe ngesandla sizoshesha, futhi inqubo yokushisela ye-shot-shot eyodwa inquma ukuthi ifaneleka kakhulu ekushiseni ngobuningi kwemigqa emide eqondile.

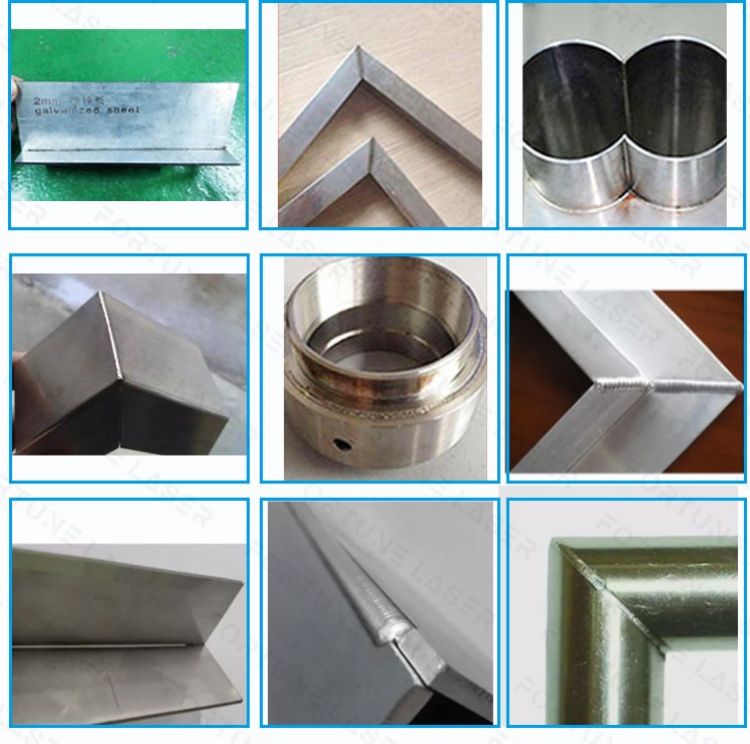

Futhi umshini wokushisela we-laser ophethwe ngesandla awuthathi isikhala esiningi, futhi uvame ukuhlonyiswa ngamakhanda ahlukahlukene aphethwe ngesandla. Ngokwezidingo ezahlukene zezingxenye zensimbi ezifana nokushisela kwangaphandle, ukushisela kwangaphakathi, ukushisela kwe-engeli yesokudla, ukushisela komphetho omncane, kanye nokushisela okukhulu, amakhanda ahlukahlukene okushisela aphethwe ngesandla angakhethwa. Imikhiqizo engashiselwa iyahlukahluka, futhi ukuma komkhiqizo kuyaguquguquka kakhudlwana. Kuma-workshop okukhiqiza ahileleke ekucutshungulweni kwezinga elincane kanye nokushisela okungekona okukhulu, imishini yokushisela ye-laser ephathwa ngesandla ngokuqinisekile iyisinqumo esingcono kakhulu.

Izinto zensimbi ezahlukene zinamaphuzu ahlukene okuncibilika: ukubekwa kwamapharamitha okushisela ezinhlobo ezahlukene zezinto zokushisela kuyinkimbinkimbi kakhulu, futhi izakhiwo ze-thermophysical zezinto zokushisela zizobonisa umehluko ohlukile ngokushintsha kwezinga lokushisa; izinga lokumuncwa kwezinhlobo ezahlukene zezinto ze-laser lizohluka futhi. Izinguquko zokushisa zibonisa umehluko ohlukile; ukuncibilika kwejoyinti le-solder kanye nokuvela kwesakhiwo sendawo ethintekile ekushiseni ngesikhathi sokuqina kwe-weldment; amaphutha ahlangene omshini wokushisela we-laser ophethwe ngesandla, ukucindezeleka kokubamba iqhaza kwe-welding kanye nokuguquguquka kokushisa, njll. Kodwa okubaluleke kakhulu ithonya lomehluko ezimpahleni zezinto zokushisela ezimpahleni ezinkulu nezincane ze-weld.

Yiziphi izinto ezingasetshenziswaumshini wokushisela we-laser ophathwa ngesandlaukushisela?

1. Insimbi engagqwali

Insimbi engagqwali inomthamo ophezulu wokwanda kokushisa, futhi ithambekele ekushiseni ngokweqile ngesikhathi sokushisela. Uma indawo ethintekile ukushisa inkulu kancane, izobangela izinkinga ezinkulu zokuguquguquka. Kodwa-ke, ukushisa okukhiqizwa umshini wokushisela we-laser ophathwa ngesandla phakathi nayo yonke inqubo yokushisela kuphansi. Uma kuhambisana nokushisa okuphansi, izinga lokumuncwa kwamandla aphezulu kanye nokusebenza kahle kokuncibilika kwensimbi engagqwali, ukushisela okwenziwe kahle, okubushelelezi nokuhle kungatholakala ngemuva kokushisela.

2. Insimbi yekhabhoni

Insimbi yekhabhoni evamile ingashintshwa ngqo ngokushiswa kwe-laser okubanjwe ngesandla, umphumela ufana nokushiswa kwensimbi engagqwali, futhi indawo ethintekile ekushiseni incane, kodwa lapho kushiswa insimbi yekhabhoni ephakathi nendawo nephezulu, izinga lokushisa elisele liphezulu kakhulu, ngakho-ke kusadingeka ukushiswa ngaphambi kokushiswa. Ukushisa nokulondolozwa kokushisa ngemva kokushiswa ukuze kuncishiswe ukucindezeleka futhi kugweme imifantu. Lapha singakhuluma ngomshini wokushiswa obandayo. Insimbi yekhabhoni ephakathi nendawo nephezulu ingashintshwa noma ilungiswe ngesivinini esiphansi ngokushiswa okubandayo kanye nocingo lokushiswa kwensimbi ephonswe. Ngokuphathelene nokulawula izinga lokushisa, ukulawula izinga lokushisa, kanye nokulawula izinga lokushisa, umshini wokushiswa obandayo ungafundisa ukushiswa kwe-laser okubanjwe ngesandla ukuthi kusebenze kangcono ekushiseni okusele ngemva kokushiswa.

3. Insimbi yomshini

Ifanele ukushisela izinhlobo ezahlukene zensimbi edayiwe, futhi umphumela wokushisela muhle kakhulu.

4. I-aluminium kanye ne-aluminium alloy

Ama-aluminium kanye nama-aluminium alloys ayizinto ezibonisa ukukhanya okukhulu, futhi ama-porosity angavela echibini elincibilikisiwe noma empandeni ngesikhathi sokushisela. Uma kuqhathaniswa nezinto zensimbi zangaphambilini, ama-aluminium kanye nama-aluminium alloys anezidingo eziphakeme zamapharamitha, kodwa uma nje amapharamitha okushisela akhethiwe efanele, umthungo wokushisela onezakhiwo ezifanayo zemishini njengensimbi eyisisekelo ungatholakala.

5. Ingxubevange yethusi nethusi

Ukushisa kwethusi kunamandla kakhulu, futhi kulula ukubangela ukungena okungaphelele kanye nokuhlangana okuyingxenye ngesikhathi sokushisela. Ngokuvamile, izinto zethusi ziyashiswa ngesikhathi senqubo yokushisela ukusiza ukushisela. Lapha sikhuluma ngezinto zethusi ezincane. Ithini lokushisela le-laser elibanjwe ngesandla ngqo Ukushisela, ngenxa yamandla alo agxilile kanye nesivinini sokushisela esisheshayo, akuthinteki kakhulu ukushisisa okuphezulu kwethusi.

6. Ukushisela phakathi kwezinto ezingafani

Umshini wokushisela we-laser ophathwa ngesandla ungenziwa phakathi kwezinhlobo ezahlukene zezinsimbi ezingafani, njenge-copper-nickel, i-nickel-titanium, i-copper-titanium, i-titanium-molybdenum, i-brass-copper, i-low carbon steel-copper kanye nezinye izinsimbi ezingafani. Ukushisela kwe-laser kungenziwa ngaphansi kwanoma yiziphi izimo (igesi noma izinga lokushisa).

Umshini wokushisela we-laser ophathwa ngesandla okwamanje uwumkhiqizo osetshenziswa kabanzi embonini yokushisela, ikakhulukazi ngoba yize lo mshini ubukeka ubiza kakhulu, ungonga kahle izindleko zabasebenzi. Izindleko zabasebenzi zabashisela zibiza kakhulu. Ukusebenzisa lokhu Umkhiqizo uxazulula inkinga yokuqashwa kwabashisela okubizayo nokunzima. Ngaphezu kwalokho, umshini wokushisela we-laser ophathwa ngesandla uzuze udumo olukhulu ezinkulungwaneni zamakhasimende ngenxa yokuphila kwawo isikhathi eside kanye nokusetshenziswa kwamandla aphansi.

Uma ufuna ukufunda kabanzi ngokuhlanzwa nge-laser, noma ufuna ukuthenga umshini wokuhlanza nge-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Disemba-03-2022