Umshini Wokusika We-Laser Wensimbi Ongabizi Kakhulu

Umshini Wokusika We-Laser Wensimbi Ongabizi Kakhulu

Izinhlamvu Zomshini Wokusika I-Laser Yensimbi

●I-Servo ekabili isakhiwo se-drive gantry:Umshini we-laser wesakhiwo se-bridge gantry, i-rack rail drive, sebenzisa idivayisi yokuthambisa ephakathi, futhi kulula ukuyilungisa;

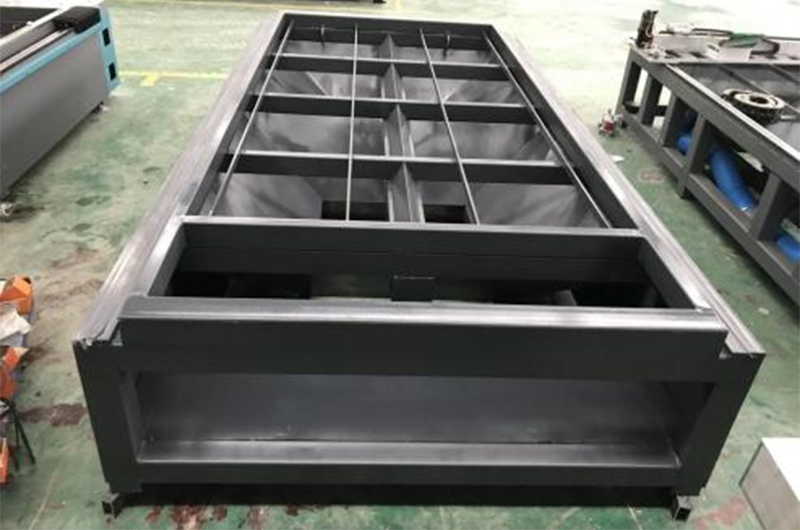

●Pubandlululo kanye neSitebele: Umbhede womshini wokushisela oqinisiwe, ukudlidliza kokwelashwa kokushisa okuphezulu ukuze kuqedwe ukucindezeleka. Ukuguqulwa kwethuluzi lomshini kungalawulwa ku-± 0.02mm;

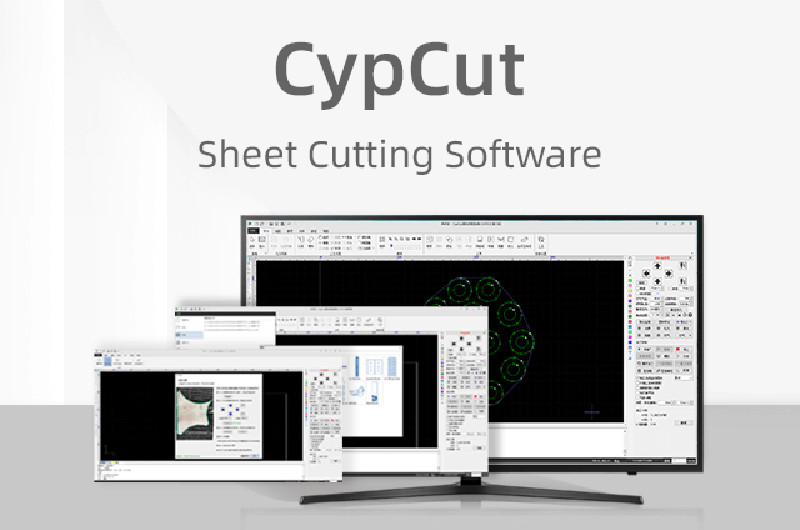

●Umsebenzi ulula: Abasebenzisi abangaphezu kuka-23000 basebenzisa lolu hlelo lokusika lwe-CNC lobuchwepheshe. Lolu hlelo lokusebenza lunomsebenzi wokulungiswa kwamandla nge-laser ukuqinisekisa ikhwalithi yokusika;

●Umklamo wobuhle bezimboni: Izindinganiso zokuthumela ngaphandle eYurophu naseMelika, ukubukeka komklamo wobuhle kwenza yamukeleke emakethe yomhlaba wonke;

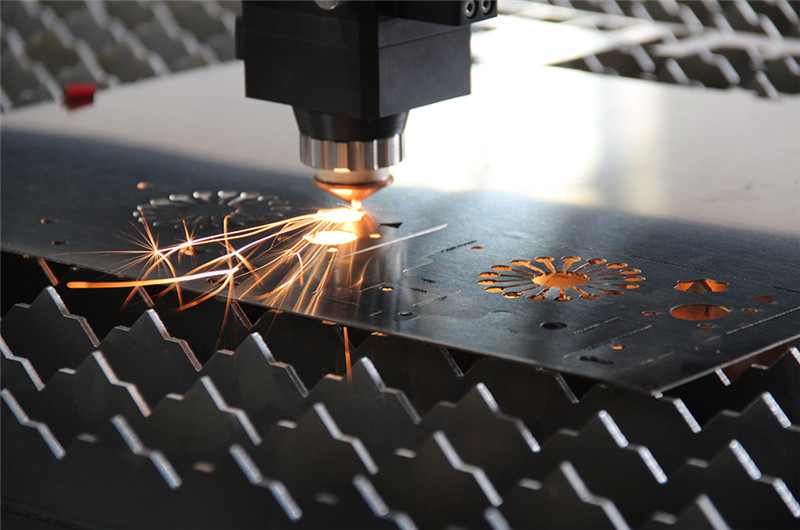

●Ukusika kwekhwalithi ephezulu:Ikhanda lokusika le-laser elinokunemba okuphezulu elilwa nokushayisana liqinisekisa umphumela omuhle kakhulu wokusika wezingxenye zakho zomsebenzi namaphrojekthi;

●Izinto ezisebenzayo:Kusetshenziswa ezimisweni ezijwayelekile zokusika ishidi lensimbi, konga isikhathi nezindleko;

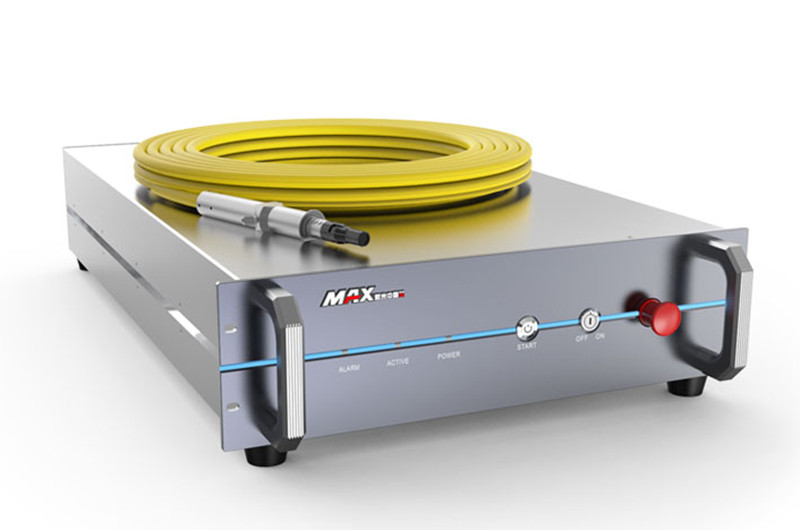

●I-laser yefayibha: Sebenzisa umthombo we-laser ye-fiber ye-Maxphotonics (Amanye ama-laser emikhiqizo ayakhethwa), amandla azinzile futhi athembekile, ukusebenza kuqinisekisiwe;

| Ukucushwa komshini | |

| Imodeli | Uchungechunge Lokusika Umshini We-Fiber Laser FL-S |

| Indawo Yokusebenza | 3000mm*1500mm |

| Umthombo we-laser | Ubukhulu obungu-1000w |

| Uhlelo Lokusika lwe-CNC | Uhlelo lokusebenza lwe-Cypcut 1000 |

| Ikhanda le-laser | Ukugxila ngesandla kwe-OSPRI |

| Umbhede womshini | I-Fortune Laser |

| Irekhi yegiya ye-X/Y axis | I-Fortune Laser |

| Umhlahlandlela oqondile oqondile | I-ROUST |

| I-Motor Drive | Injini ye-Yaskawa Servo yaseJapan (X750W/Y750W/Z400W) |

| Izingxenye ze-elekthronikhi | IFrance Schneider |

| Uhlelo lokunciphisa | UPHILANDE |

| Izingxenye zomoya | I-SMC yaseJapan |

| Izesekeli zombhede womshini | I-Fortune Laser |

| Isiqandisi samanzi | I-Hanli |

| Imishini yokuvuselela imfucuza | I-Fortune Laser |

Qaphela: Lokhu kulungiselelwa komshini kungokwereferensi yakho kuphela, ezinye izinhlobo eziningi zengxenye ngayinye yomshini ziyakhethwa ngokusekelwe ezidingweni zakho kanye nesabelomali sakho. Sicela uzizwe ukhululekile ukuxhumana nathi ukuthola imininingwane eyengeziwe.

Amapharamitha Omshini

| Imodeli | I-FL-S2015 | I-FL-S3015 | I-FL-S4020 | FL-S6020 |

| Indawo Yokusebenza (L*W) | 2000*1500mm | 3000*1500mm | 4000*2000mm | 6000*2000mm |

| Ukunemba Kwesikhundla Se-X/Y Axis | ± 0.03mm/1000mm | ± 0.03mm/1000mm | ± 0.03mm/1000mm | ± 0.03mm/1000mm |

| Ukunemba Kwesikhundla Sokuphinda I-X/Y Axis | ± 0.02mm | ± 0.02mm | ± 0.02mm | ± 0.02mm |

| Isivinini Esiphezulu Sokuhamba | 80000mm/min | 80000mm/min | 80000mm/min | 80000mm/min |

| Ukusheshisa Okuphezulu | 1.2g | 1.2g | 1.2g | 1.2g |

| Isisindo Esiphezulu Sokulayisha | 600kg | 800kg | 1200kg | 1500kg |

| Ukunikezwa kwamandla kagesi | I-AC380V/50Hz | I-AC380V/50Hz | I-AC380V/50Hz | I-AC380V/50Hz |

| Amandla Omthombo We-Laser (Ongakukhetha) | 1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW/8kW/10kW/12kW/15kW/20kW | |||

Izicelo

Ifanele ukucubungula ishidi lensimbi njengensimbi engagqwali, insimbi yekhabhoni, insimbi ye-alloy, insimbi ye-silicon, ipuleti lensimbi elihlanganisiwe, i-nickel-titanium alloy, i-inconel, i-titanium alloy, njll.

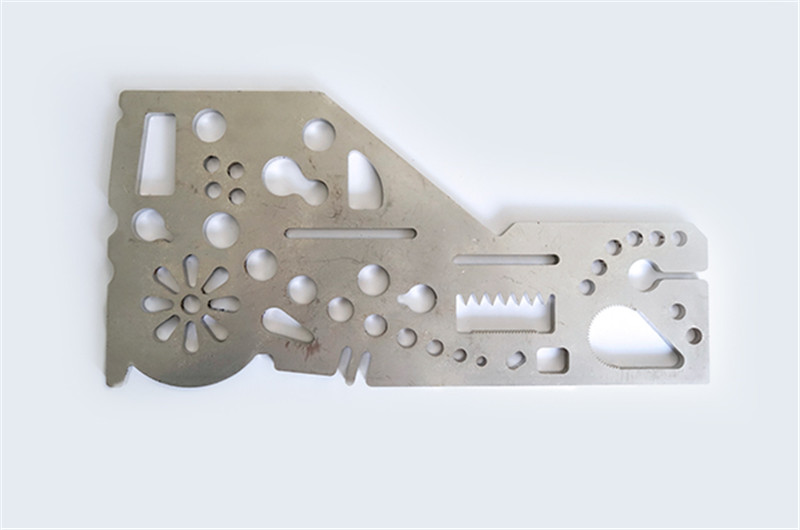

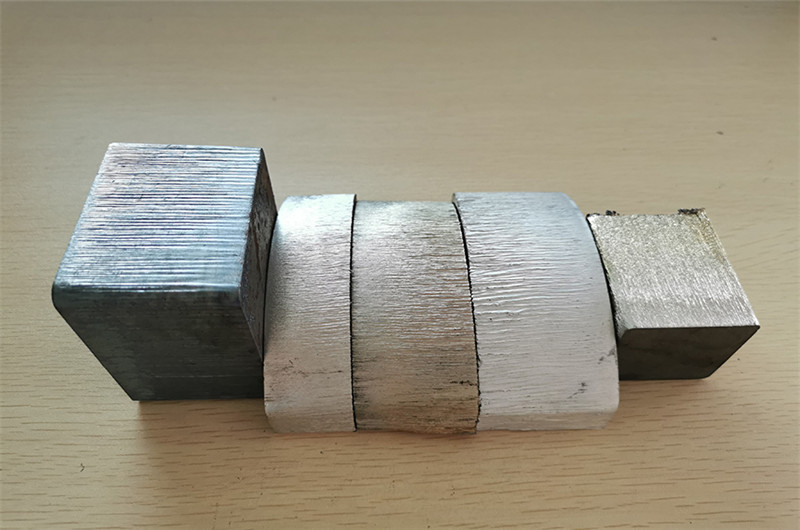

Ukuboniswa Kwamasampula

Amapharamitha Enqubo Yokusika Umthombo We-Laser Omkhulu

| Qaphela 1: Ububanzi obuyinhloko befayibha yokukhipha i-laser engu-1000W ~ 1500W kudatha yokusika bungama-microns angu-50; ububanzi obuyinhloko befayibha yokukhipha engu-2000 ~ 4000W bungama-microns ayi-100; | |||||||||

| Inothi 2: Le datha yokusika isebenzisa ikhanda lokusika le-Raytools, ubude be-lens yokugxila/yokuqopha: 100mm/125mm; | |||||||||

| Inothi 3: Ngenxa yokwehluka kokucushwa kwemishini kanye nenqubo yokusika (ithuluzi lomshini, ukupholisa amanzi, indawo ezungezile, umlomo wokusika kanye nomfutho wegesi) othathwe amakhasimende ahlukene, le datha ingeyereferensi kuphela; | |||||||||

| Mi-aterial | Ubukhulu (mm) | Gnjengezinhlobo | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | |||

| Insimbi engagqwali | 1 | N2 | 20~24 | 28~32 | 38 | 30 | 50 | 42~43 | 70~75 |

| 2 | N2 | 5.4 | 7.5 | 12 | 10 | 13 | 19~20 | 25~30 | |

| 3 | N2 | 2.2 | 4 | 7 | 6 | 8 | 11~12 | 12~15 | |

| 4 | N2 | 1.2 | 2 | 4 | 4 | 5 | 6.5~7.5 | 7.5~9 | |

| 5 | N2 |

| 1.1 | 2 | 2.5 | 2.5 | 4~5 | 6~7.5 | |

| 6 | N2 |

| 0.8 | 1.5 | 1.5 | 1.5 | 2~3 | 5~6.5 | |

| 8 | N2 |

|

| 0.8 | 0.7 | 1 | 1.5~2 | 3.5~4.5 | |

| 10 | N2 |

|

| 0.5 | 0.5 | 0.8 | 1 | 2.1 | |

| 12 | N2 |

|

|

|

| 0.5 | 0.8 | 1.1 | |

| 14 | N2 |

|

|

|

|

|

| 0.9 | |

| Mi-aterial | Ubukhulu (mm) | Gnjengezinhlobo | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) | isivinini(I-1965)m/min) |

| I-CarbonSteel | 1 | umoya | 9~12 | 27~30 | 27~30 | 30 | 50 | 43 | 70~75 |

| 2 | umoya | 6~8 | 8~10 | 10~12 | 12 | 13 | 20 | 25~30 | |

| 3 | O2 | 3 | 3 | 3 | 4 | 4.5 | 4.5 | 4.5 | |

| 4 | O2 | 2 | 2.5 | 3.1 | 3.3 | 3.5 | 3.8 | 3.8 | |

| 5 | O2 | 1.6 | 2 | 2.5~3 | 2.5 | 3 | 3.5 | 3.7 | |

| 6 | O2 | 1.4 | 1.8 | 2.2 | 2.3 | 2.5 | 2.8 | 3.3 | |

| 8 | O2 | 1.1 | 1.3 | 1.5 | 1.5 | 2 | 2.3 | 2.8 | |

| 10 | O2 | 0.9 | 1.1 | 1 | 1.2 | 1.4 | 1.8 | 2.1 | |

| 12 | O2 | 0.7 | 0.9 | 0.8 | 1 | 1.1 | 1.5 | 1.6 | |

| 14 | O2 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.95 | ||

| 16 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 0.85 | ||

| 18 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.75 | |||

| 20 | O2 | 0.4 | 0.5 | 0.6 | 0.7 | 0.65 | |||

| 22 | O2 | 0.4 | 0.5 | 0.5 | 0.5 | ||||

| I-Aluminium | 1 | umoya | 12~13 | 15 | 17~18 | 29 | 45 | 35~37 | 70~75 |

| 2 | umoya | 4~4.5 | 6 | 7.5 | 8.5 | 11 | 15 | 25~30 | |

| 3 | umoya | 1~1.5 | 3 | 5 | 5 | 7 | 8~9 | 15 | |

| 4 | umoya | 0.8~1 | 2 | 3 | 4 | 6 | 10 | ||

| 5 | umoya | 1 | 1.5 | 3 | 8 | ||||

| 6 | umoya | 0.6 | 1 | 2 | 5.5 | ||||

| 8 | umoya | 0.5 | 1 | 2.5 | |||||

| 10 | umoya | 0.5 | 1.3 | ||||||

| 12 | umoya | 0.9 | |||||||

| Ithusi | 1 | umoya | 10 | 12 | 15 | 24 | 40 | 30~33 | 65~70 |

| 2 | umoya | 3 | 5 | 6 | 7.5 | 10 | 13 | 20~25 | |

| 3 | umoya | 0.5 | 2 | 3 | 4 | 4 | 7 | 5 | |

| 4 | umoya | 0.5 | 1.5 | 2 | 3 | 5 | 4 | ||

| 5 | umoya | 0.5 | 1 | 1.5 | 2 | 3 | |||

| 6 | umoya | 0.5 | 0.8 | 1.5 | 2 | ||||

| 8 | umoya |

| 0.8 | 1.2 | |||||

| 10 | umoya |

|

| 0.5 |

Izidingo Zendawo Yokusebenza

1. Izidingo zomswakama zingama-40%-80%, akukho ukujiya.

2. Izidingo zegridi yamandla: 380V; 50Hz/60A.

3. Ukuguquguquka kwegridi yokunikezwa kwamandla: 5%, ucingo olungaphansi kwegridi luhlangabezana nezidingo zomhlaba wonke.

4. Ukusika ngegesi elisizayo: Umoya ohlanzekile, owomile ocindezelwe kanye nomoya-mpilo ohlanzekile (O2) kanye ne-nitrogen (N2), ubumsulwa obungaphansi kuka-99.9%.

5. Akufanele kube nokuphazamiseka okukhulu kwe-electromagnetic eduze kwemishini yokufaka.

6. Gwema ama-radio transmitter noma iziteshi zokudlulisa eziseduze nendawo yokufaka.

7. Ukumelana nokugqwala kwamandla: ≤ 4 ohms. Ububanzi bomhlabathi: ngaphansi kuka-50um; ukusheshisa kokudlidliza: ngaphansi kuka-0.05g.

8. Gwema inani elikhulu lamathuluzi omshini njengokunyathela eduze.

9. Umfutho womoya: 86-106kpa.

10. Izidingo zesikhala semishini ziqinisekisiwe ukuthi azinantuthu futhi azinazo uthuli, zigwema izindawo zokusebenza ezinothuli njengokupholisha nokugaya insimbi.

11. Kufanele kufakwe iphansi elingaguquki futhi kuxhunywe ikhebula elivikelwe.

12. Ikhwalithi yamanzi ajikelezayo asebenzayo apholile iyadingeka kakhulu, futhi amanzi ahlanzekile, amanzi ahlanzekile noma amanzi acwengekile kumele asetshenziswe.