Walda ta Laseryana ɗaya daga cikin muhimman fannoni na amfani da fasahar sarrafa kayan sarrafa laser. Ana amfani da shi galibi don walda kayan da ke da sirara da walda mai ƙarancin gudu. Tsarin walda yana da alaƙa da nau'in watsa zafi, wato, hasken laser yana dumama saman kayan aikin, kuma zafin saman yana bazuwa zuwa ciki ta hanyar watsa zafi. Ta hanyar sarrafa sigogi kamar faɗin, kuzari, ƙarfin kololuwa da maimaita mitar bugun laser, kayan aikin yana narkewa don samar da takamaiman wurin narkakken tafki. Ana amfani da shi sosai a masana'antar injina, sararin samaniya, masana'antar motoci, masana'antar ƙarfe foda, masana'antar microelectronics da sauran fannoni.

Tare da ƙaruwar sabbin motocin makamashi, faɗaɗa samar da batirin wutar lantarki ya haifar da haɓakar walda ta laser. Tun daga rabin na biyu na 2018, walda ta laser ta hannu ta sami karɓuwa a hankali, kuma ta zama wuri mai kyau a kasuwar walda ta laser a rabin farko na wannan shekarar. Tare da matakin fasaha na yanzu da yanayin aikace-aikacenwalda laser ta hannu, yana da yuwuwar maye gurbin kasuwar injin walda na TIG na gargajiya (walda ta argon arc).

A cikin 'yan shekarun nan,na'urorin laser na fibersun sami babban ci gaba, kuma fa'idodin su sun haɗa da: babban canjin wutar lantarki, watsa zafi mai sauri, sassauci mai kyau, ƙarfin hana tsangwama, ƙarancin farashi, tsawon rai, babu daidaitawa, babu kulawa, kwanciyar hankali mai yawa, ƙaramin girma, Kayan aikin walda na laser na hannu waɗanda ke amfani da lasers na fiber suma sun ci gaba a hankali.

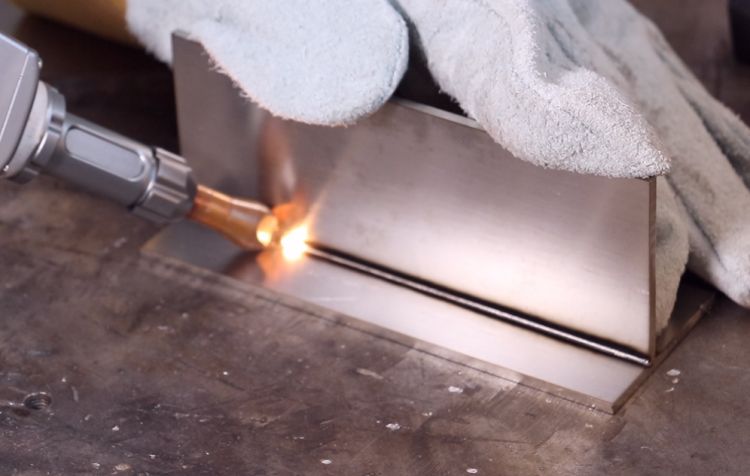

Walda ta Laseryana buƙatar daidaiton haɗa kayan aikin, kuma ɗinkin walda yana da yuwuwar samun lahani. Don magance wannan matsalar, mai ƙira ya koma ga kayan walda na laser na musamman don ƙirƙirar kayan walda na laser na hannu tare da wurin juyawa. Laser ɗin yana cikin siffar "8" ko "0" nau'in juyawa na iya rage daidaiton haɗa kayan aikin kuma ƙara shigar walda. Bayan jerin haɓakawa da haɓakawa, kayan walda na laser na hannu na yanzu suna da ƙarfin 0.5-1.5KW, kuma girman da nauyin kayan aikin sun yi daidai da na'urorin walda na argon arc, waɗanda za su iya walda faranti na ƙarfe na 3mm ko ƙasa da haka. Domin magance ƙarancin ƙarfin walda na tsarin walda na laser, a cikin 'yan shekarun nan, masana'antun kayan aiki sun haɗa na'urorin ciyar da waya ta atomatik bisa ga walda na laser, kuma sun ƙirƙiri kayan walda na laser na hannu waɗanda za su iya ciyar da wayoyi ta atomatik, waɗanda ke biyan buƙatun faranti na ƙarfe masu sirara a ƙasa da mita 4. Walda na iya maye gurbin walda argon arc da kuma wuce shi, samar da babban gudu, ƙarancin shigar zafi, ƙaramin lalacewa, walda mai ƙarancin farashi ga muhalli, kuma farashin masana'antu ya yi ƙasa da na walda argon arc a ƙarƙashin irin wannan yanayi.

Lokacin aiki, kan injin walda da ke riƙe da hannu yana da faɗin na'urar dubawa, kuma diamita na wurinsa ƙarami ne, don haka lokacin walda, yana duba daga wani wuri zuwa wani layin maki bayan layi, don haka yana samar da dutsen walda. Idan aka kwatanta da na'urar walda mai sanyi ta gargajiya, saurin walda na walda ta laser da ke riƙe da hannu zai fi sauri, kuma tsarin walda mai harbi ɗaya yana tabbatar da cewa ya fi dacewa da walda mai yawa na dogon dinki madaidaiciya.

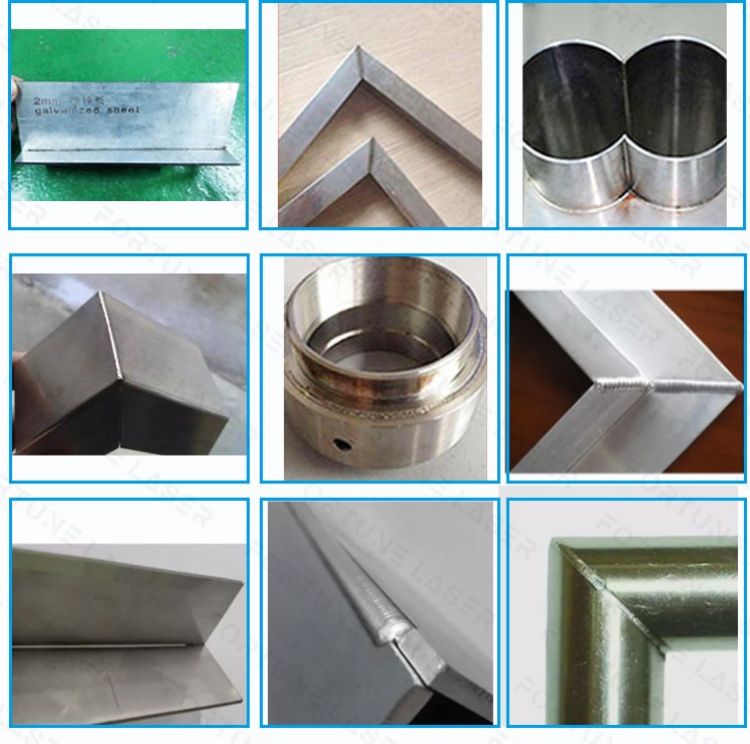

Kuma na'urar walda ta laser mai hannu ba ta ɗaukar sarari kaɗan, kuma yawanci tana da nau'ikan kawunan hannu iri-iri. Dangane da buƙatun sassa daban-daban na ƙarfe kamar walda ta waje, walda ta ciki, walda ta kusurwa ta dama, walda mai kunkuntar gefen, da walda mai manyan tabo, ana iya zaɓar kawunan walda daban-daban na hannu. Kayayyakin da za a iya walda suna da bambancin tsari, kuma siffar samfurin ta fi sassauƙa. Don bitar samarwa da ke aiki a ƙananan sikelin sarrafawa da walda marasa girma, injinan walda ta laser da hannu tabbas sune mafi kyawun zaɓi.

Kayan ƙarfe daban-daban suna da wuraren narkewa daban-daban: saitin sigogin walda don nau'ikan kayan walda daban-daban yana da rikitarwa, kuma halayen thermophysical na kayan walda zai nuna bambance-bambance daban-daban tare da canje-canjen zafin jiki; ƙimar sha na nau'ikan kayan daban-daban don laser shima zai bambanta tare da Canje-canjen zafin jiki yana nuna bambance-bambance daban-daban; narkewar haɗin solder da juyin halittar yankin da zafi ya shafa yayin ƙarfafa walda; lahani na haɗin gwiwa na injin walda laser da hannu, damuwa na haɗin walda da nakasawar zafi, da sauransu. Amma mafi mahimmanci shine tasirin bambancin halayen kayan walda akan macro da ƙananan kaddarorin walda.

Abin da kayan za su iya yiinjin walda na Laser da hannuwalda?

1. Bakin ƙarfe

Bakin karfe yana da yawan faɗaɗa zafi, kuma yana iya yin zafi sosai yayin walda. Idan yankin da zafi ya shafa ya ɗan yi girma, zai haifar da manyan matsaloli na nakasa. Duk da haka, zafi da injin walda na laser da ke aiki a hannu ke samarwa a duk lokacin walda ba shi da yawa. Tare da ƙarancin ƙarfin wutar lantarki, yawan shan makamashi mai yawa da kuma yadda ƙarfe ke narkewa, ana iya samun walda mai kyau, santsi da kyau bayan walda.

2. Karfe mai amfani da carbon

Ana iya walda ƙarfen carbon na yau da kullun kai tsaye ta hanyar walda ta laser da hannu, tasirin yana kama da walda ta bakin ƙarfe, kuma yankin da zafi ya shafa ƙarami ne, amma lokacin walda ƙarfe matsakaici da babban carbon, zafin da ya rage yana da yawa, don haka har yanzu yana da mahimmanci a walda kafin walda. Ana dumamawa da adana zafi bayan walda don rage damuwa da guje wa tsagewa. A nan za mu iya magana game da injin walda mai sanyi. Ana iya walda ƙarfe matsakaici da babban carbon a hankali ko gyara shi ta hanyar walda mai sanyi da waya mai ƙarfe. Dangane da sarrafa zafin jiki, sarrafa zafin jiki, da sarrafa zafin jiki, injin walda mai sanyi zai iya koyar walda ta laser da hannu ta fi inganci akan ragowar zafi bayan walda.

3. Karfe mai kama da ƙarfe

Ya dace da walda iri-iri na ƙarfe mai mutuwa, kuma tasirin walda yana da kyau sosai.

4. Aluminum da aluminum gami

Gilashin aluminum da aluminum kayan aiki ne masu haske sosai, kuma ramuka na iya bayyana a cikin wurin narkakken narkewa ko a tushen yayin walda. Idan aka kwatanta da kayan ƙarfe na baya, gilashin aluminum da aluminum suna da buƙatu mafi girma don sigogi, amma matuƙar sigogin walda da aka zaɓa sun dace, ana iya samun ɗinkin walda mai irin halayen injiniya kamar ƙarfe na tushe.

5. Haɗin tagulla da jan ƙarfe

Tsarin wutar lantarki na jan ƙarfe yana da ƙarfi sosai, kuma yana da sauƙi ya haifar da shigar ciki ba tare da cikakke ba da kuma haɗakar wani ɓangare yayin walda. Yawanci, ana dumama kayan jan ƙarfe yayin walda don taimakawa walda. A nan muna magana ne game da siraran kayan jan ƙarfe. Walda ta laser da hannu za ta iya yin walda kai tsaye. Walda, saboda ƙarfinta mai yawa da saurin walda, ba ta da tasiri sosai daga yawan wutar lantarki ta jan ƙarfe.

6. Walda tsakanin kayan da ba su da kama da juna

Ana iya yin walda ta laser mai riƙe da hannu tsakanin nau'ikan ƙarfe daban-daban, kamar su jan ƙarfe-nickel, nickel-titanium, jan ƙarfe-titanium, titanium-molybdenum, jan ƙarfe-copper, ƙarfe mai ƙarancin carbon-copper da sauran ƙarfe daban-daban. Ana iya yin walda ta laser a ƙarƙashin kowace irin yanayi (gas ko zafin jiki).

Injin walda na laser da hannu a halin yanzu samfuri ne da ake amfani da shi sosai a masana'antar walda, galibi saboda duk da cewa wannan kayan aikin yana da tsada, yana iya adana kuɗin aiki sosai. Kudin aikin walda yana da tsada sosai. Amfani da wannan Samfurin yana magance matsalar ɗaukar ma'aikatan walda masu tsada da wahala. Bugu da ƙari, injin walda na laser da hannu ya sami yabo gaba ɗaya daga dubban abokan ciniki saboda tsawon lokacin aikinsa da ƙarancin amfani da makamashi.

Idan kana son ƙarin koyo game da tsaftace laser, ko kuma kana son siyan mafi kyawun injin tsabtace laser a gare ka, da fatan za a bar saƙo a gidan yanar gizon mu kuma a aiko mana da imel kai tsaye!

Lokacin Saƙo: Disamba-03-2022