Fortune Laser Mini 1000W/1500W/2000W 3 In 1 Fiber Handheld Laser Welding Machine

Fortune Laser Mini 1000W/1500W/2000W 3 In 1 Fiber Handheld Laser Welding Machine

Ka nako e ts'oanang, mochine ona o monyenyane o ts'oaretsoeng ka letsoho oa laser o tšehetsa ho itšeha le ho tjheseletsa ka nako e le 'ngoe le mochine o tloaelehileng oa kabo ea terata, o ka fokotsang litlhoko tsa ho tlosoa ha likarolo le ho ntlafatsa boleng ba ho tjheseletsa. E ka boela ea sebelisoa hammoho le roboto e kopanetsoeng ho lokisa toche ea ho tjheseletsa robotong e kopanetsoeng, ho fokotsa matla a mosebetsi oa opereishene le ho ntlafatsa boleng ba tjheseletso ea weld.

1000W 1500w 2000w 3000W Mini Laser Welding Machine Molemo o Molemo

Moralo oa chassis oa All-in-one o bonolo

Mochini oa welding oa fiber laser oa Fortunelaser o nka moralo oa khabinete e kopaneng, e kopanyang laser, chiller, taolo ea software, joalo-joalo, 'me e na le melemo ea maoto a manyane, motsamao o bonolo, le ts'ebetso e matla.

Sebakeng sa "tsela e tsitsitseng ea optical", ts'ebetso e bonolo haholoanyane.

Hona joale ho sebelisoa tjheseletsa ka letsoho, ho sebelisa sethunya se ts'oaroang ka letsoho ho nka sebaka sa tsela e tsitsitseng ea optical, ts'ebetso e bonolo haholoanyane, e phunyeletsa mefokolo ea benche ea mosebetsi, ho kopana le tjheseletsa ea li-angles le maemo a sa tšoaneng. Ntle le moo, boemo ba infrared bo sebelisoa bakeng sa boemo bo nepahetseng le ho lekanya boemo ba tjheseletsa ho netefatsa li-welds tse ntle ho feta.

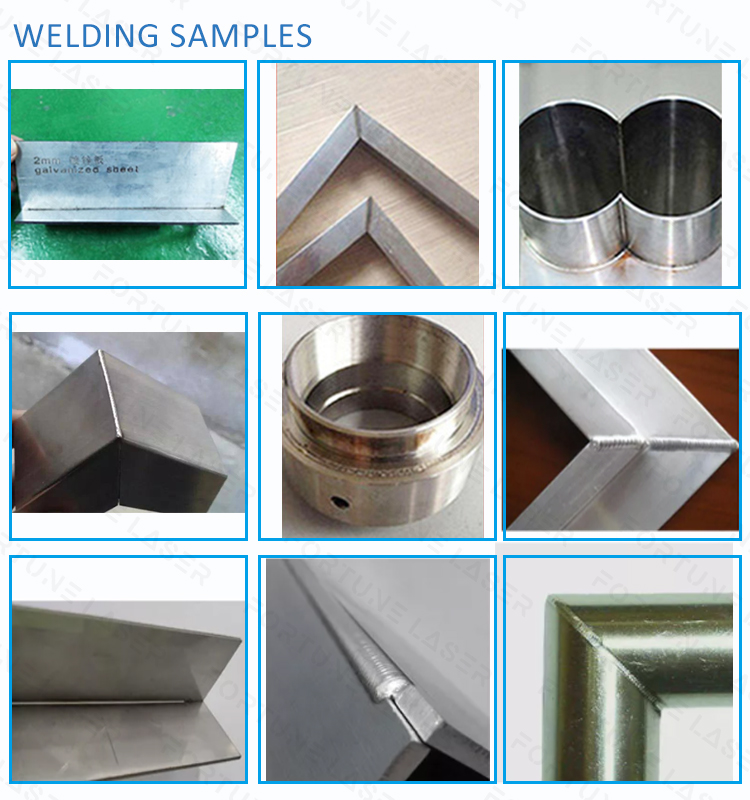

Nyenyane deformation mocheso, boreleli le e ntle weld

Re ka bona hore seam tjheseletsa oa optical faeba ka letsoho tjheseletsa ka laser tjheseletsa mochini o boreleli le ntle, workpiece tjheseletsa ha ho na deformation, ha lebali tjheseletsa, le tjheseletsa e tiile, ho fokotsa tshebetso e latelang ho sila, ho boloka nako le litšenyehelo. Tloaelo ea ho tjheseletsa ho thata ho finyella botle ba ho tjheseletsa ha li-workpieces tse rarahaneng, ha ho tjheseletsa ka letsoho ho ka finyella li-angles tse nepahetseng, likhutlo tse chitja le mekhoa e mengata ea ho tjheseletsa, ho etsa hore welding e be bonolo.

Botebo ba ho tjheseletsa bo boholo mme ho tjheseletsa ho tiile

Mochini oa welding oa fiber laser o ts'oaroang ka letsoho o sebelisoa haholo bakeng sa welding ea laser ea libaka tse telele le tse kholo tsa mosebetsi. Sebaka se amehileng ke mocheso nakong ea welding e nyenyane, e ke keng ea baka deformation ea mosebetsi, blackening, le mesaletsa ka morao. Botebo ba ho tjheseletsa bo boholo, ho tjheseletsa ho tiile, mme ho qhibidiha ho lekane.

Mochini o le mong o tšehetsa mesebetsi e meraro ea ho cheselletsa, ho kuta le ho hloekisa

Phetoho ea mesebetsi e 3 e ka bonoa feela ka hlooho ea laser.

Fortune Laser Mini Laser Welding Machine Technical Parameters

| Mohlala | FL-HW1000M | FL-HW1500M | FL-HW2000M |

| Matla a Laser | 1000W | 1500W | 2000W |

| Cooling Tsela | Pholiso ea Metsi | Pholiso ea Metsi | Pholiso ea Metsi |

| LaserWavelength | 1080nm | 1080nm | 1080nm |

| Way ea Ho sebetsa | Continuous/ Ketsiso ya ho feto-fetoha | ||

| Bolelele ba Fiber | Standard 10m, bolelele bo bolelele ka ho fetesisa bo 15m | ||

| Boemo | 100*68*45cm | ||

| Wrobedi | 165kg | ||

| Dikgetho | E nkehang | ||

| Lebelo la lebelo la welder | 0-120mm/s | ||

| Mocheso | 15-35 ℃ | ||

| Voltage e sebetsang | AV 220V | ||

| Focal Spot Diameter | 0.5 limilimithara | ||

| Botenya ba tjheseletsa | 0.5-5 limilimithara | ||

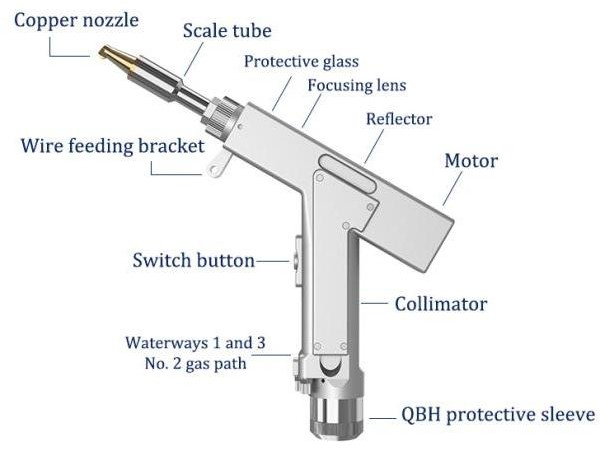

Likaroloana

l Likarolo tsa motheo: tsamaiso e ikemetseng ea ho laola tse tharo ho e le 'ngoe, phetoho e feto-fetohang ea welding, ho hloekisa le ho itšeha, lialamo tse ngata tsa tšireletso, ts'ebetso e bonolo le e bonolo.

l E tsitsitse haholoanyane: Litekanyetso tsohle li bonahala, ho lekola boemo ba mochini kaofela, ho qoba mathata esale pele, ho thusa ho rarolla mathata le ho rarolla mathata, le ho netefatsa ts'ebetso e tsitsitseng ea sistimi.

l Ts'ebetso: Litekanyetso tsa ts'ebetso li ka beoa, 'me litlamorao tse fapaneng tsa ts'ebetso li ka lekoa ka mokhoa o bonolo.

l Mekhahlelo e tsitsitseng le ho pheta-pheta ho phahameng: Khatello ea moea ea nozzle e ikemiselitseng le boemo ba lense, ha feela matla a laser a tsitsitse, litekanyetso tsa ts'ebetso li tlameha ho phetoa, tse ntlafatsang haholo ts'ebetso.

| Matla a phepelo (V) | 220V±10% AC 50/60Hz |

| Beha tikoloho | Flat, ha ho vibrate le ho makala |

| Mocheso oa ho sebetsa oa tikoloho (℃) | 10-40 |

| Mongobo wa tikoloho ya tshebetso(%) | <70 |

| Mokhoa oa ho pholisa | Pholiso ea metsi |

| Khohlano | D20*5/F60 |

| Focus (mokhoa oa ho cheselletsa ka letsoho) | D20*4.5/F150 |

| Tsepamisa maikutlo (mokhoa oa ho hloekisa) | D20*4.5/F400 |

| Ho thuisa | 30*14 T2 |

| Litlhaloso tsa lense tse sireletsang | 18*2 |

| Khatello e phahameng ea moea e tšehetsoeng | 10Bar |

| Tsepamisa maemo a feto-fetohang | ± 10 limilimithara |

| Sebaka sa phetoho ea sebaka (mokhoa oa ho ts'oara letsoho) | 0-6 limilimithara |

| Sebaka sa ho lokisa sebaka (mokhoa oa ho hloekisa) | 0 ~ 50 limilimithara |