Mohloli oa Laser bakeng sa Mochini oa Welding oa Laser Cutting

Re sebetsa haufi-ufi le lihlahisoa tse ka holimo tsa jenereithara ea Laser bakeng sa mechine ea rona ea ho itšeha ka laser, mechine ea ho tjheseletsa ea laser, mechine ea ho tšoaea laser le mechine ea ho hloekisa laser, ho finyella litlhoko le litekanyetso tse fapaneng tsa bareki.Lihlahisoa li kenyelletsa Raycus, Maxphotonics, IPG, JPT, RECI, joalo-joalo.

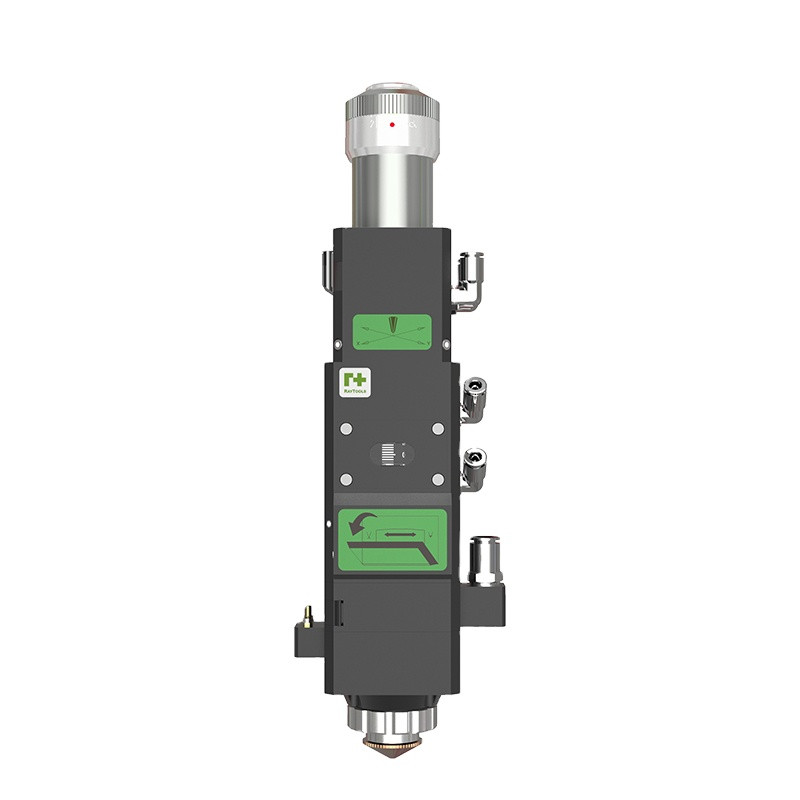

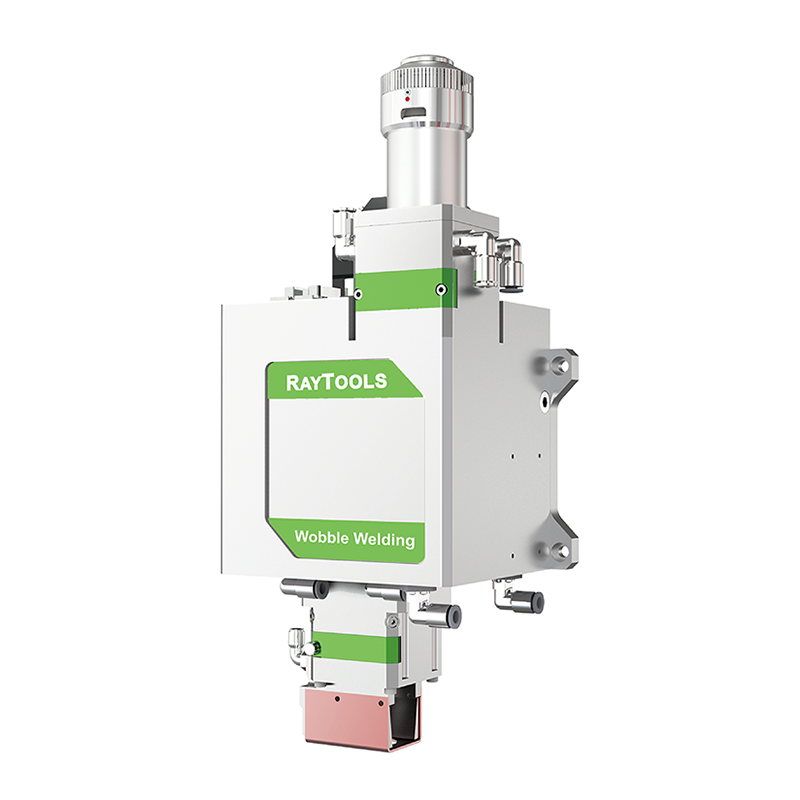

Laser Cutting Head bakeng sa Metal Laser Cutting Machines

Fortune Laser e sebetsa haufi-ufi le ba bang ba lihlahisoa tse phahameng ka ho fetisisa tsa laser ho itšeha lihlooho, ho akarelletsa le Raytools, OSPRI, WSX, Precitec, joalo-joalo Re ke ke ra beha mechine e nang le hlooho ea ho itšeha ka laser ho latela litlhoko tsa bareki, empa hape re ka fana ka laser. ho khaola hlooho ka kotloloho ho bareki ha ho hlokahala.

Theko e Otlolohileng le Phano e potlakileng

Likarolo tsa 'Nete tsa Spare le Guarantee ea Boleng bo Phahameng

Tšehetso ea Theknoloji Haeba ho na le Lipelaelo Kapa Mathata

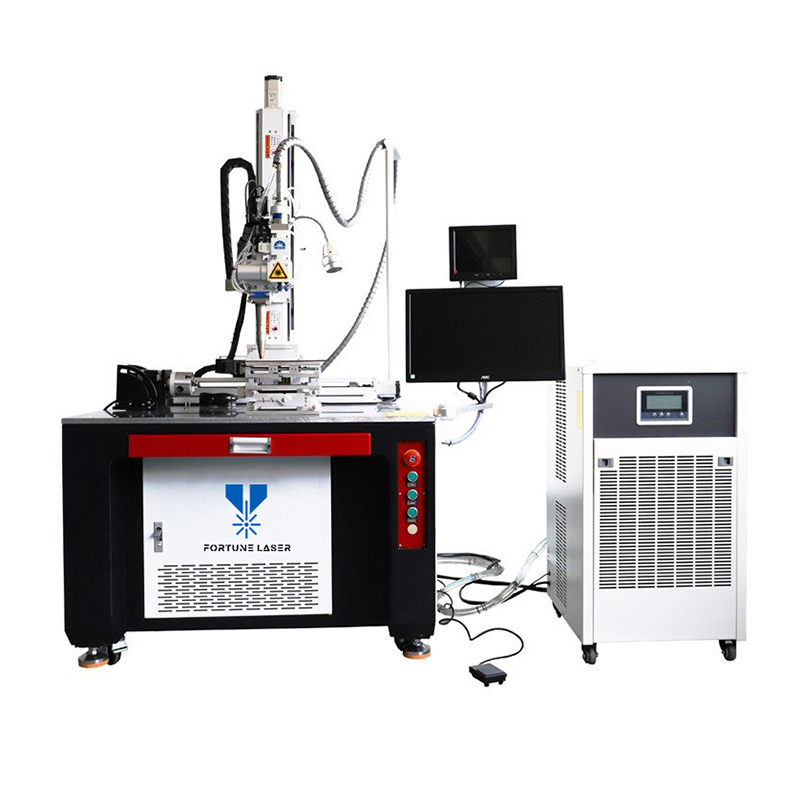

Mabenyane a Mini Spot Laser Welder 60W 100W

Li-brand tsa laser welding heads tseo re li sebelisang bakeng sa mechine ea welding hangata ke OSPRI, Raytools, Qilin, joalo-joalo Re ka boela ra hlahisa li-welder tsa laser kamoo ho hlokahalang bareki.

Laser Cooling System bakeng sa Laser Cutter Welder

CWFL-1500 water chiller e ntlafalitsoeng ke S&A Teyu e etselitsoe haholo lisebelisoa tsa laser fiber ho fihla ho 1.5KW.Setsi sena sa metsi sa indasteri ke sesebelisoa sa taolo ea mocheso se nang le lipotoloho tse peli tse ikemetseng tsa sehatsetsi ka har'a sephutheloana se le seng.Ka hona, ho ka fanoa ka pholileng e arohaneng ho tloha ho chiller e le 'ngoe bakeng sa laser fiber le hlooho ea laser, ho boloka sebaka se seholo le litšenyehelo ka nako e le 'ngoe.

Tse peli dijethale mocheso balaoli ba chiller ke desi

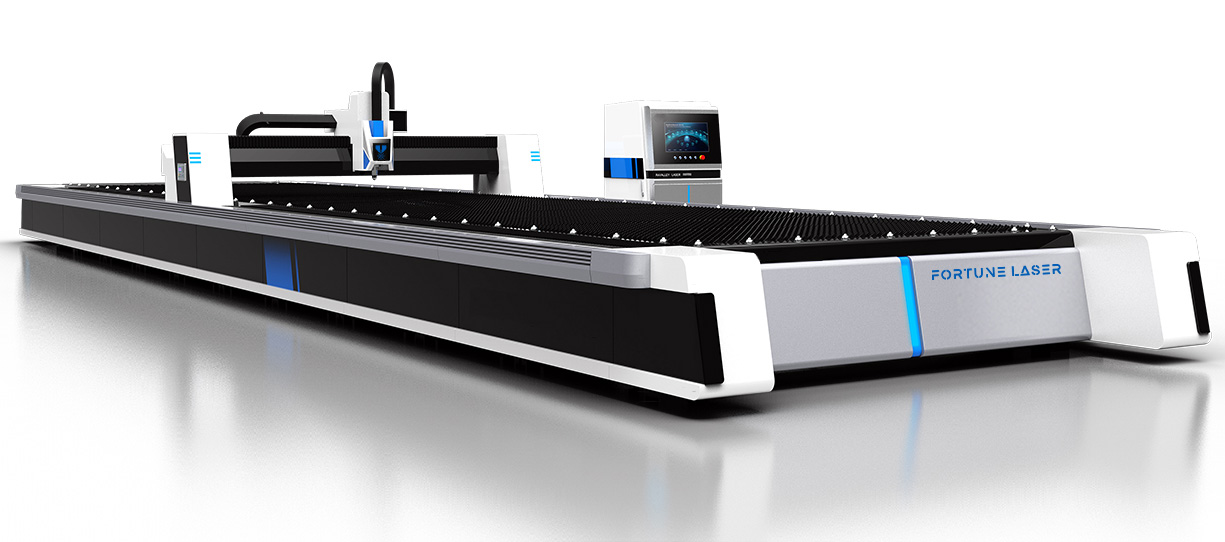

Likarolo tse 6 tse ka Sehloohong tsa Mochini o Sehang oa Fiber Laser?

Likarolo tse 6 tse ka Sehloohong tsa Mochini o Sehang oa Fiber Laser?