Fortune Laser Automatic 300W Yag Laser Mold Mold Machine

Fortune Laser Automatic 300W Yag Laser Mold Mold Machine

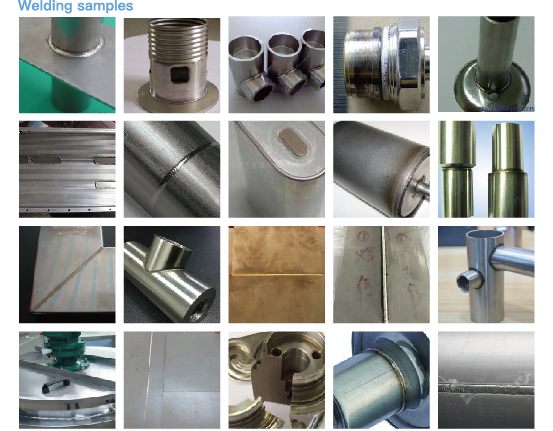

Melao-motheo ea Motheo ea Mochini oa Laser

Mochini oa welding oa laser oa li-axis tse 'ne o amohela sekoti se tsoetseng pele sa lebone le le leng la ceramic reflector cavity, matla a matla, programmable laser pulse le tsamaiso e bohlale ea tsamaiso.Z-axis ea "worktable" e ka isoa holimo le tlase ho tsepamisa maikutlo, e laoloa ke PC ea indasteri.E na le tafole e tloaelehileng e arohaneng ea X/Y/Z ea othomathike ea mahlakore a mararo, e nang le mochini o futhumatsang o kantle.Sebopeho se seng sa boikhethelo sa ho potoloha (mofuta oa 80mm kapa 125mm ke oa boikhethelo).Sistimi ea ho beha leihlo e nka microscope le CCD

300w Automatic Laser Welding Machine Tšobotsi

Fortune Laser Automatic Laser Welding Machine Technical Parameters

| Mohlala | FL-Y300 |

| Matla a Laser | 300W |

| Cooling Tsela | Pholiso ea Metsi |

| Laser Wavelength | 1064nm |

| Laser Working Medium Nd 3+ | YAG Ceramic Conde |

| Spot Diameter | φ0.10-3.0mm e ka fetolehang |

| Pulse Width | 0.1ms-20ms e ka fetolehang |

| Botebo ba Welding | ≤10 limilimithara |

| Matla a Mochini | 10KW |

| Sistimi ea Taolo | PLC |

| Maikemisetso le Maemo | Maekorosekopo |

| Stroke e sebetsang | 200×300mm (liphahamiso ea motlakase ea Z-axis) |

| Tlhokahalo ea Matla | Customized |