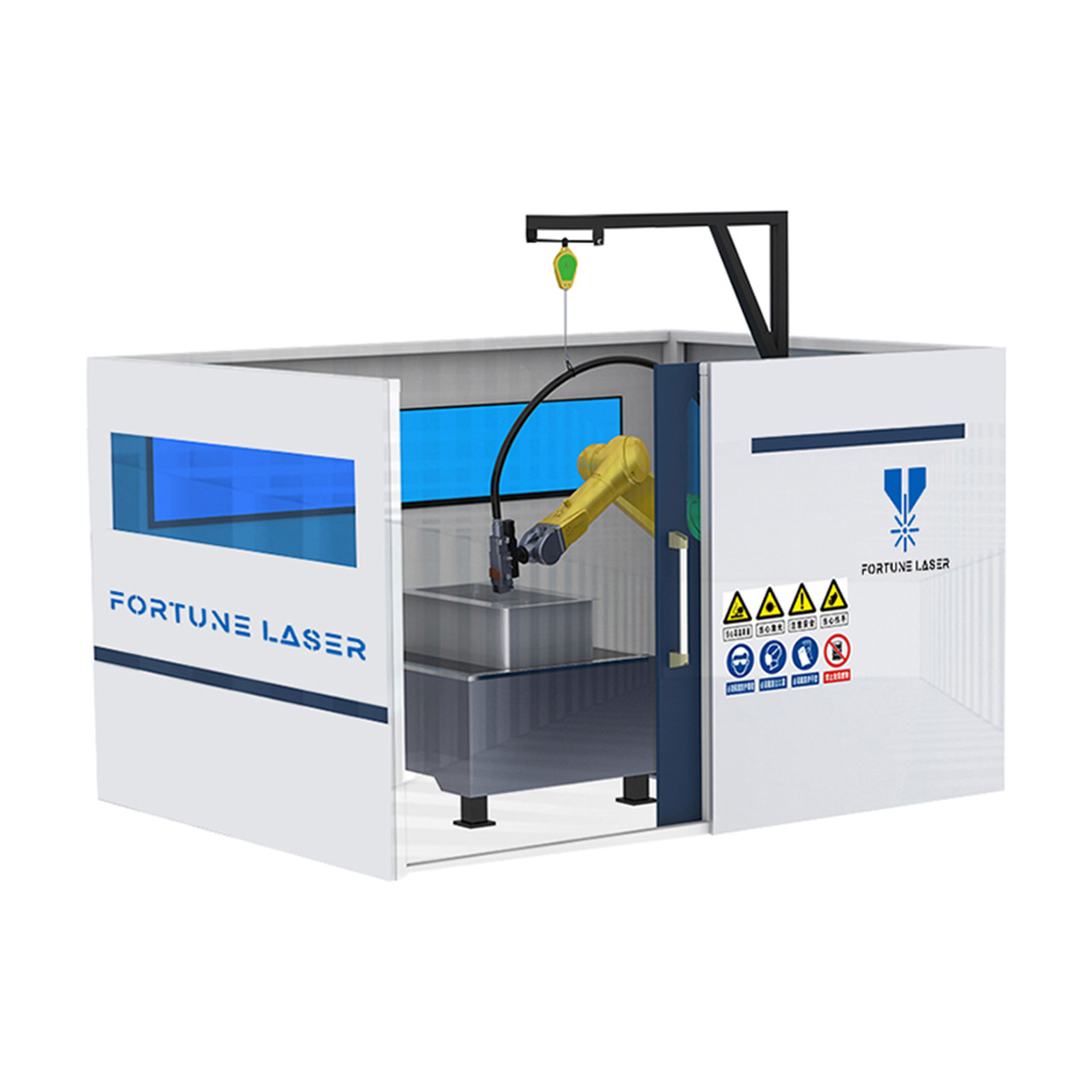

Mochini oa ho tjheseletsa oa Laser oa Robotic Fiber

Mochini oa ho tjheseletsa oa Laser oa Robotic Fiber

Mechine ea Parameters

| Mohlala | Mochini oa ho Welding oa FL-RW Series |

| Sebopeho | Liroboto tse kopaneng tse ngata |

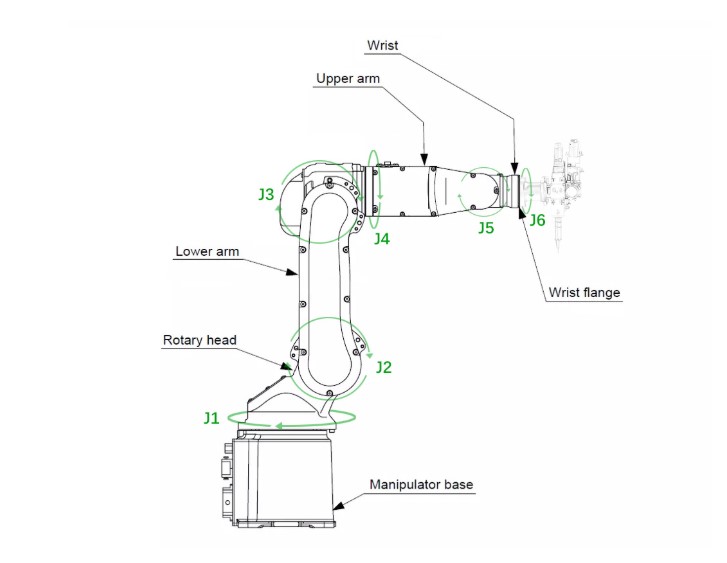

| Palo ea axis ea taolo | 6 Axis |

| Letsoho la letsoho(Ha ho boikhethelo) | 750mm/950mm/1500mm/1850mm/2100mm/2300mm |

| Mohloli oa laser | IPG2000~1PG6000 |

| Hlooho ea ho cheselletsa | Precitec |

| Mokhoa oa ho kenya | Phatlalatso, Holimo, ho kenya Bracket/setšoara |

| Lebelo le phahameng la axis ea motsamao | 360°/s |

| Pheta ho nepahala ha maemo | ± 0.08mm |

| Max Loading Weight | 20kg |

| Boima ba roboto | 235kg |

| Mocheso o sebetsang le mongobo | -20 ~ 80 ℃,Hangata ka tlase ho 75% RH (ha ho condensation) |

Portable Handheld Laser Welder bakeng sa Metals

| Lintho tse bonahalang | Matla a tsoang (W) | Boholo ba ho kenella (mm) |

| Ts'epe e sa beng le mabali | 1000 | 0.5-3 |

| Ts'epe e sa beng le mabali | 1500 | 0.5-4 |

| Ts'epe e sa beng le mabali | 2000 | 0.5-5 |

| Tšepe ea carbon | 1000 | 0.5-2,5 |

| Tšepe ea carbon | 1500 | 0.5-3.5 |

| Tšepe ea carbon | 2000 | 0.5-4.5 |

| Motsoako oa aluminium | 1000 | 0.5-2,5 |

| Motsoako oa aluminium | 1500 | 0.5-3 |

| Motsoako oa aluminium | 2000 | 0.5-4 |

| Letlapa la Galvanized | 1000 | 0.5-1.2 |

| Letlapa la Galvanized | 1500 | 0.5-1.8 |

| Letlapa la Galvanized | 2000 | 0.5-2,5 |

Lisebelisoa

E sebelisoa haholo sebakeng sa sefofane, likoloi, likepe, tlhahiso ea mechini, tlhahiso ea lifti, tlhahiso ea papatso, tlhahiso ea lisebelisoa tsa ntlo, lisebelisoa tsa bongaka, lisebelisoa tsa thepa, mokhabiso, lits'ebeletso tsa ts'ebetso ea tšepe le liindasteri tse ling.